Lab Track: RFID Tracking System for Laboratories

What is Lab Track?

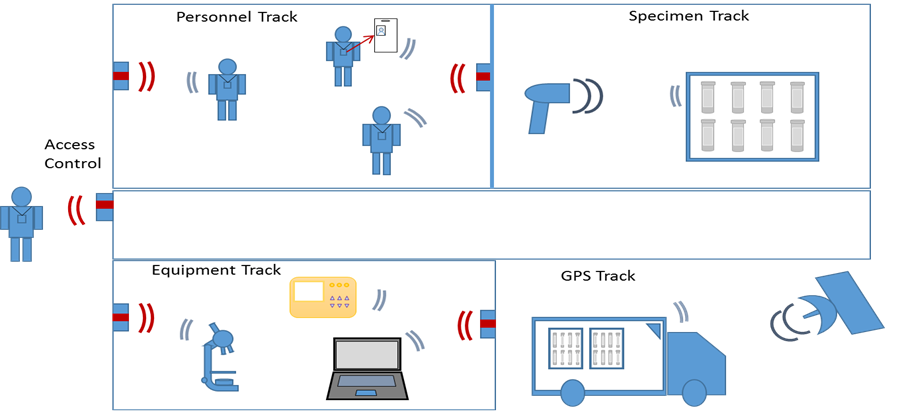

Lab Track is designed to track anything that needs to be tracked and is taggable in a medical laboratory setting. It uses RFID or barcode for tracking primarily within laboratory facilities, and GPS for tracking during transportation. It supports RFID, barcode, or GPS, and any of their combinations.

The Lab Track System can be easily configured to track one or multiple categories of lab items. The standard offering includes 4 categories:

- Specimen Track

- Lab Asset Track

- Lab People Track

- Lab Access Control

The Lab Track Software is offered in the following 3 versions:

- On a local server

- On a customer's cloud

- On GAO's cloud

Track Every Aspect of your Laboratory Environment

Learn More about Lab Track

System Integrators

We have the technology to support you. We can help tailor a Lab Track system around your healthcare client's needs including custom reports and software solutions combined with all the right hardware to help track the most important assets in the healthcare environment.

Our experts are here to help you with all questions, needs and support.