Overview

Repair and maintenance industry dedicated to maintaining, repairing, and restoring a variety of products and equipment. From automobiles and appliances to infrastructure and electronic systems, its aim is to ensure proper functioning, extend lifespan, and ensure safety. It utilizes technologies like IoT, drones, and RFID to enhance efficiency and accuracy in repair and maintenance processes.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in repair and maintenance industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as wire cutters/strippers, cordless drill, power drill, Impact wrench, circular saw and reciprocating saw.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for repair and maintenance.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Repair and Maintenance

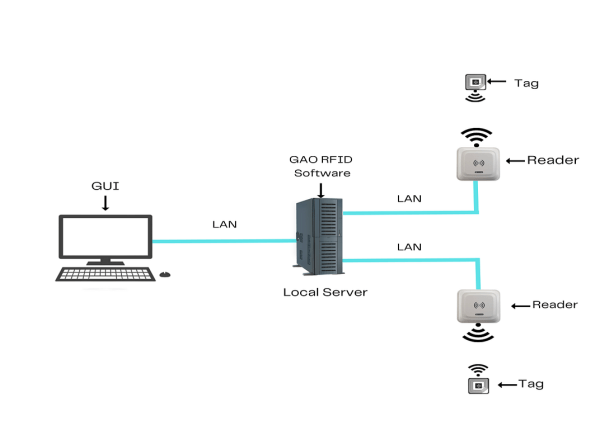

To satisfy its customers, GAO’s RFID or RFID Systems for repair and maintenance are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for repair and maintenance with its software running on a local server

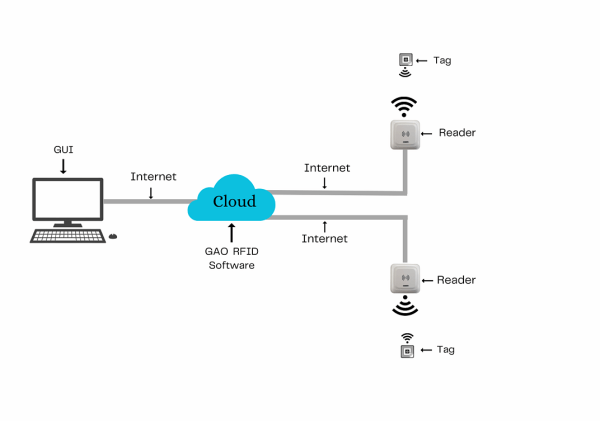

The above illustrates GAO system for repair and maintenance with its software running in cloud

GAO’s RFID technologies bring the many benefits to repair and maintenance industry:

- Asset tracking and management: GAO’s RFID tags can be attached to equipment, tools, and other assets, allowing for efficient tracking and management. It enables real-time visibility of asset location, usage history, and maintenance records, minimizing loss, theft, and misplacement.

- Improved inventory control: Our RFID can automate inventory management by providing accurate and up-to-date information on stock levels, asset availability, and replenishment needs. This reduces manual errors, optimizes stock levels, and improves supply chain efficiency.

- Streamlined maintenance processes: GAO’s RFID tags can be used to monitor maintenance schedules, track maintenance history, and trigger automatic notifications for servicing or repairs. This helps ensure timely maintenance, reduce downtime, and extend the lifespan of equipment.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within repair and maintenance industry:

- Proximity-based tracking: GAO’s BLE allows for proximity-based tracking of assets, tools, and equipment. By attaching BLE beacons or tags, technicians can easily locate and identify items within a certain range. This reduces time spent searching for tools and improves overall operational efficiency.

- Enhanced safety and security: Our BLE can be used to implement access control systems, ensuring that only authorized personnel have access to restricted areas or specific equipment. Additionally, BLE beacons can provide alerts or notifications in case of safety breaches or emergencies, improving overall workplace safety.

- Remote equipment control and diagnostics: GAO BLE-enabled devices can allow remote monitoring, control, and diagnostics of equipment. Technicians can access equipment status, perform diagnostics, and even make adjustments or repairs remotely, reducing the need for physical presence and minimizing downtime.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to repair and maintenance industry:

- Enhanced asset tracking: GAO’s RFID technology enables the tracking and identification of assets in real-time. By tagging repair and maintenance equipment, tools, or spare parts with RFID tags, and utilizing drones equipped with RFID readers, organizations can efficiently locate and manage their assets. This improves inventory management, reduces losses, and streamlines maintenance processes.

- Rapid asset Localization: When assets require repair or maintenance, drones equipped with Our RFID readers can quickly locate and retrieve the specific assets needed. This reduces manual search time, minimizes downtime, and improves the overall efficiency of repair and maintenance operations.

- Cost Savings and Efficiency: The combination of GAO RFID and drones can lead to cost savings and increased efficiency in repair and maintenance industry. By automating asset tracking, inspections, and data collection, organizations can reduce manual labor, streamline workflows, and optimize resource allocation. This results in time savings, improved productivity, and cost-effective maintenance operations.

Here are benefits of GAO’s IoT technologies to repair and maintenance industry:

- Remote Monitoring: GAO’s IoT enables real-time monitoring of equipment and assets, allowing maintenance teams to remotely track their status, performance, and condition. This proactive approach helps identify potential issues before they escalate, reducing downtime and minimizing the need for reactive repairs.

- Condition-Based Maintenance: GAO IoT sensors, equipment condition can be continuously monitored. This data-driven approach allows maintenance teams to assess the health and performance of assets in real-time. By analyzing this information, they can determine the optimal time for maintenance interventions, such as lubrication, calibration, or cleaning, based on the actual condition of the equipment.

- Improved Asset Utilization: Our IoT-enabled asset tracking and management systems provide real-time visibility into the location and utilization of equipment, tools, and spare parts. This helps streamline resource allocation, reducing unnecessary equipment purchases and optimizing inventory levels. It also enhances operational efficiency by minimizing asset downtime and maximizing utilization rates.

GAO Helps Customers Comply with Standards, Mandates & Regulations of repair and Maintenance

GAO RFID Inc. has helped many companies in repair and maintenance to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO/IEC 18000-6C (EPC Gen2): This is one of the most widely adopted RFID standards globally. It is commonly used for supply chain management, asset tracking, and inventory control, which can be relevant for repair and maintenance operations.

- Generic Attribute Profile (GATT): GATT is a profile that defines how data is organized and exchanged between BLE devices. It is widely used for creating custom services and characteristics to support specific repair and maintenance applications.

- CoAP (Constrained Application Protocol): CoAP is a specialized web transfer protocol for IoT devices in constrained networks. It is designed to provide lightweight communication, low overhead, and efficient resource utilization. CoAP can be used for device management and data exchange in repair and maintenance scenarios.

- ASTM F38: This standard, developed by ASTM International, focuses on remote ID and tracking of unmanned aircraft systems (UAS). It provides guidelines for identifying and tracking drones to ensure safety, security, and accountability in their operation.

- FDA Unique Device Identification (UDI) Rule: The U.S. Food and Drug Administration (FDA) has implemented a UDI system that requires medical devices to carry a unique identifier. While RFID is not specifically mandated, it is one of the technologies that can be used to comply with the UDI rule.

- Regulatory Compliance (e.g., FCC, CE, IC): Depending on the region and application, BLE devices must comply with specific regulatory requirements. For example, the Federal Communications Commission (FCC) in the United States, the European Conformity (CE) marking in the European Union, and Innovation, Science, and Economic Development Canada (IC) have regulations governing the radio frequency emissions and certifications for wireless devices.

- The National Institute of Standards and Technology (NIST): is a non-regulatory agency of the United States Department of Commerce. NIST plays a crucial role in developing and promoting cybersecurity standards, guidelines, and best practices to enhance the security and resilience of information systems and networks.

- Remote Pilot Certification: Pilots operating drones commercially or in specific situations may be required to obtain a remote pilot certification or license. This certification demonstrates that the pilot has the necessary knowledge and skills to operate drones safely and responsibly.

U.S. Government Regulations

- Environmental Protection Agency (EPA) Regulations: The EPA regulates environmental practices and the handling of hazardous materials.

- Internal Revenue Service (IRS) Regulations: Repair and maintenance businesses are subject to tax regulations set by the IRS

Canadian Government Regulations

- Occupational Health and Safety (OHS) Regulations: Each province and territory in Canada has its own OHS regulations that set standards and requirements for workplace health and safety.

- Environmental Regulations: The Canadian federal government, along with provincial and territorial authorities, enforces regulations to protect the environment.

Electronic Product Code

Generic Attribute Profile

Constrained Application Protoco

ASTM International

Unique Devine Identification

National Institute of Standard Technology

Remote Pilot Certification

Environmental Protection Agency

Occupational Health and Safety

Federal Communications Commissions

Environmental Regulations

Internal Revenue Service

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in repair and maintenance such as:

- Personnel Management: Efficiently schedule technicians and assign them to repair and maintenance tasks based on their skills, availability, and location.

- Equipment Management: Implement a proactive approach by scheduling routine maintenance tasks to prevent breakdowns and prolong equipment life.

- Access Control: Manage employee identification cards or credentials, granting access based on roles, permissions, and clearance levels.

- Warehouse Management:Design and optimize the layout of the warehouse to maximize storage capacity and streamline the movement of goods and materials.

- Supply Chain Management:Streamline procurement processes, including requisitions, purchase orders, and vendor management, to ensure timely and cost-effective acquisition of goods and services.

- Other Applications: Monitor and control financial aspects of repair and maintenance operations, including budgeting, cost tracking, invoicing, and financial reporting.

GAO has enabled its customers to make use of some of leading software and cloud services in repair and maintenance industry. Below are some of popular software and cloud services in repair and maintenance industry.

- Fiix: Fiix is a cloud-based maintenance and asset management software that helps track, organize, and manage equipment maintenance and repairs. It offers features such as work order management, preventive maintenance scheduling, inventory management, and reporting.

- eMaint CMMS: eMaint CMMS (Computerized Maintenance Management System) is a robust software solution that assists with maintenance and asset management. It provides features like work order management, asset tracking, preventive maintenance scheduling, inventory management, and mobile access.

- Oracle HCM Cloud: Oracle HCM Cloud is a cloud-based platform that provides a range of HR modules, including personnel management, performance management, payroll, and benefits administration. It offers features like employee self-service, talent acquisition, and workforce planning.

- BambooHR: BambooHR is a cloud-based HR software that covers various HR functions, including personnel management. It provides features for employee record keeping, onboarding, time-off tracking, performance management, and reporting. It is designed to be user-friendly and suitable for small to mid-sized businesses.

- Zebra Technologies: Zebra Technologies provides a range of warehouse management solutions that help optimize inventory control, order fulfillment, and logistics. Their software offerings include Zebra Warehouse Management, which offers features like inventory tracking, order management, and real-time visibility into warehouse operations.

- Honeywell Pro-Watch: Honeywell Pro-Watch is an advanced access control and security management software. It provides comprehensive access control features, including user management, cardholder tracking, event monitoring, and integration with various security systems.

- Amazon Web Services (AWS): AWS provides various cloud services that can be utilized for access control, warehouse management, and supply chain management needs. Services like Amazon S3 for data storage, AWS IoT for device connectivity, and AWS Lambda for serverless computing can be leveraged to build comprehensive solutions.

- IBM Cloud: IBM Cloud offers cloud-based services for access control, warehouse management, and supply chain management. It provides services like IBM Watson IoT for device management, IBM Sterling Supply Chain Suite for supply chain management, and IBM Cloud Identity and Access Management for access control.

- FieldEdge: FieldEdge is a comprehensive field service management software that caters to various industries, including repair and maintenance. It offers features like work order management, scheduling, dispatch, customer management, invoicing, and reporting. It also integrates with accounting and CRM systems.

- FieldAware: FieldAware is a cloud-based field service management software that helps optimize repair and maintenance operations. It provides features for work order management, scheduling, dispatch, inventory management, mobile access, and analytics. It also offers integration options with other business systems.

- ServiceNow: ServiceNow is a cloud-based service management platform that can be tailored for repair and maintenance industry. It offers features for incident management, problem management, change management, asset management, and service catalog.

- Microsoft Dynamics 365 Field Service: Microsoft Dynamics 365 Field Service is a cloud-based solution designed for field service management. It provides features for work order management, scheduling, dispatch, inventory management, mobile access, and customer communication.

Fiix

Emaint

Oracle HCM Cloud

BambooHR

Zebra Technologies

Honeywell

IBM Cloud

Amazon web service

FieldEdgde

FieldAware

Servicenow

Microsoft Dynamic 365 Field Service

GAO has worked with some of the leading technology companies in repair and maintenance in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in repair and maintenance industry:

- Microsoft: Microsoft provides various technology solutions that can be leveraged for repair and maintenance purposes. This includes the Dynamics 365 Field Service application, which enables organizations to optimize field operations, schedule technicians, and manage work orders efficiently.

- SAP: Offers SAP Asset Intelligence Network and SAP Enterprise Asset Management, providing solutions for asset management, maintenance planning, and predictive maintenance.

- Salesforce: Offers Salesforce Field Service, a cloud-based platform for managing field service operations, scheduling technicians, and tracking service requests.

- Siemens: Offers a range of solutions for asset management and maintenance, including Siemens Teamcenter and Siemens PLM Software for product lifecycle management.

- Keysight Technologies: Provides electronic measurement solutions, including oscilloscopes, signal generators, and network analyzers, for troubleshooting and maintenance of electronic equipment.

- Anritsu: Provides test and measurement instruments for communication equipment maintenance, including spectrum analyzers, signal analyzers, and network analyzers.

- Rohde & Schwarz: Offers electronic test and measurement solutions, including oscilloscopes, signal generators, and power analyzers, for troubleshooting and maintenance of electronic systems.

- IBM: Offers IBM Maximo, an enterprise asset management (EAM) system that helps organizations optimize maintenance operations, manage assets, and schedule preventive maintenance.

- IFS: Offers IFS Enterprise Asset Management, a system that provides end-to-end asset lifecycle management, preventive maintenance scheduling, and mobile workforce management.

- ManagerPlus: Offers maintenance management software that helps organizations track and manage assets, schedule preventive maintenance, and optimize maintenance workflows.

- UpKeep: Offers a mobile-first CMMS platform that enables maintenance teams to manage work orders, track assets, schedule maintenance tasks, and streamline communication.

- Fluke Corporation: Fluke specializes in electronic test tools for maintenance professionals. They provide a wide range of products such as multimeters, thermal imagers, power quality analyzers, and insulation testers.

Microsoft

SAP

Salesforce

Siemens

Keysight Technologies

Anritsu

Rohde & Schwarz

IBM

IFS Enterprise Asset Management

ManagerPlus

UpKeep

Fluke Corporation

Case Studies of RFID Applications

Below are some RFID application cases in repair and maintenance industry:

NASA’s RFID Asset Tracking System: NASA’s Kennedy Space Center implemented an RFID asset tracking system to streamline repair and maintenance processes of their equipment and tools. RFID tags were attached to various assets, allowing for easy identification and tracking throughout the facility.

Canadian Tire: Canadian Tire, a retail company in Canada, utilized UHF RFID technology in their repair and maintenance operations. They implemented RFID tags on various equipment and tools, enabling efficient tracking, maintenance scheduling, and inventory management.

Toronto Pearson International Airport: Toronto Pearson International Airport implemented an RFID solution for tracking and managing baggage carts. RFID tags were attached to the carts, allowing for real-time monitoring, locating, and inventory management. This improved cart utilization and reduced operational costs.

New York City Transit (NYCT) – NYCT implemented UHF RFID technology to track and manage maintenance activities for their subway systems. RFID tags are attached to various components and equipment, enabling real-time monitoring of maintenance tasks, tracking of inventory, and automated notifications for maintenance personnel. This helps streamline maintenance operations and improve asset management.

Many applications of RFID by GAO can be found here:

GAO RFID Systems & Hardware for repair and maintenance.

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including repair and maintenance industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including repair and maintenance.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including repair and maintenance:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including repair and maintenance:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including repair and maintenance:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including repair and maintenance:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- UHF 860-960 MHz RFID Modules – GAO RFID Inc.

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in repair and maintenance:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Hand Tools: Hand tools are essential for various repair and maintenance tasks. This includes wrenches, screwdrivers, pliers, hammers, socket sets, and other manual tools.

- Power Tools: Power tools provide additional strength and speed for repair and maintenance work. Examples include drills, impact wrenches, angle grinders, circular saws, reciprocating saws, and power sanders.

- Diagnostic Equipment: Diagnostic tools help identify problems and troubleshoot issues. These can include multimeters, oscilloscopes, infrared thermometers, pressure gauges, and leak detectors.

- Welding Equipment: Welding is often required for repairs involving metal components. Welding equipment includes welding machines, welding torches, electrodes, welding masks, and safety gear.

- Lifts and Hoists: Lifts and hoists are used to raise heavy equipment or vehicles, providing easier access for repairs. This can include hydraulic lifts, vehicle lifts, engine hoists, and cranes.

- Testing and Calibration Devices: Equipment used for testing and calibration ensures accuracy and performance. Examples include torque wrenches, pressure calibrators, flow meters, electrical testers, and alignment tools.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served Repair and Maintenance Extensively

GAO’s products and technologies have helped its customers in repair and maintenance industry to achieve success in predictive maintenance, condition monitoring, internet of things (IoT), robotics and automation, blockchain, remote monitoring, remote diagnostics, circular economy, energy efficiency and sustainability.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in repair and maintenance, including many in its various divisions such as:

- Automotive Repair and Maintenance: This involves repair and maintenance of vehicles, including cars, trucks, motorcycles, and other automotive equipment. It includes services such as engine repair, bodywork, electrical repairs, tire services, and routine maintenance.

- Industrial Equipment Repair and Maintenance: This division focuses on repair and maintenance of industrial machinery and equipment used in manufacturing, construction, and other industries. It includes servicing and maintaining heavy machinery, production equipment, industrial robots, and specialized tools.

- Electronics and IT Equipment Repair: This division focuses on repair and maintenance of electronic devices and IT equipment. It includes services such as computer repairs, smartphone repairs, TV repairs, and other consumer electronics maintenance.

- Aerospace and Aviation Maintenance: Aerospace and aviation maintenance involves repair, inspection, and maintenance of aircraft, aerospace components, and aviation systems. It includes aircraft maintenance, avionics repairs, engine servicing, and compliance with safety regulations.

- Power Generation and Utility Maintenance: This division encompasses repair and maintenance of power generation systems, electrical grids, and utility infrastructure. It includes maintaining power plants, transmission lines, substations, and electrical equipment.

- Medical Equipment Repair and Maintenance: Focuses on repair and maintenance of medical devices and equipment used in healthcare settings. It includes servicing and maintaining imaging equipment, laboratory instruments, patient monitors, and other medical devices.

- Home Appliance Repair: Home appliance repair involves repair and maintenance of household appliances, including refrigerators, washing machines, dishwashers, ovens, and other consumer appliances.

- Marine and Ship Maintenance: This division specializes in repair and maintenance of marine vessels, including ships, boats, yachts, and other watercraft. It includes services such as hull repairs, engine servicing, electrical work, and marine systems maintenance.

Here are some of the leading companies in repair and maintenance industry:

AECOM

Johnson Controls

Jiffy Lube

United Rentals

General Rentals

United Technologies Corporation

Jones Lang LaSalle

CBRE Group

Cushman & Wakefield

ABM Industries

Fluor Corporation

DOVER

IDEX Corporation

Stanley Black & Decker

Grainger Inc.

EMCOR

Aramark

Sodexo

Black & MC Donald

Bird

Trotter & Morton Group of Companies

Ainsworth Inc.

Stuart Olson Incorporated

North American Construction Group