Overview

The warehouse and storage industry involves the storage and handling of goods and materials, typically on behalf of other companies or individuals. This can include warehousing, distribution, transportation, and logistics services. The industry plays a critical role in supply chain management, ensuring that goods are stored and delivered efficiently and safely. It encompasses a wide range of businesses, including third-party logistics providers, public and private warehouses, distribution centers, and freight forwarders.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the warehouse and storage industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as forklifts, pallet jacks, conveyor belts, pallet racks, shelving units, loading docks, dock levelers, hand trucks, carts, shrink wrap machines, bar code scanners, cranes, and hoists.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in the warehouse and storage.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Warehouse and Storage

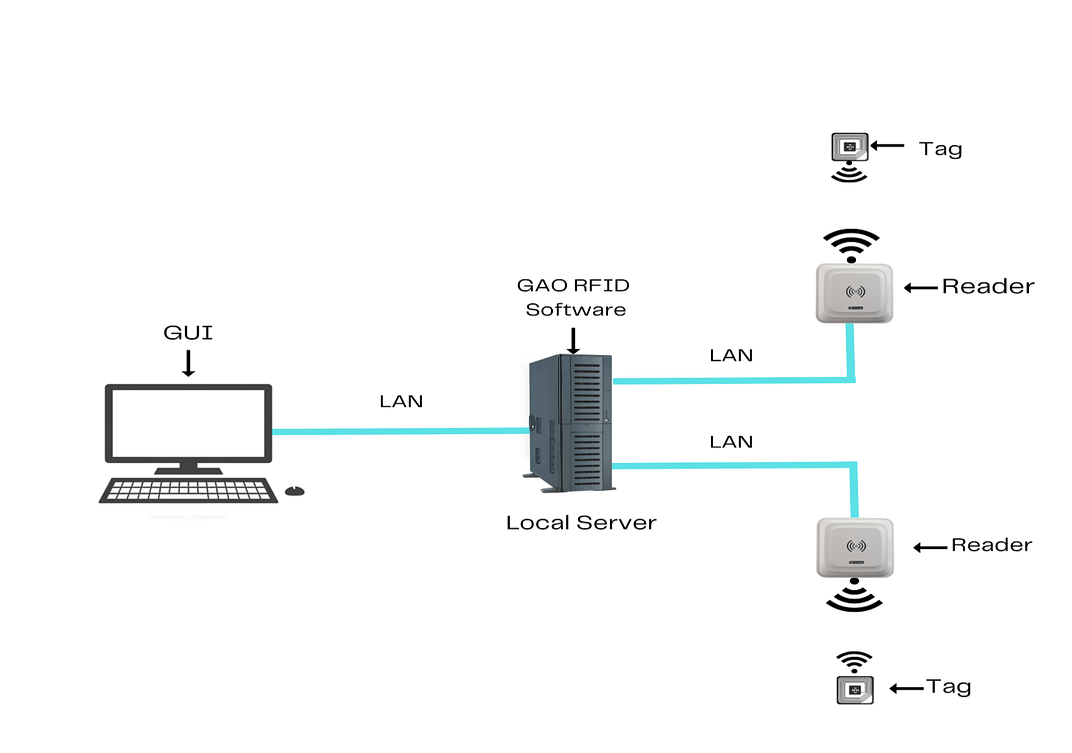

To satisfy its customers, GAO’s RFID or RFID Systems for the warehouse and storage are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the warehouse and storage with its software running on a local server

To satisfy its customers, GAO’s RFID or RFID Systems for the warehouse and storage are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the warehouse and storage with its software running on a local server

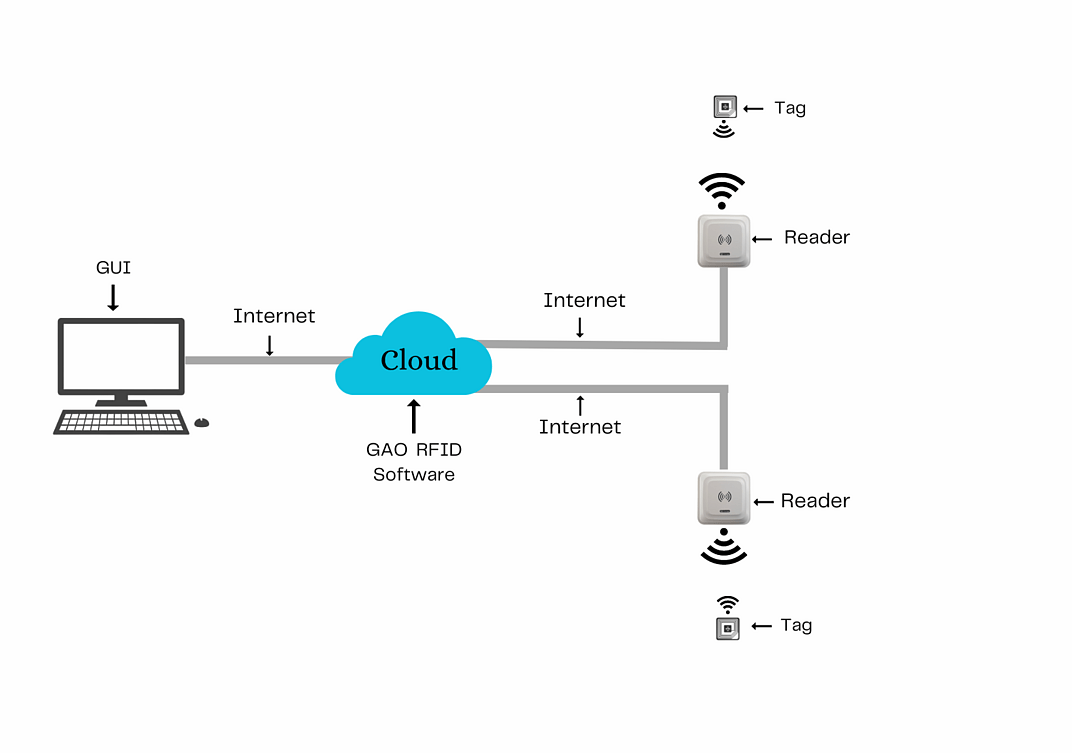

The above illustrates GAO system for the warehouse and storage with its software running in cloud.

The above illustrates GAO system for the warehouse and storage with its software running in cloud.

GAO’s RFID technologies bring the many benefits to the warehouse and storage industry:

- Improved inventory management: GAO’s RFID can provide real-time, accurate data on inventory levels and locations, reducing the need for manual counts and improving inventory accuracy.

- Increased efficiency: Our RFID can streamline processes such as receiving, picking, and shipping by automating data capture and reducing the need for manual data entry.

- Increased security: GAO RFID can be used to monitor access to sensitive areas and to track the movement of goods, improving security and reducing the risk of theft or tampering.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within the warehouse and storage industry:

- Real-time asset tracking: GAO’s BLE can be used to track the location and movement of assets, such as inventory items, pallets, and equipment like forklifts, and pallet jacks, in real-time. This allows for more accurate inventory management, reduces the risk of lost or stolen items, and improves supply chain efficiency.

- Improved worker safety: GAO’s BLE-enabled devices can be used to monitor worker movements and detect potential safety hazards, such as collisions with forklifts or other vehicles.

- Reduced costs: Our BLE-enabled devices can be less expensive than traditional RFID systems, making them an attractive option for smaller businesses or companies with limited budgets.

- Improved customer service: By providing real-time updates on order status and delivery times, GAO BLE can improve customer satisfaction and enhance the customer experience.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to the warehouse and storage industry:

- Faster inventory tracking: GAO’s RFID can provide accurate, real-time data on inventory levels, and drone technology can be used to quickly scan and verify inventory items. This can speed up the inventory tracking process and reduce the need for manual labor.

- Improved inventory accuracy: By combining GAO RFID and drone technology, companies can improve inventory accuracy and reduce the risk of errors or miscounts.

- Enhanced security: Drones can be used to monitor warehouse security, and RFID technology can be used to track the movement of goods and detect any unauthorized access or tampering.

Here are benefits of GAO’s IoT technologies to the warehouse and storage industry:

- Enhanced supply chain visibility: GAO’s IoT can provide real-time data on the movement of goods throughout the supply chain, improving traceability and reducing the risk of errors or delays.

- Reduced maintenance costs: Our IoT sensors can be used to monitor the condition and performance of equipment and machinery, allowing for proactive maintenance and reducing the risk of downtime and repair costs.

- Better utilization of resources: GAO’s IoT can provide real-time data on resource usage, enabling companies to optimize resource allocation and reduce waste.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Warehouse and Storage

GAO RFID Inc. has helped many companies in the warehouse and storage to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- EPC Gen2: The Electronic Product Code (EPC) Gen2 standard is commonly used in RFID applications, including warehouse and inventory management. It is designed to provide a unique identification code for each product or item.

- ASTM F38: This standard defines the performance specifications for small unmanned aerial systems (sUAS) used in commercial applications, including warehouse and inventory management.

- FAA Part 107: The Federal Aviation Administration (FAA) Part 107 regulations provide guidelines for the use of commercial drones, including requirements for drone pilot certification and drone operation in controlled airspace.

- The U.S. Department of Defense (DoD): This mandate requires all suppliers of certain products to the U.S. DoD to implement RFID tagging on their products and provide RFID data to the DoD for tracking and inventory purposes.

- The Retail Industry Leaders Association (RILA): This mandate requires suppliers to certain retailers to implement RFID tagging on their products and provide RFID data to the retailers for tracking and inventory purposes.

- The Industrial Internet Consortium (IIC) IoT Security Maturity Model: This model provides guidelines for securing IoT devices and networks, including those used in warehouse and inventory management applications.

- The Federal Aviation Administration (FAA) Part 107: This mandate provides guidelines for the use of commercial drones, including those used in warehouse and inventory management applications. It requires drone operators to obtain a Remote Pilot Certificate and comply with regulations related to drone operation in controlled airspace.

U.S. Government Regulations

- Occupational Safety and Health Administration (OSHA): OSHA is responsible for enforcing safety and health regulations in the workplace. Its regulations apply to all employers in the United States, including those in the warehouse and storage industry.

- Department of Transportation (DOT): The DOT regulates the transportation of hazardous materials, including those commonly found in the warehouse and storage industry.

- Environmental Protection Agency (EPA): The EPA regulates the storage and disposal of hazardous materials, including those commonly found in the warehouse and storage industry.

- International Building Code (IBC): The IBC provides minimum requirements for the design and construction of buildings and structures, including warehouses and storage facilities.

- Americans with Disabilities Act (ADA): The ADA prohibits discrimination against individuals with disabilities and requires employers to provide reasonable accommodations to employees with disabilities.

Canadian Government Regulations

- Canada Labour Code, Part II: The Canada labour code, Part II applies to federally regulated employers, including those in the warehouse and storage industry.

- Transportation of Dangerous Goods Act: This act governs the transportation of dangerous goods in Canada, including those commonly found in the warehouse and storage industry.

- Canadian Environmental Protection Act: The Canadian environmental protection act regulates the storage and disposal of hazardous materials, including those commonly found in the warehouse and storage industry.

- National Building Code of Canada: The national building code of Canada provides minimum requirements for the design and construction of buildings and structures, including warehouses and storage facilities.

- Canadian Human Rights Act: The Canadian human rights act prohibits discrimination against individuals based on race, gender, disability, and other grounds.

International Warehouse Logistics Association

International Warehouse Logistics Association

ASTM

ASTM

Retail Industry Leaders Association

Retail Industry Leaders Association

Federal Aviation Administration

Federal Aviation Administration

Occupational Safety and Health Administration

Occupational Safety and Health Administration

Department of Transportation

Department of Transportation

Environmental Protection Agency

Environmental Protection Agency

IATA Spec 2000

IATA Spec 2000

ANSI

ANSI

National Institute of Standards and Technology

National Institute of Standards and Technology

International Organization for Standardization

International Organization for Standardization

International Electrotechnical Commission

International Electrotechnical Commission

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the warehouse and storage such as:

- Personnel management: This application involves managing the workforce and includes tasks such as tracking employee time and attendance, performance management, and training. Some examples of personnel management software that can be used in the warehouse and storage industry include ADP, Workday, and Oracle HCM.

- Equipment management: This application involves tracking and managing the equipment such as dock levelers, dock seals, dock bumpers used in the warehouse and storage industry. This includes maintenance and repair schedules, tracking usage and availability, and ensuring equipment is properly stored and secured when not in use. Examples of equipment management software include CMMS, Asset Panda, and UpKeep.

- Access control: This application involves controlling who has access to the warehouse and storage facility. This includes implementing security measures such as ID cards, fingerprint scans, and facial recognition. Examples of access control software include Kisi and LenelS2.

- Warehouse management: This application involves managing the movement and storage of inventory in the warehouse and storage facility. This includes tasks such as picking and packing, inventory tracking, and order fulfillment. Some examples of warehouse management software that can be used in the warehouse and storage industry include Fishbowl Inventory, WMS360, and SAP Warehouse Management.

- Supply chain management: This application involves managing the entire supply chain, from raw materials to finished goods. This includes tasks such as demand planning, supplier management, and logistics. Examples of supply chain management software include Oracle SCM, SAP Supply Chain Management, and JDA Software.

- Other applications: Other applications that can be used in the warehouse and storage industry include transportation management software, inventory optimization software, and warehouse control systems. Examples of these types of software include MercuryGate TMS, Slimstock, and Dematic Warehouse Control System.

GAO has integrated its RFID, BLE, IoT and drone systems with some of leading software and cloud services in the warehouse and storage industry. Below are some of popular software and cloud services in the warehouse and storage industry.

- Amazon Web Services (AWS): This is a cloud-based platform that helps manage equipment like pallet racks, forklifts, pallet jacks and assets in the warehouse and storage industry. It includes features such as real-time data processing, predictive maintenance, and device management.

- Microsoft Azure: This is a cloud-based platform that helps manage equipment and assets in the warehouse and storage industry. It includes features such as real-time monitoring, predictive maintenance, and asset tracking.

- Google Cloud: This is a cloud-based platform that provides a range of services for managing data storage, analytics, and security in the warehouse and storage industry.

- IBM Cloud: This is a cloud-based platform that provides a range of services for managing data storage, analytics, and security in the warehouse and storage industry.

- Oracle Cloud: This is a cloud-based platform that provides a range of services for managing data storage, analytics, and security in the warehouse and storage industry.

- SAP Cloud Platform: This is a cloud-based platform that provides a range of services for managing data storage, analytics, and security in the warehouse and storage industry.

- WMS (Warehouse Management System): This is a software solution that helps manage warehouse operations, including inventory management, picking, packing, and shipping.

- Zebra Technologies: This is a software solution that helps manage warehouse and supply chain operations, including access control, inventory management, and asset tracking.

- DigitalOcean: It offers cloud-based storage solutions, such as spaces and block storage.

- Rackspace: provides a range of cloud storage services, such as cloud files and cloud block storage.

- Infor: This is a software solution that helps manage warehouse and supply chain operations, including access control, inventory management, and supply chain management.

- Blue Yonder (formerly JDA Software): This is a software solution that helps manage warehouse and supply chain operations, including access control, inventory management, and labor management.

- SSI Schaefer: This is a software solution that helps manage warehouse operations, including access control, inventory management, and supply chain management.

Amazon Web Services

Amazon Web Services

Google Cloud

Google Cloud

Microsoft Azure

Microsoft Azure

IBM Cloud

IBM Cloud

Oracle Cloud

Oracle Cloud

SAP Cloud Platform

SAP Cloud Platform

infor

infor

BlueYonder

BlueYonder

Zebra Technologies

Zebra Technologies

DigitalOcean

DigitalOcean

Rackspace

Rackspace

GAO has worked with some of the leading technology companies in the warehouse and storage in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the warehouse and storage industry:

- Cisco: Cisco is a leading provider of networking and communications solutions for a range of industries, including warehouse and storage. Its solutions include Internet of Things (IoT) connectivity, security, and collaboration tools.

- Honeywell: Honeywell is a leading provider of automation and control solutions for a range of industries, including warehouse and storage. Its solutions include warehouse management systems, mobile computing, and barcode scanning technologies.

- Datalogic: Datalogic is a leading provider of electronic technology solutions for a range of industries, including warehouse and storage. Its solutions include barcode scanners, mobile computers, and RFID technology.

- Impinj: Impinj is a leading provider of RFID technology solutions for a range of industries, including warehouse and storage. Its solutions include RFID readers, antennas, and software.

- Avery Dennison: Avery Dennison is a leading provider of electronic technology solutions for a range of industries, including warehouse and storage. Its solutions include RFID technology, arcode labeling and tagging, and data management software.

- Intermec: Intermec is a leading provider of electronic technology solutions for a range of industries, including warehouse and storage. Its solutions include barcode scanners, mobile computers, and RFID technology.

- Dematic: Dematic is a leading provider of automated material handling systems for a range of industries, including warehouse and storage. Its solutions include conveyor systems, automated storage and retrieval systems, and order fulfillment technologies.

- Swisslog: Swisslog is a leading provider of automated material handling systems for a range of industries, including warehouse and storage. Its solutions include automated storage and retrieval systems, conveyor systems, and robotic solutions.

- Vanderlande: Vanderlande is a leading provider of automated material handling systems for a range of industries, including warehouse and storage. Its solutions include conveyor systems, automated storage and retrieval systems, and order fulfillment technologies.

- Bastian Solutions: Bastian Solutions is a leading provider of material handling and automation systems for a range of industries, including warehouse and storage. Its solutions include conveyor systems, robotic solutions, and automated storage and retrieval systems.

- Microsoft: Microsoft is a leading provider of information technology solutions for a range of industries, including warehouse and storage. Its solutions include cloud computing, data analytics, and artificial intelligence (AI) solutions.

- Kardex: Kardex is a leading provider of automated storage and retrieval systems for a range of industries, including warehouse and storage. Its solutions include automated vertical lift modules, horizontal carousels, and shuttle systems.

Cisco Systems, Inc.

Cisco Systems, Inc.

Honeywell International Inc.

Honeywell International Inc.

Datalogic S.p.A.

Datalogic S.p.A.

Impinj, Inc.

Impinj, Inc.

Intermec

Intermec

Avery Dennison Corporation

Avery Dennison Corporation

Dematic

Dematic

Swisslog Holding AG

Swisslog Holding AG

Vanderlande

Vanderlande

Bastian Solutions

Bastian Solutions

Kardex

Kardex

Microsoft Corporation

Microsoft Corporation

Case Studies of RFID Applications

Below are some RFID application cases in the warehouse and storage industry.

Walmart: Walmart implemented an RFID system in its supply chain operations to improve inventory management and reduce out-of-stock situations. The technology allowed them to track products from the distribution center to the store shelves, enabling real-time inventory visibility and automated replenishment.

Macy’s: Macy’s, a major retail company, adopted RFID technology to enhance its inventory accuracy and reduce stock discrepancies. By using RFID tags on individual items, they achieved better visibility into stock levels, which led to improved inventory accuracy and increased sales.

Lululemon Athletica: Lululemon, a popular athletic apparel retailer, implemented an RFID solution to streamline its supply chain processes. By tagging items with RFID tags, they were able to track inventory movement, improve stock accuracy, and optimize replenishment cycles, resulting in improved efficiency and reduced stockouts.

Canadian Tire: Canadian Tire, a Canadian retail company, implemented an RFID system in its distribution centers to improve inventory management. By using RFID tags on pallets and cases, they achieved better inventory visibility, reduced manual labor, and improved order accuracy and fulfillment.

XPO Logistics: XPO Logistics, a major logistics and transportation company, utilized UHF RFID technology in its warehouses to enhance inventory management and order accuracy. By implementing RFID tags on products, they were able to automate inventory tracking, improve picking and packing processes, and achieve better overall inventory accuracy.

The Home Depot: The Home Depot, a large home improvement retailer, implemented UHF RFID technology in its distribution centers to optimize inventory management and streamline replenishment processes. By using RFID tags on products, they gained real-time visibility into inventory levels, which allowed them to improve inventory accuracy, reduce stockouts, and enhance the efficiency of order fulfillment.

Loblaw Companies Limited: Loblaw, a Canadian grocery retailer, adopted UHF RFID technology in its distribution centers to improve inventory management and reduce out-of-stock situations. By utilizing RFID tags on products, they achieved better visibility into stock levels, enabling accurate inventory tracking, streamlined replenishment, and improved overall supply chain efficiency.

Williams-Sonoma: Williams-Sonoma, a specialty retailer of high-quality home products, utilized UHF RFID technology in its warehouses to improve inventory accuracy and order fulfillment processes. By implementing RFID tags on items, they achieved better visibility into stock levels, reduced manual counting errors, and optimized inventory replenishment.

GAO RFID Systems & Hardware for the Warehouse and Storage

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the warehouse and storage.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the warehouse and storage.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the warehouse and storage:

- Gen2 UHF 902-928 MHz Passive RFID Readers

- Gen 2 UHF 865-868 MHz Passive RFID Readers

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the warehouse and storage:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the warehouse and storage:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the warehouse and storage:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the warehouse and storage:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- Forklifts: Forklifts are versatile vehicles used for lifting and moving heavy loads. They come in various sizes and configurations, including counterbalance forklifts, reach trucks, and pallet jacks, among others.

- Pallet Jacks: Also known as pallet trucks or pump trucks, pallet jacks are manually operated equipment used for moving palletized loads within a warehouse or storage area.

- Conveyor Systems: Conveyor systems automate the movement of goods or materials within a facility. They consist of belts, rollers, or chains to transport items from one location to another, reducing the need for manual handling.

- Automated Guided Vehicles (AGVs): AGVs are autonomous vehicles that can transport goods within a warehouse without the need for human operators. They are guided by sensors, magnets, or lasers and can be programmed to perform specific tasks.

- Storage and Racking Systems: These systems include pallet racking, shelving units, mezzanines, and storage bins, which provide organized and efficient storage for products or materials.

- Dock Levelers: Dock levelers are equipment installed at loading docks to bridge the height gap between the warehouse floor and incoming trucks, enabling smooth loading and unloading operations.

- Order Pickers: Order pickers are specialized forklifts or elevated platforms used to access items at various heights within a warehouse. They are particularly useful for order picking processes.

- Palletizers: Palletizers are machines used to stack or arrange products onto pallets automatically. They streamline the palletizing process, increasing efficiency and reducing manual labor.

- Stretch Wrappers: Stretch wrapping machines are used to secure palletized loads with plastic wrap, providing stability and protection during transportation and storage.

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Warehouse and Storage Extensively

GAO’s products and technologies have helped its customers in the warehouse and storage industry to achieve success in automation & robotics, artificial intelligence (AI), augmented reality (AR), Internet of Things (IoT), blockchain technology, predictive analytics, digital twins, cloud computing, smart warehousing, last-mile delivery optimization, green warehousing and sustainability, autonomous vehicles and drones, mobile technologies & apps, real-time location systems (RTLS), collaborative robots (Cobots), predictive maintenance, warehouse management systems (WMS), voice picking and wearables.

GAO RFID Inc. has served many customers in the warehouse and storage, including its various divisions such as

- Warehousing and Storage Services: This includes companies that provide third-party warehousing and storage services to other businesses. These companies offer various services such as inventory management, order fulfillment, and transportation.

- Material Handling Equipment: This includes companies that manufacture or distribute equipment used for moving, storing, and handling materials within warehouses and storage facilities. Examples of equipment include forklifts, pallet jacks, and conveyors.

- Packaging and Labeling: This includes companies that provide packaging and labeling solutions for products stored and transported within warehouses and storage facilities. These companies offer packaging materials, labeling equipment like wire decking, pallet jacks, plastic bins and totes, and other related services.

- Cold Storage: This includes companies that specialize in the storage and handling of temperature-sensitive products such as food and pharmaceuticals. These companies typically have specialized facilities equipped with refrigeration and other temperature-control technologies.

- Self-Storage: This includes companies that provide storage units to individuals and businesses for storing personal belongings, equipment such as storage bins, shelving units, rolling ladders, and other items. These companies typically offer various sizes of storage units for rent on a short-term or long-term basis.

- E-commerce Fulfillment: This includes companies that specialize in fulfilling orders for e-commerce businesses. These companies provide services such as inventory management, order processing, and shipping.

Here are some of the leading companies in the warehouse and storage industry:

Americold Realty Trust, Inc.

Americold Realty Trust, Inc.

Prologis, Inc.

Prologis, Inc.

CBRE Group, Inc.

CBRE Group, Inc.

Duke Realty Corporation

Duke Realty Corporation

Public Storage

Public Storage

Extra Space Storage Inc.

Extra Space Storage Inc.

CubeSmart

CubeSmart

Life Storage, Inc.

Life Storage, Inc.

U-Haul International, Inc

U-Haul International, Inc

Iron Mountain Inc.

Iron Mountain Inc.

DHL Supply Chain

DHL Supply Chain

Hub Group, Inc.

Hub Group, Inc.

Expeditors International of Washington, Inc.

Expeditors International of Washington, Inc.

C.H. Robinson Worldwide, Inc.

C.H. Robinson Worldwide, Inc.

J.B. Hunt Transport Services, Inc.

J.B. Hunt Transport Services, Inc.

Schneider National, Inc.

Schneider National, Inc.

Purolator Inc.

Purolator Inc.

Ryder System, Inc.

Ryder System, Inc.

VersaCold

VersaCold

Hub Group, Inc.

Hub Group, Inc.

Federated Co-operatives Limited

Federated Co-operatives Limited

Weston Foods Canada Inc.

Weston Foods Canada Inc.

SCI Group Inc.

SCI Group Inc.

United Parcel Service Canada Ltd.

United Parcel Service Canada Ltd.