Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Agrochemicals Manufacturing Industry

GAO’s Assists Clients with Standards, Mandates & Regulations of Agrochemicals Manufacturing Industry

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Agrochemicals Manufacturing Industry

GAO Makes Efforts to Satisfy Customers

GAO Has Served Agrochemicals Manufacturing Industry Extensively

Related Products & Systems on Other Pages on This Website

Pallet & Return Asset Tracking System

Tool & Industrial Equipment Tracking System

WIP RFID Tracking System | RFID WIP Software – GAO (gaorfid.com)

Employee & Attendance Access Control System

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

High-Temperature Tolerant RFID Tags

On Metal RFID Tags – All Types

Hazardous Environment (ATEX) RFID Tags

Overview

This category includes insecticides (to control insects), herbicides (to control weeds), and fungicides (to control fungal diseases). Pesticides are essential for protecting crops and ensuring high yields. Fertilizers provide essential nutrients to crops, such as nitrogen, phosphorus, and potassium, to promote healthy growth and maximize yields. They can be synthetic or organic in nature. These products encompass a range of chemicals, including insect repellents, plant growth regulators, and soil conditioners, aimed at improving crop health and productivity. Some segments of the agrochemical industry focus on developing biological and biopesticide products, which use naturally occurring organisms or compounds to manage pests and enhance soil and crop health in an environmentally friendly way.

These chemicals are applied to seeds before planting to protect them from diseases and pests and promote early seedling growth. These substances are added to agrochemical formulations to enhance their effectiveness, penetration, and stability when applied to crops. Agrochemical manufacturers invest heavily in research and development to create new, more effective, and environmentally sustainable products. This includes genetic engineering and biotechnology advancements to develop genetically modified crops (GMOs) that are resistant to pests or tolerant of specific herbicides. The agrochemical industry is subject to stringent regulations to ensure the safety of agricultural products, the environment, and human health. Companies in this sector must adhere to various legal and regulatory frameworks.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in agrochemicals manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as:

Reactors, Mixers, Dryers, Centrifuges, Filtration systems, Heat exchangers, Distillation columns, Pumps, Tanks and vessels, Blenders, Granulators, Homogenizers, Conveyors, Packaging machinery, Analytical instruments (spectrophotometers, chromatographs, etc.), Safety equipment (gloves, masks, goggles, etc.), Control systems and automation equipment, Cooling towers, Dust collectors, Laboratory equipment (balances, pH meters, etc.).

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra-high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in agrochemicals manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Agrochemicals Manufacturing Industry

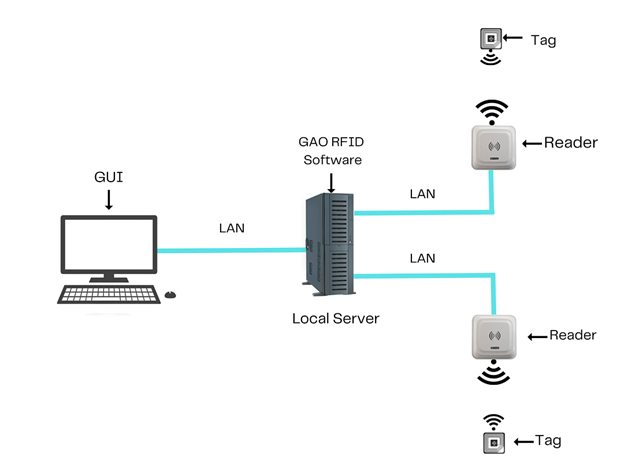

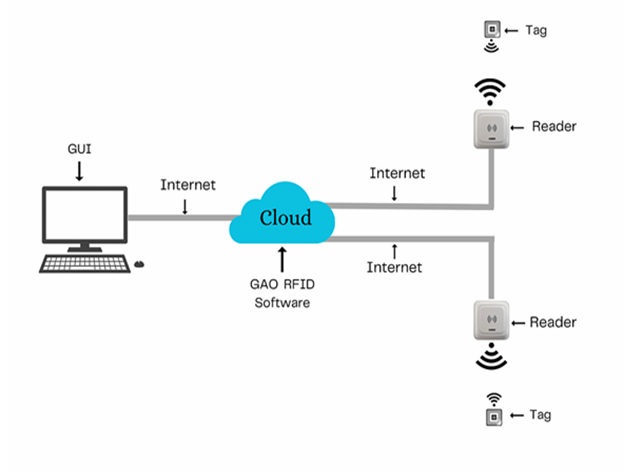

To satisfy its customers, GAO’s RFID or RFID Systems for the agrochemicals manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace.The above illustrates GAO system for agrochemicals manufacturing industry with its software running on a local server.

The above illustrates GAO system for agrochemicals manufacturing industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in agrochemicals manufacturing industry:

- Inventory Management: RFID tags and readers are used to track and manage inventory of raw materials, chemicals, and finished agrochemical products. This allows for real-time visibility into stock levels, reducing the risk of shortages or overstocking.

- Quality Control: RFID can be employed to monitor the manufacturing process, ensuring that ingredients are used correctly, and quality standards are met at each production stage. It helps in identifying and rectifying any deviations or quality issues.

- Asset Tracking: Agrochemical manufacturers can use RFID to track and manage their equipment and machinery. This helps in maintenance scheduling, reducing downtime, and optimizing equipment usage.

- Supply Chain Visibility: RFID technology enables end-to-end supply chain visibility. It allows manufacturers to monitor the movement of products from production facilities to distribution centers and ultimately to retailers or farmers.

- Batch and Lot Tracking: RFID tags can be attached to batches or lots of agrochemical products, facilitating precise tracking and tracing of products. This is crucial for recalls, quality control, and compliance with regulatory requirements.

- Authentication and Anti-Counterfeiting: RFID can be used to verify the authenticity of agrochemical products. Consumers and distributors can scan RFID tags to confirm the product’s origin and ensure it is not counterfeit.

- Security and Access Control: RFID access cards or badges can be used to control access to sensitive areas within manufacturing facilities, ensuring that only authorized personnel have access to critical areas and materials.

- Environmental Monitoring: RFID sensors and tags can be utilized to monitor environmental conditions such as temperature and humidity during storage and transportation of agrochemical products. This helps ensure product quality and safety.

- Labor Management: RFID can be used to track and manage labor resources within manufacturing facilities, enabling better labor allocation and productivity management.

- Compliance and Reporting: RFID systems can automate data collection and reporting for regulatory compliance. This is particularly important in industries with strict environmental and safety regulations.

- Traceability for Recall Management: In case of a product recall, RFID technology can help quickly identify affected batches or lots, allowing for targeted and efficient recall processes, which can be critical for public safety.

- Pest and Disease Control: RFID-enabled monitoring systems can track the movement of pests and disease vectors, aiding in the development of targeted control strategies and helping farmers make informed decisions about pesticide application.

- Farm Management: RFID can also extend its benefits to the agricultural side of the industry. Smart agriculture solutions use RFID technology to monitor crop growth, manage livestock, and optimize farming practices.

GAO’s drone technologies find the following applications in the agrochemicals manufacturing industry:

- Aerial Imagery: Drones equipped with cameras and sensors capture high-resolution images of crops. This data is used for assessing crop health, growth, and identifying stress factors such as pests, diseases, or nutrient deficiencies.

- Multispectral and Hyperspectral Imaging: Drones equipped with specialized cameras can capture data beyond visible light, allowing for advanced analysis of plant health and identifying issues not visible to the naked eye.

- Variable Rate Application: Drones can distribute agrochemicals (e.g., pesticides, fertilizers) with precision, applying them only where needed based on the data collected. This minimizes waste and reduces environmental impact.

- Soil Sampling: Drones can collect soil samples from multiple locations, providing valuable data for soil analysis and tailored nutrient application.

- Thermal Imaging: Drones equipped with thermal cameras can detect variations in crop temperature, which may indicate the presence of pests or diseases.

- Remote Sensing: Drones can monitor large areas quickly and identify signs of infestations or disease outbreaks, enabling rapid response and targeted treatment.

- Irrigation Management: Drones can assess the effectiveness of irrigation systems by providing data on soil moisture levels, helping farmers optimize water usage.

- Crop Yield Estimation: Drones can estimate crop yields by analyzing plant density and health, aiding in production planning and resource allocation.

- Weed Control: Drones equipped with herbicide applicators can identify and selectively target weeds, reducing the need for widespread herbicide use and minimizing crop damage.

- Environmental Monitoring: Drones can survey environmental conditions in and around agricultural areas, such as tracking weather patterns, assessing water quality, and monitoring wildlife.

- Mapping and Land Surveying: Drones create accurate 3D maps and models of fields, helping with land management, boundary identification, and infrastructure planning.

- Livestock Monitoring: Drones can assist in monitoring and managing livestock, checking for signs of distress, assessing herd health, and locating animals in large grazing areas.

- Safety and Security: Drones enhance security by monitoring farms and facilities for unauthorized access, theft, or vandalism.

- Disaster Assessment and Response: In the event of natural disasters (e.g., floods, wildfires), drones can quickly survey the extent of damage, helping with insurance claims and emergency response efforts.

- Remote Access Areas: Drones can access hard-to-reach or dangerous areas for inspections, maintenance, or data collection.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the agrochemicals manufacturing industry:

- Inventory Management: IoT sensors can track the levels of raw materials, chemicals, and finished products in real time, ensuring efficient stock management and minimizing production disruptions.

- Predictive Maintenance: IoT devices can monitor equipment and machinery conditions, detecting signs of wear or malfunction early. This enables proactive maintenance to prevent costly breakdowns and downtime.

- Quality Control and Assurance: IoT sensors and cameras can monitor and record various production parameters and processes, ensuring that quality standards are met and providing data for quality control and compliance reporting.

- Energy Management: IoT systems can optimize energy usage in manufacturing facilities by monitoring energy consumption and adjusting equipment settings for efficiency.

- Process Automation: IoT-connected devices and sensors can automate various manufacturing processes, improving consistency and reducing the need for manual intervention.

- Supply Chain Visibility: IoT technology enables real-time tracking of raw materials and finished products as they move through the supply chain, providing visibility into shipping, delivery, and inventory levels.

- Environmental Monitoring: IoT sensors can monitor environmental conditions within manufacturing facilities, ensuring compliance with safety and environmental regulations. This includes monitoring air quality, temperature, humidity, and chemical emissions.

- Water Management: IoT sensors can monitor water usage and quality, helping manufacturers manage water resources efficiently and responsibly.

- Remote Monitoring and Control: Manufacturers can remotely monitor and control equipment and processes, enabling adjustments and troubleshooting from anywhere, reducing the need for on-site personnel.

- Traceability and Serialization: IoT systems can provide end-to-end traceability of products by tracking them from production to distribution, aiding in recalls and regulatory compliance.

- Data Analytics and Decision Support: IoT-generated data can be analyzed to gain insights into manufacturing efficiency, product quality, and process optimization. Advanced analytics and machine learning can provide predictive insights.

- Safety Compliance: IoT sensors and devices can monitor safety compliance, such as tracking the usage of personal protective equipment (PPE) and ensuring adherence to safety protocols.

- Labor Management: IoT can track the movement and productivity of personnel within manufacturing facilities, optimizing labor allocation and improving worker safety.

- Remote Sensing in Agriculture: IoT devices and sensors can be deployed in agricultural fields to monitor soil conditions, weather, and crop health, providing data for precision agriculture practices.

- Integration with ERP Systems: IoT data can be integrated with Enterprise Resource Planning (ERP) systems to streamline operations, inventory management, and financial reporting.

GAO’s Assists Clients with Standards, Mandates & Regulations of Agrochemicals Manufacturing Industry

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in agrochemicals manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000

- ISO 15693

- EPCglobal Gen2

- Bluetooth 4.0 and later versions (BLE is part of the Bluetooth specification)

- IEEE 802.15.1

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- Zigbee

- LoRaWAN (Long Range Wide Area Network)

- OPC UA (Unified Architecture) for Industrial IoT

- OneM2M (Machine-to-Machine) standard

- ASTM F38 – Standard Specification for Unmanned Aircraft System (UAS) Remote ID and Tracking

- ISO 21384-3 – Unmanned aircraft systems (UAS) — Part 3

- ANSI/UL 3030 – Standard for Drones

- IEEE 802.11 (Wi-Fi) standards, which are often used for drone communication

Government Regulations

- Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)

- Toxic Substances Control Act (TSCA)

- Federal Food, Drug, and Cosmetic Act (FFDCA)

- Occupational Safety and Health Administration (OSHA) Regulations

- Environmental Protection Agency (EPA) Pesticide Regulations

- Endangered Species Act (ESA) Consultation Requirements

- Clean Air Act (CAA) Emission Standards

- Clean Water Act (CWA) Discharge Regulations

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- Resource Conservation and Recovery Act (RCRA)

- Hazardous Materials Transportation Act (HMTA) Regulations

- National Pollutant Discharge Elimination System (NPDES) Permits

- Emergency Planning and Community Right-to-Know Act (EPCRA) Reporting Requirements

- U.S. Department of Agriculture (USDA) Regulations for Genetically Modified Organisms (GMOs)

- Occupational Safety and Health Administration (OSHA) Hazard Communication Standard (HCS)

- Federal Hazardous Substances Act (FHSA)

Canadian Government Regulations

- Pest Control Products Act (PCPA)

- Pest Control Products Regulations

- Fertilizers Act

- Fertilizers Regulations

- Feeds Act

- Feeds Regulations

- Canadian Environmental Protection Act, 1999 (CEPA)

- Transportation of Dangerous Goods Act

- Occupational Health and Safety Regulations (Canada Labour Code)

- Canada Agricultural Products Act (CAPA)

- Health of Animals Act

- Seeds Act

- Seeds Regulations

- Food and Drugs Act

- Food and Drug Regulations

- Canadian Seed Institute Act

- Canadian Seed Institute Regulations

- Hazardous Products Act

- Transportation of Dangerous Goods Regulations

- Environmental Emergency Regulations

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in agrochemicals manufacturing industry such as:

Personnel Management:

- Employee Scheduling and Shift Management

- Training and Certification Tracking

- Health and Safety Compliance

- Labor Productivity Monitoring

- Payroll and Compensation Management

Equipment Management:

- Preventive Maintenance Scheduling

- Equipment Monitoring and Condition-Based Maintenance

- Asset Tracking and Inventory Control

- Equipment Efficiency and Utilization Analytics

- Energy Management and Equipment Efficiency

Access Control:

- Secure Facility Access Control

- Visitor Management and Logbooks

- Biometric Authentication

- Video Surveillance and Monitoring

- Intrusion Detection Systems

Warehouse Management:

- Inventory Tracking and Optimization

- Order Fulfillment and Shipping Management

- Temperature and Humidity Monitoring

- RFID-Based Warehouse Automation

- Quality Control and Inspection

Supply Chain Management:

- Supplier Relationship Management

- Demand Forecasting and Inventory Planning

- Transportation and Logistics Optimization

- Supplier Compliance and Quality Assurance

- Traceability and Recall Management

Other Applications:

- Environmental Monitoring and Compliance

- Regulatory Compliance Reporting

- Research and Development (R&D) Data Management

- Sustainability Tracking and Reporting

- Customer Relationship Management (CRM)

GAO has enabled its customers to make use of some of the leading software and cloud services in the agrochemicals manufacturing industry. Below are some popular software and cloud services in the agrochemicals manufacturing industry.

SAP SuccessFactors, Workday, ADP Workforce Now, Oracle HCM Cloud, BambooHR, IBM Maximo, Maintenance Connection, eMaint CMMS, Fiix, Infor EAM, Honeywell Access Control, Genetec Security Center, Brivo Access Control, AMAG Technology, Kantech Access Control, Manhattan Associates, Oracle Warehouse Management Cloud, HighJump Warehouse Management System, Blue Yonder (formerly JDA Software), Fishbowl Inventory, SAP Integrated Business Planning, Kinaxis RapidResponse, Oracle Supply Chain Management Cloud, Infor Nexus, GEP SMART.

GAO has worked with some of the leading technology companies in the agrochemicals manufacturing industry to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in agrochemicals manufacturing industry:

SAP, Oracle, IBM, Schneider Electric, Siemens, Emerson Electric, Rockwell Automation, Honeywell, AVEVA, GE Digital, Wonderware (by AVEVA), Trimble

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in agrochemicals manufacturing industry.

Macy’s used RFID to enhance inventory accuracy and optimize stock levels. The implementation resulted in reduced out-of-stock situations and increased sales.

Simplot, a major agricultural company, employed RFID to monitor and manage the movement of livestock. This improved animal welfare and reduced losses due to theft or health issues.

The Port of Long Beach in California implemented RFID to streamline cargo tracking and improve security. It reduced congestion and enhanced the overall efficiency of the port.

Canadian Tire, a retail and automotive service company, used RFID to improve supply chain visibility and inventory management. This led to reduced stockouts and improved customer service.

Toronto General Hospital adopted RFID for tracking medical equipment and patient records. This reduced the time spent searching for equipment and enhanced patient care.

CEMEX, a global building materials company, employed RFID in its concrete production process. RFID tags helped monitor the quality and location of concrete blocks, enhancing quality control and logistics.

Grupo Bimbo, a major bakery company, used RFID to track its bread delivery trucks. This improved route optimization, reduced fuel consumption, and enhanced delivery efficiency.

DHL implemented RFID to improve parcel tracking and inventory management in its European distribution centers. This reduced shipment errors and enhanced the speed of order processing.

Airbus uses RFID for tracking aircraft components throughout the manufacturing process. This ensures compliance with safety standards and helps in maintenance and repair tasks.

ZARA, a clothing retailer, implemented RFID for inventory management in its stores across Europe. This led to improved stock accuracy and reduced discrepancies between inventory and sales data.

Many applications of RFID by GAO can be found here.

https://gaorfid.com/manufacturing-industry-rfid-solutions/

Case Studies of IoT Applications

Below are some IoT application cases in agrochemicals manufacturing industry.

Monsanto implemented IoT technologies in its agricultural chemical manufacturing processes to enhance crop protection product quality and reduce production downtime. IoT sensors monitored equipment conditions, allowing for predictive maintenance and optimizing production efficiency.

Corteva Agriscience adopted IoT solutions for monitoring and controlling various aspects of agrochemical manufacturing, including environmental conditions, storage, and distribution. This helped ensure product quality and compliance with regulatory standards.

Syngenta, a global agrochemical company, leveraged IoT for monitoring and managing pesticide production. Sensors and data analytics helped in optimizing the manufacturing process and ensuring the quality of their products.

FMC, a leading agrochemical manufacturer, implemented IoT solutions to enhance the efficiency of their production facilities in Mexico. This included monitoring and controlling equipment and processes to reduce energy consumption and improve product quality.

BASF, a prominent chemical company, has integrated IoT technologies into its agrochemical manufacturing processes in Europe. IoT sensors are used to monitor raw material levels, equipment performance, and environmental conditions to optimize production.

Syngenta, headquartered in Switzerland, has implemented IoT solutions in various European manufacturing sites. These solutions help in real-time monitoring of chemical processes, reducing energy consumption, and ensuring compliance with safety and environmental regulations.

Case Studies of Drone Applications

Below are some drone application cases in the agrochemicals manufacturing industry.

Vineyard owners in Napa Valley use drones equipped with multispectral cameras to monitor vine health, assess irrigation needs, and identify areas requiring attention. This data-driven approach has improved crop yields and resource efficiency.

Bechtel, a major construction company, has integrated drones into its projects for site inspections, progress tracking, and safety assessments. Drones have helped reduce inspection time and enhance project management.

Goldcorp (now part of Newmont Corporation) deployed drones for surveying and mapping underground mines in Canada. Drones improved safety by reducing the need for personnel to enter hazardous areas and enhanced geological mapping accuracy.

Dairy farmers in Quebec use drones to monitor cattle, assess pasture conditions, and track animal health. This technology has led to better herd management and increased milk production.

Pemex, the state-owned oil company of Mexico, utilizes drones for inspecting offshore oil platforms and pipelines. Drones help identify corrosion, leaks, and other maintenance issues more efficiently and safely.

Several AgriTech startups in Mexico employ drones for crop monitoring, pest control, and precision agriculture. These applications have led to higher crop yields and reduced chemical usage.

The RNLI uses drones equipped with thermal cameras to locate and rescue people in distress at sea. Drones have significantly reduced response times and improve the success rate of rescue missions.

Conservationists in the Netherlands deploy drones to monitor wildlife populations, especially in protected areas and wetlands. Drones aid in wildlife tracking, anti-poaching efforts, and habitat assessment.

Infrastructure companies in France employ drones for inspecting bridges, railways, and power lines. Drones can access hard-to-reach areas and capture high-resolution images for maintenance assessment.

GAO RFID Systems & Hardware for Agrochemicals Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

- BLE Gateway (Receiver)

- as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

- BLE Tags / Beacons

GAO’s BLE technology is suitable for many industries, including Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

list of special equipment used by Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry harvesters, washing machines, cutters, peelers, slicers, blenders, mixers, cookers, evaporators, dryers, canners, bottlers, packers, labelers, palletizers, conveyors, robots, drones.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Fruit and Vegetable Preserving and Specialty Food Manufacturing Industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

To satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

To shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in agrochemicals manufacturing industry we have worked with to serve our joint customers:

- Accenture

- Deloitte

- IBM Global Business Services

- Capgemini

- Cognizant

- Wipro

- Infosys

- PwC (PricewaterhouseCoopers)

- Ernst & Young (EY)

- KPMG

- Tata Consultancy Services (TCS)

- CGI

- HCL Technologies

- Tech Mahindra

- LTI (Larsen & Toubro Infotech)

- DXC Technology

- NTT DATA

- Atos

- Grant Thornton

- Synechron

- Unisys

GAO Has Served Agrochemicals Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in agrochemicals manufacturing industry to achieve success in:

Sustainable Agriculture, Precision Farming, Digital Agriculture, AgTech (Agricultural Technology), Crop Protection, Biopesticides, Microbial Solutions, Bio stimulants, Fertilizer Optimization, Crop Health Monitoring, Integrated Pest Management (IPM), Green Chemistry, AI in Agriculture, Blockchain in Supply Chain, Smart Farming, Data Analytics, Remote Sensing, Soil Health Management, Organic Farming, Agrochemical Regulations.

GAO RFID Inc. has served many customers in agrochemicals manufacturing industry, including its various divisions such as

- Crop Protection Chemicals: This division focuses on the production of pesticides, herbicides, and fungicides used to protect crops from pests, diseases, and weeds.

- Fertilizers: Fertilizer manufacturing involves the production of various types of fertilizers, including nitrogen-based, phosphorus-based, and potassium-based fertilizers. These products are essential for providing essential nutrients to crops.

- Biopesticides and Biologicals: Biopesticides and biologicals are derived from natural sources and are used for pest control and disease management in a more environmentally friendly way. This division produces products like biopesticides, beneficial microorganisms, and plant extracts.

- Seed Treatment Chemicals: Seed treatment chemicals include fungicides, insecticides, and other protective coatings applied to seeds before planting to enhance germination and protect against pests and diseases.

- Adjuvants and Surfactants: Adjuvants and surfactants are chemical additives used to improve the effectiveness and application of pesticides and herbicides. They help to enhance the spreading, wetting, and sticking properties of these chemicals.

- Agrochemical Formulation: This division focuses on the development and production of various formulations of agrochemical products, such as emulsifiable concentrates, granules, liquids, and powders.

- Fertilizer Blending and Mixing: Companies specializing in this segment blend and mix various fertilizer components to create custom fertilizer blends tailored to specific crops and soil needs.

- Contract Manufacturing (Toll Manufacturing): Some companies offer contract manufacturing services to produce agrochemicals on behalf of other agrochemical companies, often for products like proprietary formulations.

- Research and Development (R&D): R&D divisions in agrochemical manufacturing companies work on developing new and innovative products, improving existing formulations, and conducting regulatory compliance studies.

- Packaging and Distribution: This division involves packaging the final agrochemical products and distributing them to retailers, wholesalers, and end-users.

- Regulatory Affairs: Regulatory affairs professionals ensure that agrochemical products comply with national and international regulations, including safety, labeling, and environmental standards.

- Environmental Stewardship: This division focuses on sustainability and environmentally responsible practices, such as waste management, emissions reduction, and the development of eco-friendly agrochemical products.

GAO’s technologies enable its customers in agrochemicals manufacturing industry to effectively track their workforces such as:

Chemical Engineer, Research Scientist, Production Manager, Quality Control Analyst, Regulatory Affairs Specialist, Agronomist, Environmental Compliance Officer, Formulation Chemist, Packaging Technician, Supply Chain Manager, Seed Treatment Specialist, Fertilizer Blending Operator, Pest Control Technician, Microbiologist, Field Technician, Crop Health Analyst, Product Development Manager, Laboratory Technician, Sales Representative, Logistics Coordinator, Safety Inspector, Process Operator, Sustainability Coordinator, Compliance Manager, Agronomy Consultant and effectively track operational assets such as:

Reactors, Mixers and Blenders, Extruders, Spray Dryers, Fermentation Tanks, Distillation Equipment, Filtration Systems, Packing and Filling Machines, Formulation and Dispensing Units, Bulk Storage Tanks, Conveyor Systems, Quality Control Equipment, Safety Equipment, Heat Exchangers, Powder Handling Equipment.

Here are some of the leading companies in agrochemicals manufacturing industry GAO has served:

- Monsanto Company

- Dow AgroSciences LLC

- Corteva Agriscience

- Syngenta AG

- BASF Corporation

- FMC Corporation

- Agrium Inc.

- The Mosaic Company

- Nufarm Americas Inc.

- AMVAC Chemical Corporation

- Gowan Company LLC

- Valent U.S.A. LLC

- WinField United

- Albaugh, LLC

- Pinnacle Agriculture Holdings, LLC

- Sipcam Agro USA, Inc.

- Arysta LifeScience North America, LLC

- Marrone Bio Innovations, Inc.

- Certis USA LLC

- Isagro USA, Inc.

- Suncor Energy

- Helena Agri-Enterprises, LLC

- UPL Limited

- Cheminova

- Bayer CropScience Canada Inc.

- Syngenta Canada Inc.

- K+S Potash Canada GP

- Nufarm Agriculture Inc.

- Loveland Products Canada Inc.

- Adama Agricultural Solutions Canada Ltd.

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

https://gaorfid.com/ask-the-experts/

or email us at sales@gaorfid.com