Overview

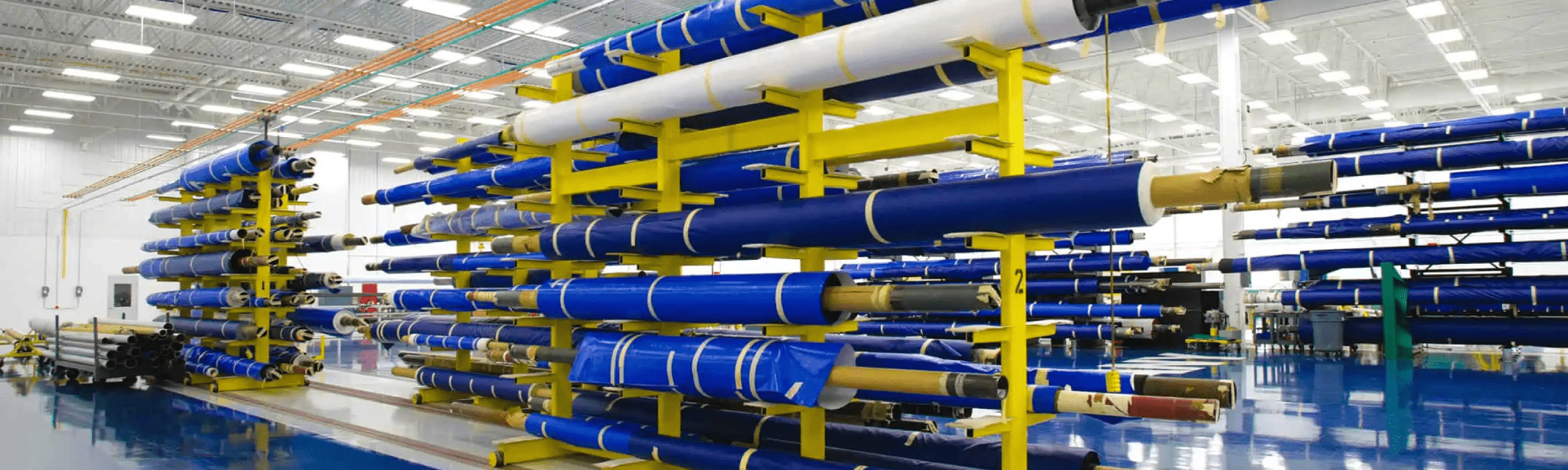

The textile and fabric finishing and fabric coating mills industry involves the processing and treatment of fabrics to enhance their appearance, performance, and functionality. This industry includes activities such as dyeing, printing, coating, and finishing fabrics to achieve desired colors, patterns, textures, and properties. Fabric coating mills apply various chemical treatments to improve durability, water resistance, flame retardancy, or other specialized characteristics. These processes are vital in the production of textiles for apparel, home furnishings, and industrial applications.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in textile and fabric finishing and fabric coating mills Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as dyeing machines, printing machines, coating machines, calendering machines, bleaching machines, sizing machines, embossing machines, brushing machines, laminating machines, curing ovens, steaming machines, washing machines, drying machines, cutting machines, inspection machines, mixing tanks, conveyors, rollers and cylinders, heat transfer machines, testing and quality control equipment.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra-high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in textile and fabric finishing and fabric coating mills.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Textile and Fabric Finishing and Fabric Coating Mills

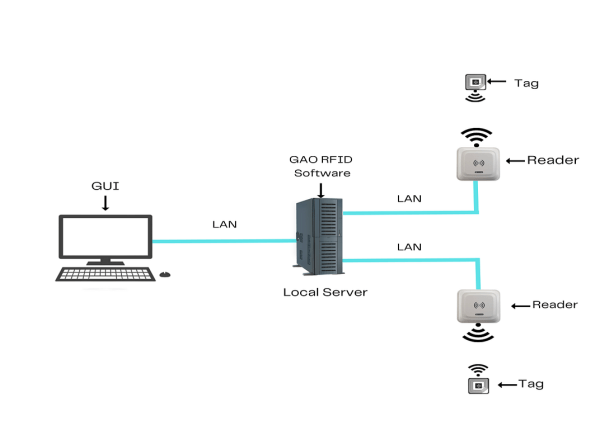

To satisfy its customers, GAO’s RFID or RFID Systems for the textile and fabric finishing and fabric coating mills are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for textile and fabric finishing and fabric coating mills with its software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for the textile and fabric finishing and fabric coating mills are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for textile and fabric finishing and fabric coating mills with its software running on a local server.

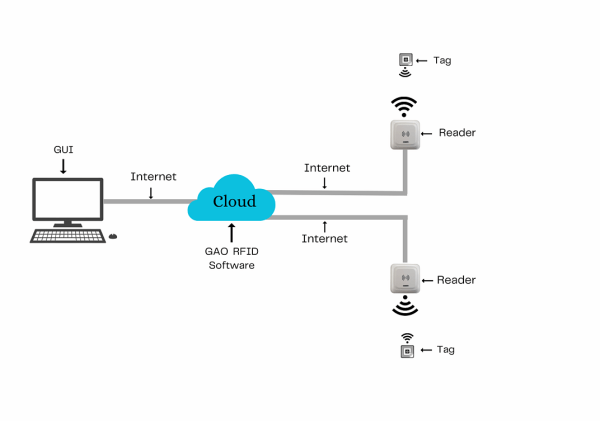

The above illustrates GAO system for textile and fabric finishing and fabric coating mills with its software running in cloud.

The above illustrates GAO system for textile and fabric finishing and fabric coating mills with its software running in cloud.

GAO’s RFID and BLE technologies bring the many benefits to textile and fabric finishing and fabric coating mills industry:

- Improved Inventory Management: GAO’s RFID tags can be attached to fabric rolls, allowing for accurate and real-time tracking of inventory. This enhances inventory control, reduces manual errors, and streamlines supply chain management.

- Enhanced Traceability: Our RFID enables the tracking of fabrics throughout the production process, providing detailed information about the origin, processing steps, and quality control. It facilitates traceability, quality assurance, and compliance with industry standards.

- Increased Efficiency: GAO’s RFID technology enables automated data collection, eliminating the need for manual scanning or paperwork. This improves operational efficiency, reduces labor costs, and speeds up processes in areas like inventory management, production tracking, and order fulfillment.

- Error Reduction: By automating data capture and minimizing manual input, GAO’s RFID reduces human errors in fabric identification, inventory reconciliation, and order processing. This leads to improved accuracy, reduced rework, and enhanced customer satisfaction.

- Loss Prevention and Security: Our RFID tags can be used for anti-theft purposes, enabling the detection of unauthorized removal of fabric rolls from the facility. Additionally, RFID helps prevent counterfeiting and unauthorized duplication of fabrics by providing a unique digital identifier for each item.

- Real-time Visibility and Analytics: GAO’s RFID technology provides real-time visibility into the movement and status of fabric rolls. This data can be leveraged for analytics and business intelligence, allowing for better decision-making, process optimization, and proactive maintenance.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to textile and fabric finishing and fabric coating mills industry:

- Enhanced Inventory Management: GAO’s RFID tags attached to fabric rolls combined with drones equipped with RFID readers enable rapid and accurate inventory counts. Drones can fly over the storage areas, automatically scanning and identifying the tagged fabric rolls, providing real-time inventory data and improving inventory accuracy.

- Efficient Asset Tracking: Drones equipped with GAO’s RFID readers can swiftly locate and track the movement of fabric rolls within the facility. This enhances asset visibility, reduces the time spent searching for specific rolls, and ensures better asset utilization.

- Improved Quality Control: Drones equipped with cameras can capture high-resolution images of fabric rolls, while GAO’s RFID tags provide associated data such as production details, quality parameters, and inspection results.

- Rapid Warehouse Management: Drones combined with GAO’s RFID technology can efficiently manage warehouse operations. They can scan RFID tags on fabric rolls, identify optimal storage locations, and assist in organizing and arranging inventory.

- Enhanced Security and Loss Prevention: Drones equipped with GAO’s RFID readers can monitor and patrol restricted areas or access points in the facility. They can detect unauthorized movements or theft attempts by tracking the RFID signals of fabric rolls, thus enhancing security and preventing losses.

- Efficient Facility Maintenance: Drones equipped with GAO’s RFID readers can perform regular inspections of equipment, machinery, and infrastructure within the facility. They can quickly identify and report any RFID-tagged assets requiring maintenance or repair, enabling timely interventions and reducing downtime.

Here are benefits of GAO’s IoT technologies to textile and fabric finishing and fabric coating mills industry:

- Real-time Monitoring and Control: GAO’s IoT enables real-time monitoring of various parameters such as temperature, humidity, machine performance, and energy consumption. This allows for proactive decision-making, timely adjustments, and effective control over the production processes, leading to optimized operations.

- Predictive Maintenance: GAO’s IoT-connected sensors can collect data on equipment performance and detect anomalies or signs of potential failures. This facilitates predictive maintenance, where maintenance activities can be scheduled based on actual equipment conditions, minimizing downtime, and reducing maintenance costs.

- Enhanced Efficiency and Productivity: GAO’s IoT devices and sensors enable the automation and optimization of processes. By collecting and analyzing data, IoT can identify bottlenecks, inefficiencies, and opportunities for improvement.

- Supply Chain Visibility: GAO’s IoT technology allows for end-to-end visibility of the supply chain. It enables tracking and tracing of raw materials, work-in-progress, and finished goods, providing insights into inventory levels, production status, and delivery timelines.

- Quality Assurance and Compliance: GAO’s IoT enabled sensors can monitor various quality parameters throughout the production process. They can automatically collect data on fabric characteristics, detect defects, and ensure compliance with industry standards.

- Energy Optimization: GAO’s IoT devices and sensors can monitor energy consumption in real-time, identify energy-intensive processes, and detect opportunities for optimization. By optimizing energy usage, the industry can reduce costs, improve sustainability, and contribute to environmental conservation.

GAO’s Assists Clients with Standards, Mandates & Regulations of Textile and Fabric Finishing and Fabric Coating Mills

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in textile and fabric finishing and fabric coating mills to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- EPC Gen2 (Electronic Product Code Generation 2): Widely adopted RFID standard for supply chain management and inventory control. It provides a global standard for RFID tags, readers, and communication protocols, ensuring interoperability and compatibility across different systems and vendors.

- ANSI/ASHRAE 201: Standard developed by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) for managing wireless communication in building automation and control systems.

- MQTT (Message Queuing Telemetry Transport): Lightweight messaging protocol designed for efficient communication between IoT devices and systems. It is commonly used for publishing and subscribing to data streams, enabling efficient and scalable data exchange in IoT applications.

- OPC UA (Unified Architecture): Machine-to-machine communication protocol widely used in industrial IoT applications. It provides a standardized framework for secure and reliable data exchange between devices, systems, and applications.

- ICAO (International Civil Aviation Organization) Standards and Recommended Practices: ICAO, a specialized agency of the United Nations, develops international standards and recommended practices for aviation safety and efficiency.

- FAA (Federal Aviation Administration) Regulations: The regulatory body governing aviation in the United States, establishes regulations for drone operations. These regulations outline requirements for drone registration, pilot certification, airspace restrictions, and operational limitations.

US. Government Regulations

- Environmental Protection Agency (EPA) Regulations: Establishes regulations to protect the environment and promote sustainability. Textile and fabric mills must comply with EPA regulations governing wastewater treatment, air emissions, hazardous waste management, and other environmental concerns.

- Consumer Product Safety Commission (CPSC) Regulations: Regulates the safety of consumer products. Textile and fabric mills must adhere to CPSC regulations regarding product labeling, flammability standards, lead content limits, and other safety requirements.

- Federal Trade Commission (FTC) Regulations: Related to advertising, labeling, and fair business practices. Textile and fabric mills must comply with FTC regulations such as the textile Fiber Products Identification Act (TFPIA) that require accurate and informative labeling of textile products, including fiber content and country of origin.

- U.S. Customs and Border Protection (CBP) Regulations: Regulates imports and enforces trade-related laws. Textile and fabric mills must comply with CBP regulations, such as the textile and Apparel Importer Program (TAIP) and the Trade Agreements Act (TAA).

Canadian Government Regulations

- Workplace Hazardous Materials Information System (WHMIS): Provides a standardized system for communicating information about hazardous materials in the workplace. Textile and fabric mills must comply with WHMIS regulations by properly classifying, labeling, and providing safety data sheets for hazardous substances.

- Employment Standards Act: Establishes minimum employment standards in Canada, including provisions related to wages, hours of work, overtime, and other employment conditions.

- Canadian Textile Labelling Act: Regulates the labeling and advertising of textile fiber content in consumer products. Textile and fabric mills must comply with CTLA requirements by accurately labeling textile products, including providing information on fiber content, country of origin, and care instructions.

- Canadian Trade-marks Act: Governs the registration and protection of trademarks in Canada. Textile and fabric mills must comply with trademark regulations to protect their brand identity and intellectual property rights.

- Canadian Food Inspection Agency (CFIA) Regulations: Oversees the safety and quality of textiles used in food processing and manufacturing. Textile and fabric mills supplying materials for food-related applications must comply with CFIA regulations, ensuring their products meet hygiene and safety standards.

EPC Gen2 (Electronic Product Code Generation 2)

MQTT (Message Queuing Telemetry Transport)

FAA (Federal Aviation Administration) Regulations

ANSI/ASHRAE 201

Occupational Safety and Health Administration (OSHA) Regulations

Environmental Protection Agency (EPA) Regulations

CGSB Canadian General Standards Board

Federal Trade Commission (FTC) Regulations

Workplace Hazardous Materials Information System (WHMIS)

CEPA

CCPSA

HPA

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in textile and fabric finishing and fabric coating mills such as:

Personnel Management:

- Employee scheduling and shift management

- Training and skills development tracking

- Performance evaluation and feedback systems

- Health and safety management for workers

- Employee attendance and time tracking

Equipment Management:

- Maintenance and repair scheduling for machinery and equipment

- Asset tracking and inventory management

- Energy management and optimization

- Equipment utilization monitoring

- Remote monitoring and diagnostics for machinery

Access Control:

- Restricted access to sensitive areas within the facility

- Identification and authentication of employees and visitors

- Time-limited access permissions for contractors and temporary staff

- Security and surveillance systems integration

- Visitor management and tracking

Warehouse Management:

- Inventory tracking and stock control

- Order management and fulfillment

- Warehouse layout optimization for efficient storage and retrieval

- Real-time monitoring of stock levels and reordering

- Pick-and-pack optimization for order processing

Supply Chain Management:

- Supplier relationship management

- Demand forecasting and planning

- Order tracking and delivery management

- Vendor performance evaluation and selection

- Supply chain visibility and traceability

Other Applications:

- Quality control and product testing

- Compliance management with industry regulations and standards

- Environmental sustainability and waste management

- Product lifecycle management

- Customer relationship management for order management and customer support

GAO has enabled its customers to make use of some of leading software and cloud services in textile and fabric finishing and fabric coating mills industry. Below are some of popular software and cloud services in textile and fabric finishing and fabric coating mills industry.

- SAP SuccessFactors: Is a comprehensive human capital management (HCM) software suite that includes modules for talent acquisition, performance management, learning and development, and workforce analytics. It provides tools for managing employee data, tracking performance, and supporting strategic HR initiatives.

- Workday HCM: A cloud-based software platform designed to streamline human resources processes. It offers modules for core HR management, payroll, talent management, and workforce planning. Workday HCM provides features such as employee self-service, performance management, and workforce analytics.

- Microsoft Azure: Comprehensive cloud computing platform that offers a wide range of services, including those related to personnel and equipment management. Azure provides services such as Azure Active Directory for user management and authentication.

- Amazon Web Services (AWS): Widely used cloud computing platform that provides various services suitable for personnel and equipment management. AWS offers services like Amazon Cognito for user authentication and access control and AWS IoT for managing and monitoring equipment

- Oracle Warehouse Management (WMS): Is a comprehensive warehouse management system that helps streamline operations, optimize inventory, and improve order fulfillment. It offers features such as inventory tracking, picking and packing optimization, order management, and integration.

- SAP Extended Warehouse Management (EWM): Advanced warehouse management system that provides real-time visibility and control over warehouse operations. It offers features for inventory management, order fulfillment, labor management, and integration with transportation and supply chain systems.

- Google Cloud Platform (GCP): Offers cloud services for access control, warehouse management, and supply chain management. Google Cloud Identity provides identity and access management capabilities, while Google Cloud IoT Core allows for device management and data ingestion from equipment.

- IBM Cloud: Provides a range of services that can support access control, warehouse management, and supply chain management requirements. IBM Cloud Identity and Access Management offers identity management capabilities, while IBM Watson IoT provides tools for equipment monitoring and management.

- Lectra Fashion PLM: Is a product lifecycle management (PLM) software specifically designed for the fashion and textile industry. It provides end-to-end management of product development processes, including design, prototyping, sourcing, and production.

- Gerber Technology AccuMark: A widely used software suite for pattern design, grading, and marker making in the textile industry. It offers tools for creating and modifying patterns, generating markers for efficient fabric cutting, and integrating with cutting machines.

- Oracle Cloud: Includes a comprehensive suite of cloud services tailored to the needs of textile and fabric mills. It offers scalable infrastructure, data management, and analytics solutions for applications such as supply chain management, inventory optimization, and production planning.

- SAP Cloud Platform: Robust cloud-based platform that offers a wide range of services for the textile and fabric industry. It provides tools for supply chain management, manufacturing execution, and quality control.

SAP SuccessFactors

Workday HCM

Oracle Warehouse Management (WMS)

Amazon Web Services (AWS)

Gerber Technology AccuMark

Lectra Fashion PLM

IBM Cloud

SAP Extended Warehouse Management (EWM)

SAP Cloud Platform

Oracle Cloud

Microsoft Azure

Google Cloud Platform (GCP)

GAO has worked with some of the leading technology companies in textile and fabric finishing and fabric coating mills in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in textile and fabric finishing and fabric coating mills industry:

- Coats Digital: Provides digital solutions for the fashion and textiles industries, including software for design, product development, and supply chain management. Their technologies help optimize efficiency and collaboration.

- Tukatech: Offers a range of software solutions for pattern making, grading, and 3D virtual prototyping. Their innovative technologies streamline the design and production processes for textiles and apparel.

- EFI (Electronics for Imaging): Is a leading provider of digital imaging and print management solutions, catering to various industries, including textiles. Their software solutions for textile printing, such as EFI Reggiani, offer advanced capabilities for digital textile production, including color management, design creation, and workflow automation.

- FastReact Systems: A software provider specializing in production planning, scheduling, and critical path management for the apparel and textile industry. Their solutions help textile mills optimize production processes, minimize lead times, and improve resource utilization.

- Honeywell: Is a multinational conglomerate that provides a wide range of electronic technologies and solutions. In the textile industry, Honeywell offers products such as industrial automation systems, sensors, and control systems. Their technologies help textile and fabric mills optimize processes, improve productivity, and ensure quality control.

- Siemens: Global technology company that offers electronic solutions for various industries, including textiles. Siemens provides automation, control, and drive technologies for textile and fabric mills. Their solutions enable efficient production processes, energy management, and quality assurance in textile manufacturing.

- ABB: Leading provider of power and automation technologies. They offer electronic solutions for textile mills, including systems for process automation, motor control, and energy efficiency. ABB’s technologies help textile and fabric mills optimize operations, reduce energy consumption, and enhance productivity.

- Schneider Electric: Specializes in providing energy management and automation solutions for various industries, including textiles. They offer electronic technologies for power distribution, control systems, and energy monitoring. Schneider Electric’s solutions help textile mills improve energy efficiency, ensure operational reliability, and optimize resource utilization.

- Datacolor: Is a leading provider of color management solutions for the textile industry. They offer software, spectrophotometers, and color measurement devices that ensure accurate and consistent color reproduction throughout the production process.

- Baldwin Technology: Focuses in providing process automation and control solutions for various industries, including textiles. They offer systems for fabric and textile finishing, including solutions for moisture control, drying, and coating.

- Montex Maschinenbau GmbH: A renowned manufacturer of textile machinery and systems. They offer a range of finishing systems, including stenter frames and coating machines, for textile and fabric mills

- James Heal: Leading provider of testing and quality assurance solutions for the textile industry. They offer a wide range of testing instruments and systems, including abrasion testers, pilling testers, and colorfastness testing equipment .

Coats Digital

Tukatech

EFI (Electronics for Imaging)

FastReact Systems

Honeywell

Siemens

ABB

Schneider Electric

Datacolor

Baldwin Technology

Montex Maschinenbau GmbH

James Heal

Case Studies of RFID Applications

Below are some RFID application cases in textile and fabric finishing and fabric coating mills industry.

Milliken & Company, a global textile manufacturer, implemented an RFID system to improve inventory management and enhance supply chain visibility. RFID tags were attached to fabric rolls, allowing real-time tracking and monitoring throughout the production and distribution processes. This enabled accurate inventory counts, reduced manual labor, and enhanced operational efficiency, resulting in better customer service and cost savings.

Burlington, a leading textile company, adopted RFID technology to optimize its manufacturing and logistics operations. RFID tags were integrated into fabric labels, providing real-time visibility and traceability of products throughout the supply chain. This enabled streamlined production processes, improved order accuracy, and enhanced inventory management. Burlington also leveraged RFID to enable quick and accurate replenishment of materials on the shop floor.

Westex by Milliken, a manufacturer of flame-resistant fabrics, implemented an RFID tracking system to enhance product traceability and ensure compliance with safety standards. RFID tags were embedded in fabric rolls, enabling automatic identification and tracking from production to end-use. This allowed improved quality control, increased supply chain transparency, and facilitated efficient product recalls, if necessary.

Cone Denim, a leading denim fabric producer, incorporated UHF RFID technology to enhance its inventory management and supply chain operations. UHF RFID tags were integrated into fabric rolls, enabling automated tracking and identification throughout the production and distribution processes. This resulted in improved accuracy in inventory management, reduced material waste, and enhanced overall operational efficiency.

Standard Textile, a prominent textile manufacturer, implemented a UHF RFID system to optimize its textile management and laundry operations. UHF RFID tags were attached to textile products, such as bedding and towels, enabling automated tracking and sorting during the laundry process. This improved inventory control, reduced loss of items, and increased operational efficiency in linen management for hospitality and healthcare industries.

Many applications of RFID by GAO can be found here.

GAO RFID Systems & Hardware for the Textile and Fabric Finishing and Fabric Coating Mills

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including textile and fabric finishing and fabric coating mills.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including textile and fabric finishing and fabric coating mills.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including textile and fabric finishing and fabric coating mills:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including textile and fabric finishing and fabric coating mills:

- Gen 2 UHF 902-928 MHz RFID Tags

- Gen 2 UHF 865-868 MHz RFID Tags

- Semi Passive UHF Gen2 RFID Tags

- and an array of antennas to address different applications:

- UHF 860 – 960 MHz RFID Antennas

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including textile and fabric finishing and fabric coating mills:

- HF 13.56 MHz Passive RFID Readers

- LF 134 kHz Passive RFID Readers

- LF 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including textile and fabric finishing and fabric coating mills:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

The RFID systems by GAO are highly popular for clients in textile and fabric finishing and fabric coating mills:

Physical asset or operational equipment tracking system:

GAO Has Served Textile and Fabric Finishing and Fabric Coating Mills Extensively

GAO’s products and technologies have helped its customers in textile and fabric finishing and fabric coating mills Industry to achieve success in sustainable manufacturing, digital printing, smart textiles, nanotechnology, circular economy, eco-friendly materials, customization, blockchain, Industry 4.0, automation, dye sublimation, antimicrobial finishes, performance fabrics, bio-based coatings, fast fashion, supply chain transparency, digitalization, additive manufacturing, and green chemistry.

GAO RFID Inc. has served many customers in textile and fabric finishing and fabric coating mills, including its various divisions such as:

- Dyeing and Printing Mills: These mills specialize in applying color and patterns to fabrics through processes like dyeing, printing, and other surface treatments.

- Textile Finishing Mills: These mills focus on enhancing the properties and aesthetics of fabrics through processes such as calendering, brushing, embossing, and chemical treatments.

- Fabric Coating Mills: These mills apply a layer of chemical or polymer material to the fabric surface to impart specific properties such as waterproofing, flame resistance, or antimicrobial properties.

- Specialty Textile Mills: These mills produce specialized textiles for specific applications, such as automotive textiles, industrial textiles, medical textiles, and technical textiles.

- Home Furnishings Mills: These mills specialize in producing fabrics used in home furnishings, including upholstery, curtains, bedding, and other household textile products.

- Apparel Manufacturing Mills: These mills focus on producing fabrics for the apparel industry, supplying textiles to clothing manufacturers for garments such as shirts, pants, dresses, and more.

Here are some of the leading companies in textile and fabric finishing and fabric coating mills industry:

Burlington Industries

Milliken & Company

Mohawk Industries

Glen Raven Incorporated

Springs Global

Culp Incorporated

Parkdale Mills

Mount Vernon Mills

Albany International Corporation

Unifi Incorporated

ITG Brands

Fabri-Kal Corporation

International Textile Group

American Cord & Webbing Company Incorporated

Highland Industries

Ascend Performance Materials Limited Liability Company

Pacific Coast Feather Company

Carolina Cotton Works

Gildan Activewear Incorporated

Canada Goose Holdings Incorporated

Cintas Corporation Canada

Mill Street & Company Incorporated

Textile Corporation of America Incorporated

Royal Apparel Limited