RFID Antenna Design: Electronic, Mechanical, and Software Components

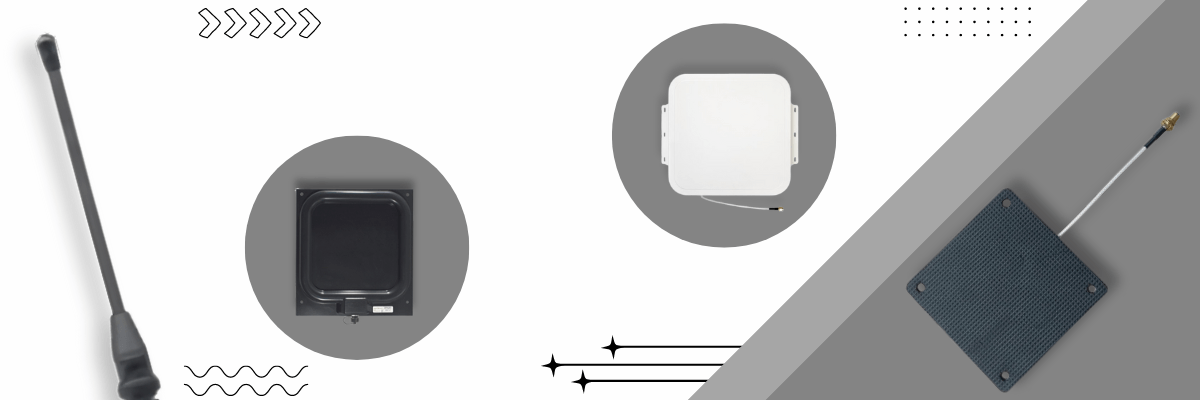

An RFID antenna is a fundamental part of any RFID system, acting as the medium for communication between RFID tags and readers. Its design encompasses several key components in electronic, mechanical, and software aspects, all of which work together to ensure reliable data transmission.

Electronic Design and Components

The electronics in an RFID antenna are critical to its function, driving the signal transmission and reception. Core electronic elements include the impedance matching network, which ensures efficient power transfer between the antenna and RFID reader, and the balun (balanced-unbalanced transformer), which converts balanced antenna signals to unbalanced signals compatible with the reader. These components are essential to maximize antenna efficiency, minimizing signal loss.

For example, some RFID antennas include a resonant circuit that allows for fine-tuned signal handling across multiple frequencies. Another example is the integration of a directional coupler, which enables the antenna to split signals into different paths, optimizing for varied RFID applications and ranges.

Mechanical Design and Components

Mechanical design ensures that RFID antennas can withstand environmental and physical demands. Housing materials, such as reinforced polycarbonate or stainless steel, provide durability, making the antenna resilient against elements like moisture, dust, and temperature extremes. Mechanical elements like ground planes help control the directionality of the antenna’s signal, ensuring consistent and reliable communication with RFID tags.

The radome, a protective cover, is another crucial component that shields the internal electronics without distorting the electromagnetic signal. Depending on the deployment environment, additional features like shock absorption mounts may be included to protect the antenna from physical impacts in industrial settings.

Software and Firmware Integration

While RFID antennas do not contain complex software, firmware often plays a role in their tuning and calibration. Many RFID antennas are designed to interface with software platforms that control power settings, polarization, and other variables to optimize performance. For example, beamforming capabilities in software help adjust the radiation pattern to focus the signal where needed, improving tag readability. GAO RFID provides RFID antennas that are easily integrated with advanced software platforms for seamless configuration and diagnostics.

Connections and Interfaces

RFID antennas typically feature standard RF connections, such as SMA or N-type connectors, which provide stable links to RFID readers and other devices. These connectors allow flexibility in deployment, whether for short-range systems or wide-area networks. Some antennas may also include additional ports or adapters for integrating with systems such as power-over-Ethernet (PoE) setups or directly connecting to communication hubs for remote monitoring.

Working Principles

The working principle of an RFID antenna revolves around the transmission and reception of electromagnetic waves. The antenna generates a radio frequency field that activates RFID tags, powering passive tags or exchanging data with active ones. Once the tag responds, the antenna receives the reflected or backscattered signal and relays it to the RFID reader for data processing. Antenna design, such as polarization and frequency, plays a significant role in determining how effectively signals can be read under different conditions.

Compliance with Industry Standards

To ensure interoperability and performance, RFID antennas must adhere to several industry standards. ISO/IEC 18000 is one such standard that governs the technical specifications of RFID systems, including antennas. Additionally, antennas designed for UHF RFID must comply with FCC regulations in the United States, specifically concerning frequency allocation and power output, particularly in the 902-928 MHz range. Similarly, antennas in Canada must meet the regulatory requirements of Innovation, Science and Economic Development (ISED) Canada, ensuring they operate without interference in designated frequency bands.

Quality Assurance and Testing

Quality assurance is integral to ensuring that RFID antennas perform reliably over time. Testing includes environmental assessments, such as exposure to extreme temperatures, humidity, and physical vibrations, to guarantee that antennas can withstand harsh conditions. Electromagnetic compatibility (EMC) testing is also critical to ensure the antenna’s performance is unaffected by external RF noise. GAO RFID’s antennas undergo rigorous testing to meet the highest standards of reliability, ensuring they perform optimally in both standard and demanding environments.

Ports and Interfaces

RFID antennas are designed with standardized ports that connect to RFID readers and other devices. SMA, N-type, and TNC connectors are commonly used for connecting coaxial cables, ensuring minimal signal loss. Additionally, some antennas feature Ethernet or USB ports for integration into more complex systems, such as IoT networks or automated inventory management systems.

Our products are in stock and can be shipped overnight to Continental U.S. and Canada from one of our local warehouses. If you have any questions, our technical experts can help you. Please fill out this form or email us.