Related Products & Systems on Other Pages on This Website

Tool & Industrial Equipment Tracking System

Work In Process WIP Asset Tracking System

Manufacturing Employee Tracking System – GAO (gaorfid.com)

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

Rugged RFID Tags | GAO RFID Inc.

On Metal RFID Tags – All Types

Printable RFID Tags | Printable RFID Labels – GAO RFID

High Temperature RFID Tags – GAO RFID

Overview

The motor vehicle parts manufacturing industry is a vital sector that produces various components and systems for automobiles. It encompasses the design, development, and production of parts such as engines, transmissions, brakes, electrical systems, suspension systems, and more. These parts are essential for the functioning and performance of vehicles, including cars, trucks, motorcycles, and other motorized vehicles.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the motor vehicle parts manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as

CNC machines, lathes, milling machines, welding equipment, stamping presses, die casting machines, injection molding machines, robotic assembly systems, testing and inspection equipment, paint booths, conveyor systems, material handling equipment, cutting tools, grinding machines, heat treatment furnaces, CAD/CAM software, metrology instruments, hydraulic presses, computer systems, electrical systems, pneumatic tools, jigs and fixtures, soldering equipment, CNC routers, laser cutting machines, plasma cutters, vibratory finishing machines, sandblasting equipment, packaging machinery, forklifts, industrial ovens, air compressors, industrial fans, safety equipment, workbenches, and tool storage systems.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the motor vehicle parts manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Motor Vehicle Parts Manufacturing

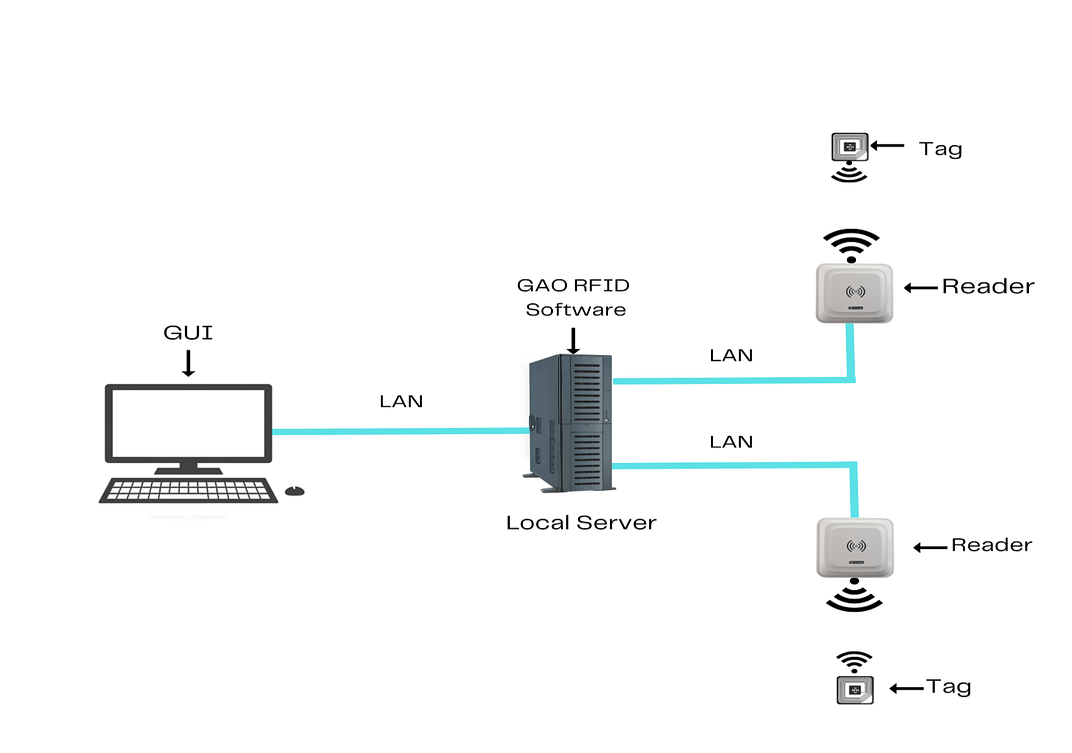

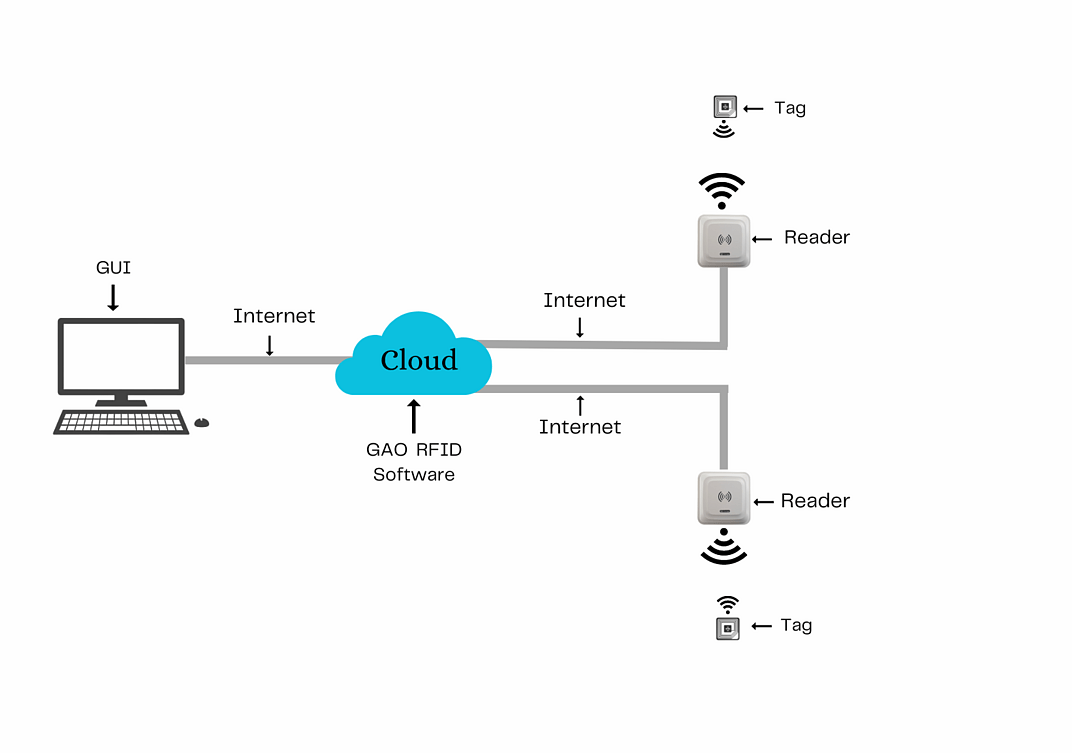

To satisfy its customers, GAO’s RFID or RFID Systems for the motor vehicle parts manufacturing are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the motor vehicle parts manufacturing with its software running on a local server.

GAO’s RFID technologies bring the many benefits to the motor vehicle parts manufacturing industry:

- Improved Inventory Management: GAO’s RFID enables real-time tracking and monitoring of motor vehicle parts, optimizing inventory levels, reducing stockouts, and streamlining supply chain operations.

- Enhanced Traceability and Quality Control: Our RFID solutions provide unique identification and tracking capabilities, allowing manufacturers to trace parts throughout the production process, ensuring quality control, and facilitating recalls if needed.

- Increased Efficiency in Production and Assembly: By incorporating GAO RFID technology into the manufacturing process, we can automate data capture, reducing manual errors, improving assembly line efficiency, and enhancing productivity.

- Enhanced Asset Management: Our RFID solutions enable accurate and automated tracking of tools, equipment, and assets, reducing loss or misplacement, minimizing downtime, and optimizing resource allocation.

- Streamlined Maintenance and Service: With GAO’s RFID, motor vehicle parts can be tagged and monitored for maintenance schedules, ensuring timely servicing, minimizing breakdowns, and prolonging the lifespan of components.

- Heightened Supply Chain Visibility: Our RFID technology provides real-time visibility into the movement of parts within the supply chain, enabling better coordination, reducing delays, and improving overall logistics management.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within the motor vehicle parts manufacturing industry:

- Enhanced Asset Tracking: GAO BLE allows precise tracking of motor vehicle parts, tools, and equipment, improving asset visibility, minimizing loss, and optimizing resource utilization.

- Efficient Production Monitoring: With our BLE technology, real-time data collection and monitoring of production processes enable timely decision-making, improved efficiency, and reduced downtime.

- Improved Safety and Compliance: GAO BLE enables the implementation of safety protocols and compliance measures, ensuring adherence to regulations, minimizing risks, and enhancing workplace safety.

- Enhanced Equipment Maintenance: By utilizing our BLE solutions, motor vehicle manufacturers can implement predictive maintenance strategies, reducing equipment breakdowns, and optimizing maintenance schedules, leading to improved operational efficiency.

- Seamless Workflow Integration: With our BLE technology, manufacturers can integrate different processes and systems seamlessly, improving workflow efficiency, reducing bottlenecks, and enhancing overall operational performance.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to the motor vehicle parts manufacturing industry:

- Efficient Inventory Management: Our RFID technology integrated with drones enables fast and accurate inventory counts, minimizing manual labor, reducing errors, and improving overall inventory management efficiency.

- Rapid Asset Location: GAO’s RFID combined with drones allows for quick and precise locating of motor vehicle parts, optimizing asset retrieval times, and minimizing search efforts.

- Enhanced Site Security: With our RFID-enabled drones, we can conduct regular surveillance and monitoring of manufacturing sites, detecting unauthorized access, and ensuring heightened security measures.

- Streamlined Warehouse Operations: By utilizing our RFID technology in combination with drones, we can automate stock movement, locate parts in real-time, and optimize warehouse processes, resulting in improved operational efficiency.

- Improved Maintenance Inspections: GAO RFID integrated with drones enables efficient inspections of motor vehicle parts, identifying maintenance needs, reducing downtime, and ensuring optimal equipment performance.

- Enhanced Supply Chain Visibility: Our RFID technology with drones provides real-time tracking of parts throughout the supply chain, improving visibility, reducing delays, and optimizing logistics management.

Here are benefits of GAO’s IoT technologies to the motor vehicle parts manufacturing industry:

- Enhanced Equipment Utilization: GAO’s IoT technology enables real-time monitoring of equipment performance and utilization, optimizing resource allocation, reducing downtime, and improving overall equipment efficiency.

- Energy Efficiency: Our IoT solutions allow monitoring and controlling energy consumption in motor vehicle parts manufacturing industry facilities, identifying energy-saving opportunities, and reducing operational costs.

- Smart Workflow Automation: GAO’s IoT enables the automation of manual tasks and processes, leveraging data analytics and machine learning algorithms to streamline workflows and improve operational productivity.

- Remote Diagnostics and Troubleshooting: With our IoT technology, manufacturers can remotely diagnose equipment issues, troubleshoot problems, and provide timely maintenance support, reducing the need for on-site visits and minimizing downtime.

- Enhanced Safety and Compliance: By integrating GAO’s IoT devices and sensors, IoT enables real-time monitoring of safety parameters, ensuring compliance with regulatory standards, and enhancing worker safety within the manufacturing environment.

GAO’s Assists Clients with Standards, Mandates & Regulations of the Motor Vehicle Parts Manufacturing

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in the motor vehicle parts manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-63 (RFID): This international standard defines the air interface protocol for RFID technology, ensuring interoperability and compatibility across different RFID systems.

- EPCglobal Gen2 (RFID): This standard specifies the communication protocol and data structure for RFID tags and readers, enabling efficient supply chain management and inventory tracking.

- FCC Part 15 (RFID, BLE, IoT): This regulation by the Federal Communications Commission (FCC) sets limits on radio frequency emissions, ensuring interference-free operation of RFID, BLE, and IoT devices

- Health Insurance Portability and Accountability Act (HIPAA) (IoT): HIPAA ensures the privacy and security of patient information in healthcare applications of IoT technology, safeguarding sensitive data.

- NIST Cybersecurity Framework (IoT): Issued by the National Institute of Standards and Technology (NIST), this framework provides guidelines for managing cybersecurity risks associated with IoT devices, protecting critical infrastructure.

- Transport Canada Guidelines (Drone): These guidelines regulate the use of drones for commercial purposes, ensuring compliance with safety standards and operational limitations in the Canadian airspace.

- FAA Part 107 (Drone): This regulation by the Federal Aviation Administration (FAA) sets rules for commercial drone operations in the United States, including pilot certification requirements and operational restrictions.

- UL 2900 (IoT): UL 2900 is a cybersecurity certification standard that ensures IoT devices meet specific security requirements, safeguarding against cyber threats and vulnerabilities.

- National Electric Code (NEC) (IoT): NEC provides guidelines for the safe installation and use of electrical systems, including those associated with IoT devices, promoting electrical safety.

- CSA C22.2 No. 0.15 (IoT): This Canadian standard covers general requirements for electrical equipment, ensuring the safety and compatibility of IoT devices used in the motor vehicle parts manufacturing.

Government Regulations

- National Highway Traffic Safety Administration (NHTSA) Regulations: NHTSA establishes safety standards and regulations for motor vehicle parts, ensuring compliance with crashworthiness, emissions, and other safety requirements.

- Environmental Protection Agency (EPA) Regulations: EPA sets emissions standards for motor vehicle parts manufacturing, aiming to reduce air pollution and promote environmental sustainability within the industry.

- Occupational Safety and Health Administration (OSHA) Regulations: OSHA enforces workplace safety regulations, ensuring motor vehicle parts manufacturing facilities maintain a safe and healthy working environment for employees.

- Federal Trade Commission (FTC) Regulations: FTC regulates advertising and marketing practices in the motor vehicle parts manufacturing, ensuring fair competition, accurate product claims, and consumer protection.

- Department of Transportation (DOT) Regulations: DOT oversees regulations related to transportation safety, including standards for packaging, labeling, and transporting motor vehicle parts to ensure safe and secure transportation.

Canadian Government Regulations

- Canadian Motor Vehicle Safety Standards (CMVSS): CMVSS sets safety standards for motor vehicle parts, ensuring compliance with requirements related to crashworthiness, emissions, and safety features.

- Canadian Environmental Protection Act (CEPA): CEPA regulates the environmental impact of motor vehicle parts manufacturing industry, including emissions control, hazardous substance management, and pollution prevention measures.

- Occupational Health and Safety (OHS) Regulations: OHS regulations in Canada govern workplace safety in the motor vehicle parts manufacturing industry, ensuring employee health, safety training, and hazard prevention.

- Canadian Anti-Spam Legislation (CASL): CASL regulates commercial electronic messages, including email marketing, ensuring compliance with consent and information disclosure requirements to protect consumers from unsolicited messages.

- Transportation of Dangerous Goods Act (TDGA): TDGA regulates the transportation of hazardous materials, including certain motor vehicle parts, ensuring proper labeling, handling, and transportation safety standards are followed.

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the motor vehicle parts manufacturing such as:

Personnel Management:

- Employee scheduling and shift management

- Performance evaluation and tracking

- Training and skills management

- Safety and compliance management

- Employee engagement and communication platforms

Equipment Management:

- Maintenance scheduling and tracking

- Equipment utilization monitoring

- Predictive maintenance and condition monitoring

- Asset tracking and management

- Equipment calibration and certification management

Access Control:

- Restricted access to sensitive areas and data

- Employee identification and authentication

- Visitor management and tracking

- Access logs and audit trails

- Integration with security systems and surveillance

Warehouse Management:

- Inventory tracking and management

- Order fulfillment and picking optimization

- Stock location and layout management

- Receiving and shipping coordination

- Real-time stock visibility and replenishment

Supply Chain Management:

- Supplier relationship management

- Demand forecasting and planning

- Logistics and transportation management

- Vendor performance monitoring

- Collaborative planning and inventory management

Other Applications:

- Quality control and defect tracking

- Production process monitoring and optimization

- Product traceability and recalls management

- Data analytics and business intelligence

- Regulatory compliance management.

GAO has enabled its customers to make use of some of leading software and cloud services in the motor vehicle parts manufacturing industry. Below are some of popular software and cloud services in the motor vehicle parts manufacturing industry:

- SAP SuccessFactors: A comprehensive cloud-based HR management software that covers personnel management, employee performance, and learning and development.

- Oracle NetSuite: An integrated cloud-based ERP system that offers modules for equipment management, warehouse management, and supply chain management.

- Microsoft Dynamics 365: A versatile business application suite that includes modules for personnel management, equipment management, and supply chain management.

- Infor CloudSuite Industrial (SyteLine): A robust cloud-based ERP system designed for manufacturing industries, offering features for equipment management and warehouse management.

- Epicor ERP: A flexible and scalable ERP solution that covers personnel management, equipment tracking, and warehouse management for the manufacturing industry.

- JDA Warehouse Management System: A leading warehouse management system (WMS) that optimizes warehouse operations, inventory control, and order fulfillment.

- Blue Yonder (formerly JDA Software): A comprehensive supply chain management (SCM) software that enables demand planning, transportation management, and supply chain visibility.

- Manhattan Associates Warehouse Management System: A feature-rich WMS that provides advanced inventory management, labor optimization, and order fulfillment capabilities.

- Plex Manufacturing Cloud: A cloud-based ERP system tailored for the manufacturing industry, including modules for personnel management and equipment maintenance.

- Fishbowl Inventory: A popular inventory management software that integrates with QuickBooks and offers robust features for warehouse management and order fulfillment.

- HighJump Warehouse Management System: A scalable WMS that streamlines warehouse operations, automates inventory control, and optimizes order fulfillment processes.

- 3PL Warehouse Manager: A cloud-based warehouse management system designed for third-party logistics providers, offering inventory tracking, order management, and reporting capabilities.

GAO has worked with some of the leading technology companies in the motor vehicle parts manufacturing in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the motor vehicle parts manufacturing industry:

- Bosch: A global leader in automotive technology and solutions, providing a wide range of electronic systems.

- Continental: An automotive technology company specializing in powertrain, chassis, safety, and interior systems.

- Denso Corporation: A leading supplier of advanced automotive technology and systems, including electronic components, powertrain systems, and thermal management solutions.

- Magna International: A diversified automotive supplier offering a wide range of systems and components, including body and chassis, powertrain, and electronics solutions.

- Panasonic Automotive: A subsidiary of Panasonic Corporation, providing innovative electronics and infotainment systems.

- Aisin Seiki Co., Ltd.: A global supplier of automotive components and systems, specializing in drivetrain, body, chassis, and electronics products.

- Valeo: A leading automotive technology company offering advanced systems and components, including lighting, thermal management, and powertrain systems.

- Lear Corporation: A manufacturer of automotive seating and electrical systems, providing advanced electronic components and connectivity solutions.

- ZF Friedrichshafen: A global technology company specializing in driveline and chassis technology, offering innovative systems and solutions for the automotive industry.

- Hella GmbH & Co. KGaA: A leading supplier of automotive lighting and electronic products, providing advanced lighting systems and electronic components.

- Harman International Industries: A subsidiary of Samsung Electronics, specializing in connected car solutions, infotainment systems, and automotive audio technologies.

- Aptiv PLC: A global technology company specializing in advanced electrical architecture, vehicle connectivity solutions, and autonomous driving technologies for the automotive industry.

Case Studies of RFID Applications

Below are some RFID application cases in the motor vehicle parts manufacturing industry.

- Magna International, a global automotive parts manufacturer based in Canada and the United States, implemented RFID technology to improve their inventory management and production processes. They integrated RFID tags on their parts and components to track and trace them throughout the manufacturing and assembly stages. The RFID system provided real-time visibility into the location and status of the parts, reducing errors, minimizing stockouts, and optimizing production efficiency for Magna International.

- BorgWarner, a leading supplier of automotive components in Canada and the United States, utilized RFID technology to enhance their supply chain operations. They implemented RFID tags on their products and packaging to enable automated inventory tracking and management. The RFID system streamlined their shipping and receiving processes, improved order accuracy, and enabled real-time visibility into inventory levels. BorgWarner achieved better supply chain visibility, reduced costs, and enhanced customer satisfaction through efficient order fulfillment.

- Continental Automotive Systems, a prominent automotive parts manufacturer operating in Canada and the United States, implemented RFID technology to optimize their production and quality control processes. They used RFID tags to track and trace components throughout their manufacturing facilities, ensuring accurate assembly and quality checks. The RFID system facilitated error-proofing, reduced rework, and enabled real-time monitoring of production progress. Continental Automotive Systems achieved higher productivity, improved quality control, and enhanced overall operational efficiency through RFID implementation.

- Denso Corporation, a global automotive parts supplier with operations in Canada and the United States, adopted UHF RFID technology to streamline their inventory management and distribution processes. They utilized UHF RFID tags and readers to automate the tracking and locating of parts in their warehouses and distribution centers. The UHF RFID system improved inventory accuracy, reduced search time, and enabled real-time visibility into stock levels. Denso Corporation achieved optimized inventory management, enhanced order fulfillment, and increased operational efficiency.

- Lear Corporation, a leading automotive seating and electrical systems supplier in Canada and the United States, implemented UHF RFID technology to enhance their production and logistics operations. They utilized UHF RFID tags on their parts and packaging to automate the identification and tracking of components during assembly and shipment. The UHF RFID system improved process efficiency, reduced errors, and enabled real-time visibility into production and logistics processes. Lear Corporation achieved better supply chain visibility, reduced costs, and enhanced overall operational performance.

- Autoliv Inc., a global leader in automotive safety systems operating in Canada and the United States, deployed UHF RFID technology to optimize their warehouse management and order fulfillment processes. They integrated UHF RFID tags and readers to track and locate parts within their warehouses, ensuring accurate inventory management and efficient picking processes. The UHF RFID system improved order accuracy, reduced picking errors, and enabled real-time visibility into warehouse operations. Autoliv Inc. achieved increased productivity, improved customer service, and enhanced overall warehouse efficiency through UHF RFID implementation.

GAO RFID Systems & Hardware for the Motor Vehicle Parts Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the motor vehicle parts manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the motor vehicle parts manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the motor vehicle parts manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the motor vehicle parts manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the motor vehicle parts manufacturing:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the motor vehicle parts manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the motor vehicle parts manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- CNC Machines (Computer Numerical Control): Used for precision machining and fabrication of various parts, including engine components, chassis parts, and transmission components.

- Injection Molding Machines: Utilized for mass production of plastic parts, such as dashboard components, interior trim, and exterior body panels.

- Die Casting Machines: Employed to produce metal parts with high accuracy and complexity, including engine blocks, cylinder heads, and transmission casings.

- Press Machines: Used for metal forming operations like stamping, bending, and cutting. Press machines are vital for manufacturing components such as body panels, brackets, and structural parts.

- Robotic Welding Systems: Automated welding systems that ensure precise and consistent welds on components like frames, exhaust systems, and suspension parts.

- Powder Coating Equipment: Utilized for applying a durable and protective coating to metal parts, including wheels, brackets, and engine components.

- CNC Tube Bending Machines: Employed for bending and shaping metal tubes used in exhaust systems, fuel lines, and hydraulic systems.

- Coordinate Measuring Machines (CMM): Used to measure the dimensions and geometric characteristics of parts to ensure they meet the required specifications.

- Assembly Line Systems: Integrated systems that include conveyor belts, automated workstations, and robots to facilitate the assembly of various components into a finished product.

- Testing and Inspection Equipment: This includes equipment for conducting performance tests, leak tests, vibration tests, and other quality control measures to ensure the reliability and functionality of the manufactured parts.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Motor Vehicle Parts Manufacturing Extensively

GAO’s products and technologies have helped its customers in the motor vehicle parts manufacturing industry to achieve success in smart manufacturing, industry 4.0, internet of things (IoT), artificial intelligence (AI), big data analytics, robotics, additive manufacturing, electric vehicles (EVs), autonomous driving, digital twins, predictive maintenance, supply chain optimization, augmented reality (AR), cybersecurity, blockchain, sustainability, advanced materials, connected cars, data-driven decision making, cloud computing, human-machine collaboration.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the motor vehicle parts manufacturing, including many in its various divisions such as

- Powertrain Components: This division focuses on manufacturing components related to engines, transmissions, and drivetrain systems, such as pistons, gears, and shafts.

- Chassis and Suspension Systems: This sub-industry involves the production of components for the vehicle’s frame, suspension, steering, and braking systems, including control arms, shock absorbers, and brake calipers.

- Electrical and Electronics: This division deals with the production of electrical and electronic components, including wiring harnesses, sensors, switches, and control modules, essential for vehicle functions and connectivity.

- Interior Components: This sub-industry involves manufacturing parts related to the vehicle’s interior, including seats, dashboards, instrument clusters, infotainment systems, and interior trim components.

- Exterior Components: This division focuses on producing components related to the vehicle’s exterior, including body panels, bumpers, lights, mirrors, and aerodynamic features.

- Safety Systems: This sub-industry specializes in manufacturing safety-related components, such as airbags, seatbelts, anti-lock braking systems (ABS), and electronic stability control (ESC) systems.

- Exhaust and Emissions Systems: This division deals with manufacturing components related to exhaust and emissions control, including catalytic converters, mufflers, and exhaust pipes.

- Fuel Systems: This sub-industry involves producing components for fuel storage, delivery, and injection systems, such as fuel tanks, fuel pumps, and fuel injectors.

- Sealing and Weatherstripping: This division focuses on manufacturing seals, gaskets, and weatherstrips that provide airtight and watertight sealing for doors, windows, and other vehicle openings.

- Aftermarket Parts: This sub-industry caters to the production of replacement parts and accessories for vehicles, including performance upgrades, maintenance components, and customization options.

- Hybrid and Electric Vehicle Components: This division specializes in manufacturing components specifically designed for hybrid and electric vehicles, such as batteries, electric motors, power electronics, and charging systems.

- Tooling and Equipment: This sub-industry involves producing specialized tooling, machinery, and equipment used in the manufacturing processes of motor vehicle parts, including molds, presses, and assembly line systems.

Here are some of the leading companies in the motor vehicle parts manufacturing industry: