How to Choose Low-Frequency RFID Tags

Selecting the right low-frequency (LF) RFID tags is crucial for ensuring the success of your RFID system. LF RFID operates in the 125 kHz to 134.2 kHz range and is commonly used for access control, animal tracking, and industrial applications. These tags are ideal for close-range reads and environments with high interference, making them highly reliable in challenging conditions. 1. Understand Your Application Needs

Your application largely determines the type of LF RFID tag you should choose. Since low-frequency tags offer shorter read ranges (usually up to 10 cm), they are best suited for use cases that do not require long-distance tracking. Typical applications include:

- Access Control: LF tags are commonly used in building access systems, where proximity reads are preferred.

- Animal Tracking: The LF frequency is ideal for animal identification due to its ability to read through non-metallic materials like water, which is present in animal bodies.

- Industrial Use: In manufacturing environments where metallic interference or other challenges exist, LF RFID tags can provide reliable, consistent reads.

2. Tag Form Factor and Design

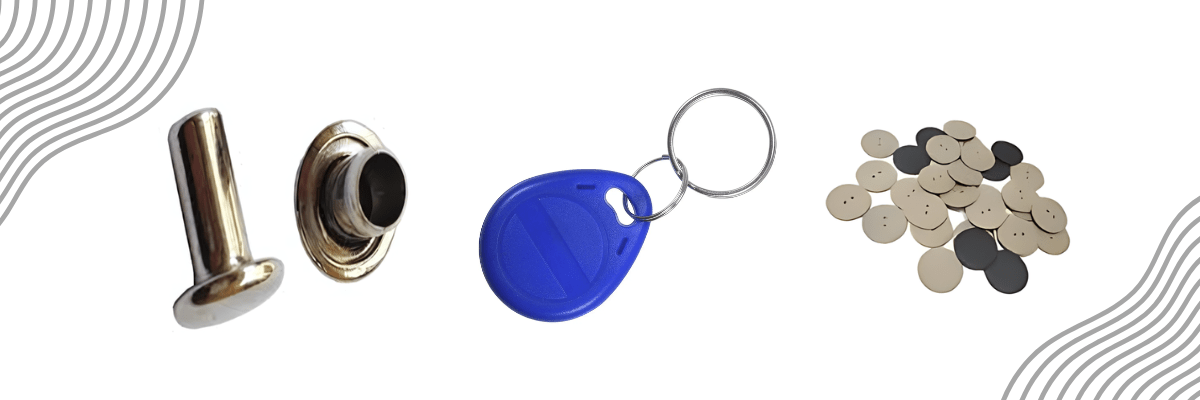

The physical size and design of an RFID tag are key factors based on where and how the tag will be attached or embedded. LF RFID tags come in a variety of shapes, sizes, and materials, including:

- Key Fob or Card Tags: These are typically used in access control systems where portability is essential.

- Ear Tags for Livestock: These rugged, durable tags are designed for attachment to animals, withstanding weather, and outdoor conditions.

- Embedded Tags for Industrial Equipment: For applications requiring tracking of assets or tools, LF tags can be embedded into plastic, rubber, or other protective materials.

3. Material and Durability

The environment in which the LF RFID tags will be used plays a significant role in determining the type of material and durability required.

- Indoor Environments: For applications like building access control or asset tracking inside facilities, plastic or PVC-based LF RFID tags provide sufficient durability.

- Outdoor or Harsh Environments: For outdoor installations, such as tracking livestock or industrial assets, choose tags made of rugged materials such as ABS plastic or epoxy-coated tags that can withstand extreme temperatures, moisture, and physical wear.

- Animal Tags: For tracking livestock, look for tags specifically designed for biosecurity and animal-friendly materials that can endure long-term use.

4. Memory Size and Data Storage

Depending on the complexity of your application, the memory size of the LF RFID tag might be an important factor. While LF tags typically have smaller memory capacities than UHF tags, they can still hold enough data for many applications.

- Basic Identification: For simple applications like access control or basic asset tracking, LF tags with standard memory sizes are sufficient.

- More Detailed Information: In cases where you need to store more information, such as for complex industrial processes or supply chain data, tags with additional memory can be beneficial.

5. Read Range and Tag Sensitivity

LF RFID tags are designed for short-range reads, typically between a few centimeters to about 10 cm. While the read range is generally consistent across LF tags, environmental factors such as metal interference or proximity to water can affect performance.

- Proximity-Based Applications: For applications like door access systems or animal identification, the shorter read range of LF tags is ideal as it allows for controlled reads.

- Improving Read Performance: In challenging environments, ensure that the tags you select are designed to minimize interference and maximize readability.

6. Environment-Specific Considerations

The performance of LF RFID tags can be influenced by the environment in which they are deployed. LF tags are more resistant to interference from liquids and metals than other frequency tags, making them ideal for use in:

- Water-Rich Environments: For animal tracking or use in humid environments, LF RFID tags offer superior performance because they are less affected by water content.

- Metallic Environments: In manufacturing settings where metal is prevalent, LF tags are a reliable choice because they function well even with metallic interference.

7. Customization Options

Depending on the needs of your application, you may need tags with specific features such as unique IDs, tamper-proof designs, or specific attachment methods. Customizable options can include:

- Tamper-Evident Tags: Useful in secure environments to detect unauthorized access or tampering.

- Custom Shape and Size: For specific industries like healthcare or agriculture, custom tag shapes or sizes may be required to fit unique applications.

Case Studies:

- Access Control System, New York, NY: A large corporate office building in New York implemented LF RFID tags for their secure access control system. Using durable key fob tags, employees could easily access restricted areas while ensuring high-level security with short-range reads.

- Animal Identification, Omaha, NE: A livestock management company in Omaha utilized rugged, waterproof LF RFID ear tags to track and monitor cattle. These tags provided reliable, accurate reads even in wet and muddy outdoor conditions, significantly improving livestock tracking.

- Tool Tracking System, Vancouver, BC: An industrial firm in Vancouver deployed LF RFID tags embedded in metal tools to manage inventory and tool usage in their factory. The rugged tags ensured accurate data collection in a high-interference metal environment, boosting efficiency and reducing loss.

Our products are in stock and can be shipped overnight to Continental U.S. and Canada from one of our local warehouses. If you have any questions, our technical experts can help you. Please fill out this form or email us.