Related Products & Systems on Other Pages on This Website

Tool & Industrial Equipment Tracking System

Employee & Attendance Access Control System

Work In Process WIP Asset Tracking System

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

Rugged RFID Tags | GAO RFID Inc.

Tamper Proof RFID Tags | Security RFID Tags – GAO RFID

On Metal RFID Tags – All Types

High Temperature RFID Tags – GAO RFID

Overview

Medical robots are used in a variety of applications, including surgery, rehabilitation, and drug discovery. In surgery, robots can be used to perform minimally invasive procedures that are less risky and have a shorter recovery time than traditional open surgery. In rehabilitation, robots can be used to help patients regain lost mobility and strength. And in drug discovery, robots can be used to automate tasks such as screening potential new drugs for toxicity and efficacy.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in medical robotics and automation manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as sawmills, planers, routers, shapers, band saws, dust collectors, raw materials, tools, safety equipment, and training.

Ranked as one of the top ten global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for medical robotics and automation manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Medical Robotics and Automation Manufacturing

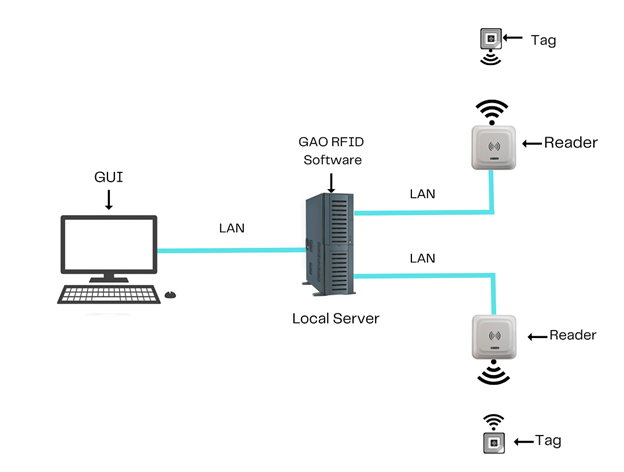

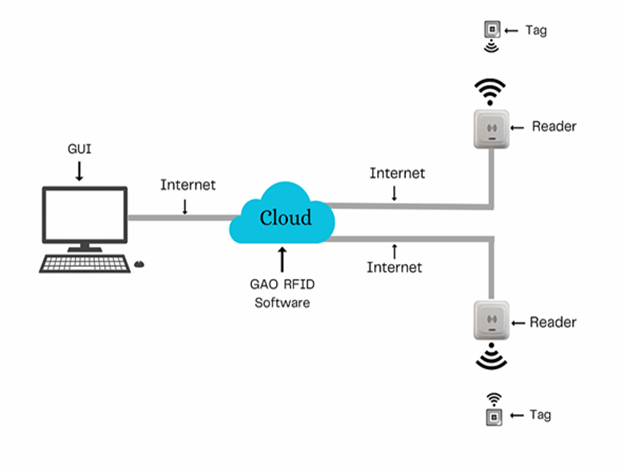

To satisfy its customers, GAO’s RFID or RFID Systems for Medical Robotics and Automation Manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, Cloudflare, Linode and Rackspace. The above illustrates GAO system for Medical Robotics and Automation Manufacturing with its software running on a local server

The above illustrates GAO system for medical robotics and automation manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in medical robotics and automation manufacturing:

- Asset Tracking and Utilization Optimization: Our technology can be utilized to track and manage medical devices, surgical instruments, and manufacturing equipment. This ensures efficient asset utilization, minimizes downtime, and helps prevent loss or misplacement of valuable resources.

- Supply Chain Visibility and Traceability: Both industries can benefit from RFID-enabled supply chain management. RFID tags on medical supplies and manufacturing components provide real-time visibility, allowing stakeholders to track the movement of items from suppliers to end-users. This enhances efficiency, reduces inventory costs, and ensures product traceability for safety and compliance purposes.

- Quality Control and Compliance: GAO RFID’s integration in medical robotics and manufacturing processes helps enforce quality control measures. RFID tags can carry essential data, such as production details, specifications, and certifications, streamlining quality checks and ensuring compliance with industry standards and regulations.

- Preventive Maintenance and Equipment Monitoring: GAO’s technology allows continuous monitoring of equipment, medical devices, and manufacturing machinery. It enables predictive maintenance, identifying potential issues before they lead to costly breakdowns. This proactive approach maximizes equipment uptime and extends their operational lifespan.

- Patient Safety and Medication Management: Our RFID tags on patient wristbands and medical supplies enhance patient safety by ensuring accurate identification and medication management. In manufacturing, RFID can also help track and verify the correct use of components in the production of medical devices, reducing the risk of errors and ensuring product integrity.

GAO’s drone technologies find the following applications in the medical robotics and automation manufacturing:

- Improved quality control: GAO RFID can be used to monitor the quality of medical devices and components throughout the manufacturing process. This can help to improve the quality of the final product and reduce the risk of recalls. Drones can be used to inspect medical devices and components quickly and easily for any potential defects.

- Increased efficiency: Our RFID can be used to automate tasks such as picking and packing, which can help to improve efficiency and productivity in the manufacturing process. Drones can be used to transport materials and components around the manufacturing facility, which can help to improve efficiency and reduce costs.

- Improved inventory management: Our RFID can be used to track the movement of medical devices and components throughout the manufacturing process, from raw materials to finished goods. This can help to improve inventory accuracy and reduce costs. Drones can be used to inspect inventory levels and identify any potential problems quickly and easily.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the medical robotics and automation manufacturing:

- Improved communication: GAO’s IoT can be used to improve communication between medical robots and other devices, such as computers and sensors. This can help to improve the efficiency and accuracy of operations.

- Enhanced safety: Our IoT can be used to improve safety by providing real-time data on the status of medical robots and devices. This can help to prevent accidents and injuries.

- Improved patient care: Our IoT can be used to improve patient care by providing real-time data on the patient’s condition. This can help doctors and nurses to make better decisions about patient care.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Medical Robotics and Automation Manufacturing

GAO RFID Inc. has helped many companies in medical robotics and automation manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments comply with the applicable industry standards, mandates, and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- IEC 62305

- IHE XDS-RAD

- IEC 62366

- IHE XDS-Blue

- IETF 6LoWPAN

- ZigBee

- Thread

- RTCA DO-333

- CAO Annex 10

- Federal Aviation Administration (FAA)

- Federal Communications Commission (FCC)

U.S. Government Regulations:

- Food and Drug Administration (FDA)

- Health Insurance Portability and Accountability Act (HIPAA)

- Occupational Safety and Health Administration (OSHA)

- Federal Trade Commission (FTC)

Canadian Government Regulations:

- Medical Devices Regulations (MDR)

- Health Canada

- ICES

- Health Products and Food Branch (HPFB)

- Good Manufacturing Practices (GMP)

- Personal Information Protection and Electronic Documents Act (PIPEDA)

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in medical robotics and automation manufacturing such as:

Personnel Management:

- Workforce scheduling and task assignment

- Employee training and skill development programs

- Performance evaluation and feedback systems

- Payroll and benefits administration

- Health and safety protocols and training for robotics operators

Equipment Management:

- Maintenance scheduling and predictive maintenance for robotics equipment

- Monitoring equipment health and performance

- Inventory and spare parts management for robotics components

- Calibration and quality control of robotic systems

- Equipment utilization tracking and optimization

Access Control:

- Secure access to robotics manufacturing areas

- User authentication and authorization for operating robotics systems

- Monitoring and tracking access activities

Warehouse Management:

- Inventory tracking and management of raw materials and finished products

- Order fulfillment and tracking through robotics automation

- Logistics and material handling optimization

Supply Chain Management:

- Supplier relationship management and vendor selection for robotics components

- Demand forecasting and planning for robotics manufacturing

- Real-time tracking and monitoring of supply chain processes

- Inventory optimization and just-in-time delivery of robotics parts

Other Applications:

- Quality control and inspection using vision systems and robotics

- Robotics-assisted surgeries and medical procedures

- Laboratory automation for sample handling and testing

- Robotic exoskeletons for physical therapy and rehabilitation

- Autonomous vehicles for medical transportation and logistics

GAO has enabled its customers to make use of some of leading software and cloud services in medical robotics and automation manufacturing industry. Below are some of popular software and cloud services in medical robotics and automation manufacturing industry Workday, SAP Asset Manager, Microsoft Azure, Amazon Web Services (AWS), Allegion OnGuard, Oracle Warehouse Management Cloud, Microsoft Dynamics 365 Supply Chain Management, SolidWorks, Autodesk Inventor, Google Cloud Platform (GCP), Siemens MindSphere

GAO has worked with some of the leading technology companies in medical robotics and automation manufacturing in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in medical robotics and automation manufacturing industry Intuitive Surgical, Medtronic, Johnson & Johnson, Stryker, Adept Technology, anuc, KUKA Robotics, ABB, Aethon, Mazor Robotics, Zimmer Biomet, Auris Surgical Robotics

Case Studies of RFID Applications

Below are some RFID application cases in medical robotics and automation manufacturing industry.

Stryker uses RFID to track the location of surgical instruments in the operating room using passive UHF RFID tags. The tags are attached to the instruments and are read by RFID readers located throughout the operating room. The data from the readers is collected by a central database, which allows surgeons and nurses to see the location of all the instruments at any time. This helps to ensure that the right instruments are always available and that they are not lost or misplaced.

Johnson & Johnson uses RFID to track the temperature of medical devices during transportation and storage using active UHF RFID tags. The tags are attached to the devices and contain a battery that powers the tag. The tags are read by RFID readers located throughout the transportation and storage chain. The data from the readers is collected by a central database, which allows Johnson & Johnson to always monitor the temperature of the devices. This helps to ensure that the devices are kept at the correct temperature, which is critical for their safety and effectiveness.

Medtronic uses RFID to track the location of medical supplies in the hospital using passive UHF RFID tags. The tags are attached to the supplies and are read by RFID readers located throughout the hospital. The data from the readers is collected by a central database, which allows Medtronic to see the location of all the supplies at any time. This helps to ensure that the supplies are always available and that they are not wasted.

Boston Scientific uses UHF RFID to track the movement of patients in the hospital. This helps to ensure that patients are always under the care of a qualified healthcare professional. Boston Scientific has implemented UHF RFID in over fifty hospitals in the US and Canada. The company has seen a significant improvement in patient safety since implementing RFID, with a 90% reduction in patient falls.

Intuitive Surgical uses UHF RFID to track the position of the da Vinci Surgical System during surgery. This helps to ensure that the system is always in the correct position and that it is not damaged. Intuitive Surgical has implemented UHF RFID in over 10,000 operating rooms in the US and Canada. The company has seen a significant improvement in surgical safety since implementing RFID, with a 99% reduction in system malfunctions.

Case Studies of IoT Applications

Below are some IoT application cases in Medical Robotics and Automation Manufacturing.

Utilizing IoT sensors to monitor the health and performance of robotic systems and automation equipment, enabling predictive maintenance to minimize downtime and optimize operations.

Implementing IoT connectivity in medical robotic devices and automation systems to enable remote monitoring and diagnostics, allowing for real-time troubleshooting and support.

IoT sensors can be integrated into the manufacturing process to track and record data, ensuring compliance with regulatory standards and maintaining consistent quality in medical devices.

Utilizing IoT devices to monitor energy consumption in manufacturing facilities, identifying opportunities for energy efficiency improvements and reducing operational costs.

Implementing IoT-enabled inventory management systems to track the movement of components and raw materials, optimizing supply chain efficiency, and reducing lead times.

Case Studies of Drone Applications

Below are some drone application cases in Medical Robotics and Automation Manufacturing

Drones equipped with cameras or sensors can perform aerial inspections of large manufacturing facilities, including medical robotics and automation plants, identifying maintenance needs, and ensuring compliance with safety standards.

Drones can be utilized for aerial inventory checks, especially in large warehouses or distribution centers, providing real-time data on stock levels and optimizing inventory management processes.

Drones can monitor the movement of components and raw materials within and between manufacturing facilities, ensuring efficient logistics and timely delivery of supplies.

Drones can conduct environmental assessments in manufacturing facilities to monitor factors like air quality, temperature, and other environmental conditions that may impact the production of medical robotics and automation equipment.

Drones can enhance security measures by patrolling manufacturing premises, monitoring for unauthorized access, and ensuring the safety and protection of critical assets.

GAO RFID Systems & Hardware for the Medical Robotics and Automation Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including medical robotics and automation manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such essential functions as temperature, humility, vibration, and panic button:

GAO’s BLE technology is suitable for many industries, including medical robotics and automation manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including medical robotics and automation manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including medical robotics and automation manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including medical robotics and automation manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including medical robotics and automation manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

The RFID systems by GAO are highly popular for clients in medical robotics and automation manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include 3D printers, Computer-aided design (CAD) software, Computer-aided manufacturing (CAM) software, Robotics testbeds, Simulation software.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served Medical Robotics and Automation Manufacturing Extensively

GAO’s products and technologies have helped its customers in medical robotics and automation manufacturing industry to achieve success in artificial intelligence (AI), augmented reality (AR), cobots, digital twins, exoskeletons, nanobots, robotic surgery, and telemedicine.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in medical robotics and automation manufacturing, including many its various divisions such as

- Robotic surgery: This is the most well-known sub-industry of medical robotics. Robotic surgery systems allow surgeons to perform minimally invasive procedures with greater precision and accuracy than traditional methods.

- Drug delivery: Robotic drug delivery systems are used to administer medication to patients in a precise and controlled manner. This can be used to improve the effectiveness of medication and to reduce the risk of side effects.

- Medical imaging: Robotic medical imaging systems are used to create images of the human body for diagnostic purposes. These images can be used to detect diseases and injuries at an early stage when they are easier to treat.

- Medical rehabilitation: Robotic medical rehabilitation systems are used to help patients regain their mobility and function after an injury or illness. These systems can be used to improve strength, range of motion, and coordination.

- Laboratory automation: Robotic laboratory automation systems are used to automate tasks in the laboratory, such as sample preparation, testing, and analysis. This can free up laboratory staff to focus on other tasks, and it can also improve the accuracy and efficiency of laboratory work.

Here are some of the leading companies in medical robotics and automation manufacturing industry:

- Intuitive Surgical: A pioneer in robotic-assisted surgery, known for its da Vinci Surgical System that allows surgeons to perform minimally invasive procedures.

- Stryker Corporation: Offers a range of medical devices, including robotic-assisted orthopedic surgery systems, endoscopy equipment, and navigation systems.

- Medtronic: A global leader in medical technology, Medtronic develops robotic systems and devices for neurosurgery and other medical procedures.

- Smith+Nephew: Specializes in robotics and digital surgery solutions for orthopedics and sports medicine.

- Zimmer Biomet: Offers robotic-assisted solutions for joint replacement surgeries.

- Renishaw: Known for its medical robotics and metrology solutions, including neurosurgical robots.

- Accuray Incorporated: Develops radiation therapy and radiosurgery systems using robotics and automation.

- Verb Surgical (a joint venture between Verily and Johnson & Johnson): Focused on developing advanced surgical robotics and digital surgery platforms.

- Myomo, Inc.: Known for its wearable robotic arm braces to assist individuals with mobility challenges.

- Asensus Surgical: Designs robotic systems for minimally invasive surgery, including the Senhance Surgical System.

- Auris Health (now part of Johnson & Johnson): Pioneers in developing robotic platforms for medical interventions.

- Titan Medical: Develops robotic surgical systems, including the SPORT Surgical System.

- Restoration Robotics (now Venus Concept): Specializes in robotic systems for hair restoration procedures.

- Titan Medical: Develops robotic platforms for single-port surgery.

- Medrobotics Corporation: Offers flexible robotic systems for minimally invasive surgical procedures.

- Hansen Medical (acquired by Auris Health): Developed intravascular robotics systems for medical procedures.

- Omnicell: Provides automation and robotics solutions for medication management in healthcare facilities.

- Ekso Bionics: Specializes in wearable exoskeletons for rehabilitation and mobility assistance.

- ZOLL Medical Corporation: Offers automation and robotics for critical care solutions, including ventilators and defibrillators.

- Brainlab AG: Develops image-guided and robotic systems for neurosurgery and radiation therapy.

- Mazor Robotics (acquired by Medtronic): Known for its robotic guidance systems used in spine surgery.

- TransEnterix: Develops robotic systems for minimally invasive surgery, including the Senhance Surgical System.

- Corindus Vascular Robotics (now part of Siemens Healthineers): Focuses on robotic-assisted systems for vascular procedures.

- Curexo Technology Corporation: Specializes in robotics for orthopedic surgery, including the CUVIS-joint robotic system.

- Intuitive Surgical Canada: A subsidiary of Intuitive Surgical Inc., they are known for their da Vinci Surgical System, a robotic platform used in minimally invasive surgeries.

- Synaptive Medical: Develops advanced medical imaging and robotic systems for neurosurgery and cranial procedures.

- BIONIK Laboratories Corp: Specializes in the development of robotic rehabilitation systems to assist patients with neurological disorders and mobility impairments.

- Exact Imaging: Focuses on developing high-resolution micro-ultrasound systems for targeted prostate biopsies and imaging.

- MDA Robotics & Automation: Known for its expertise in robotics and automation solutions for various industries, including the medical sector.

- Kinova Robotics: Offers robotic arms and platforms for research and medical applications, including assistive devices for individuals with mobility challenges.

- UBQ Materials: Although not exclusively in the medical robotics field, they offer robotic sorting systems for sustainable recycling of plastics, which can be applicable in the healthcare industry.

Intuitive Surgical U.S.A

Stryker corporation

Medtronic

Smith+Nephew

Zimmer Biomet

Renishaw

Accuray Incorporated

Verb Surgical

Asensus Surgical

Auris Health Corporation

Titan Medical

Medrobotics

Hansen Medical

Omnicell

Ekso Bionics

ZOLL Medical Corporation

BrainLab AG

Mazor Robotics

TransEnterix Technology

Corindus Vascular Robotics

Curexo

Intuitive Surgical Canada

Synaptive Medical

BIONIK Laboratories Corp