Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Framing Contractors

GAO Helps Customers Comply with Standards, Mandates & Regulations of Framing Contractors

GAO Software Provides Easy Integration with API

Case Studies of RFID Applications

Overview

Framing contractor’s industry is a sector within the construction field that focuses on the structural framework of buildings. Framing contractors are responsible for constructing the skeletal framework of a structure, including walls, floors, and roofs, using various materials such as wood, steel, or concrete. They interpret architectural plans and blueprints to determine the precise measurements and layout of the framing components.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in framing contractor’s industry to improve their work processes, their operations and productivity by better management of their staff, materials, and operational equipment such as nail guns, framing hammers, circular saws, levels, chalk lines, tape measures, ladders, safety harnesses, scaffolding, power drills, pneumatic staplers, and angle grinders.

Ranked as a top 10 global GAO’s RFID supplier and based in New York City and Toronto, GAO RFID Inc. offers a wide choice of RFID (radio frequency identification) readers and tags at ultra-high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in farming contractor.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Framing Contractors

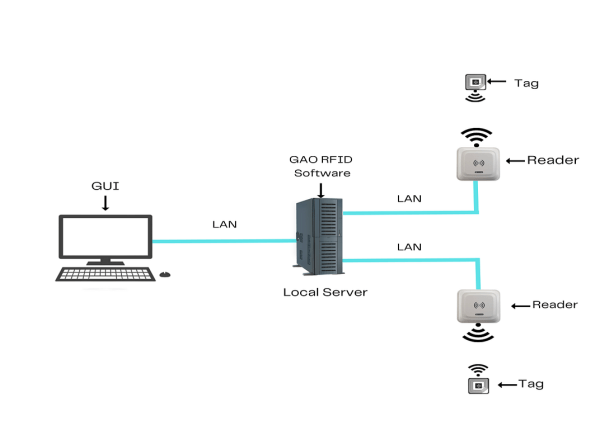

To satisfy its customers, GAO’s RFID or RFID Systems for framing contractors are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for framing contractors with its software running on a local server.

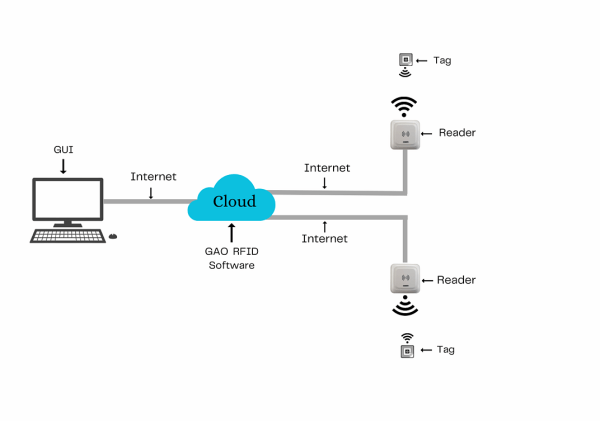

The above illustrates GAO system for framing contractors with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in framing contractor industry:

- Tool and Equipment Tracking: Framing contractors often work with various tools and equipment on construction sites. GAO’s RFID tags can be attached to these items, enabling contractors to easily track their location and movement. This reduces the risk of loss or theft and optimizes resource allocation.

- Material Inventory Management: GAO’s RFID tags can be affixed to construction materials, such as lumber, steel, and other building components. This allows contractors to maintain a real-time inventory of available materials, ensuring they have what they need when it’s required, and minimizing waste.

- Workforce Tracking: GAO’s RFID badges or wearables can be issued to the workforce, allowing contractors to monitor their movements within the job site. This can improve safety by identifying potential hazards or ensuring employees stay within designated areas.

- Access Control and Site Security: GAO’s RFID-enabled access control systems can restrict entry to authorized personnel only. This helps prevent unauthorized individuals from entering the construction site, enhancing security and safety.

- Equipment Maintenance and Service: GAO’s RFID tags can store maintenance histories and service schedules for construction equipment and machinery. This data helps contractors schedule timely maintenance, reducing downtime and increasing equipment lifespan.

- Worksite Safety Monitoring: GAO’s RFID-based sensors can be installed on machinery and equipment to monitor their operation and detect any abnormal behavior. This can help identify potential safety hazards and prevent accidents.

- Prefabricated Component Management: In projects involving prefabricated components, GAO’s RFID tags can be used to track the movement and installation of each unit, ensuring proper assembly and avoiding errors.

- Time and Attendance Tracking: GAO’s RFID badges or cards can automate timekeeping for workers, providing accurate records of hours worked and simplifying payroll processes.

- Automated Billing and Inventory Replenishment: By integrating GAO’s RFID systems with supplier databases, framing contractors can automate billing and inventory replenishment processes, streamlining procurement and reducing administrative overhead.

- Quality Control and Inspection: GAO’s RFID tags can be used to track the progress of construction tasks and ensure that each step meets quality standards. This helps in identifying and addressing potential issues early in the process.

- Waste Management: GAO’s RFID technology can help in sorting and tracking construction waste, making it easier to recycle and dispose of materials responsibly.

GAO’s drone technologies find the following applications in framing contractors industry:

- Site Surveying and Mapping: GAO’s Drones equipped with high-resolution cameras and LiDAR sensors can quickly survey construction sites and generate detailed 3D maps. These maps aid framing contractors in understanding the terrain, identifying potential obstacles, and planning the layout of structures.

- Progress Monitoring: GAO’s Drones can be deployed periodically to capture aerial images or videos of the construction site’s progress. This helps contractors monitor and document the evolution of the project, making it easier to track milestones and assess the timeline.

- Safety Inspections: GAO’s Drones can access areas that might be difficult or dangerous for workers to reach, such as rooftops, high walls, or unstable structures. By using drones for safety inspections, framing contractors can reduce the risk of accidents and injuries.

- Material Deli very: In some cases, GAO’s drones can be used to transport lightweight construction materials to specific locations on the job site. This can save time and reduce the need for manual labor in carrying materials across large sites.

- Precision Measurements: GAO’s Drones equipped with advanced sensors can provide accurate measurements of distances, areas, and volumes. This data is invaluable for estimating material quantities, ensuring proper dimensions, and verifying adherence to project specifications.

- Thermal Imaging and Energy Audits: GAO’s Drones equipped with thermal cameras can help identify heat leaks and energy inefficiencies in buildings. Framing contractors can use this data to suggest improvements and optimize the energy performance of the structures they work on.

- Marketing and Client Communication: Aerial photography and videography captured by GAO’s drones can be utilized for marketing purposes, showcasing completed projects, and providing clients with a unique perspective on their property.

- Quality Control: GAO’s Drones can be used to inspect the quality of framing work and identify any potential defects or issues early in the construction process. This allows for timely corrections and ensures that the final structure meets industry standards.

- Environmental Impact Assessments: GAO’s Drones can be used to monitor and assess the environmental impact of construction activities. This includes tracking erosion, soil movement, and changes in vegetation, helping framing contractors mitigate their projects’ ecological footprint.

- Project Planning and Collaboration: GAO’s Drones provide accurate and up-to-date data that can be shared easily with architects, engineers, and other stakeholders. This facilitates collaborative decision-making and ensures that everyone involved in the project is working with the most current information.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in framing contractor industry:

- Smart Construction Equipment: GAO’s IoT-enabled sensors and devices can be integrated into construction equipment, such as cranes, excavators, and bulldozers, to monitor their health, usage, and location. This data helps in predictive maintenance, reducing downtime and improving equipment lifespan.

- Real-time Asset Tracking: Framing contractors often have a large number of tools and materials scattered across job sites. GAO’s IoT tracking solutions can be deployed to monitor and locate these assets in real-time, preventing theft, loss, and minimizing time spent searching for tools.

- Environmental Monitoring: GAO’s IoT sensors can monitor various environmental factors on construction sites, such as temperature, humidity, air quality, and noise levels. This data can be used to ensure optimal working conditions, safety compliance, and early detection of potential hazards.

- Safety and Security: Wearable GAO’s IoT devices like smart helmets, vests, and badges can track workers’ locations and vital signs, enabling real-time safety monitoring. Additionally, connected cameras and sensors can enhance site security and identify potential safety risks.

- Smart Energy Management: GAO’s IoT-based energy management systems can regulate lighting, heating, and cooling in construction trailers and temporary facilities, reducing energy waste and lowering operational costs.

- Remote Monitoring and Control: GAO’s IoT technology allows framing contractors to remotely monitor and control construction processes, equipment, and tasks, enhancing project management and decision-making capabilities.

- Construction Site Automation: Automation through GAO’s IoT can streamline various processes, such as prefabrication, material handling, and construction assembly, leading to increased efficiency and reduced labor requirements.

- Predictive Analytics: GAO’s IoT-generated data can be analyzed using AI and machine learning algorithms to predict equipment failures, identify patterns, and optimize construction processes for better resource allocation.

- Inventory Management: Connected sensors can track the usage of construction materials, tools, and equipment, providing real-time inventory updates and enabling just-in-time procurement, reducing waste and costs.

- Fleet Management: GAO’s IoT-based fleet tracking systems can optimize the movement of vehicles, reducing fuel consumption, improving scheduling, and ensuring timely delivery of materials and equipment.

- Construction Worker Health and Safety: GAO’s IoT wearables can monitor workers’ biometrics and detect signs of fatigue or stress, promoting a safer work environment and reducing the risk of accidents.

- Quality Control and Compliance: GAO’s IoT sensors can continuously monitor construction processes and ensure compliance with building codes and industry standards, helping to maintain high-quality construction work.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Framing Contractors

GAO RFID Inc. has helped many companies in framing contractors to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates:

- EPCglobal Gen2

- NFC Forum

- ANSI INCITS 256

- RAIN

- Generic Attribute Profile (GAP)

- OCF (Open Connectivity Foundation)

- Zigbee

- Thread

- LoRaWAN

- AllJoyn

- ASTM International F38 Committee

- Safety and compliance

US. Government Regulations for Farming Contractors:

- Licensing and permitting

- Davis-Bacon Act

- Contracting and business regulations

- Federal Acquisition Regulation (FAR)

- Environmental Protection Agency (EPA) regulations

- Fair Labor Standards Act

Canadian Government Regulations for Farming Contractors:

- Employment and Social Development Canada (ESDC)

- Canadian Construction Association (CCA)

- Canadian Home Builders’ Association (CHBA)

- Provincial and territorial regulatory bodies

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in framing contractors such as:

Personnel Management Applications in Framing Contractors:

- Employee scheduling and shift management

- Time and attendance tracking

- Training and certification management

- Performance evaluation and appraisal

- Employee communication and collaboration platforms

Equipment Management Applications in Framing Contractors:

- Asset tracking and inventory management

- Preventive maintenance and equipment servicing

- Equipment allocation and utilization monitoring

- Equipment calibration and inspection management

- Tracking equipment availability and location

Access Control Applications in Framing Contractors:

- Secure access to construction sites and restricted areas

- Visitor management and temporary access authorization

Warehouse Management Applications in Framing Contractors:

- Inventory management

- Order fulfillment and logistics

Supply Chain Management Applications in Framing Contractors:

- Supplier management

- Demand forecasting and procurement

Other Applications in Framing Contractors:

- Quality control and inspections

- Subcontractor management

- Document management

GAO has enabled its customers to make use of some of leading software and cloud services in framing contractors. Below are some of popular software and cloud services in framing contractors:

Paycor, BambooHR, Gusto, Asset Panda, Avigilon Access Control Manager, Honeywell Pro-Watch, SAP Extended Warehouse Management, Brivo Access Control, Genetec Security Center, STACK Estimating, QuickBook, Sage 100 Contractor, BuilderTREND, CoConstruct, Procore, PlanGrid.

GAO has worked with some of the leading technology companies in framing contractors to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in framing contractors industry:

Trimble Inc., Autodesk, Inc., Viewpoint, a Trimble Company, ComputerEase Construction Software, Bosch Security Systems, Johnson Controls, Siemens AG, Schneider Electric., Tyco International Ltd, Axis Communications AB, Leviton Manufacturing Co., Inc., ABB Ltd., Crestron Electronics, Inc., Control4 Corporation, Lutron Electronics Co., Inc., KNX Association., Legrand Group.

Case Studies of RFID Applications

Below are some RFID application cases in framing contracts:

A leading general construction company in the USA prioritized safety and took proactive measures by implementing an innovative RFID-based monitoring system. Using RFID tags on workers’ safety gear, such as helmets and vests, the company achieved real-time tracking and monitoring of their locations within the construction site. The system leveraged RFID readers strategically placed throughout the site to collect data and proactively detect potential hazards. In hazardous areas, the system issued alerts, allowing workers to take immediate action and avoid accidents. This comprehensive safety solution significantly enhanced worker safety reduced the risk of workplace incidents, and ensured compliance with stringent safety regulations. As a result, the company experienced improved safety practices, increased regulatory compliance, and a positive impact on overall project performance.

Renovation contractors operating in Canada recognized the potential of RFID technology to revolutionize their inventory management practices. By deploying RFID tags on materials, supplies, and equipment, they gained accurate and real-time visibility into their inventory levels. The RFID system provided detailed information on item locations, quantities, and movements, enabling contractors to streamline their inventory management processes. With this enhanced control over their inventory, contractors could ensure timely reordering, minimize instances of stockouts, and optimize project scheduling. As a result, they experienced improved efficiency, minimized delays, and increased customer satisfaction. Furthermore, the streamlined inventory management enabled them to achieve cost savings by minimizing carrying costs and reducing waste.

A highly regarded framing contractor in the USA recognized the potential of UFH (Ultra-High Frequency) RFID technology to streamline workflow and enhance task coordination. Leveraging UFH RFID tags, the contractor seamlessly tracked workers, materials, and equipment throughout the construction project. The UFH RFID system provided real-time visibility into the project progress, enabling efficient coordination and communication among team members. With the ability to monitor and track resources in real-time, the contractor could make data-driven decisions, proactively address bottlenecks, and optimize resource allocation. This streamlined workflow led to improved project execution, increased productivity, and enhanced collaboration among teams. As a result, the contractor achieved notable improvements in project timelines, cost control, and customer satisfaction, establishing themselves as a reliable and efficient player in framing contractors.

In Canada, a leading framing contractor recognized the value of UFH RFID technology for efficient equipment management. By utilizing UFH RFID tags for quick and precise equipment identification, the contractor achieved optimized asset utilization, reduced equipment downtime, and improved resource allocation. The UFH RFID system provided real-time visibility into the location, status, and availability of equipment, enabling the contractor to make informed decisions and efficiently manage their equipment inventory. With improved control over equipment, the contractor could minimize delays, streamline operations, and enhance project productivity. This resulted in substantial cost savings, increased operational efficiency, and improved project outcomes. The contractor successfully met project milestones, mitigated potential delays, and ensured timely project completion, thereby strengthening their reputation in the industry, and gaining a competitive edge.

Many applications of RFID by GAO can be found here

Case Studies of IoT Applications

Below are some IoT application cases in farming contractor industry.

A case study involved using IoT sensors to monitor heavy construction equipment, such as cranes and excavators, on a construction site. These sensors gather real-time data on equipment health, usage patterns, and maintenance needs. This information helps optimize equipment performance, reduce downtime, and improve safety and efficiency in construction projects.

In this case study, IoT devices were integrated into a warehouse’s framing material inventory system. Sensors were placed on racks and storage areas to track the quantity and location of framing materials. This real-time data enables warehouse managers to optimize inventory management, reduce waste, and improve order fulfillment processes.

IoT-enabled energy management systems were implemented on construction sites to monitor and control energy consumption. Smart meters and sensors were used to track electricity, water, and other utility usage, allowing contractors to identify areas of high energy consumption and implement measures to conserve energy and reduce costs.

IoT wearables, such as smart helmets and vests, were deployed to monitor the safety of construction workers on framing contracts. These wearables can track workers’ vital signs, detect potential accidents or hazards, and provide real-time alerts to supervisors, enhancing safety on the construction site.

An IoT-based quality control system was implemented in a framing materials manufacturing facility. Sensors were integrated into the production line to monitor various parameters, such as dimensions, weight, and material strength. The data collected helped ensure that the produced framing materials meet industry standards and maintain consistent quality.

In this case study, IoT sensors were attached to machinery used in framing production processes. These sensors continuously monitor the equipment’s condition, analyzing data to predict maintenance needs accurately. By implementing predictive maintenance strategies, the company reduced downtime, extended equipment lifespan, and minimized unexpected breakdowns.

Case Studies of Drone Applications

Below are some drone application cases in farming contractor industry.

A farming contracting company employed drones equipped with multispectral or hyperspectral cameras to monitor crop health and detect early signs of disease or stress. The drones flew over large agricultural fields, capturing high-resolution images. The imagery was processed using specialized software to create detailed vegetation health maps, enabling the contractors to identify specific areas that required targeted treatment, resulting in improved crop yield and reduced chemical usage.

A farming contractor utilized drones equipped with precision spraying systems to apply fertilizers, pesticides, and herbicides more efficiently. The drones’ GPS-guided flight paths and onboard sensors ensured accurate and targeted application, minimizing product waste and environmental impact. The contractor reported cost savings, increased productivity, and better crop protection using this drone-based approach.

A drone service provider collaborated with farming contractors to conduct aerial surveys of large fields and generate high-resolution maps. These maps provided detailed information about soil variations, water drainage patterns, and topography. Armed with this data, farming contractors could optimize planting patterns, irrigation strategies, and overall land use planning for better resource management and increased productivity.

In a case study involving farming contractors with livestock operations, drones were used to monitor large herds across extensive grazing areas. Thermal cameras and GPS tracking enabled contractors to detect and locate animals, ensuring their safety and health. Drones allowed for more efficient monitoring of livestock without the need for extensive manual labor, saving time and resources.

Drone technology was employed to assess the effectiveness of irrigation systems in large-scale farming operations. Drones equipped with thermal cameras could identify areas of over or under-watering, assisting contractors in making data-driven decisions for better water resource management and reduced irrigation costs.

Drones equipped with LiDAR sensors and photogrammetry capabilities were used to estimate crop yields in farming contractor projects. By generating 3D models of crops, contractors could accurately assess the volume and potential yield of produce. This data allowed for better logistical planning and improved financial forecasting.

GAO RFID Systems & Hardware for Framing Contractors

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including framing contractors.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

As well as versatile beacons with such important functions as temperature, humility, vibration, and panic button:

GAO’s BLE technology is suitable for many industries, including framing contractors.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including framing contractors:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including framing contractors:

And an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including framing contractors:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including framing contractors:

And antennas:

GAO also offers RFID printers:

Digital I/O adapters:

And relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

The RFID systems by GAO are highly popular for clients in framing contractors:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Framing nailers: Used for fast and efficient installation of nails into wood framing members, such as studs and joists.

- Framing squares: Essential measuring and marking tools for ensuring accurate angles and lengths during framing construction.

- Circular saws: Used for cutting various materials, including lumber, plywood, and engineered wood, to size during framing projects.

- Framing hammers: Heavy-duty hammers with a straight claw for driving nails and connecting framing components.

- Laser levels: Precise leveling tools used to ensure accurate alignment and layout of walls, floors, and other framing elements.

- Ladders and scaffolding: Necessary for accessing elevated areas during framing work, providing stability and safety for workers.

- Power drills: Versatile tools used for drilling holes, driving screws, and attaching framing components together.

- Air compressors and air tools: Used for powering pneumatic tools like nailers, staplers, and spray guns for efficient framing work.

- Tape measures: Essential measuring tools for taking accurate dimensions and marking layouts during framing projects.

- Safety equipment: Including hard hats, safety glasses, gloves, and protective clothing to ensure the safety of workers on the job site.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served Framing Contractors Extensively

GAO’s products and technologies have helped its customers in framing contractors to achieve success in sustainable construction, off-site modular construction, digital transformation, green building, prefabrication, lean construction, building information modeling (BIM), smart home technology, energy efficiency, and cost optimization.

GAO RFID Inc. has served many customers in framing contracting, including its various divisions such as:

- Residential framing: Specializing in framing services for residential construction projects, such as single-family homes, townhouses, and apartments.

- Commercial framing: Focusing on framing services for commercial buildings, including offices, retail stores, restaurants, and industrial facilities.

- Industrial framing: Providing framing services for large-scale industrial projects, such as warehouses, factories, and manufacturing plants.

- Institutional framing: Catering to framing needs in institutional settings, such as schools, hospitals, government buildings, and religious institutions.

- Renovation and remodeling framing: Offering framing services for renovation and remodeling projects, including additions, extensions, and structural modifications.

- Exterior framing: Specializing in framing for exterior elements, such as roofs, walls, decks, and balconies.

- Interior framing: Focusing on framing services for interior elements, such as partition walls, ceilings, staircases, and built-in features.

- Timber framing: A specialized division that focuses on traditional timber framing techniques for structures, emphasizing the use of heavy timbers and joinery.

- Panelized framing: Providing pre-manufactured framing panels that are assembled on-site, offering increased speed and efficiency in construction.

- Sustainable framing: Concentrating on eco-friendly framing practices, utilizing sustainable materials and energy-efficient design principles.

- Deere & Company: Deere & Company, commonly known as John Deere, is a multinational corporation that manufactures agricultural machinery and equipment. They offer a diverse range of products, including tractors, harvesters, planters, and precision agriculture technologies that enable farming contractors to optimize their operations and improve productivity.

- CNH Industrial: CNH Industrial is a global company that designs and manufactures agricultural machinery and equipment under various brands like Case IH and New Holland Agriculture. They provide a wide array of products, from tractors and combines to hay and forage equipment, catering to the needs of farming contractors in both the USA and Canada.

- AGCO Corporation: AGCO Corporation is a major player in the agricultural equipment industry, producing agricultural machinery under well-known brands like Massey Ferguson, Challenger, and Fendt. They offer a broad portfolio of tractors, combines, and other specialized equipment used by farming contractors worldwide.

- Raven Industries, Inc.: Raven Industries is a technology company that develops precision agriculture solutions, including guidance and steering systems, variable rate application technology, and cloud-based data management platforms. Their products help farming contractors optimize inputs, reduce waste, and increase efficiency.

- Trimble Inc.: Trimble is a technology company providing a wide range of precision agriculture solutions. Their offerings include GPS guidance systems, flow and application control systems, drone-based imaging solutions, and farm management software. Farming contractors use Trimble’s tools to enhance precision and decision-making on the field.

- Topcon Positioning Systems Inc.: Topcon is a manufacturer of positioning and surveying equipment, including technologies tailored for precision agriculture. They offer GPS-based guidance systems, machine control solutions, and remote sensing technologies to assist farming contractors in their operations.

- PrecisionHawk Inc.: PrecisionHawk is a company specializing in drone technology for agriculture. Their platform provides aerial data collection, analytics, and mapping solutions for farming contractors to monitor crops, assess field health, and make data-driven decisions.

- The Climate Corporation: The Climate Corporation, a subsidiary of Bayer, offers a digital agriculture platform known as Climate. The platform gathers and analyzes data from various sources, such as sensors and satellites, to provide insights and tools for farming contractors to optimize field performance and sustainability.

- AGI : AGI (Ag Growth International) is a leading provider of grain handling and storage solutions. They offer a wide range of products, including grain bins, conveyors, bucket elevators, and grain dryers, supporting farming contractors in their post-harvest processes.

- Ceres Imaging: Ceres Imaging provides aerial imagery and analytics services for agriculture. Using proprietary sensors mounted on aircraft, they offer high-resolution images that help farming contractors identify crop stress, optimize irrigation, and improve overall field management.

- Iteris, Inc.: Iteris develops advanced technologies for traffic and weather management, but they also offer precision agriculture solutions. Their offerings include weather data and advisory services, providing valuable insights to farming contractors to optimize planting, irrigation, and harvesting.

- AG Leader Technology: AG Leader Technology specializes in precision agriculture and offers a range of products, including GPS and guidance systems, planting and application controls, and data management software. Their solutions enable farming contractors to implement precise farming practices and increase productivity.

Here are some of the leading companies in farming contractor industry:

PulteGroup Incorporated

D.R. Horton Incorporated

Lennar Corporation

KB Home Corporation

Taylor Morrison Home Corporation

Toll Brothers Incorporated

NVR Incorporated

Hovnanian Enterprises Incorporated

Meritage Homes Corporation

Beazer Homes USA Incorporated

Drees Homes Limited Private Partnership

Ashton Woods USA Private Limited Liability Company

Fischer Homes Private Limited Partnership

Shea Homes Private Limited Partnership

Century Communities Incorporated

M I Homes Incorporated

Clayton Properties Group Incorporation

Ryan Homes Incorporated

Minto Group Incorporated

Tridel Corporation

Brookfield Residential Properties Incorporation

Empire Communities Incorporated

Great Gulf Group Limited

Ledcor Group of Companies