The military aerospace manufacturing industry is a sector that produces aircraft, spacecraft, and related components and systems for military purposes. It includes companies that design, develop, manufacture, and maintain military aircraft and related equipment, such as engines, avionics, and weapons systems. The industry has a significant impact on national defense capabilities and international relations, but is also subject to criticism for its environmental impact and role in perpetuating conflict. GAO RFID Inc., a global top 10 RFID leader based in the cities of New York and Toronto, has served many companies in the military aerospace manufacturing industry.

GAO RFID Systems & Hardware for the Military Aerospace Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the military aerospace manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for all kinds of industries, including the military aerospace manufacturing industry:

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the military aerospace manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the military aerospace manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the military aerospace manufacturing industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the military aerospace manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the military aerospace manufacturing industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

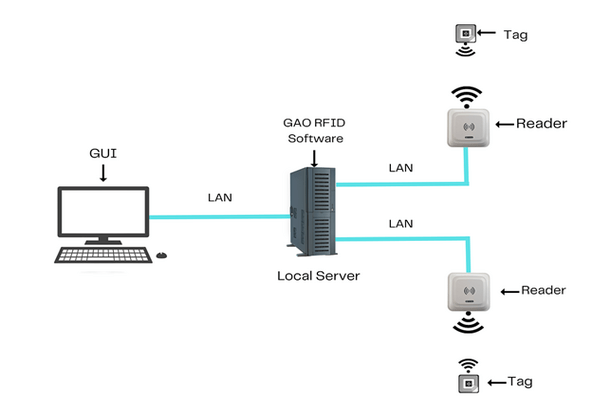

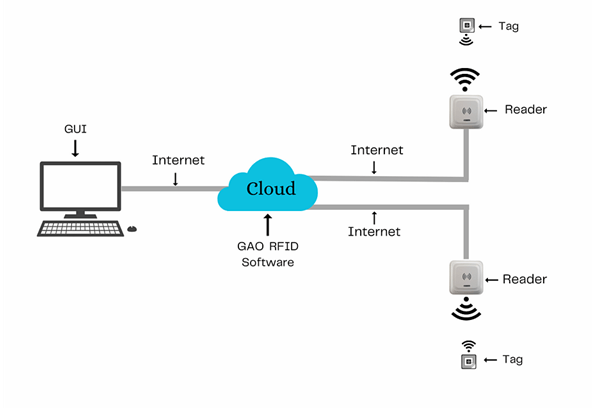

There are two versions of GAO’s software, one is running on a local server, another running in the cloud.

GAO offers free samples of its RFID tags, labels, badges, and wristbands

GAO offers a free trial for all of its software available.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Military Aerospace Manufacturing

Applications & benefits of applying RFID to the military aerospace manufacturing

- Asset tracking and management: GAO RFID tags can be used to track and manage military aerospace assets such as aircraft, vehicles, and equipment like GPS tracking devices, barcode scanners, IoT sensors. By attaching RFID tags to these assets, their location and status can be monitored in real-time, allowing for more efficient utilization and maintenance.

- Improved supply chain management: Our RFID solution can also be used to track the movement of materials like metals, composites, plastics, and components like sensors, processors, controllers throughout the supply chain. This can help ensure that critical components are available when needed and can reduce the risk of delays or disruptions.

- Enhanced security: GAO RFID solution can also be used to enhance security by providing real-time tracking and monitoring of personnel, vehicles, and equipment like biometric identification systems, metal detectors, x-ray machines, cybersecurity systems. This can help prevent unauthorized access to sensitive areas and improve overall situational awareness.

Applications & benefits of applying BLE technology to the military aerospace manufacturing

- Reduced Size and Weight: GAO BLE solution is designed to be very small and lightweight, making it ideal for use in military and aerospace applications where space and weight are at a premium. By using BLE solution, military and aerospace companies can reduce the size and weight of their equipment like sensors, wearable solution, and helmets making it easier to transport and deploy in the field.

- Improved Connectivity: BLE solution allows for wireless communication between devices over short distances, which can be particularly useful in military and aerospace applications where reliable connectivity is essential. By using GAO BLE solution, military and aerospace companies can improve the connectivity of their equipment like radios, headsets and ensure that it can communicate seamlessly with other devices in the field.

Applications & benefits of applying combination of RFID and drones to the military aerospace manufacturing

- Inventory Management: GAO RFID solution can be used to track the inventory of raw materials like titanium, aluminum, steel and components like avionics, landing gear, weapons systems and finished products like aircraft engines, missiles, aircraft seats in real-time. Drones equipped with RFID readers can fly around the warehouse or manufacturing facility to locate and track the movement of items, eliminating the need for manual scanning and reducing the risk of errors. This will improve inventory accuracy, reduce costs, and improve overall efficiency.

- Asset Tracking: GAO Drones can be used to fly around the facility and read the RFID tags, providing real-time location information. This will help to prevent loss, theft, or misplacement of assets, reducing downtime and increasing productivity.

- Quality Control: Drones equipped with cameras and sensors can inspect aircraft components and structures for defects or damage. GAO RFID tags can be used to identify and track the components, allowing the drone to quickly locate and inspect them. This will improve the accuracy and speed of quality control inspections, reducing downtime and improving safety.

Applications & benefits of applying combination of RFID and IoT to the military aerospace manufacturing

- Increased Efficiency: The combination of GAO RFID and IoT can enable manufacturers to automate many manual tasks, such as inventory tracking, asset management, and quality control. This can lead to increased efficiency, reduced labor costs, and improved production output.

- Enhanced Supply Chain Visibility: GAO RFID and IoT can help manufacturers gain real-time visibility into their entire supply chain, from raw material suppliers to finished goods delivery. This can help identify bottlenecks and inefficiencies, allowing manufacturers to optimize their supply chain operations and improve customer satisfaction.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Military Aerospace Manufacturing

GAO RFID Inc. has helped many companies in the military aerospace manufacturing industry to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

- MIL-STD-129: This standard is used by the U.S. Department of Defense to label and track military assets. It requires the use of RFID tags that meet specific requirements for data encoding, durability, and readability including in the US and Canada.

- ATA Spec 2000: This is a standard developed by the Air Transport Association of America (ATA) for the aerospace industry in the US and Canada. It includes requirements for the use of RFID tags for inventory tracking, asset management, and maintenance tracking.

- DoD UID Policy: This policy requires all items valued at $5,000 or more to be marked with a unique identifier (UID) in the form of an RFID tag. The tag must contain information such as the part number, serial number, and the UID of the manufacturer.

- International Traffic in Arms Regulations (ITAR): This regulation is administered by the U.S. Department of State and controls the export and import of defense-related items and services.

- Federal Acquisition Regulations (FAR): The FAR is administered by the U.S. government and sets out the rules and regulations for federal procurement.

- Defense Federal Acquisition Regulation Supplement (DFARS): The DFARS is a supplement to the FAR and sets out additional regulations specifically for defense contractors.

- National Industrial Security Program Operating Manual (NISPOM): The NISPOM is administered by the U.S. Department of Defense and sets out the guidelines for safeguarding classified information.

- Defense Production Sharing Agreement (DPSA): This agreement is a bilateral arrangement between the United States and Canada that establishes a framework for the sharing of defense procurement and production opportunities.

GAO’s Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking, access control, parking system control, are work in progress, offer a free trial and offers an API to each of the common software in the military aerospace manufacturing industry:

Personnel Management

- Recruitment, training, and retention of skilled engineers, technicians, and other personnel

- Ensuring compliance with health and safety regulations and industry standards

- Implementing employee engagement and career development programs

Equipment Management

- Maintenance, repair, and overhaul of military aircraft, spacecraft, and related equipment

- Development and implementation of predictive maintenance systems to minimize downtime

- Upgrades and modifications to improve performance and extend the service life

Supply Chain Management

- Sourcing and procurement of raw materials, components, and subsystems

- Managing supplier relationships and ensuring quality and reliability of purchased components

- Logistics and inventory management to ensure timely delivery of materials and components

Other Applications

- Research and development of new aircraft designs, materials, and technologies

- Quality control and assurance to ensure compliance with industry standards and specifications

- Environmental impact management to minimize the industry’s carbon footprint and other negative environmental impacts.

Case Studies of RFID Applications

One notable case study of RFID applications in the military aerospace manufacturing industry in the US is Lockheed Martin’s implementation of RFID technology to improve its supply chain management. In 2013, Lockheed Martin began using RFID tags on its products to track them throughout the manufacturing process, from assembly to delivery. The company installed RFID readers at key points in its production facilities to capture real-time data on the location of its products, which helped to streamline its inventory management and reduce its lead times.

Another example is the US Air Force’s use of RFID technology for asset tracking and maintenance management. The Air Force began using RFID tags on its aircraft and equipment in 2004 to improve the accuracy and efficiency of its asset tracking system. The technology enabled the Air Force to track the location and status of its assets in real-time, which helped to reduce the time and cost associated with manual inventory management. Additionally, the RFID system helped the Air Force to improve its maintenance management by providing accurate data on the usage and maintenance history of its equipment.

GAO Has Served the Military Aerospace Manufacturing Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the military aerospace manufacturing industry including its various divisions such as

- Aircraft manufacturing: This involves the design, development, and production of military aircraft such as fighter jets, bombers, transport planes, and unmanned aerial vehicles (UAVs).

- Missile and rocket manufacturing: This includes the production of missiles, rockets, and other guided munitions used in military operations.

- Spacecraft manufacturing: This involves the design and development of spacecraft for military applications such as reconnaissance and surveillance, communication, and navigation.

- Avionics manufacturing: This involves the production of electronic systems and equipment used in aircraft, such as radar systems, navigation systems, and communication systems.

- Engine manufacturing: This includes the design, development, and production of military aircraft engines, as well as the maintenance and repair of these engines.

- Defense electronics manufacturing: This involves the production of electronic systems and equipment used in defense applications, such as radar systems, electronic warfare systems, and communication systems.

- Maintenance, repair, and overhaul (MRO): This includes the maintenance, repair, and overhaul of military aircraft, engines, and other components.

- Support equipment manufacturing: This involves the production of support equipment and systems used in military aviation, such as ground support equipment, weapons loading systems, and maintenance equipment.

List of the some leading companies in the military aerospace manufacturing industry in the US

List of the some leading companies in the military aerospace manufacturing industry in the Canada