Index

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Beverage and Tobacco Product Manufacturing Industry

GAO Makes Efforts to Satisfy Customers

GAO Has Served Beverage and Tobacco Product Manufacturing Industry Extensively

Related Products & Systems on Other Pages on This Website

GAO RFID Tobacco Manufacturing Asset Management System

Return & Pallet Asset Tracking – GAO RFID

Tool & Industrial Equipment Tracking System

Employee & Attendance Access Control System

WIP RFID Tracking System | RFID WIP Software – GAO (gaorfid.com)

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

RFID Sticker Tags | RFID Label Tags – GAO RFID Inc.

On Metal RFID Tags – All Types

Printable RFID Tags | Printable RFID Labels – GAO RFID

Overview

Beverage and tobacco product manufacturing industry includes carbonated beverages like cola, fruit-flavored sodas, and energy drinks, as well as non-carbonated drinks like bottled water, fruit juices, and sports drinks. It includes the production of alcoholic drinks such as beer, wine, spirits, and liqueurs. Companies in this sector produce coffee beans, tea leaves, and related products such as ground coffee, tea bags, and instant coffee. It includes milk, dairy alternatives like almond and soy milk, and other non-dairy beverages. The production of cigarettes, which are the most common form of tobacco consumption worldwide. These are larger tobacco products that vary in size and flavor.

Products like chewing tobacco, snuff, and snus, which are consumed without burning. The manufacturing of vaping devices and e-liquids used for inhaling vapor instead of smoke. The tobacco industry is subject to stringent regulations due to health concerns, which include warning labels, age restrictions, and taxation. Both the beverage and tobacco sectors face health-related challenges. Health-conscious consumers are driving demand for healthier beverage options, while tobacco manufacturers often face declining sales due to increasing awareness of health risks associated with smoking. The industry is constantly evolving to meet changing consumer preferences. This includes the introduction of new flavors, innovative packaging, and marketing strategies. Major players in these industries operate on a global scale, with products distributed in many countries. Regional preferences can influence product offerings.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in beverage and tobacco product manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as:

Mixing Tanks, Pasteurizers, Bottle Filling Machines, Canning Machines, Fermentation Tanks, Carbonation Equipment, Filtration Systems, Homogenizers, Labeling Machines, Capping Machines, Conveyor Systems, Quality Control Equipment, Refrigeration Units, Blending Equipment, Packaging Machinery, Cigarette Making Machines, Cigar Rolling Machines, Smokeless Tobacco Processing Equipment, Filter Attachment Machines, Tobacco Cutting Machines, Moistening Equipment, Drying and Curing Chambers, Packaging and Wrapping Machines, Flavoring and Aroma Application Machines, Quality Testing Instruments, Storage Silos, Conveyor Systems, Dust Collection Systems, Heat-Sealing Equipment.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in beverage and tobacco product manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Beverage and Tobacco Product Manufacturing Industry

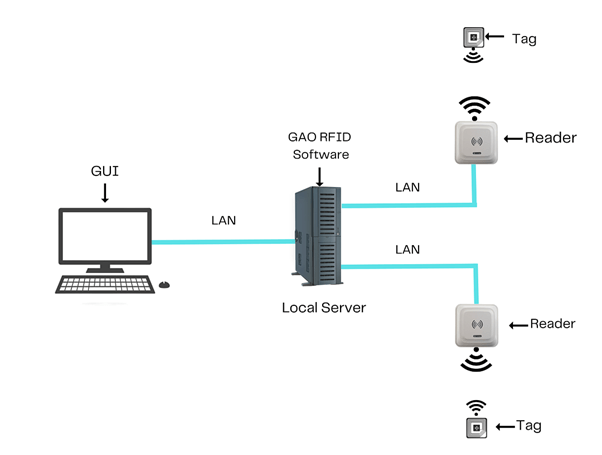

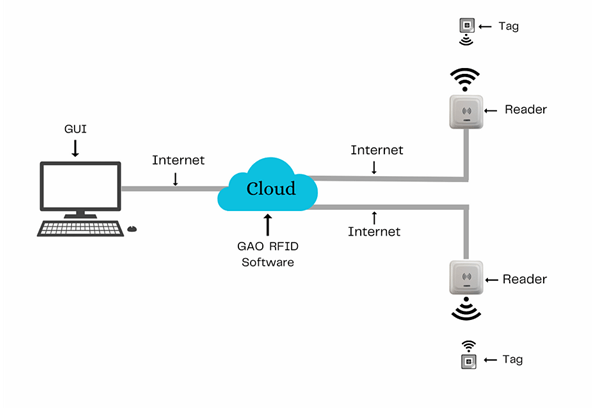

To satisfy its customers, GAO’s RFID or RFID Systems for beverage and tobacco product manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for beverage and tobacco product manufacturing industry with its software running on a local server.

The above illustrates GAO system for beverage and tobacco product manufacturing industry with its software running in cloud.

The above illustrates GAO system for beverage and tobacco product manufacturing industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in beverage and tobacco product manufacturing industry:

- Inventory Tracking: GAO’s RFID tags can be attached to raw materials, packaging materials, and finished products to provide real-time visibility into inventory levels, helping optimize stock levels and reduce the risk of stockouts.

- Quality Control: GAO’s RFID can be used to monitor and trace the production process of beverages, ensuring that each product meets quality standards at every stage of manufacturing.

- Batch and Lot Tracking: GAO’s RFID enables manufacturers to track batches and lots of products from production to distribution, simplifying recalls and quality control.

- Pallet and Case Labeling: GAO’s RFID tags can be affixed to pallets and cases to automate the tracking of large quantities of products within warehouses and during transportation.

- Anti-Counterfeiting: GAO’s RFID tags with unique identification codes can be used to verify the authenticity of high-end or premium beverages, reducing the risk of counterfeiting.

- Supply Chain Visibility: GAO’s RFID technology can provide real-time data on the movement of goods within the supply chain, allowing for better tracking and management of shipments.

- Shelf Management: GAO’s RFID-enabled shelf labels can help retailers manage their beverage inventory more efficiently, optimizing product placement and reducing stockouts.

- Crop Management: GAO’s RFID tags on tobacco plants or containers can track the growth and handling of tobacco crops, aiding in quality control and traceability.

- Quality Assurance: GAO’s RFID can monitor and verify the quality of tobacco leaves during the curing and processing stages, ensuring consistent product quality.

- Inventory Control: GAO’s RFID technology can be used to manage inventory of tobacco leaves, packaging materials, and finished tobacco products, reducing errors and minimizing waste.

- Warehouse Management: GAO’s RFID tags on pallets and containers help streamline the movement and storage of tobacco products in warehouses.

- Anti-Counterfeiting: High-value tobacco products can be equipped with GAO’s RFID tags to verify authenticity and combat counterfeit products.

- Regulatory Compliance: GAO’s RFID can assist in compliance with regulatory requirements by tracking and recording important data points related to manufacturing and distribution.

- Batch and Lot Traceability: GAO’s RFID allows for precise tracking of batches and lots of tobacco products, facilitating recalls and quality control.

- Access Control: GAO’s RFID-based access control systems can enhance security at manufacturing facilities and ensure that only authorized personnel enter certain areas.

- Packing and Labeling: GAO’s RFID technology can automate packing and labeling processes, improving efficiency and reducing errors.

GAO’s drone technologies find the following applications in the beverage and tobacco product manufacturing industry:

- Crop Monitoring: GAO’s Drones equipped with cameras and sensors can be used to monitor agricultural fields where ingredients like fruits, grains, and herbs are grown for beverages. They can assess crop health, identify disease outbreaks, and optimize irrigation.

- Inventory Management: GAO’s Drones can help with inventory tracking by scanning barcodes or RFID tags on pallets or storage bins. This improves stock accuracy and reduces the likelihood of shortages or overstocking.

- Supply Chain Management: GAO’s Drones can monitor the movement of raw materials and finished products within the supply chain, enhancing visibility and ensuring timely deliveries.

- Quality Control: GAO’s Drones equipped with cameras and image recognition software can inspect product quality and packaging on production lines, helping to identify defects and ensuring consistency.

- Environmental Monitoring: GAO’s Drones can be used to monitor environmental conditions, such as temperature and humidity in warehouses or storage facilities, ensuring that products are stored under optimal conditions.

- Field Inspection: GAO’s Drones can assess the health of tobacco crops by capturing high-resolution images of the fields, which can help in crop management decisions.

- Crop Spraying: Agricultural drones can be used for precise pesticide and herbicide application, reducing the need for manual labor and ensuring even coverage.

- Warehouse Management: GAO’s Drones can assist in tracking and managing inventory in large warehouses, helping to locate specific batches of tobacco leaves or finished products.

- Security and Surveillance: GAO’s Drones can be deployed for security purposes to monitor manufacturing facilities, preventing unauthorized access and ensuring employee safety.

- Environmental Compliance: GAO’s Drones can monitor emissions and environmental compliance at manufacturing facilities, helping companies adhere to regulatory requirements.

- Site Inspection: GAO’s Drones equipped with cameras and sensors can inspect manufacturing equipment and infrastructure for maintenance and safety checks.

- Transportation: GAO’s Drones have the potential to be used for the transportation of small, high-value items between manufacturing facilities or distribution centers.

- Surveying and Mapping: GAO’s Drones can create detailed topographic maps and 3D models of manufacturing sites, aiding in site planning and expansion.

- Marketing and Promotion: Aerial photography and videography from drones can be used for marketing and promotional purposes, showcasing manufacturing facilities or product launches.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the beverage and tobacco product manufacturing industry:

- Quality Control: GAO’s IoT sensors can monitor various parameters such as temperature, humidity, and pressure during the beverage production process, ensuring product quality and consistency.

- Inventory Management: GAO’s IoT devices can track the levels of raw materials, packaging materials, and finished products in real-time, helping with inventory optimization and reducing waste.

- Predictive Maintenance: GAO’s IoT-enabled sensors on production equipment can monitor their condition and performance. Predictive analytics can then identify when maintenance is needed, reducing downtime and preventing costly breakdowns.

- Supply Chain Visibility: GAO’s IoT can provide real-time visibility into the movement of goods within the supply chain, allowing for better tracking and management of shipments.

- Energy Efficiency: Sensors can monitor energy consumption in manufacturing facilities, helping to identify opportunities for energy savings and sustainability improvements.

- Product Traceability: GAO’s IoT technology can enable end-to-end product traceability, allowing manufacturers to track and trace each product’s journey from raw materials to finished goods, enhancing transparency and safety.

- Remote Monitoring: Manufacturers can remotely monitor and control production processes and equipment, making it possible to adjust settings or troubleshoot issues from a distance.

- Crop Monitoring: GAO’s IoT sensors in agricultural fields can monitor soil conditions, temperature, and humidity to optimize tobacco crop growth and quality.

- Warehouse Management: GAO’s IoT devices can track the temperature and humidity in tobacco storage facilities to ensure proper storage conditions and prevent spoilage.

- Quality Assurance: Sensors can continuously monitor the quality of tobacco leaves during processing, identifying any anomalies or deviations from quality standards.

- Predictive Maintenance: Similar to the beverage industry, GAO’s IoT-enabled sensors on manufacturing equipment can predict maintenance needs and prevent costly downtime.

- Security and Access Control: GAO’s IoT-based security systems can provide real-time surveillance of manufacturing facilities and control access to sensitive areas.

- Compliance Monitoring: GAO’s IoT can help ensure compliance with regulatory requirements by monitoring environmental conditions, emissions, and workplace safety.

- Batch Tracking: GAO’s IoT can facilitate batch tracking and tracing of tobacco products, enabling quick recalls in case of safety concerns.

- Energy Management: GAO’s IoT sensors can optimize energy use in manufacturing facilities, reducing costs and environmental impact.

- Remote Diagnostics: Manufacturers can remotely diagnose and address equipment issues, reducing the need for on-site maintenance teams.

- Data Analytics: GAO’s IoT-generated data can be analyzed to gain insights into production processes, identify inefficiencies, and make data-driven decisions.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Beverage and Tobacco Product Manufacturing Industry

GAO RFID Inc. has helped many companies in beverage and tobacco product manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 series

- EPCglobal Gen2

- GS1 EPCglobal standards

- Bluetooth SIG Standards

- IEEE 802.15.4

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- OPC UA (Unified Architecture)

- LoRaWAN Sigfox

- ASTM F38

- ISO 21384 series

- FAA Part 107

Government Regulations

- Federal Food, Drug, and Cosmetic Act (FD&C Act)

- Tobacco Control Act

- Alcohol and Tobacco Tax and Trade Bureau (TTB) Regulations

- Federal Alcohol Administration Act (FAA Act)

- Occupational Safety and Health Administration (OSHA) Regulations

- Food Safety Modernization Act (FSMA) Regulations

- Environmental Protection Agency (EPA) Regulations

- Federal Trade Commission (FTC) Regulations

- Internal Revenue Code (IRC) – Alcohol and Tobacco Tax Regulations

- Alcohol and Tobacco Excise Tax Requirements (Title 26, CFR)

- Labeling and Advertising Regulations for Tobacco Products (Title 21, CFR)

- Dietary Supplement Health and Education Act (DSHEA) Regulations (for certain beverage products)

- State-Specific Regulations (varies by state)

- Customs and Border Protection (CBP) Import Regulations (for international trade)

Canadian Government Regulations

- Tobacco and Vaping Products Act (TVPA)

- Food and Drugs Act (F&D Act)

- Tobacco Products Information Regulations

- Canada Consumer Product Safety Act (CCPSA)

- Canadian Environmental Protection Act, 1999 (CEPA)

- Canadian Tobacco, Alcohol, and Drugs (CTADS) Survey Regulations

- Canada Agricultural Products Act (CAPA)

- Canadian Food Inspection Agency (CFIA) Regulations

- Import Control List (ICL)

- Excise Act, 2001

- Food and Drug Regulations

- Packaging and Labeling Regulations for Tobacco Products

- Health Canada’s Tobacco Reporting Regulations

- Canadian Standards Association (CSA) Standards (related to equipment and safety)

- Occupational Health and Safety Regulations (varies by province)

- Provincial and Territorial Regulations (varies by region)

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in beverage and tobacco product manufacturing industry such as:

Personnel Management:

- Employee Attendance Tracking

- Workforce Scheduling and Shift Management

- Performance Evaluation and Management

- Training and Certification Tracking

- Health and Safety Compliance Monitoring

Equipment Management:

- Predictive Maintenance for Manufacturing Equipment

- Asset Tracking and Management

- Equipment Utilization Monitoring

- Calibration and Quality Control of Machinery

- Energy Consumption Monitoring for Equipment

Access Control:

- Facility Access Control and Security

- Restricted Area Access Management

- Visitor Registration and Monitoring

- Compliance with Regulatory Access Requirements

Warehouse Management:

- Inventory Tracking and Management

- Batch and Lot Control

- FIFO/LIFO Inventory Management

- Order Picking and Packing Optimization

- Temperature and Humidity Monitoring for Storage

- Shelf-Life Tracking

Supply Chain Management:

- Supplier Relationship Management

- Demand Forecasting and Planning

- Vendor-Managed Inventory (VMI)

- Traceability and Product Recall Management

- Transportation and Route Optimization

Other Applications:

- Quality Control and Assurance

- Environmental Compliance and Reporting

- Sustainability and Resource Management

- Labeling and Packaging Compliance

- Product Serialization for Anti-Counterfeiting

GAO has enabled its customers to make use of some of the leading software and cloud services in the beverage and tobacco product manufacturing industry. Below are some of popular software and cloud services in beverage and tobacco product manufacturing industry:

Workday HCM, Oracle HCM Cloud, SAP SuccessFactors, eMaint CMMS, Fiix, Brivo, Honeywell Access Control, NetSuite, HighJump, SAP Integrated Business Planning (IBP), Oracle Cloud, Kinaxis RapidResponse.

GAO has worked with some of the leading technology companies in the beverage and tobacco product manufacturing industry to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in beverage and tobacco product manufacturing industry:

IBM, SAP, Oracle, Microsoft, Salesforce, Infor, Plex Systems, Aptean, Epicor, Syspro, Siemens, Rockwell Automation, Schneider Electric, ABB, Omron, Yokogawa, Mitsubishi Electric, Emerson Electric, Honeywell Process Solutions, Beckhoff Automation, Wonderware (Schneider Electric), Inductive Automation, GE Digital, Invensys (Schneider Electric), Lighthouse Systems, Parsec Automation, Werum IT Solutions, Redzone, Dassault Systemes, Parseq Lab.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in beverage and tobacco product manufacturing industry.

RFID tags are used to track the movement of raw materials, packaging materials, and finished products in real-time, optimizing inventory levels and reducing the risk of stockouts. This ensures that the right materials are available when needed for production.

RFID technology helps monitor and trace the production process of beverages and tobacco products, ensuring that each product meets quality standards at every stage of manufacturing. It can detect defects and deviations from standards, helping maintain product consistency.

RFID provides real-time data on the movement of goods within the supply chain. This allows for better tracking and management of shipments, enabling companies to respond quickly to disruptions and improve overall supply chain efficiency.

RFID tags with unique identification codes can be used to verify the authenticity of high-end or premium beverages and tobacco products, reducing the risk of counterfeiting and protecting brand integrity.

RFID technology can assist in compliance with various regulations related to product labeling, traceability, and reporting. It helps ensure that products meet regional and international standards.

RFID-enabled systems facilitate precise tracking of batches and lots of products from production to distribution. This simplifies recalls, improves traceability, and enhances overall product management.

RFID tags on pallets and cases streamline the movement and storage of products in warehouses. This leads to improved inventory accuracy and efficient order fulfillment.

RFID-based access control systems enhance security at manufacturing facilities. They ensure that only authorized personnel have access to sensitive areas, helping maintain product integrity and safety.

Many applications of RFID by GAO can be found here.https:

Manufacturing Industry | RFID Solutions

Case Studies of IoT Applications

Below are some IoT application cases in beverage and tobacco product manufacturing industry.

IoT sensors are used to monitor the condition of manufacturing equipment in real-time. For example, sensors can track temperature, pressure, and vibration levels in machinery to detect potential issues and schedule maintenance proactively, reducing downtime.

IoT sensors can monitor and collect data on various parameters during the production process, ensuring product quality and consistency. For example, sensors can measure pH levels, moisture content, or tobacco leaf properties to ensure that products meet desired standards.

IoT solutions help optimize energy consumption in manufacturing facilities. Smart meters and sensors monitor energy usage and provide insights to identify opportunities for energy savings, reducing operational costs and environmental impact.

IoT-enabled RFID tags and sensors track the movement of raw materials, packaging materials, and finished products throughout the supply chain. This real-time visibility improves inventory accuracy and reduces the risk of shortages or overstocking.

IoT sensors on equipment collect data on performance and wear. Machine learning algorithms analyze this data to predict when maintenance is needed. This proactive approach reduces unexpected breakdowns and increases equipment lifespan.

IoT sensors monitor environmental conditions within manufacturing facilities, ensuring that products are stored and processed under optimal conditions. This is crucial for products with specific storage requirements, such as tobacco.

IoT technology provides real-time data on the movement of goods within the supply chain, enhancing traceability and allowing companies to optimize logistics and respond quickly to disruptions.

IoT sensors can monitor safety conditions in manufacturing facilities, ensuring that regulatory requirements are met. For example, they can detect the presence of hazardous materials or monitor air quality.

IoT applications can help reduce waste in manufacturing processes by providing data on material usage and production efficiency. This supports sustainability goals and cost reduction.

IoT-generated data is valuable for data analytics. Companies can gain insights into production processes, identify inefficiencies, and make data-driven decisions to improve overall operations.

Case Studies of Drone Applications

Below are some drone application cases in beverage and tobacco product manufacturing industry.

Drones equipped with cameras and sensors are used to monitor tobacco fields and agricultural areas where ingredients for beverages are grown. They can assess crop health, detect diseases, optimize irrigation, and ensure the quality of raw materials.

Drones can be used for aerial surveys of large warehouses and storage facilities, providing real-time data on inventory levels and conditions of stored products. This improves inventory accuracy and facilitates timely restocking.

Drones equipped with environmental sensors can monitor air quality, temperature, humidity, and other conditions within manufacturing facilities and storage areas to ensure that products are stored under optimal conditions.

Drones are used for security and surveillance purposes to monitor manufacturing facilities and storage yards, helping prevent unauthorized access, theft, and ensuring overall security.

Drones equipped with cameras and sensors can inspect manufacturing equipment, chimneys, and other critical infrastructure for maintenance and safety checks. They provide a quick and efficient way to assess equipment’s condition.

Drones can create detailed topographic maps and 3D models of manufacturing sites. These maps aid in site planning, expansion, and facility layout optimization.

Aerial photography and videography from drones can be used for marketing and promotional purposes. This includes showcasing manufacturing facilities, product launches, and capturing captivating visuals for advertising campaigns.

In the supply chain, drones can be used for the transportation of small, high-value items between manufacturing facilities, distribution centers, and other points in the logistics network, improving efficiency and reducing costs.

GAO RFID Systems & Hardware for Beverage and Tobacco Product Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including beverage and tobacco product manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

- BLE Gateway (Receiver)

- as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

- BLE Tags/Beacons

GAO’s BLE technology is suitable for many industries, including support activities for mining.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including support activities for mining:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including support activities for mining:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including support activities for mining:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including support activities for mining:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 KHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones are offered:

The RFID systems by GAO are highly popular for clients in support activities for mining:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include drilling rigs, seismic survey instruments, core sampling equipment, geological survey tools, heavy machinery (e.g., excavators, bulldozers, haul trucks), crushers, processing machinery, safety equipment (e.g., helmets, respirators), communication and monitoring systems, environmental monitoring equipment, explosives handling equipment, and specialized maintenance and repair tools for mining equipment.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for support activities for mining and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in beverage and tobacco product manufacturing industry we have worked with to serve our joint customers:

- Accenture

- IBM Global Business Services

- Deloitte

- Capgemini

- Cognizant

- Wipro

- TCS (Tata Consultancy Services)

- DXC Technology

- Infosys

- HCL Technologies

- CGI Group

- Deloitte Canada

- Accenture Canada

- Wipro Canada

- TCS Canada

- Capgemini Canada

- IBM Canada

- Cognizant Canada

- Fujitsu Canada

- Softchoice

- Softtek

- Neoris

- Cognizant Mexico

- Tata Consultancy Services (TCS) Mexico

- Wipro Mexico

- IBM Mexico

- KIO Networks

- Infosys Mexico

- PwC Mexico

- Deloitte Mexico

- Atos

- Capgemini Europe

- Accenture Europe

- CGI Europe

- Wipro Europe

- IBM Europe

- Deloitte Europe

- TCS Europe

- Cognizant Europe

- DXC Technology Europe

GAO Has Served Beverage and Tobacco Product Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in beverage and tobacco product manufacturing industry to achieve success in:

Health and Wellness, Sustainability, Digital Transformation, Product Innovation, E-commerce and DTC (Direct-to-Consumer), Premiumization, Clean Label, Craft and Artisanal, Functional Beverages, Reduced-Risk Tobacco Products, Industry 4.0, IoT (Internet of Things), AI (Artificial Intelligence), Automation, Eco-Friendly Packaging, Traceability, Smart Manufacturing, Plant-Based, Convenience, Single-Origin Tobacco.

GAO RFID Inc. has served many customers in beverage and tobacco product manufacturing industry, including its various divisions such as:

- Non-Alcoholic Beverages: This division includes the production of non-alcoholic beverages such as soft drinks, bottled water, fruit juices, energy drinks, and ready-to-drink (RTD) teas and coffees.

- Alcoholic Beverages: This segment encompasses the production of alcoholic beverages, including beer, wine, spirits, and liquors.

- Functional Beverages: Manufacturers produce functional beverages like sports drinks, nutritional drinks, and wellness beverages that offer specific health benefits or functionality.

- Dairy and Dairy Alternatives: This division focuses on the production of dairy-based beverages like milk and yogurt drinks, as well as plant-based alternatives such as almond milk and soy milk.

- Cigarettes: Companies in this segment manufacture conventional cigarettes, which are a significant part of the tobacco industry.

- Cigars: This division includes the production of cigars, which vary in size, flavor, and quality.

- Smokeless Tobacco: Manufacturers produce smokeless tobacco products like chewing tobacco, snuff, and snus.

- E-cigarettes and Vaping Products: This rapidly growing segment involves the manufacturing of electronic cigarettes (e-cigarettes) and vaping products, including e-liquids and vaping devices.

- Packaging and Labeling: While not a product division, the packaging and labeling sector plays a crucial role in both the beverage and tobacco industries. It includes the manufacturing of packaging materials, labels, and containers specifically designed for these products.

- Equipment Manufacturing: Companies in this division produce specialized equipment and machinery used in beverage and tobacco product manufacturing, such as bottling and packaging machines, smoking equipment, and labeling machinery.

- Ingredients and Additives: Manufacturers of ingredients and additives provide essential components for beverage and tobacco product formulations. This includes flavorings, sweeteners, preservatives, and tobacco blends.

- Distribution and Supply Chain: This division involves the logistics, distribution, and supply chain management aspects of the industry, ensuring products are transported efficiently from manufacturing facilities to retailers and consumers.

- Regulatory and Compliance: This segment comprises organizations and agencies responsible for monitoring and enforcing regulatory compliance, including health and safety standards, labeling requirements, and age restrictions for tobacco products.

GAO’s technologies enable its customers in beverage and tobacco product manufacturing industry to effectively track their workforces such as:

Production Supervisor, Quality Control Inspector, Machine Operator, Packaging Technician, Line Operator, Warehouse Manager, Process Engineer, Research and Development Specialist, Maintenance Technician, Supply Chain Manager, Packaging Designer, Regulatory Compliance Officer, Materials Handler, Lab Technician, Forklift Operator, Distribution Manager, Sales Representative, Brand Manager, Environmental Health and Safety Coordinator, Production Planner and effectively track operational assets such as:

Mixing Tanks, Pasteurizers, Bottle Filling Machines, Canning Machines, Fermentation Tanks, Carbonation Equipment, Filtration Systems, Homogenizers, Labeling Machines, Capping Machines, Conveyor Systems, Quality Control Equipment, Refrigeration Units, Blending Equipment, Packaging Machinery, Cigarette Making Machines, Cigar Rolling Machines, Smokeless Tobacco Processing Equipment, Filter Attachment Machines, Tobacco Cutting Machines, Moistening Equipment, Drying and Curing Chambers, Flavoring and Aroma Application Machines, Storage Silos, Dust Collection Systems, Heat-Sealing Equipment.

Here are some of the leading companies in beverage and tobacco product manufacturing industry GAO has served:

- Zamsi Tobacco Company

- PepsiCo, Inc.

- Anheuser-Busch InBev

- Diageo plc

- Philip Morris International Inc.

- Altria Group, Inc.

- Constellation Brands, Inc.

- Keurig Dr Pepper Inc

- Heineken N.V.

- British American Tobacco

- Reynolds American Inc.

- Molson Coors Beverage Company

- Brown-Forman Corporation

- Pernod Ricard S.A.

- Imperial Brands plc

- Fomento Economico Mexicano, S.A.B. de C.V. (FEMSA)

- Japan Tobacco Inc.

- SABMiller

- Japan Tobacco International

- Monster Beverage Corporation

- The Kraft Heinz Company

- Constellation Brands

- British American Tobacco Canada

- Fabricas Monterrey

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com