Related Products & Systems on Other Pages on This Website

Pallet & Return Asset Tracking System

Work In Process WIP Asset Tracking System

Employee & Attendance Access Control System

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

High-Temperature Tolerant RFID Tags

On Metal RFID Tags – All Types

Overview

The Pulp & Paper Manufacturing Industry is a sector that involves the production of pulp, which is a fibrous material primarily derived from wood, and the subsequent manufacturing of paper products. It plays a significant role in producing various paper products we use in our daily lives, such as newspapers, books, magazines, packaging materials, tissue papers, and many others.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in Pulp & Paper Manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as debarker, chipper, digester, washer, bleaching equipment, refiner, paper machine, headbox, wire section, press section, dryer section, calendar, coating machine, slitter rewinder, reel, roll handling equipment, winder, recovery boiler, steam and power generation equipment, water treatment equipment, conveyors, pulp and paper testing equipment.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for Pulp & Paper Manufacturing Industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Pulp & Paper Manufacturing Industry

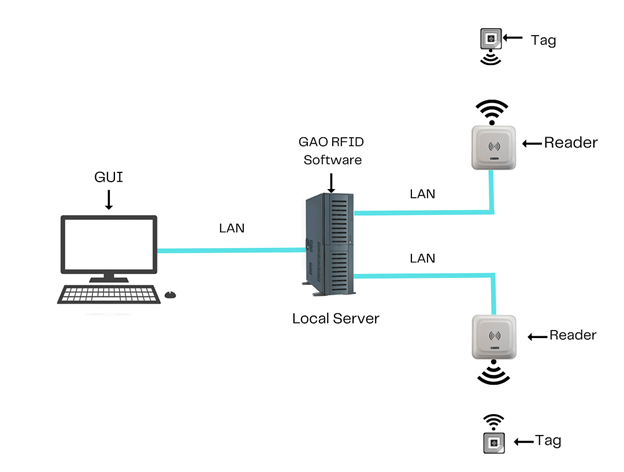

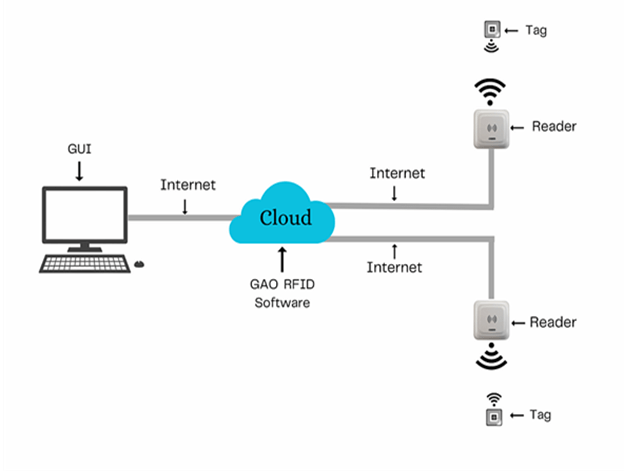

To satisfy its customers, GAO’s RFID or RFID Systems for Pulp & Paper Manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates the GAO system for Pulp & Paper Manufacturing industry with its software running on a local server.

The above illustrates GAO system for Pulp & Paper Manufacturing industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Pulp & Paper Manufacturing industry:

- Inventory Management: GAO’s RFID tags can be attached to raw materials, finished products, and intermediate goods to track movement and location throughout the manufacturing process. This ensures real-time visibility into inventory levels and reduces the risk of stockouts or overstocking.

- Asset Tracking: GAO’s RFID tags can be used to monitor and manage the location of equipment, machinery, and tools within the facility. This helps optimize asset utilization and minimizes the time spent searching for essential equipment.

- Product Authentication: GAO’s RFID tags embedded in paper products can serve as a means of product authentication, helping to combat counterfeiting and ensure customers receive genuine products.

- Quality Control: Our RFID technology can be used to associate specific data, such as manufacturing parameters or quality test results, with individual rolls or batches of paper. This allows for easy retrieval of quality information and facilitates process improvement.

- Supply Chain Visibility: GAO’s RFID-enabled supply chain management provides real-time information on the movement of raw materials, intermediate goods, and finished products, enhancing coordination and efficiency among suppliers, manufacturers, and distributors.

- Production Tracking: Our RFID tags attached to paper rolls can track their progress through various stages of production, from raw material to finished product. This data can be used for process optimization and to identify bottlenecks.

- Maintenance Management: GAO’s RFID tags can be used to track equipment maintenance schedules and trigger maintenance tasks based on actual usage rather than predetermined schedules, improving equipment reliability and reducing downtime.

- Environmental Compliance: Our RFID technology can help track the origin of raw materials, ensuring compliance with sustainability and environmental regulations related to sourcing practices.

- Automated Logistics: GAO’s RFID-based automated systems can streamline material handling and logistics operations, reducing manual labor and human errors while improving efficiency.

- Real-time Process Monitoring: Our RFID sensors can be used to monitor process parameters such as temperature, humidity, and pressure, allowing for real-time adjustments and ensuring consistent product quality.

- Product Lifecycle Tracking: Our RFID tags can be used to record essential information about paper products throughout their lifecycle, from production to disposal or recycling, providing valuable data for sustainability and recycling initiatives.

- Safety and Security: GAO’s RFID can be integrated into access control systems, helping to regulate personnel access to restricted areas and improve overall plant security.

GAO’s drone technologies find the following applications in the Pulp & Paper Manufacturing industry:

- Forest Inventory: GAO’s Drones equipped with sensors and cameras can conduct aerial surveys of forested areas to assess the quantity and health of trees, aiding in sustainable forest management and raw material planning.

- Land Surveying: Our Drones can be used for land surveying to gather accurate topographic data, which is essential for site planning, layout, and infrastructure development within the manufacturing facility.

- Inventory Management: GAO’s Drones can assist in tracking the inventory of raw materials, finished products, and equipment stored in large outdoor yards, providing real-time visibility and optimizing supply chain management.

- Remote Sensing: GAO’s Drones equipped with remote sensing technologies, such as LiDAR or hyperspectral cameras, can gather detailed data on vegetation health, forest density, and land use, assisting in resource planning and environmental monitoring.

- Environmental Monitoring: Our Drones can monitor water bodies, air quality, and other environmental factors, helping the industry comply with environmental regulations and minimize ecological impact.

- Infrastructure Inspection: Our Drones can inspect tall structures, such as chimneys, towers, and roofs, for maintenance purposes, reducing the need for manual inspections at elevated heights and improving safety for personnel.

- Process Monitoring: GAO’s Drones equipped with cameras and sensors can monitor various stages of the pulp and paper manufacturing process, providing real-time data on production activities and identifying potential issues.

- Security Surveillance: GAO’s Drones can be used for perimeter surveillance and monitoring of remote areas of the manufacturing facility, enhancing security measures and deterring trespassing or theft.

- Emergency Response: Our Drones can be deployed to assess and survey areas in case of accidents, fires, or other emergencies, providing critical information to emergency response teams.

- Transporting Small Items: our Drones can be used for the rapid and efficient transport of small items, tools, or spare parts within the facility, saving time and labor.

- Inspecting Pipelines: GAO’s Drones can inspect pipelines and conveyors for potential leaks, damages, or blockages, facilitating maintenance and preventing disruptions in the manufacturing process.

- Training and Simulation: GAO’s Drones can be used in training programs to simulate various operational scenarios, allowing employees to practice emergency responses and improve overall operational preparedness.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the Pulp & Paper Manufacturing industry:

- Condition Monitoring: GAO’s IoT sensors can be used to monitor the health and performance of critical equipment and machinery in real-time, helping detect early signs of wear, tear, or malfunctions.

- Predictive Maintenance: GAO RFID analyzes data from IoT sensors, machine learning algorithms can predict when equipment is likely to fail, allowing for proactive maintenance to reduce downtime and repair costs.

- Energy Management: GAO RFID IoT-enabled smart meters and sensors can monitor energy consumption throughout the manufacturing process, optimizing energy usage and reducing costs.

- Supply Chain Optimization: GAO RFID IoT devices can track the movement of raw materials, finished products, and shipments, providing real-time visibility and optimizing logistics.

- Environmental Monitoring: GAO RFID IoT sensors can monitor air and water quality, as well as other environmental parameters, helping industry meet regulatory compliance and sustainability goals.

- Asset Tracking: GAO RFID IoT devices can track the location and status of assets, such as raw materials, finished products, and equipment, improving inventory management and asset utilization.

- Quality Control: GAO RFID IoT sensors can monitor and collect data on product quality parameters during production, ensuring consistent quality and enabling immediate corrective actions if deviations occur.

- Smart Inventory Management: GAO RFID IoT-enabled systems can monitor inventory levels in real-time, automating inventory replenishment and reducing stockouts.

- Safety and Compliance: GAO RFID IoT sensors can monitor workplace conditions and worker safety, helping to identify potential hazards and ensure compliance with safety regulations.

- Remote Monitoring and Control: GAO RFID IoT technology enables remote monitoring and control of manufacturing processes, allowing operators to manage operations from a central location or through mobile devices.

- Paper Moisture Control: GAO RFID IoT sensors can measure and control the moisture content of paper during the drying process, ensuring the production of high-quality paper products.

- Real-time Data Analytics: GAO RFID IoT-generated data can be analyzed in real-time, providing valuable insights to improve efficiency and optimize processes.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Pulp & Paper Manufacturing Industry

GAO RFID Inc. has helped many companies in Pulp & Paper Manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6C (EPC Gen2)

- ISO 15693

- ISO 28560

- ISO 18046

- ISO 17367

- GS1 EPCglobal

US. Government Regulations

- Clean Air Act (CAA)

- Clean Water Act (CWA)

- Resource Conservation and Recovery Act (RCRA)

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- Toxic Substances Control Act (TSCA)

- Occupational Safety and Health Act (OSHA)

- National Emission Standards for Hazardous Air Pollutants (NESHAP)

- National Pollutant Discharge Elimination System (NPDES)

- Safe Drinking Water Act (SDWA)

- Environmental Protection Agency (EPA) Regulations

- Forest Stewardship Program Regulations

- Endangered Species Act (ESA)

- Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)

- Occupational Safety and Health Administration (OSHA) Regulations

- Federal Water Pollution Control Act (FWPCA)

Canadian Government Regulations

- Canadian Environmental Protection Act (CEPA)

- Fisheries Act

- Canadian Environmental Assessment Act (CEAA)

- National Emission Guidelines for Pulp and Paper Mills

- Canadian Environmental Quality Guidelines

- Transportation of Dangerous Goods Act (TDGA)

- Canada Labour Code (CLC)

- Hazardous Products Act (HPA)

- Canadian Environmental Protection Act, 1999 (CEPA 1999)

- Canadian Environmental Assessment Act, 2012 (CEAA 2012)

- Forest Act

- Forest Stewardship Program Regulations

- Canadian Environmental Assessment Act, 2012 (CEAA 2012)

- Species at Risk Act (SARA)

- Fisheries Protection Regulations

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Pulp & Paper Manufacturing such as:

Personnel Management:

- Employee Attendance Tracking

- Workforce Scheduling and Shift Management

- Training and Certification Management

- Health and Safety Compliance Monitoring

- Employee Performance Evaluation

- Workforce Skill and Competency Tracking

- Payroll and Compensation Management

- Labor Union Management

Equipment Management:

- Equipment Maintenance Scheduling and Tracking

- Asset Tracking and Inventory Management

- Condition Monitoring and Predictive Maintenance

- Equipment Calibration and Certification

- Equipment Utilization Analysis

- Spare Parts Inventory Management

- Equipment Lifecycle Management

Access Control:

- Employee Access Management to Restricted Areas

- Visitor Management and Access Authorization

- Time-Based Access Control for Specific Zones

- Access Logs and Audit Trails

- Biometric Authentication for Enhanced Security

Warehouse Management:

- Inventory Tracking and Control

- Real-Time Stock Management

- Receiving and Shipping Management

- Pick-and-Pack Optimization

- Order Processing and Fulfilment

- Warehouse Layout and Space Optimization

- Cross-Docking and Just-in-Time (JIT) Delivery

Supply Chain Management:

- Supplier Relationship Management

- Demand Forecasting and Planning

- Supplier Performance Monitoring

- Procurement and Purchase Order Management

- Transportation and Logistics Optimization

- Inventory Visibility Across the Supply Chain

- Supply Chain Traceability and Compliance

Other Applications:

- Environmental Compliance Tracking

- Product Traceability and Quality Assurance

- RFID-Based Product Authentication

- Sustainability Reporting and Management

- Waste Management and Recycling

- Energy Consumption Monitoring and Optimization

- Regulatory Compliance Tracking

- Product labelling and Tracking throughout the Lifecycle

GAO has enabled its customers to make use of some of the leading software and cloud services in the Pulp & Paper Manufacturing industry. Below are some of popular software and cloud services Pulp & Paper Manufacturing industry:

SAP SuccessFactors, Workday Human Capital Management, Oracle HCM Cloud, ADP Workforce Now, Kronos Workforce Ready, UltiPro, BambooHR, Infor Cloud Suite HCM, Epicor HCM, Ramco HCM, Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), IBM Cloud, Oracle Cloud Infrastructure (OCI), SAP Cloud Platform, Salesforce Platform, Adobe Experience Cloud, ServiceNow, Workday Cloud Platform, Honeywell Access Control, LenelS2 OnGuard, Genetec Security Center, FortiGate (for Access Control), HighJump Warehouse Management System (WMS), SAP Extended Warehouse Management (EWM), Manhattan Associates Warehouse Management System (WMOS), JDA Warehouse Management, Oracle Warehouse Management Cloud, Blue Yonder (formerly JDA) Supply Chain Management, Microsoft Azure IoT Hub, AWS IoT Core, Google Cloud IoT Core, IBM Watson IoT Platform, Oracle Internet of Things (IoT) Cloud, SAP Leonardo IoT, Alibaba Cloud IoT Platform, Honeywell Forge Platform, Blue Yonder (formerly JDA) Luminate Control Tower, Infor Nexus Supply Chain Management, ABB Ability Paper Machine Drive System, Andritz Integrated Production Management (IPM), Siemens PCS 7 Paper, Honeywell Experion PMD, Valmet DNA Automation System, Emerson DeltaV DCS, Rockwell Automation PlantPAx, Mitsubishi Electric Pulp & Paper Control System, Schneider Electric EcoStruxure Plant, Voith Paper IT Solutions, Microsoft Azure for Industrial IoT, AWS IoT Solutions, Google Cloud IoT Solutions, IBM Cloud for Industry, Siemens MindSphere, Honeywell Forge Cloud Platform, ABB Ability, Schneider Electric EcoStruxure Platform, Emerson Plantweb Digital Ecosystem, SAP Industry Cloud.

GAO has worked with some of the leading technology companies in Pulp & Paper Manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in Pulp & Paper Manufacturing industry:

SAP, Oracle, IBM, Microsoft, Infor, Epicor, Honeywell, Siemens, ABB, Rockwell Automation, Emerson Electric Co., Schneider Electric, Yokogawa Electric Corporation, Endress+Hauser, Pepperl+Fuchs, Omron Corporation, GE Digital, Valmet Corporation, Andritz AG, Voith Group, Kadant Inc., Metso Outotec, GLV Group (Groupe GLV Inc.), TietoEVRY, Bühler Group, IBS Paper Performance Group.

Case Studies of RFID Applications

Below are some RFID application cases in pulp & paper manufacturing industry.

International Paper implemented RFID to track rolls of paper in its converting plant. This helped the company to improve inventory accuracy, reduce paper waste, and increase production efficiency.

Domtar implemented RFID to track pulp bales in its logistics network. This helped the company to improve traceability, reduce theft, and increase efficiency

WestRock implemented RFID to track paper rolls in its distribution centres. This helped the company to improve inventory accuracy, reduce picking errors, and increase customer service.

Metsä Fibre implemented RFID to track pulp bales in its logistics network. This helped the company to improve traceability, reduce theft, and increase efficiency.

Canfor implemented RFID to track lumber in its distribution centres. This helped the company to improve inventory accuracy, reduce picking errors, and increase customer service.

Resolute Forest Products implemented RFID to track paper rolls in its distribution centres. This helped the company to improve inventory accuracy, reduce picking errors, and increase customer service.

UHF RFID (ultra-high frequency RFID) is a type of RFID technology that is used in applications where long-range read range is required. This makes it ideal for applications in the pulp and paper industry, where large objects need to be tracked over long distances.

In the USA, they implemented UHF RFID to track rolls of paper in its converting plant. This helped the company to improve inventory accuracy, reduce paper waste, and increase production efficiency.

They implemented UHF RFID to track pulp bales in its logistics network. This helped the company to improve traceability, reduce theft, and increase efficiency.

They implemented UHF RFID to track paper rolls in its distribution centres. This helped the company to improve inventory accuracy, reduce picking errors, and increase customer service.

In Canada, they implemented UHF RFID to track lumber in its distribution centres. This helped the company to improve inventory accuracy, reduce picking errors, and increase customer service.

They implemented UHF RFID to track paper rolls in its distribution centres. This helped the company to improve inventory accuracy, reduce picking errors, and increase customer service.

Many applications of RFID by GAO can be found here:

Case Studies of IoT Applications

Below are some IoT application cases in pulp & paper manufacturing industry.

In the USA, they implemented IoT to monitor the performance of its paper machines. This helped the company to identify potential problems early on and prevent unplanned downtime.

They implemented IoT to track the quality of its pulp. This helped the company to ensure that its pulp met customer specifications and avoid costly rejections.

They implemented IoT to monitor the energy consumption of its mills. This helped the company to identify areas where it could save energy and reduce costs.

They implemented IoT to track the moisture content of its wood chips. This helped the company to ensure that its wood chips were properly dried and avoid problems with the papermaking process.

In Canada, they implemented IoT to monitor the temperature and humidity of its lumber drying kilns. This helped the company to ensure that its lumber was dried to the correct specifications and avoid problems with warping or cracking.

They implemented IoT to track the location of its logging trucks. This helped the company to improve efficiency and reduce fuel consumption.

They implemented IoT to monitor the water quality in its mills. This helped the company to ensure that its water met environmental regulations and avoid costly fines.

Case Studies of Drone Applications

Below are some drones application cases in pulp & paper manufacturing industry.

In the USA, they used drones to inspect their paper machines for damage. This helped the company to identify and repair problems before they caused major damage or downtime.

They used drones to survey its timberlands. This helped the company to assess the health of its trees and identify areas that needed to be replanted.

They used drones to inspect its pulp mills for leaks and other damage. This helped the company to prevent costly repairs and environmental damage.

In Canada, they used drones to inspect its lumber drying kilns. This helped the company to ensure that the kilns were operating properly and that the lumber was being dried evenly.

They used drones to monitor its logging operations. This helped the company to ensure that the logging was being conducted safely and sustainably.

They used drones to survey its watercourses. This helped the company to identify areas that were prone to erosion or flooding, and to take steps to mitigate these risks.

GAO RFID Systems & Hardware for Pulp & Paper Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Pulp & Paper Manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration, and panic button:

GAO’s BLE technology is suitable for many industries, including the Pulp & Paper Manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Pulp & Paper Manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Pulp & Paper Manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Pulp & Paper Manufacturing industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including hospitals:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Module

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in Pulp & Paper Manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include, Debarker, Chipper, Digester, Washer, Refiner, Paper Machine, Headbox, Wire Section, Press Section, Dryer Section, Calendar, Coating Machine, Slitter Rewinder, Reel, Roll Handling Equipment, Winder, Recovery Boiler, Steam and Power Generation Equipment, Water Treatment Equipment, Conveyors, Pulp and Paper Testing Equipment.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Pulp & Paper Manufacturing Industry for various industries in all metropolitans in the U.S. and Canada:

GAO Has Served Pulp & Paper Manufacturing industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in Pulp & Paper Manufacturing industry to achieve success in Sustainable Forestry and Responsible Sourcing, Digitalization and Industry 4.0, Circular Economy and Recycling, Bio-based and Biodegradable Products, Energy Efficiency and Carbon Neutrality, Smart Manufacturing and Industrial IoT, Advanced Process Automation, Digital Twins and Virtual Reality, Artificial Intelligence and Machine Learning, Robotics and Autonomous Systems, Paperless Operations and E-documents, Remote Monitoring and Predictive Maintenance, Supply Chain Transparency and Traceability, Water Conservation and Waste Reduction, Green Packaging and Eco-friendly Solutions, Bioeconomy, Digital Transformation, Sustainability, Green Packaging, Industry 4.0, Internet of Things (IoT), Big Data Analytics, Machine Learning, Blockchain, Smart Manufacturing, Circular Economy, Decarbonization, Renewable Resources, Paperless Factory, Smart Sensors.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in Pulp & Paper Manufacturing industry, including many in its various divisions such as:

- Pulp Manufacturing: Process of converting wood fibers into pulp for papermaking.

- Paper Manufacturing: Transformation of pulp into various paper products.

- Paperboard Manufacturing: Production of thick and sturdy paperboard for packaging.

- Packaging Manufacturing: Manufacturing of packaging materials like boxes and cartons.

- Tissue and Hygiene Products: Production of tissues, paper towels, and hygiene items.

- Specialty Paper Manufacturing: Production of papers for specific applications.

- Pulp and Paper Chemicals: Chemicals used to enhance the papermaking process.

- Paper Recycling: Recycling used paper to create new paper products.

- Pulp and Paper Machinery: Specialized equipment for the papermaking process.

- Forest Management: Sustainable planning and use of forest resources.

GAO’s technologies enable its customers in “Pulp & Paper Manufacturing industry” to effectively track their workforces such as Plant Manager, Production Supervisor, Process Operator, Maintenance Technician, Quality Control Inspector, Environmental Engineer, Safety Coordinator, Pulp Mill Operator, Paper Machine Operator, Shipping and Receiving Clerk, Lab Technician, Electrical Engineer, Mechanical Engineer, Boiler Operator, Maintenance Electrician, Inventory Control Specialist, Forklift Operator, Chemical Engineer, Environmental Health and Safety Specialist, Materials Handler, Digester, Washer, Refiner, Paper Machine, Headbox, Press Section, Dryer Section, Calendar, Coating Machine, Slitter Rewinder, Reel, Chipper, Debarker, Recovery Boiler, Steam Boiler, Turbine, Generator, Conveyor System, Screening Equipment, Winder.

Here are some of the leading companies in Pulp & Paper Manufacturing industry:

- International Paper Company

- Domtar Corporation

- Twin Rivers Paper Company

- ND Paper Company

- Stora Enso Company

- Sappi North America Company

- Tembec Company

- Mercer Company

- MeadWestvaco Company

- Domtar Company

- Norbord Company

- Canfor Company

- Georgia Pacific LLC

- Packaging Corporation of America

- Graphic Packaging International

- Clearwater Paper Corporation

- Green Bay Packaging INC

- Alberta Newsprint Company

- Weyerhaeuser Company

- West Fraser Company

- Kruger INC

- Irving Pulp & Paper Limited