Construction and Mining Using UHF RFID

The construction and mining industries face unique challenges in managing assets, ensuring safety, and maintaining operational efficiency. Utilizing Ultra High Frequency (UHF) RFID technology, companies in these sectors can automate and streamline numerous processes, optimizing their operations. GAO RFID Inc., headquartered in New York City and Toronto, Canada, stands as a global leader in RFID and BLE solutions. By integrating advanced UHF RFID systems, GAO RFID helps construction and mining organizations maximize productivity, safeguard employees, and reduce equipment downtime. Backed by extensive R&D investments and a stringent quality assurance process, GAO RFID offers cutting-edge solutions for Fortune 500 companies, universities, government agencies, and other organizations across North America.

Applications of UHF RFID in Construction and Mining

- Asset Tracking and Inventory Management

GAO RFID’s UHF RFID solutions streamline asset tracking, allowing construction and mining companies to monitor equipment location, usage, and status. Tagged assets like machinery, tools, and vehicles can be tracked in real-time, preventing loss or misplacement and reducing downtime. This visibility is critical for inventory management, as companies can quickly locate specific items, ensuring equipment availability and enhancing workflow efficiency.

- Personnel Monitoring and Safety Compliance

Worker safety is paramount in high-risk industries like mining and construction. Using UHF RFID tags, GAO RFID’s systems enable continuous monitoring of personnel in real-time, tracking their location within designated zones. This functionality enhances emergency response by locating individuals quickly and helps enforce safety protocols. For instance, RFID-enabled access control can prevent unauthorized entry to hazardous areas.

- Heavy Equipment Maintenance and Servicing

Mining and construction equipment require regular maintenance to remain operational. With GAO RFID’s UHF RFID solutions, companies can automatically log equipment usage and maintenance history. This system alerts management when servicing is due, helping avoid costly breakdowns and ensuring equipment operates within safety standards. It also reduces manual record-keeping, allowing for more accurate maintenance schedules.

- Tool Management and Loss Prevention

RFID technology minimizes tool loss by providing real-time tracking and automated check-in/check-out systems. Construction sites benefit from GAO RFID’s tool management solutions, which track each tool’s location and usage, making it easier to monitor high-value assets and prevent theft. As a result, companies reduce replacement costs and enhance productivity by ensuring tools are readily available.

- Vehicle Tracking and Fuel Management

UHF RFID tags facilitate fleet management by tracking the location, usage, and fuel consumption of vehicles across sites. GAO RFID’s systems help companies analyze usage patterns, optimize fuel consumption, and improve logistical planning. Accurate data on vehicle movement and fuel levels can also assist in route optimization, reducing costs and carbon footprint.

- Site Access Control

Access control is crucial to managing site security. GAO RFID provides UHF RFID-based access solutions that restrict unauthorized access, ensuring only qualified personnel enter designated areas. This level of control is vital for sites where hazardous materials or high-value assets are stored, helping companies comply with industry safety and security regulations.

- Waste and Resource Management

For resource-heavy operations, waste management is a significant concern. GAO RFID offers UHF RFID-enabled waste tracking solutions, allowing companies to monitor waste levels and disposal schedules. This tracking helps companies reduce environmental impact, comply with environmental regulations, and improve resource utilization by minimizing waste.

- Temperature and Environmental Monitoring

Construction and mining sites often face challenging environmental conditions. GAO RFID’s UHF RFID sensors can track environmental parameters like temperature, humidity, and gas levels. This data is essential for maintaining a safe working environment and for equipment that must operate within specific temperature ranges. Real-time alerts can prevent accidents by informing personnel when environmental conditions reach unsafe levels.

- Automated Payroll and Attendance Systems

UHF RFID technology simplifies payroll management by automating attendance tracking. Employees wear RFID tags that log entry and exit times, which is particularly useful on large or remote sites. GAO RFID’s automated systems reduce administrative tasks, ensuring accurate attendance records and enabling faster payroll processing.

GAO RFID’s UHF RFID systems bring transformative benefits to construction and mining, improving asset management, safety, and operational efficiency

Navigation Menu for UHF RFID:

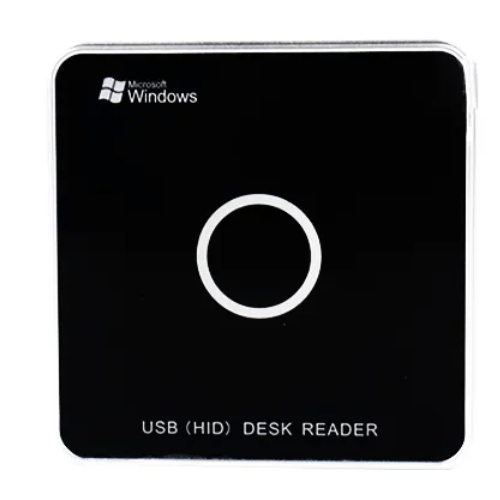

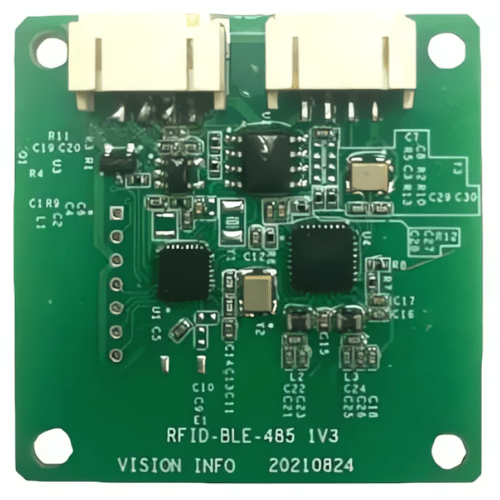

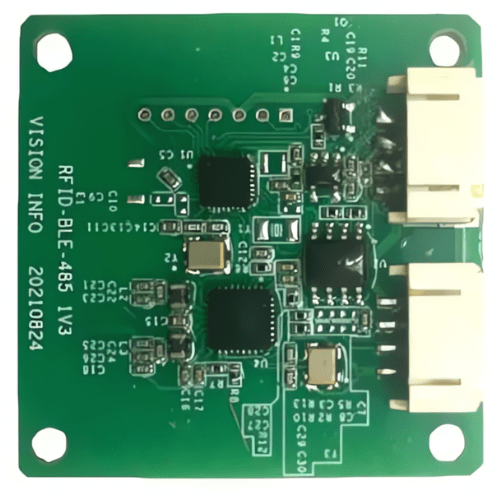

Here are UHF RFID readers offered by GAO:

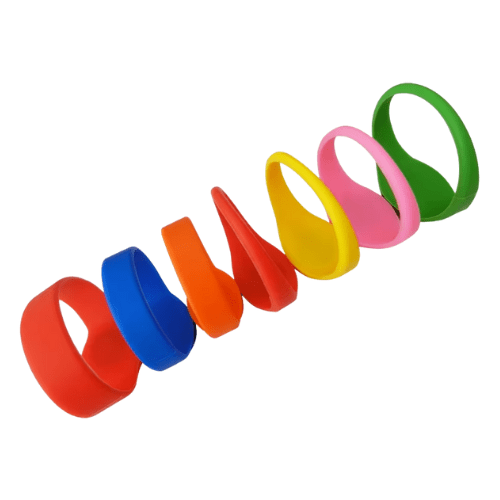

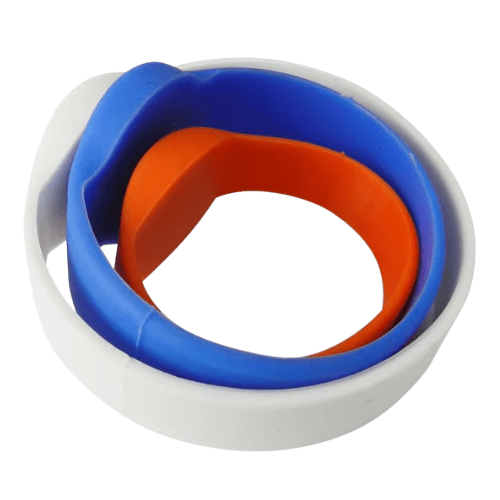

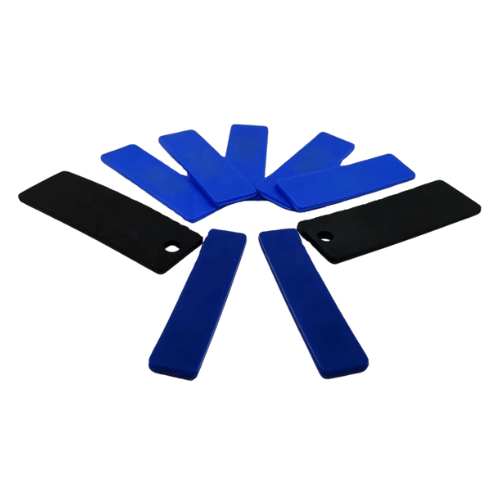

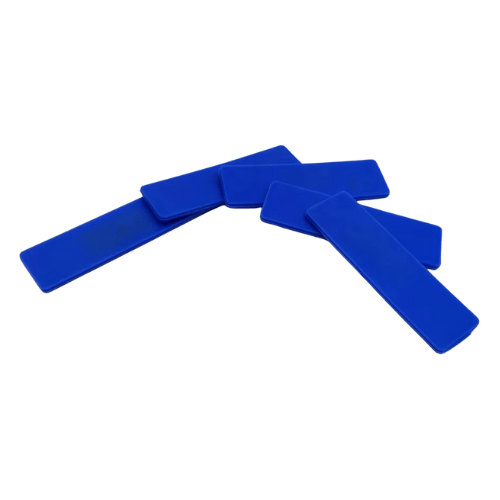

Here are UHF RFID tags offered by GAO:

Here are lists of UHF RFID readers offered by GAO:

- UHF High-Power RFID Readers

- UHF Directional RFID Readers

- UHF Multi-Antenna RFID Readers

- Rugged / IP Rated RFID Readers

- Vehicle Identification RFID Readers

- Waterproof RFID Readers

- Explosion-Proof RFID Readers

- Integrated Fixed RFID Readers

- Industrial RFID Readers

- Long Range RFID Readers

- UHF Anti-Collision RFID Readers

- UHF Omnidirectional RFID Readers

Here are lists of UHF RFID tags offered by GAO:

- Asset Tracking RFID Tags

- High-Temperature Tolerant RFID Tags

- Rugged RFID Tags

- Inventory Management RFID Tags

- Hazardous Environment (ATEX) RFID Tags

- Vehicle RFID Tags

- Tamper Proof RFID Tags

- Traceability/E-seal RFID Tags

- Long Range RFID Tags

- Anti-Theft RFID Tags

Our products are in stock and can be shipped to anywhere in continental U.S. or Canada from our local warehouse. For any further information, please fill out this form or email us.