Mining construction involves the design, engineering, and construction of mining facilities such as mines, processing plants, and storage facilities. These facilities are designed to extract, process, and store minerals and other resources from the earth for various industries. The construction of these facilities requires specialized knowledge and equipment to ensure safe and efficient operations. GAO RFID Inc., one of the global top 10 RFID leaders, is based in the cities of New York and Toronto and it has deployed many RFID, BLE and IoT projects in the mining construction industry.

GAO RFID Systems & Hardware for the Mining Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the mining construction industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for all kinds of industries, including the mining construction industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the mining construction industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the mining construction industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the mining construction industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the mining construction industry:

and antennas:

GAO also offers RFID printers, Digital I/O adapters and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the mining construction industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

- GAO RFID Industrial Sand Mining Asset Management System

- GAO RFID Peat Extraction Asset Management System

- GAO RFID Tool & Industrial Equipment Tracking System

Personnel or people access control system:

Parking or vehicle control system:

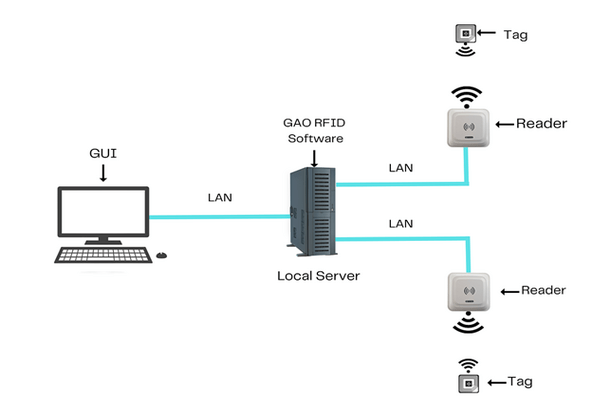

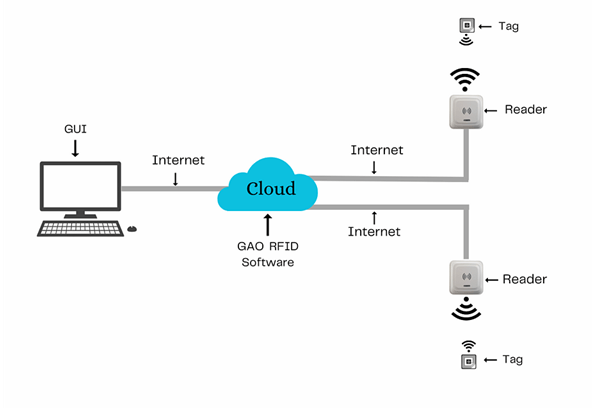

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

Benefits of GAO’s RFID, BLE, IoT & Drone for Mining Construction

The mining construction industry can significantly benefit from the integration of BLE, drones with RFID, and IoT with RFID technologies. These technologies can enhance the monitoring, tracking, and safety of workers and equipment, increase productivity, and reduce costs.

BLE technology is particularly useful in mining construction sites as it has a long range of up to 300 meters, which is more than the normal RFID range. This makes it an excellent choice for tracking workers and equipment at large mining sites. BLE can be used for access control, where authorized personnel can access specific zones while unauthorized individuals are restricted. By adding beacons to equipment such as drills, trucks, loaders, dozers, excavators, safety gear, and other tools, workers can easily track them within the mining site. This reduces the need for manual processes and ensures that the necessary equipment like bulldozers, excavator, crushers, blasting equipment, core drilling equipment is available when needed.

Drones equipped with RFID readers offer a portable and flexible option for tracking workers, tools, and equipment at large mining sites. They can detect safety hazards and provide a bird’s-eye view of the job site, allowing for better planning and monitoring of the mining process. Safety officers can use drones with RFID readers for safety management, eliminating the need for human intervention and automating time stamping. Drones flying around the site can also be used for cost-effective asset tracking and people tracking all over the active mining construction site.

IoT sensors, such as humidity, temperature, and vibration sensors, can monitor inventory levels in real-time, ensuring that necessary components are available when needed. This reduces manual processes and allows workers to focus on critical tasks. By automating data such as storage area, supply levels, and usage, which can be achieved with BLE, workers can track wires, cables, pipes, and other components that are often stored in various locations. Strategically placed gateways can ensure that theft and loss of equipment are prevented. Miners, mining engineers, project managers, estimators, inspectors, foremen, and other construction workers can also use BLE to track which tools have been tested and which ones have not, depending on the requirements of the work at an active mining construction site. The system can also be customized to track the utilization of each supplied part, ensuring proper resource utilization. This helps project managers and warehouse managers create a decentralized inventory management system.

GAO RFID and BLE products come in a wide range. Some of our RFID products are rugged, waterproof, and dustproof. These sensors are used to sensor humidity, temperature, vibration, and movements of the items they are attached to.

GAO Helps Customers Comply with Standards, Mandates & Regulations

GAO RFID Inc. has helped many companies in the mining construction industry to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

- National Environmental Policy Act (NEPA) – This law requires federal agencies to consider the environmental impacts of their actions and decisions, and to involve the public in the decision-making process mining construction industry.

- Occupational Safety and Health Administration (OSHA) – This federal agency sets and enforces safety and health standards for workers in the United States mining construction industry.

- Mine Safety and Health Act of 1977 (MSHA) – This federal law established minimum health and safety standards for miners and mine operators in the United States.

- ASTM F3077 – This is a standard developed by ASTM International for RFID tracking of equipment and materials in the mining construction industry.

- ISO 18000-7 – This standard is used for tracking vehicles and equipment in mining and construction environments for active RFID tags operating at 433 MHz.

- Clean Water Act (CWA) – This law regulates the discharge of pollutants into navigable waters of the United States to prevent water pollution in mining construction industry.

- Canadian Environmental Assessment Act, 2012 (CEAA) – This law requires the assessment of the environmental effects of proposed mining projects before they can be approved.

- Canadian Environmental Protection Act, 1999 (CEPA) – This law regulates the use, import, and export of substances that are harmful to human health and the environment mining construction industry.

- Canadian Nuclear Safety and Control Act – This law regulates the use of nuclear materials and facilities in Canada, including uranium mining and processing. And requires compliance with safety standards and the management of radioactive waste.

Case Studies Of RFID Applications

Here is a case study of RFID tracking of mining equipment for construction projects. A large mining construction company was facing challenges with keeping track of their expensive equipment and tools on job sites. This resulted in delays, increased costs, and decreased productivity. To address this problem, they implemented an RFID system. RFID tags were attached to each piece of equipment and tool, which contained information such as the type of equipment, its location on the site, and its current status. RFID readers were installed at the entrance and exit points of the job sites, as well as at various checkpoints throughout the site. Whenever a piece of equipment entered or exited a job site or a checkpoint, the RFID tag was read, and the equipment’s location was updated in the system. The mining construction company was able to track the location of their equipment in real-time and monitor their usage patterns. If a piece of equipment was missing or misplaced, they could quickly locate it, resulting in a significant reduction in the time and cost associated with searching for lost equipment. The RFID system also helped to deter theft, as the company was alerted whenever a piece of equipment left a job site without authorization.

Here is another case study of RFID tracking of mining personnel and vehicles for safety and efficiency. A large mining construction company was looking for a way to improve safety and efficiency on their job sites. They turned to RFID technology to track their personnel and vehicles in real-time. RFID tags were attached to the safety vests worn by personnel and to the vehicles used on site. The RFID readers were installed at various checkpoints throughout the site, as well as at the entrance and exit points. Whenever a person or a vehicle passed through a checkpoint, the RFID tag was read, and the location of the person or vehicle was updated in the system. The mining construction company was able to monitor the location of their personnel and vehicles in real-time, which helped to ensure their safety and improve efficiency. If a person was missing or a vehicle was out of place, they could quickly locate them, resulting in a significant reduction in the time and cost associated with searching for missing personnel or vehicles. The RFID system also helped to improve safety by alerting the company if a person or vehicle entered a restricted area.

GAO Has Served the Mining Construction Extensively

GAO RFID Inc., one of the global top 10 RFID leaders, is based in the cities of New York and Toronto and it has deployed RFID, BLE and IoT projects for many leading companies in the mining construction industry including its various divisions such as:

- Exploration and Mine development: It is focused on identifying potential mining sites and developing mines.

- Materials handling: It deals with the movement and transportation of materials within mines.

- Mineral processing: It is the refining of raw materials extracted from mines into usable products.

- Environmental management: It involves monitoring and managing environmental impacts associated with mining operations.

Some of the leading companies in the mining construction industry in the US:

Some of the leading companies in the mining construction industry in Canada: