Related Products & Systems on Other Pages on This Website

Return & Pallet Asset Tracking – GAO RFID

Tool & Industrial Equipment Tracking System

WIP RFID Tracking System | RFID WIP Software – GAO (gaorfid.com)

Manufacturing Employee Tracking System – GAO

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

On Metal RFID Tags – All Types

Printable RFID Tags | Printable RFID Labels – GAO RFID

Laundry RFID Tags | Waterproof RFID Tags – GAO RFID

Wet Inlay RFID Tags | Peel & Stick RFID Tags – GAO RFID

Overview

Carpet and rug manufacturing industry is involved in the production of carpets and rugs for various purposes, including residential, commercial, and industrial applications. The process typically begins with the selection of raw materials, such as natural or synthetic fibers, which are then processed and transformed into yarns. The industry encompasses a wide range of products, including wall-to-wall carpets, area rugs, carpet tiles, and mats.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in carpet and rug manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as carding machines, spinning frames, twisting machines, power looms, ax minster looms, wilton looms, tufting machines, tufting guns dyeing vats, jet dyeing machines and screen-printing machines.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for carpet and rug manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Carpet and Rug Manufacturing

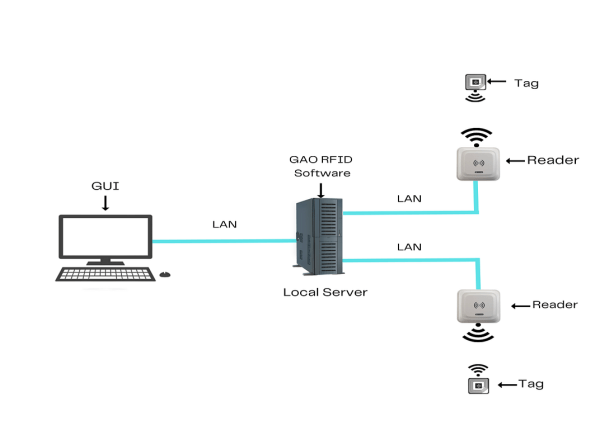

To satisfy its customers, GAO’s RFID or RFID Systems for carpet and rug manufacturing are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for carpet and rug manufacturing with its software running on a local server.

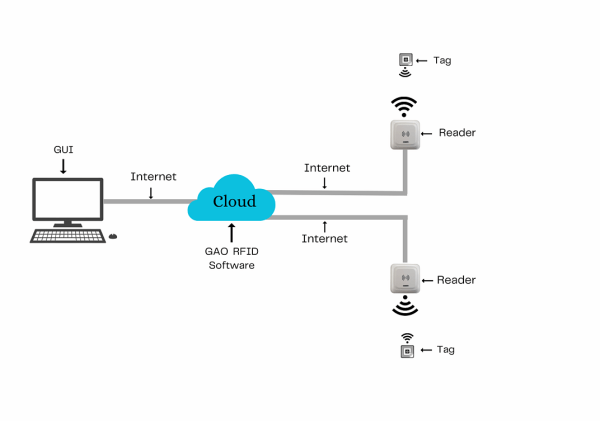

The above illustrates GAO system for carpet and rug manufacturing with its software running in cloud.

GAO’s RFID technologies bring the many benefits to carpet and rug manufacturing industry:

- Streamlined Production Processes: GAO RFID can automate various aspects of production, such as material handling, machine operation, and quality control. By using RFID-enabled systems, manufacturers can reduce manual data entry, minimize errors, and increase production efficiency. This leads to faster turnaround times and cost savings.

- Anti-Theft and Loss Prevention: Our RFID tags can act as a deterrent against theft or loss of carpets and rugs. If a tagged item is moved or taken without authorization, the RFID system can trigger alarms or notifications, enabling quick response and recovery. This helps protect valuable inventory and prevents revenue loss.

- Enhanced Supply Chain Visibility: GAO’s RFID technology enables real-time tracking of products as they move through the supply chain, from manufacturing facilities to distribution centers and retailers. This visibility allows manufacturers to optimize logistics, identify bottlenecks, and improve overall supply chain efficiency.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within carpet and rug manufacturing industry:

- Indoor Localization: GAO BLE technology enables accurate indoor positioning and localization. By deploying BLE beacons throughout the manufacturing facility, manufacturers can track the movement of carpets and rugs, monitor workflow, and optimize production processes.

- Workflow Automation: Our BLE technology can automate various aspects of the manufacturing workflow. For example, when a carpet or rug reaches a specific production stage, BLE beacons can trigger notifications or alerts to relevant personnel or systems. This streamlines communication, reduces manual intervention, and improves overall process efficiency.

- Maintenance and Service Reminders: GAO’s BLE-enabled sensors or beacons can collect and transmit data regarding the condition, usage, or maintenance requirements of carpets and rugs. This enables manufacturers to schedule timely maintenance, detect potential issues, and provide proactive service reminders to customers. It helps in extending the lifespan of products and improving customer satisfaction.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to carpet and rug manufacturing industry:

- Remote Asset Inspection: Drones can be equipped with cameras or sensors to capture images or data from hard-to-reach or elevated areas. When combined with our RFID technology, manufacturers can remotely inspect assets, such as high shelves or storage racks, without physically accessing those areas. This simplifies maintenance, reduces safety risks, and enables timely inspections.

- Real-Time Tracking During Production: Drones equipped with our RFID readers can monitor the progress of carpets and rugs on the production floor. As items move through different stages, drones can scan the RFID tags, providing real-time tracking information. This enables manufacturers to monitor production flow, identify bottlenecks, and optimize workflow for improved efficiency.

- Improved Data Collection and Analytics: By combining GAO’s RFID and drone technologies, manufacturers can collect extensive data on inventory, asset movements, and production processes. This data can be analyzed to gain insights, identify trends, and make data-driven decisions. It helps in optimizing operations, enhancing product quality, and improving overall business performance.

Here are benefits of GAO’s IoT technologies to carpet and rug manufacturing industry:

- Quality Control: GAO IoT devices can collect real-time data from the manufacturing equipment, enabling constant monitoring of production parameters like temperature, humidity, and pressure. This helps identify and rectify quality issues promptly, leading to higher-quality carpets and rugs.

- Predictive Maintenance: Our IoT sensors can be used to monitor the health and performance of machinery, detecting anomalies and predicting maintenance needs. This allows for proactive maintenance scheduling, minimizing unplanned downtime and reducing repair costs.

- Energy Efficiency: By incorporating GAO’s IoT devices and smart sensors, manufacturers can optimize energy consumption in their production processes. Monitoring energy usage and implementing automated controls can lead to significant cost savings and reduced environmental impact.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Carpet and Rug Manufacturing

GAO RFID Inc. has helped many companies in carpet and rug manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- EPC Class 1 Gen 2: This is an RFID standard developed by EPC global, which is an organization that sets standards for Electronic Product Code (EPC) and RFID technology. EPC Class 1 Gen 2 is widely adopted for passive UHF RFID systems, providing a common framework for interoperability and communication between tags and readers.

- NFC Forum: Near Field Communication (NFC) is a short-range wireless communication technology that enables contactless data transfer between devices. The NFC Forum develops and promotes standards for NFC technology, which can be utilized in carpet and rug industry for applications such as authentication, smart labeling, and customer engagement.

- Generic Attribute Profile (GATT): GATT is a BLE profile that specifies a hierarchical data structure for organizing data transferred between BLE devices. It defines how data is organized into services, characteristics, and descriptors, enabling standardized communication between devices.

- Apple HomeKit: Apple HomeKit is a framework that enables smart home connectivity and control using BLE and other communication protocols. It provides a standardized approach for integrating BLE-enabled devices, including carpets and rugs, into the Apple Home ecosystem.

- MQTT (Message Queuing Telemetry Transport): MQTT is a lightweight messaging protocol designed for IoT applications. It enables efficient communication between devices, making it suitable for real-time monitoring and control in carpet and rug manufacturing process.

- CoAP (Constrained Application Protocol): CoAP is a specialized protocol for constrained devices and networks. It provides a lightweight, efficient way to exchange data between IoT devices, making it well-suited for resource-constrained environments and enabling seamless integration in carpet and rug manufacturing industry.

- ASTM F38: ASTM F38 is a committee that develops standards for unmanned aircraft systems (UAS). They create guidelines and standards for the design, construction, and operation of drones. These standards cover various aspects of drone operations, including safety, performance, and testing procedures.

- GUTMA: The Global UTM Association (GUTMA) is an international association that develops standards and promotes interoperability for unmanned traffic management (UTM) systems. UTM systems facilitate the integration of drones into the airspace, enabling safe and efficient drone operations in various industries.

US Government Regulations

- Customs and Border Protection (CBP): CBP is responsible for enforcing import and export regulations.

- Department of Labor (DOL): The DOL enforces various labor laws, such as minimum wage, overtime, and child labor regulations. Carpet and rug manufacturing industry must comply with these regulations to ensure fair employment practices.

Canadian Government Regulations

- Canadian Centre for Occupational Health and Safety (CCOHS): The CCOHS sets and promotes occupational health and safety standards in Canada. They provide resources and guidelines for workplace safety, including regulations related to machinery, hazardous materials, and ergonomics.

- Canada Border Services Agency (CBSA): CBSA is responsible for regulating imports and exports in Canada. If carpet and rug manufacturing industry involves international trade, businesses must comply with CBSA requirements related to customs, tariffs, and documentation.

Electronic Product Code Global

Near Field Communication Forum

Generic Attribute Profile

Apple HomeKit

Message Queuing Telemetry Transport

Constrained Application Protocol

ASTM F38

Global UTM Association

Customs and Border Protection

Department of Labor

Canadian Centre for Occupational Health and Safety

Canada Border Services Agency

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in carpet and rug manufacturing such as:

- Employee Attendance Tracking: Implementing attendance tracking systems can help monitor employee attendance, work hours, and time-off requests, streamlining workforce management.

- Performance Management: Performance management software allows tracking and evaluating employee performance, setting goals, conducting performance appraisals, and providing feedback to optimize productivity.

- Asset Tracking: RFID or barcode-based asset tracking systems can be employed to monitor and track equipment, tools, and machinery, ensuring efficient utilization and maintenance.

- Preventive Maintenance: Implementing a preventive maintenance system allows scheduling and tracking routine maintenance activities for machinery and equipment, reducing downtime and increasing longevity.

- Access Control Systems: Utilizing access control systems, such as keycards or biometric readers, helps regulate access to sensitive areas within the manufacturing facility, ensuring security and safety.

- Other Applications: A few more applications that can be relevant to carpet and rug manufacturing industry include: visitor management, product lifecycle management (PLM), internet of things (IoT) integration, data analytics and business intelligence, robotics and automation, augmented reality (AR) and virtual reality (VR), customer relationship management (CRM) and energy management.

GAO has enabled its customers to make use of some of leading software and cloud services in carpet and rug manufacturing industry. Below are some of popular software and cloud services in carpet and rug manufacturing industry.

- BambooHR: BambooHR is an intuitive HR software that offers features such as employee self-service, applicant tracking, performance management, and reporting. It simplifies HR processes and streamlines personnel management tasks.

- SAP SuccessFactors: SAP SuccessFactors is an integrated human capital management (HCM) software suite that provides tools for recruitment, performance management, learning and development, and employee engagement.

- Workday HCM: Workday HCM is a cloud-based human capital management platform that offers comprehensive features for personnel management, including workforce planning, talent acquisition, performance management, and employee self-service.

- Oracle HCM Cloud: Oracle HCM Cloud is a scalable and integrated cloud-based solution that covers various aspects of personnel management, including recruitment, onboarding, performance management, and workforce analytics.

- Honeywell Access Control: Honeywell Access Control is a comprehensive solution for access control and security management. It offers features such as card-based access control, biometric authentication, visitor management, and integration with surveillance systems.

- LenelS2 OnGuard: LenelS2 OnGuard is an advanced access control and security management software that provides centralized control over access permissions, video surveillance integration, visitor management, and alarm monitoring.

- Brivo: Brivo is a cloud-based access control and security platform that offers features such as card-based access control, mobile credentials, visitor management, and integration with video surveillance systems.

- Kisi: Kisi is a cloud-based access control solution that provides modern access control features, including mobile access, keyless entry, visitor management, and integration with other building management systems.

- Lectra Fashion PLM: Lectra Fashion PLM is a product lifecycle management (PLM) software designed specifically for the fashion and textile industry. It provides features for design, pattern-making, marker-making, and cutting, helping to streamline the manufacturing process for carpets and rugs.

- Gerber Technology AccuMark: Gerber Technology AccuMark is a comprehensive software solution for pattern design, grading, and marker-making. It enables precise pattern development and nesting, optimizing material utilization and reducing waste.

- Microsoft Azure: Microsoft Azure is a comprehensive cloud computing platform that offers a wide range of services, including virtual machines, storage, analytics, and machine learning. It provides scalability, security, and flexibility for various aspects of carpet and rug manufacturing industry.

- Amazon Web Services (AWS): AWS is a popular cloud services platform that provides a broad set of infrastructure and application services. It offers solutions for storage, compute power, database management, analytics, and more, catering to the needs of carpet and rug manufacturing industry.

BambooHR

SAP SuccessFactors

Workday HCM

Oracle HCM Cloud

LenelS2

Honeywell

Brivo

Kisi

Lectra

Gerber Technology

Microsoft Azure

Amazon Web Services

GAO has worked with some of the leading technology companies in carpet and rug manufacturing in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in carpet and rug manufacturing industry:

- IFS: IFS offers an enterprise resource planning (ERP) software suite that covers various aspects of manufacturing, including supply chain management, production planning, and asset management. Their solutions can be tailored to the needs of carpet and rug manufacturing industry.

- JDA Software: JDA Software provides supply chain management solutions for a wide range of industries, including textiles and apparel. Their software helps optimize inventory, distribution, and logistics processes, which can benefit carpet and rug manufacturers.

- EFI Optitex: EFI Optitex is a leading provider of 2D and 3D CAD/CAM software solutions for the fashion and textile industry. Their technology enables efficient design, development, and production processes, which can be adapted for carpet and rug manufacturing.

- Simparel: Simparel is a software company that offers a unified enterprise resource planning (ERP) solution for the apparel and textile industry. Their software covers various aspects of manufacturing, including product development, sourcing, production planning, and supply chain management.

- AtlasIED: AtlasIED offers a range of electronic solutions for carpet and rug industry, including sound masking systems, audio distribution systems, and communication devices. These technologies can enhance workplace environments and improve communication within manufacturing facilities.

- Infineon Technologies: Infineon Technologies specializes in semiconductor and electronic solutions. Their offerings include power management systems, sensors, and microcontrollers that can be utilized in various aspects of carpet and rug manufacturing process, such as automation and control systems.

- Omron Corporation: Omron Corporation provides automation and electronic control solutions for a wide range of industries. Their product portfolio includes programmable logic controllers (PLCs), sensors, robotics, and vision systems that can enhance productivity and efficiency in carpet and rug manufacturing.

- Siemens : Siemens is a global technology company that offers automation, control, and electronic solutions for multiple industries. Their offerings for carpet and rug manufacturing industry include industrial automation systems, drive technology, and digitalization solutions.

- Prodsmart: Prodsmart offers a cloud-based production management software that can be utilized in carpet and rug manufacturing industry. Their solution provides real-time data collection, production tracking, quality control, and reporting capabilities.

- Visual Next: Visual Next offers an integrated suite of software solutions for the fashion, textile, and apparel industries. Their comprehensive platform includes modules for design, production planning, inventory management, and supply chain management, which can be customized for carpet and rug manufacturers.

- Datatex: Datatex is a leading provider of software solutions for the textile and apparel industry. Their product portfolio includes modules for production planning, scheduling, material management, and quality control that can be adapted for carpet and rug manufacturing.

- Crea Solution: Crea Solution specializes in software solutions for the textile and fashion industry. Their offerings cover various aspects of manufacturing, including design, pattern-making, production planning, and costing, which can be applied to carpet and rug manufacturing sector.

Industrial and Financial Systems

JDA Software

EFI Optitex

Simparel

AtlasIED

Infineon Technologies

Omron Corporation

Siemens

Prodsmart

Visual Next

Datatex

Crea Solution

Case Studies of RFID Applications

Below are some RFID application cases in carpet and rug manufacturing industry:

Interface (USA): Interface, a global modular carpet manufacturer, has incorporated RFID technology in their production and distribution processes. They use RFID tags on individual carpet tiles to track inventory movement, streamline logistics, and improve traceability across the supply chain.

Beaulieu Canada: Beaulieu Canada, a prominent carpet and flooring manufacturer, has adopted RFID technology to enhance their warehouse management system. They employ RFID tags on carpet rolls and utilize RFID readers at various checkpoints to automate inventory tracking, reduce errors, and improve overall efficiency in their warehouses.

Mohawk Industries (USA): Mohawk Industries has implemented UFH RFID technology in their operations to enhance inventory management and supply chain efficiency. By utilizing UFH RFID tags on rolls of carpet and rugs, they can track and monitor inventory levels accurately, reduce stockouts, and improve order fulfillment.

Northern Wide Plank (Canada): Northern Wide Plank, a Canadian manufacturer of high-quality wood flooring, has implemented UFH RFID technology to enhance their inventory management and customer experience. By utilizing UFH RFID tags on their flooring products, they are able to track inventory levels, improve order accuracy, and provide real-time product information to customers.

Many applications of RFID by GAO can be found here:

GAO RFID Systems & Hardware for Carpet and Rug Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including carpet and rug manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button

GAO’s BLE technology is suitable for many industries, including carpet and rug manufacturing

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including carpet and rug manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including carpet and rug manufacturing :

and an array of antennas to address different applications

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including carpet and rug manufacturing:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including carpet and rug manufacturing:

and antennas

GAO also offers RFID printers

Digital I/O adapters

and relay controllers

For embedded applications, GAO offers UHF, HF and LF RFID reader modules

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in carpet and rug manufacturing:

Assets that can be effectively tracked using GAO’s technologies include

- Tufting Machines: Tufting machines are used to create the primary structure of carpets and rugs by inserting yarns into a primary backing material. These machines come in various types, including cut pile, loop pile, and cut-loop pile tufting machines.

- Dyeing Machines: Dyeing machines are used to apply color to carpet or rug materials. They can be used for batch dyeing, continuous dyeing, or printing processes to achieve desired colors and patterns.

- Weaving Looms: Weaving looms are used in the production of woven carpets and rugs. These machines interlace the yarns to create intricate patterns and designs.

- Spinning Machines: Spinning machines are used to spin the yarns that are used in carpet and rug manufacturing process. These machines can spin various types of yarns, such as synthetic fibers, natural fibers, or blends.

- Cutting and Edging Machines: Cutting and edging machines are used to trim and finish the edges of carpets and rugs. They ensure clean and precise cuts, and can also add binding or serging to the edges for a finished look.

- Finishing Machines: Finishing machines are used to add final touches to carpets and rugs, such as shearing, brushing, or steaming. These processes help enhance the appearance, texture, and durability of the finished products.

- Backing Machines: Backing machines are used to apply secondary backing materials to carpets and rugs. These machines attach a secondary layer to the tufted or woven surface to provide stability and reinforcement.

- Latexing Machines: Latexing machines are used to apply latex or other adhesive materials to the back of carpets and rugs. This process helps secure the yarns and backing together, providing stability and durability.

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served Carpet and Rug Manufacturing Extensively

GAO’s products and technologies have helped its customers in carpet and rug manufacturing industry to achieve success in sustainability, green label, customization, digitalization, smart carpets, circular economy, natural fibers, VOC (Volatile Organic Compounds), luxury vinyl tiles, hybrid flooring, carpet tiles, seamless flooring, antimicrobial, low pile, high traffic, broadloom, modularity, stain resistance and acoustics.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in carpet and rug manufacturing, including many in its various divisions such as

- Tufted Carpets and Rugs: This division includes the manufacturing of carpets and rugs through the tufting process, where yarns are inserted into a backing material and then secured.

- Woven Carpets and Rugs: Woven carpets and rugs are produced on weaving looms, where yarns are interlaced to create intricate patterns and designs.

- Knotted Carpets and Rugs: Knotted carpets and rugs are handmade using a technique where individual knots are tied onto a warp to form the surface pile.

- Carpet Tiles: Carpet tiles are modular carpet units that are typically smaller in size and can be easily installed, replaced, and rearranged. This division focuses on the production of carpet tiles.

- Broadloom Carpets: Broadloom carpets refer to carpets that are produced in wide rolls and installed as a continuous flooring surface. This division focuses on the manufacturing of broadloom carpets.

- Automotive Carpets: This sub-industry specializes in the manufacturing of carpets used in automobiles, including carpets for floor coverings, trunk liners, and other automotive applications.

Here are some of the leading companies in carpet and rug manufacturing industry:

Mohawk Industries

Shaw Industries Group

Dixie Group

Interface

Beaulieu of America

Tarkett North America

Milliken and Company

Engineered Floors

J+J Flooring Group

Bentley Mills

Mannington Mills

Stanton

Karastan

Couristan

Masland Carpets & Rugs

Oriental Weavers USA

Nourison Industries

Joy Carpets & Co.

Balta Group Canada

Beaulieu Canada

Kraus Flooring

Peerless Contract

Kane Carpet

Colonial Mills Canada