Overview of Manufacturing and Industrial Automation using UHF RFID

Manufacturing and industrial automation are undergoing significant transformations with the adoption of Ultra High-Frequency (UHF) Radio Frequency Identification (RFID) technology. UHF RFID enables seamless, automated tracking and management of assets, inventory, and workflow within complex manufacturing environments. Its long read range and ability to operate in challenging industrial conditions make it an ideal solution for industries seeking to increase productivity and accuracy. At GAO RFID Inc., with headquarters in New York City and Toronto, Canada, we leverage our expertise and rigorous R&D to offer top-tier RFID solutions to businesses across the U.S. and Canada, including major Fortune 500 companies and leading research institutions.

UHF RFID-based automation systems streamline industrial processes by minimizing manual interventions, reducing errors, and enhancing real-time data visibility across the production line. GAO RFID’s solutions are built on stringent quality standards, ensuring durability, reliability, and optimal performance even in high-stress manufacturing settings. Our team offers expert support, whether onsite or remotely, helping industries transition smoothly into a fully automated environment.

Applications of UHF RFID in Manufacturing and Industrial Automation

- Asset Tracking and Management

UHF RFID systems are ideal for tracking assets like machinery, tools, and vehicles within a facility. GAO RFID’s UHF tags allow continuous asset monitoring, reducing losses and ensuring equipment availability when needed. This visibility is critical for optimizing asset usage and preventing unexpected downtimes. - Inventory Management

With UHF RFID, managing raw materials and finished goods becomes highly efficient. Inventory levels are updated in real-time, and materials can be located instantly. GAO RFID’s inventory solutions help prevent stockouts or overstock situations, ensuring smooth production flow and efficient supply chain management. - Work-in-Progress (WIP) Monitoring

UHF RFID tags on workpieces allow for real-time tracking of each stage of the manufacturing process. This WIP monitoring reduces bottlenecks and provides precise information on production timelines, enhancing GAO RFID’s clients’ operational transparency and enabling better process planning. - Quality Control and Compliance

UHF RFID ensures products meet quality standards by recording production data directly linked to individual items. This traceability, a GAO RFID specialty, helps industries maintain regulatory compliance and enhances quality assurance, particularly useful for sectors like automotive, aerospace, and pharmaceuticals. - Employee Safety and Facility Access Control

By integrating UHF RFID badges, manufacturers can monitor employees’ access to restricted zones and improve safety compliance. GAO RFID solutions provide secure access and safety protocols, reducing unauthorized entries and ensuring regulatory adherence. - Production Line Automation

GAO RFID’s UHF RFID solutions are instrumental in automating conveyor belt processes, where tagged items are identified, sorted, or redirected without human intervention. This automation speeds up production, reduces errors, and lowers labor costs. - Maintenance Scheduling

UHF RFID tags provide precise usage data on equipment, enabling predictive maintenance. This data-driven maintenance avoids unexpected breakdowns, and GAO RFID’s robust UHF tags withstand harsh conditions, ensuring durability and accurate readings even under heavy wear. - Cold Chain and Environmental Monitoring

UHF RFID sensors allow real-time monitoring of environmental conditions in temperature-sensitive processes. GAO RFID’s UHF tags track temperature, humidity, and other environmental factors to ensure product integrity, making them ideal for food, pharmaceutical, and chemical industries. - Shipment Verification and Logistics

UHF RFID speeds up outbound logistics by verifying shipments against orders automatically. GAO RFID’s UHF RFID systems can reduce dispatch errors, improve loading accuracy, and optimize supply chain visibility, benefitting warehousing and distribution. - Anti-Counterfeit Measures

UHF RFID tags provide an added layer of security by enabling traceability of individual products, from production to delivery. GAO RFID’s anti-counterfeit solutions help safeguard brand reputation and customer trust by ensuring genuine product delivery, particularly important for luxury goods and electronics.

By offering reliable UHF RFID solutions backed by a robust quality assurance process, GAO RFID Inc. enables businesses to embrace cutting-edge manufacturing and industrial automation with confidence. Whether in asset tracking, quality assurance, or automated logistics, our RFID solutions are designed to optimize efficiency, accuracy, and compliance across all stages of production.

Navigation Menu for UHF RFID:

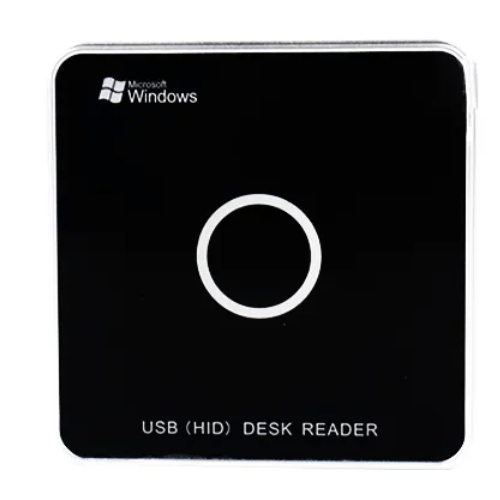

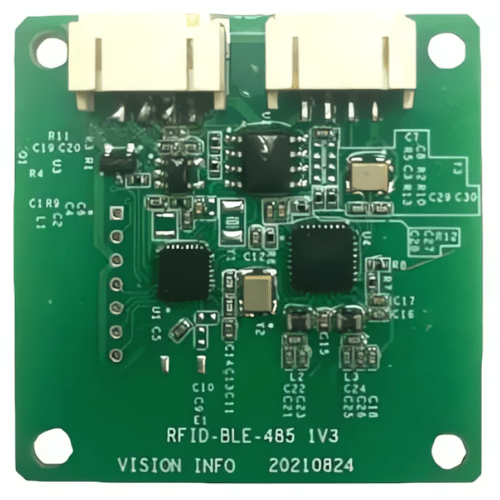

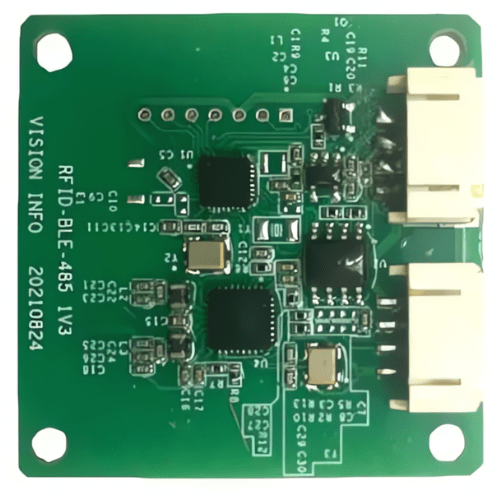

Here are UHF RFID readers offered by GAO:

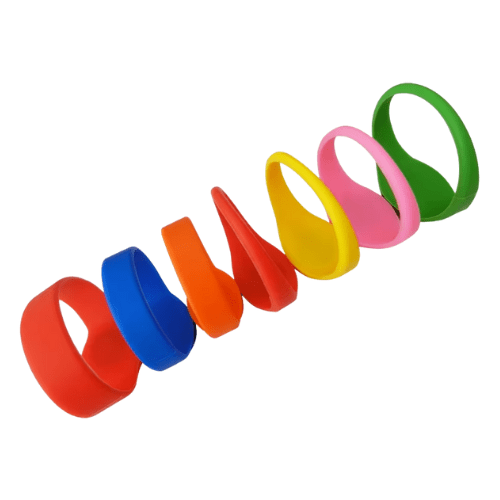

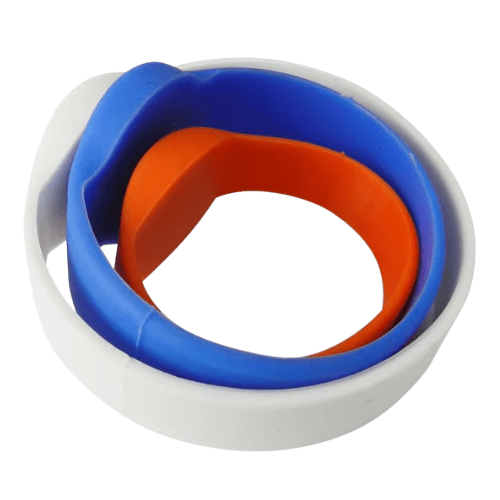

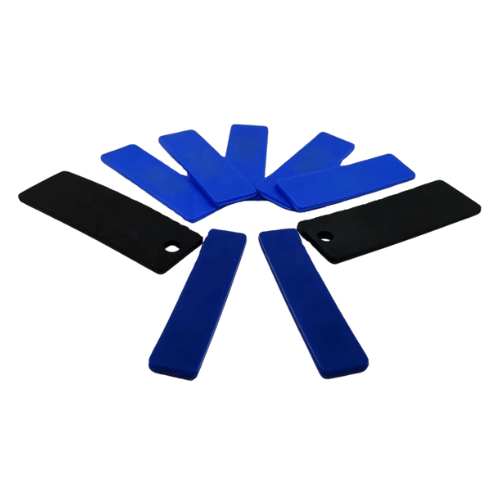

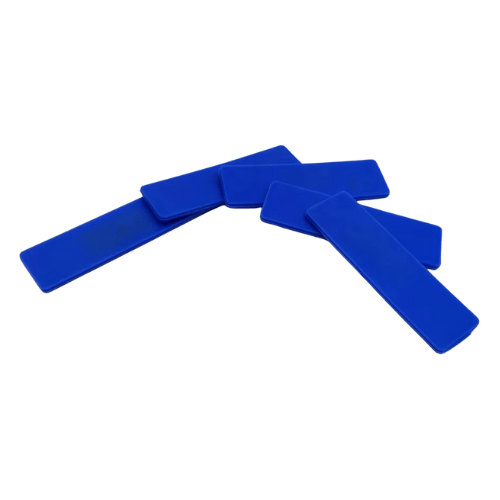

Here are UHF RFID tags offered by GAO:

Here are lists of UHF RFID readers offered by GAO:

- UHF RFID Readers

- Industrial RFID Readers

- UHF High-Speed RFID Readers

- UHF Multi-Tag RFID Readers

- UHF Anti-Collision RFID Readers

- UHF Vehicle-Mounted RFID Readers

- Integrated Fixed RFID Readers

- Long Range RFID Readers

- Battery-Powered RFID Readers

- Rugged / IP Rated RFID Readers

- PoE (Power over Ethernet) RFID Readers

- Cloud-Enabled RFID Readers

Here are lists of UHF RFID tags offered by GAO:

- Asset Tracking RFID Tags

- Cold Chain RFID Tags

- Inventory Management RFID Tags

- Logistics and Supply Chain RFID Tags

- Rugged RFID Tags

- Tamper Proof RFID Tags

- Temperature Sensing RFID Tags

- Waste Management RFID Tags

- RFID Tags for Tool Tracking

- High-Temperature Tolerant RFID Tags

- Dual Frequency RFID Tags

- On Metal UHF EPC Gen 2 RFID Tags

Our products are in stock and can be shipped to anywhere in continental U.S. or Canada from our local warehouse. For any further information, please fill out this form or email us.