Overview

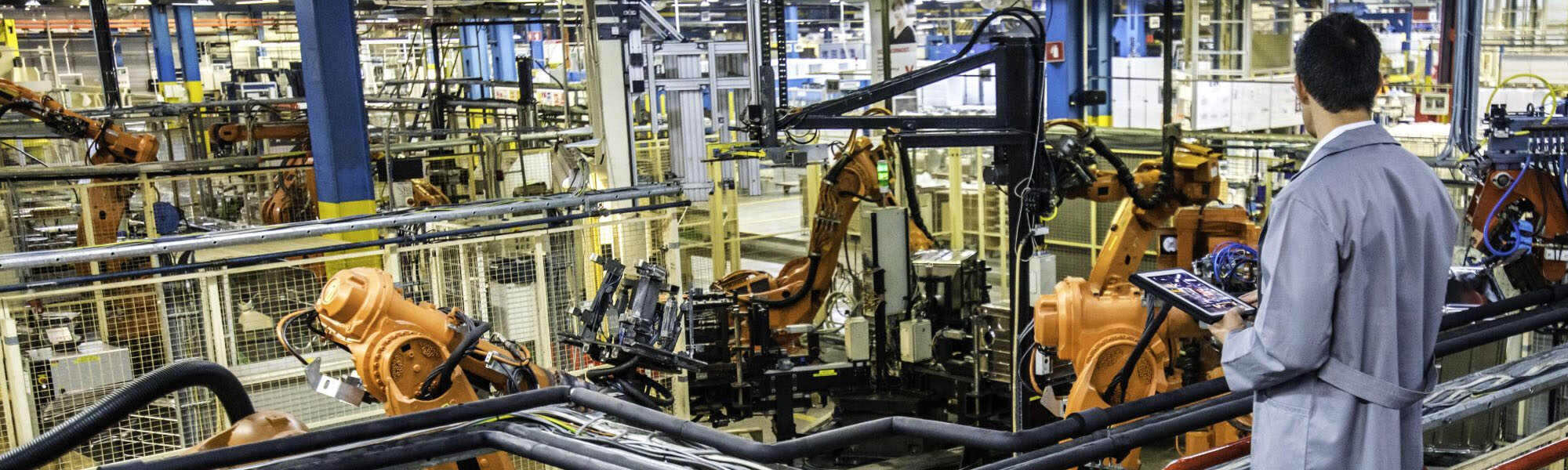

The RFID (Radio Frequency Identification) Miscellaneous Manufacturing Industry refers to a sector that specializes in the production of various RFID-related products and components. RFID technology is used for identification, tracking, and data capture purposes in a wide range of applications across different industries. In this industry, companies manufacture RFID tags, readers, antennas, and other related equipment. RFID tags are small electronic devices that contain a unique identifier and can communicate wirelessly with RFID readers using radio waves. These tags can be attached to objects, products, or assets, enabling efficient tracking, inventory management, and authentication. Atomation, asset tracking, and quality control.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for RFID Miscellaneous Manufacturing Industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for RFID Miscellaneous Manufacturing Industry

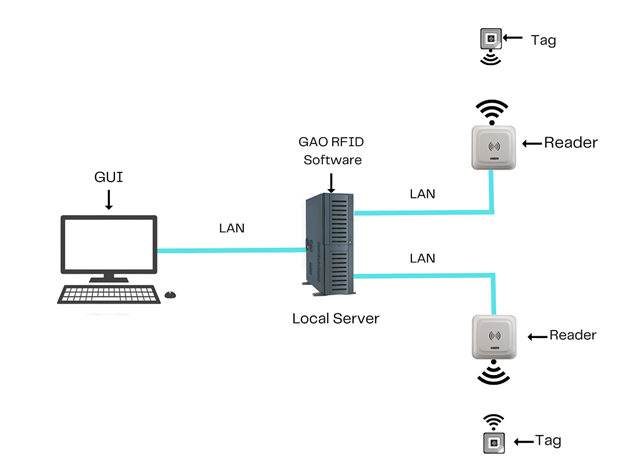

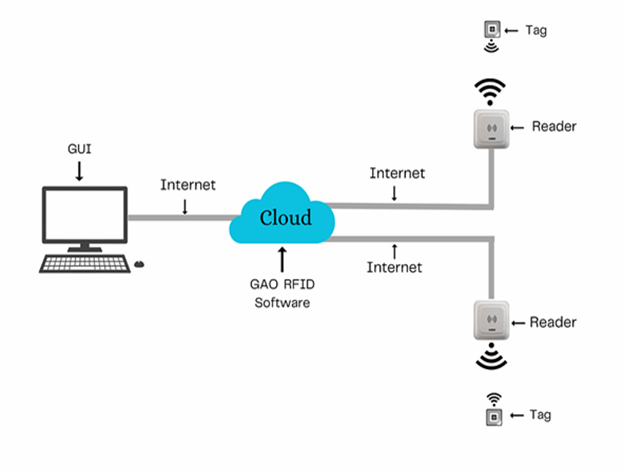

To satisfy its customers, GAO’s RFID or RFID Systems for Miscellaneous Manufacturing Industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for RFID Miscellaneous Manufacturing Industry with its software running on a local server.

The above illustrates the GAO system RFID Miscellaneous Manufacturing Industry with its software running in the cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in RFID Miscellaneous Manufacturing Industry:

- Asset Tracking: RFID tags and BLE beacons can be attached to assets, equipment, and inventory items, allowing manufacturers to monitor and track their movement and location in real-time. This enables better inventory management, reduces losses, and enhances asset utilization.

- Inventory Management: RFID technology facilitates automated and accurate inventory management by providing real-time data on stock levels, item locations, and movement. Manufacturers can conduct inventory checks faster and with greater precision, leading to reduced stockouts and better demand forecasting.

- Production Process Automation: RFID and BLE technologies can be integrated into manufacturing processes to automate workflows. For example, RFID readers and tags can be used to trigger automated actions at different stages of production, improving process efficiency and reducing human errors.

- Work-in-Progress Tracking: Manufacturers can use RFID and BLE tags to monitor the progress of work-in-progress items as they move through different stages of production. This allows for better control over production schedules and helps identify bottlenecks in the manufacturing process.

- Quality Control: RFID tags can be used to store data related to product specifications and quality requirements. As products move through the manufacturing process, RFID readers can verify whether each item meets the specified criteria, ensuring consistent quality standards.

- Maintenance and Service Tracking: RFID tags can be applied to machinery and equipment to monitor their maintenance schedules and track service history. This helps in timely maintenance, reducing downtime, and optimizing the lifespan of assets.

- Personnel Tracking and Safety: BLE beacons can be utilized for personnel tracking within manufacturing facilities, ensuring the safety of workers, and monitoring their movements in restricted areas.

- Supply Chain Visibility: RFID and BLE technologies enable better supply chain visibility by providing real-time data on the movement of goods and raw materials. This information helps in optimizing logistics and reducing delays in the supply chain.

- Anti-counterfeiting and Authentication: RFID tags with unique identifiers can be used for anti-counterfeiting measures, ensuring the authenticity of products, and protecting the brand reputation.

- Energy Efficiency: RFID and BLE technologies can also be applied to monitor and control energy consumption in manufacturing facilities, contributing to sustainability efforts and cost savings.

GAO’s drone technologies can be utilized in the RFID Miscellaneous Manufacturing Industry:

- Inventory Management: Drones equipped with RFID readers can be used to conduct large-scale and high-speed inventory checks in manufacturing facilities, warehouses, or outdoor storage areas. They can quickly scan RFID tags on products and assets, providing real-time data on inventory levels and locations.

- Asset Tracking and Location: Drones can fly over manufacturing facilities to track and locate assets tagged with RFID. This helps in locating specific items, identifying misplaced assets, and ensuring their proper usage and maintenance.

- Warehouse Optimization: Drones can assist in optimizing warehouse layouts by scanning RFID tags and collecting data on the flow of goods. This information can be used to improve storage arrangements, reduce congestion, and streamline material handling processes.

- Security and Surveillance: Drones equipped with RFID readers can be used for security purposes, patrolling manufacturing facilities, and monitoring access points. They can verify the presence of RFID-tagged personnel or assets in restricted areas, enhancing overall security measures.

- Environmental Monitoring: Drones can be used to monitor environmental conditions in manufacturing facilities, such as temperature, humidity, or air quality. RFID sensors and other IoT devices can be integrated with drones to collect relevant data, aiding in maintaining optimal manufacturing conditions.

- Inspections and Maintenance: Drones can assist in inspecting equipment, infrastructure, and hard-to-reach areas in manufacturing facilities. By carrying RFID readers, drones can identify RFID-tagged machinery and equipment, facilitating maintenance planning and reducing downtime.

- Supply Chain Visibility: Drones equipped with RFID readers can be deployed along the supply chain to monitor the movement of goods and raw materials. This enhances supply chain visibility and enables better tracking of shipments and inventory levels.

- Quality Control: Drones can be used to perform quality control checks in manufacturing processes. By scanning RFID tags on products, they can verify whether items meet specific quality standards and identify potential defects or irregularities.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the RFID Miscellaneous Manufacturing industry:

- Real-time Data Collection: IoT sensors can be deployed alongside RFID tags to gather additional data beyond identification, such as temperature, humidity, vibration, or pressure. This real-time data helps manufacturers monitor environmental conditions, equipment health, and product quality throughout the manufacturing process.

- Predictive Maintenance: By using IoT sensors to monitor machinery and equipment, manufacturers can implement predictive maintenance strategies. The sensors can detect anomalies or deviations in performance, helping predict maintenance needs and preventing unexpected breakdowns, reducing downtime, and optimizing maintenance schedules.

- Condition Monitoring: IoT sensors can continuously monitor the condition of goods and raw materials during transportation and storage. Manufacturers can ensure that the specified conditions are maintained, preventing damage, spoilage, or quality degradation.

- Supply Chain Optimization: By deploying IoT sensor networks throughout the supply chain, manufacturers can gain real-time insights into the movement and status of goods. This data helps optimize logistics, reduce lead times, and improve overall supply chain efficiency.

- Process Automation: IoT technologies can be integrated with RFID systems to automate various processes in manufacturing. For example, IoT sensors can trigger actions based on predefined conditions, such as adjusting production parameters or notifying operators when certain thresholds are reached.

- Environmental Monitoring: IoT sensors can monitor and control environmental parameters, such as energy consumption, air quality, and lighting, within manufacturing facilities. This helps in achieving energy efficiency goals and maintaining a safe working environment.

- Quality Control and Traceability: IoT sensors can augment RFID tags in providing detailed information about the manufacturing process and product journey. This level of traceability enhances quality control efforts and enables efficient recall management if issues arise.

- Worker Safety: IoT sensors can be used to monitor worker safety, ensuring compliance with safety regulations, and identifying potential hazards in real-time.

- Waste Management: IoT technologies can assist in waste management by monitoring waste levels, optimizing collection routes, and reducing waste through data-driven decisions.

- Continuous Process Improvement: The combination of RFID and IoT data allows manufacturers to analyze production processes comprehensively. Data-driven insights facilitate continuous improvement initiatives, leading to enhanced efficiency and cost-effectiveness.

GAO Helps Customers Comply with Standards, Mandates & Regulations of RFID Miscellaneous Manufacturing Industry

GAO RFID Inc. has helped many companies in Miscellaneous Manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 series (RFID air interface standards)

- EPC Gen2 (EPCglobal UHF Gen2 standard)

- FCC Part 15 (U.S. regulations for RFID)

- IATA RFID guidelines (for aviation industry)

- AIM Global RFID Data Standard

- FAA Part 107 (U.S. regulations for commercial drones)

- Transport Canada regulations (for drones in Canada)

- EASA regulations (for drones in Europe)

- ISO 21384 series (Unmanned aircraft systems)

U.S. Government Regulations

- FCC Part 15

- NIST SP 800-53

- S. Export Administration Regulations (EAR)

- CPSC Safety Standards

- DOT Hazardous Materials Regulations

- EPA Environmental Regulations

Canadian Government Regulations

- Radiocommunication Act and Regulations

- Personal Information Protection and Electronic Documents Act (PIPEDA)

- Canada Consumer Product Safety Act

- Hazardous Products Act

- Canada Border Services Agency (CBSA) Regulations

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in RFID Miscellaneous Manufacturing Industry:

Personnel Management:

- Recruitment and Selection

- Training and Development

- Performance Evaluation and Feedback

- Employee Engagement and Retention

Equipment Management:

- Equipment Inventory and Tracking

- Preventive Maintenance Scheduling

- Equipment Calibration and Testing

- Equipment Replacement and Upgrades

Access Control:

- Secure Entry and Exit Points

- Visitor Management System

- Access Control for Restricted Areas

- Biometric Authentication

Warehouse Management:

- Inventory Control and Tracking

- Stock Replenishment and Ordering

- Shelf Life and Expiry Date Management

- Space Optimization and Layout Planning

Supply Chain Management:

- Vendor Selection and Management

- Procurement and Purchase Order Management

- Demand Forecasting and Inventory Planning

- Distribution and Logistics Optimization

Other Applications:

- Quality Assurance and Compliance Management

- Patient Safety and Risk Management

- Health Information Management and Electronic Records

- Financial Management and Revenue Cycle Management

GAO has enabled its customers to make use of some of the leading software and cloud services in the Manufacturing Industry. Below are some of the popular software and cloud services in RFID Miscellaneous Manufacturing Industry:

Cerner Corporation, Allscripts Healthcare Solutions, Inc., Meditech, McKesson Corporation, Siemens Healthineers, Athenahealth, Inc., GE Healthcare, NextGen Healthcare, eClinicalWorks, Philips Healthcare, EpicCare, Carestream Health.

GAO has worked with some of the leading technology companies in RFID Miscellaneous Manufacturing Industry to provide integrated RFID, BLE, IoT, and drone solutions to customers. Here are some of the technology leaders in RFID Miscellaneous Manufacturing Industry:

Cisco Systems, Inc., Microsoft Corporation, IBM Corporation, Oracle Corporation, Dell Technologies, Hewlett Packard Enterprise (HPE), Intel Corporation, VMware, Inc., Citrix Systems, Inc., Change HealthcareNuance Communications, Inc., Zebra Technologies Corporation.

Case Studies of RFID Applications

Below are some RFID application cases in RFID Miscellaneous Manufacturing industry:

A manufacturing company produces a wide range of products, each with unique specifications. By applying RFID tags to each product at different stages of manufacturing, the company achieves real-time visibility into inventory levels and product locations. This allows them to streamline the production process, optimize stock levels, and quickly locate specific items for shipping. Additionally, RFID enables complete traceability, ensuring compliance with quality standards and facilitating recall management if necessary.

A heavy machinery manufacturer utilizes RFID technology to monitor the location and condition of their equipment. RFID tags on machinery transmit data to a central system, allowing maintenance teams to schedule proactive maintenance based on usage and condition data, resulting in reduced equipment breakdowns and optimized maintenance schedules.

An aerospace manufacturer implements RFID-based access control to secure restricted areas within their manufacturing facility. Employees are issued RFID badges that grant them access based on their authorization levels, ensuring a secure and controlled environment.

A luxury goods manufacturer integrates RFID tags with secure authentication features into their products. Customers can verify the authenticity of each item by scanning the RFID tag with a mobile app, helping combat counterfeit products in the market.

A chemical manufacturing company deploys RFID sensors to monitor temperature and humidity levels in storage areas. The data collected by the RFID sensors ensures that chemicals are stored within optimal conditions, complying with safety and regulatory requirements.

Case Studies of IoT Applications

Below are some IoT application cases in RFID Miscellaneous Manufacturing Industry.

A manufacturing company implements IoT sensors on their production equipment to monitor various parameters such as temperature, vibration, and energy consumption. The data from these sensors is sent to a centralized system for analysis. By applying predictive maintenance algorithms, the manufacturer can predict equipment failures and schedule maintenance proactively, reducing unplanned downtime and optimizing equipment performance.

IoT sensors are deployed throughout the manufacturing facility to monitor environmental conditions like temperature, humidity, and air quality. The data from these sensors is used to maintain optimal conditions for manufacturing processes, ensuring product quality and the safety of workers.

IoT sensors are attached to storage bins, shelves, or racks to monitor inventory levels automatically. The sensors communicate with the inventory management system, triggering automated reordering when stock levels reach predefined thresholds, reducing stockouts, and optimizing inventory carrying costs.

IoT sensors are integrated with RFID tags on products to monitor temperature, humidity, and other relevant environmental conditions during production and transportation. This data is stored in a blockchain-based system, providing an immutable record of the product’s journey, ensuring quality control, and enhancing traceability for regulatory compliance and customer confidence.

IoT wearables, such as smart helmets or wristbands, are provided to workers in the manufacturing facility. These wearables monitor vital signs, detect falls or accidents, and alert supervisors in case of emergencies, ensuring worker safety. Additionally, the data collected can be used to analyze worker activity and optimize workflows for improved productivity.

IoT sensors are installed to monitor energy usage in various areas of the manufacturing facility. The data is collected in real-time, enabling the manufacturer to identify energy inefficiencies and implement energy-saving strategies, leading to cost reductions and improved sustainability.

Case Studies of Drone Applications

Drones equipped with RFID readers can conduct aerial scans of large manufacturing facilities or warehouses, reading RFID tags on products and assets. This allows for quick and efficient inventory checks, enabling manufacturers to monitor stock levels and asset locations in real-time.

Drones can fly over manufacturing floors, reading RFID tags on work-in-progress items as they move through different production stages. This provides real-time tracking of production progress and identifies potential bottlenecks in the manufacturing process.

Drones equipped with environmental sensors can monitor various parameters, such as temperature, humidity, and air quality within the manufacturing facility. By integrating this data with RFID-tagged product information, manufacturers can ensure that environmental conditions are optimal during production and storage.

Drones can be utilized to inspect products on the manufacturing line, reading RFID tags to verify their authenticity and quality. This supports quality control efforts and provides an additional layer of traceability throughout the manufacturing process.

Drones equipped with RFID readers can be deployed along the supply chain to track the movement of goods and raw materials. This data helps manufacturers gain real-time visibility into the supply chain, optimize logistics operations, and respond to unexpected delays or disruptions.

GAO RFID Systems & Hardware for RFID Miscellaneous Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including RFID Miscellaneous Manufacturing Industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration, and panic button:

GAO’s BLE technology is suitable for many industries, including coal mining.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including coal mining:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including coal mining:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including coal mining:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including coal mining:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

The RFID systems by GAO are highly popular for clients in the miscellaneous manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include Hospital Beds Patient Monitors Ventilators Defibrillators, Infusion Pumps, Surgical Instruments, Anesthesia Machines Diagnostic, Imaging Equipment, Endoscopy Equipment Electrocardiogram (ECG), Machines Laser Systems, Dialysis Machines Laparoscopic, Equipment Operating Room Lights and Tables Laboratory, Equipment, Wound Care Devices, Orthopedic Implants and Instruments Patient Lifts and Transfer, Equipment Cryotherapy, Machines Hyperbaric Chambers.

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for RFID Miscellaneous Manufacturing Industry and for various industries in all metropolitans in the U.S. and Canada: https://gaorfid.com/services.

GAO Makes Efforts to Satisfy Customers

Large Choice of Products: To satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery: To shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada.

Local to Our Customers: We are in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in the U.S. and Canada. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Miscellaneous Manufacturing Industry, we have worked with to serve our joint customers:

- Avery Dennison Corporation

- Omni-ID

- Xerafy

- Metalcraft, Inc.

- RF Code, Inc.

- Balluff Inc.

- Confidex Ltd.

- William Frick & Company

- Vizinex RFID

- GuardRFID Solutions Inc.

- Intelliwave Technologies Inc.

- WaveMark, Inc. (Part of Cardinal Health)

GAO Has Served in Miscellaneous Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in RFID Miscellaneous Manufacturing Industry to achieve success in the Internet of Things (IoT), Digital Twin, Additive Manufacturing, Electric Vehicles (EVs), Lightweight Materials, Artificial Intelligence (AI), Augmented Reality (AR), Supply Chain Visibility, Sustainable Manufacturing, Big Data Analytics, Advanced Robotics, Predictive Maintenance, Cybersecurity, Human-Machine Collaboration.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in RFID Miscellaneous Manufacturing Industry, including many in its various divisions such as However, based on GAO RFID Inc.’s expertise in RFID, BLE, and IoT technologies, they might have been involved in a variety of projects for different companies within the manufacturing sector. These projects could have included applications such as:

- Inventory Management and Tracking: Implementing RFID systems to monitor and track inventory levels, ensuring efficient inventory management and reducing stockouts.

- Asset Tracking and Management: Deploying RFID and IoT solutions to track and manage manufacturing equipment and assets, optimizing maintenance schedules and preventing loss.

- Process Automation: Integrating RFID and IoT technologies to automate manufacturing processes, streamlining workflows, and reducing manual intervention.

- Quality Control and Traceability: Applying RFID and IoT for product traceability and quality control, enabling manufacturers to ensure compliance with industry standards and regulations.

- Environmental Monitoring: Implementing IoT sensors for monitoring environmental conditions within manufacturing facilities, ensuring optimal conditions for production.

- Supply Chain Visibility: Utilizing RFID and IoT solutions to gain real-time visibility into the supply chain, enhancing logistics efficiency and reducing delays.

- Work-in-Progress Tracking: Using RFID and IoT technologies to track the progress of work-in-progress items as they move through different production stages

- Energy Management and Sustainability: Deploying IoT sensors to monitor energy consumption and support sustainability efforts within manufacturing facilities.

- Security and Access Control: Implementing RFID and BLE solutions for access control and security purposes in manufacturing facilities.

- Product Authentication and Anti-Counterfeiting: Integrating secure RFID and IoT features into products to authenticate their origin and protect against counterfeiting.

Here are some of the leading companies in the RFID Miscellaneous Manufacturing industry:

- Allien Technology

- Impinj

- GAO RFID Inc.

- HID Global

- Honeywell

- Invengo Technology

- NXP Semiconductors

- Siemens AG

- Zebra Technologies

- Avery Dennison

- Omron Corporation

- SATO Holdings Corporation

- R4i Technologies

- Data Logic

- Omni-ID

- Intellifi

- Balluff Inc.

- ID Tronic

- Wavetrend Technologies

- CISC Semiconductor

- Farsens S.L.

- CSL (Convergence Systems Limited)

- Mojix Inc.

- Xerafy Ltd.

- Smartrac Technology

- Savi Technology

- Confidex Ltd.

- CAEN RFID

- MetalCraft Inc.

- Xpans Technologies