Index for Contents on This Page:

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones in Paper Manufacturing Industry

GAO Helps Customers Comply with Standards, Mandates & Regulations in Paper Manufacturing Industry

Case Studies of RFID Applications

GAO RFID Systems & Hardware for Paper Manufacturing Industry

Related Products & Systems on Other Pages on This Website

Tool & Industrial Equipment Tracking System

Pallet & Return Asset Tracking System

Employee & Attendance Access Control System

Work In Process WIP Asset Tracking System

People Tracking System for Manufacturing Facilities

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

Printable RFID Tags | Printable RFID Labels – GAO RFID

On Metal RFID Tags – All Types

Overview

The RFID (Radio Frequency Identification) technology in the Paper Manufacturing Industry plays a pivotal role in enhancing operational efficiency and traceability throughout the production and distribution processes. RFID involves the use of small electronic tags that can be affixed to paper rolls, pallets, and equipment. These tags contain unique identifiers and can be wirelessly scanned by RFID readers, enabling real-time data collection and communication. By integrating RFID technology into various stages of the paper manufacturing workflow, companies can achieve accurate inventory tracking, streamlined logistics, and improved quality control. RFID tags facilitate automated identification and location tracking of paper products, optimizing inventory management and reducing manual labor. Additionally, RFID enhances supply chain visibility, enabling manufacturers to monitor the movement of raw materials and finished products, enhance traceability, and comply with regulatory requirements. Ultimately, RFID technology in the paper manufacturing industry drives efficiency, transparency, and data-driven decision-making for improved production processes and product quality.

GAO’s products and technologies have helped its customers in Paper Manufacturing Industry to achieve success in the Internet of Things (IoT), Digital Twin, Additive Manufacturing, Electric Vehicles (EVs), Lightweight Materials, Artificial Intelligence (AI), Augmented Reality (AR), Supply Chain Visibility, Sustainable Manufacturing, Big Data Analytics, Advanced Robotics, Predictive Maintenance, Cybersecurity, Human-Machine Collaboration.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for RFID Miscellaneous Manufacturing Industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones in Paper Manufacturing Industry

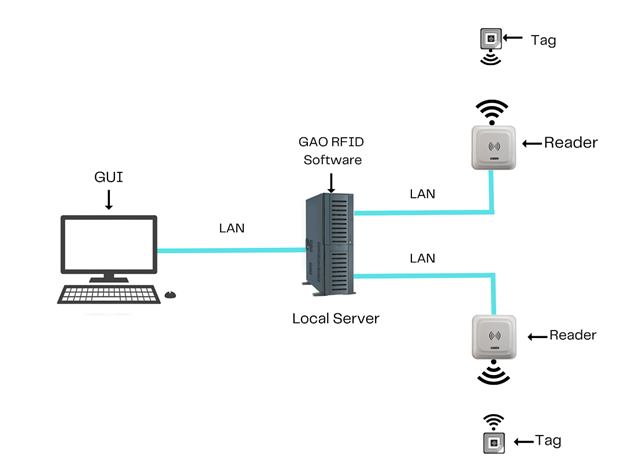

To satisfy its customers, GAO’s RFID or RFID Systems for Paper Manufacturing Industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, Cloudflare, Linode and Rackspace. The above illustrates GAO system for Manufacturing Industry with its software running on a local server.

The above illustrates the GAO system uses Paper Manufacturing Industry with its software running in the cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Paper Manufacturing Industry:

Asset Tracking: RFID tags attached to paper rolls, equipment, and inventory enable real-time tracking and management throughout the manufacturing process. This enhances inventory accuracy, reduces manual data entry, and streamlines asset management.

Inventory Management: RFID technology automates inventory tracking, ensuring accurate stock levels of raw materials, finished products, and intermediate stages. This minimizes stockouts, overstocking, and production delays.

Quality Control: RFID tags can be associated with production details, allowing manufacturers to monitor and verify paper product specifications, origin, and quality. This aids in identifying defects or discrepancies and ensuring product consistency.

Process Monitoring: RFID readers placed at different stages of production enable real-time process monitoring. This helps identify bottlenecks, track progress, and optimize workflow for increased operational efficiency.

Supply Chain Visibility: RFID technology enhances visibility across the supply chain, from raw materials to distribution. It enables manufacturers to track the movement of paper products, improving logistics planning and reducing lead times.

Traceability and Compliance: RFID technology provides accurate and automated data capture, facilitating traceability and compliance with industry regulations and standards. It helps manufacturers maintain proper records of paper product handling and movement.

Maintenance and Asset Management: RFID technology can track the maintenance history and condition of machinery and equipment used in paper production. This assists in preventive maintenance planning and reducing downtime.

Authentication and Anti-Counterfeiting: RFID tags can be embedded in high-value paper products to ensure authenticity and prevent counterfeiting. This protects against unauthorized duplication and maintains product integrity.

Environmental Sustainability: RFID supports sustainability efforts by tracking the sourcing of raw materials, promoting responsible forestry practices, and facilitating recycling efforts.

Data-Driven Decision-Making: RFID-generated data provides insights into production processes, inventory levels, and supply chain performance, enabling data-driven decision-making for improved operational efficiency.

GAO’s drone technologies can be utilized in the Paper Manufacturing Industry:

Environmental Monitoring: Drones equipped with sensors can monitor air quality, temperature, and humidity within paper mills and surrounding areas. This data helps ensure optimal manufacturing conditions and compliance with environmental regulations.

Infrastructure Inspection: Drones can inspect tall structures, such as smokestacks and machinery, for maintenance needs and structural integrity. This enhances safety and reduces the need for manual inspections in challenging areas.

Asset Tracking and Inventory Management: Drones equipped with RFID or barcode scanners can perform aerial inventory counts and track raw materials, finished products, and equipment in large manufacturing facilities, improving accuracy and efficiency.

Security and Surveillance: Drones with cameras and sensors can provide real-time surveillance of paper manufacturing facilities, deterring unauthorized access and enhancing overall security.

Mapping and Surveying: Drones can create accurate 3D maps and models of paper mills, aiding in facility planning, expansion, and optimization of workflow.

Environmental Impact Assessment: Drones can survey and monitor nearby areas for any environmental impact caused by paper manufacturing operations, supporting compliance with regulations and sustainability efforts.

Emergency Response: Drones can be deployed during emergencies such as fires or chemical spills to assess the situation, guide response teams, and minimize potential hazards.

Efficiency Improvement: Drones can monitor the movement of raw materials, track production progress, and identify operational inefficiencies for process optimization.

GAO’s IoT technologies, consisting of IoT sensors, sensor networks and systems, find the following applications in the Paper Manufacturing Industry:

Temperature and Humidity Monitoring: IoT sensors can monitor temperature and humidity levels in paper mills and storage areas, ensuring optimal conditions for paper production and storage to prevent damage and maintain product quality.

Vibration and Equipment Monitoring: IoT sensors placed on machinery can detect abnormal vibrations and performance fluctuations, helping prevent equipment breakdowns and improving maintenance planning.

Energy Management: IoT sensors can track energy consumption within paper manufacturing facilities, identifying areas for energy efficiency improvements and cost savings.

Environmental Monitoring: IoT sensors can measure air and water quality in and around paper mills, supporting compliance with environmental regulations and ensuring a healthy work environment.

Material Tracking: IoT-enabled RFID tags can track the movement of raw materials, finished products, and equipment throughout the production process, enhancing supply chain visibility and inventory management.

Predictive Maintenance: IoT sensors can gather data on equipment performance, allowing predictive maintenance strategies to be implemented based on real-time conditions and usage patterns.

Workflow Optimization: IoT sensors can monitor workflow and production processes, identifying bottlenecks and inefficiencies that can be addressed for improved operational efficiency.

Quality Control: IoT sensors can monitor and collect data on various production parameters, contributing to quality control efforts by ensuring consistency and adherence to specifications.

Safety Enhancement: IoT sensors can detect hazardous conditions, such as high temperatures or gas leaks, and send alerts to prevent accidents and ensure the safety of workers.

Remote Monitoring: IoT systems enable remote monitoring of paper manufacturing processes and facilities, allowing managers to stay informed and make timely decisions even when off-site.

GAO Helps Customers Comply with Standards, Mandates & Regulations in Paper Manufacturing Industry

GAO RFID Inc. has helped many companies in the Paper Manufacturing Industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6C

- ISO 13485

- ISO 9001

- ISO 14001

- GS1 Standards

- NIST Cybersecurity Framework

- FAA Part 107

- EU General Data Protection Regulation (GDPR)

- California Consumer Privacy Act (CCPA)

- Environmental Regulations

U.S. Government Regulations

- Clean Water Act

- Clean Air Act

- Resource Conservation and Recovery Act (RCRA)

- Occupational Safety and Health Administration (OSHA) regulations

- Environmental Protection Agency (EPA) regulations

- Federal Aviation Administration (FAA) regulations (for drones)

- National Institute of Standards and Technology (NIST) guidelines (for IoT security)

- Federal Communications Commission (FCC) regulations (for RFID and wireless technologies)

Canadian Government Regulations

- Canadian Environmental Protection Act

- Canadian Environmental Assessment Act

- Occupational Health and Safety Regulations

- Canadian Environmental Quality Guidelines

- Canada Labour Code

- Transportation of Dangerous Goods Regulations

- Fisheries Act

- Species at Risk Act

- Pest Control Products Act

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Paper Manufacturing Industry such as:

Personnel Management:

- Recruitment and Selection

- Training and Development

- Performance Evaluation and Feedback

- Employee Engagement and Retention

Equipment Management:

- Equipment Inventory and Tracking

- Preventive Maintenance Scheduling

- Equipment Calibration and Testing

- Equipment Replacement and Upgrades

Access Control:

- Secure Entry and Exit Points

- Visitor Management System

- Access Control for Restricted Areas

- Biometric Authentication

Warehouse Management:

- Inventory Control and Tracking

- Stock Replenishment and Ordering

- Shelf Life and Expiry Date Management

- Space Optimization and Layout Planning

Supply Chain Management:

- Vendor Selection and Management

- Procurement and Purchase Order Management

- Demand Forecasting and Inventory Planning

- Distribution and Logistics Optimization

Other Applications:

- Quality Assurance and Compliance Management

- Production Workflow Optimization

- Product Lifecycle Management

- Compliance and Regulatory Tracking

- Energy Management and Sustainability Monitoring

- Financial Management and Revenue Cycle Management

GAO has enabled its customers to make use of some of the leading software and cloud services in the Paper Manufacturing Industry. Below are some of the popular software and cloud services in Paper Manufacturing Industry:

SAP for Paper and Packaging, Microsoft Dynamics 365, and Oracle Cloud for Manufacturing provide tailored enterprise resource planning (ERP) capabilities, streamlining production, inventory, and supply chain management. Platforms including IBM Maximo, Plex Manufacturing Cloud, and Epicor ERP bolster maintenance, manufacturing execution, and process optimization. Cloud behemoths AWS, Microsoft Azure, and Google Cloud Platform offer secure and scalable infrastructure for data management and analysis.

GAO has worked with some of the leading technology companies in Paper Manufacturing Industry to provide integrated RFID, BLE, IoT, and drone solutions to customers. Here are some of the technology leaders in Paper Manufacturing Industry:

In the realm of the Paper Manufacturing Industry, several technology leaders stand at the forefront of innovation and advancement. Companies like SAP, Microsoft, and Oracle are trailblazers with their cutting-edge enterprise resource planning (ERP) solutions such as SAP for Paper and Packaging, and Microsoft Dynamics 365. IBM with its Maximo platform, Plex Manufacturing Cloud, and Epicor ERP contribute to process optimization and maintenance efficiency. Cloud giants AWS (Amazon Web Services), Microsoft Azure, and Google Cloud Platform lead the charge in providing secure and scalable infrastructure for data management and analytics. Salesforce Manufacturing Cloud revolutionizes customer relationship management, while AVEVA Manufacturing Execution System drives production execution excellence. Furthermore, the industry witnesses the influence of specialized players like Paperless Manufacturing Software and Quality Management Systems providers, contributing to the digital transformation and quality assurance imperative for the paper manufacturing sector.

Case Studies of RFID Applications

Below are some RFID application cases in Paper Manufacturing Industry:International Paper, a leading paper manufacturer, implemented RFID technology to streamline inventory management. RFID tags were attached to paper rolls, enabling real-time tracking of inventory movement and levels. This resulted in improved accuracy, reduced labor costs, and enhanced inventory visibility, enabling better production planning and order fulfillment.

Case Studies of IoT Applications

Below are some IoT application cases in Paper Manufacturing Industry. A paper manufacturing facility implemented IoT sensors on critical machinery to monitor equipment health in real time. The sensors collected data on vibration, temperature, and other parameters, which were transmitted to a central system. By analyzing this data, the facility could predict potential equipment failures and plan maintenance proactively, reducing unplanned downtime and improving overall operational efficiency.

Case Studies of Drone Applications

Below are some drone application cases in Paper Manufacturing Industry.A major paper manufacturing company utilized drones for facility inspection and maintenance optimization. Drones equipped with high-resolution cameras and sensors were deployed to inspect tall structures, machinery, and equipment. By conducting aerial inspections, the company could identify maintenance needs, structural issues, and potential hazards more efficiently. This proactive approach resulted in reduced downtime, improved worker safety, and optimized maintenance schedules.

GAO RFID Systems & Hardware for the Paper Manufacturing Industry:

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antennae, printers, and integrated RFID systems for various industries, including Paper Manufacturing Industry:

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

GAO’s BLE technology is suitable for many industries, including Paper Manufacturing Industry:

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Paper Manufacturing Industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, and wristbands for various industries, including Paper Manufacturing Industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications), and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Paper Manufacturing Industry:

HF, NFC, and LF RFID tags, labels, badges, and wristbands for various industries, including Paper Manufacturing Industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

The RFID systems by GAO are highly popular for clients in Paper Manufacturing Industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products: In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery: In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada.

Local to Our Customers: We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in the U.S. and Canada. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Paper Manufacturing Industry we have worked with to serve our joint customers:

- International Paper Company

- Georgia-Pacific LLC

- Kimberly-Clark Corporation

- WestRock Company

- Stora Enso Oyj

- UPM-Kymmene Corporation

- Sappi Limited

- Mondi Group

- Nippon Paper Industries Co., Ltd.

- Neenah, Inc.

- Boise Cascade Company

GAO Has Served in Paper Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have played a pivotal role in assisting customers within the Paper Manufacturing Industry in achieving enhanced operational efficiency and quality standards. By leveraging RFID solutions, paper manufacturers have streamlined inventory management, reduced manual tracking efforts, and optimized production planning. The integration of IoT sensors has enabled real-time monitoring of equipment health, improving predictive maintenance strategies and minimizing costly downtime. Additionally, drones equipped with advanced cameras and sensors have facilitated efficient facility inspections, contributing to maintenance optimization and ensuring compliance with safety standards. GAO’s contributions extend to asset tracking, environmental monitoring, and quality control, enabling paper manufacturing companies to harness cutting-edge technologies to address industry challenges and achieve higher levels of productivity, quality, and operational excellence.

RFID-Based Inventory Management, Asset Tracking and Traceability, IoT-Enabled Monitoring, Process Automation, Quality Control and Compliance, Enhanced Customer Experience, Risk Mitigation and Safety, Efficient Recall Management.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in Paper Manufacturing Industry, including many in its various divisions such as:

Inventory Precision: RFID enhances accuracy in tracking raw materials, finished products, and inventory levels, minimizing errors.

Automated Workflows: RFID streamlines production by automating stages, optimizing efficiency across paper manufacturing divisions.

Quality Assurance: RFID tags monitor production stages, ensuring consistent quality and identifying potential issues.

Equipment Management: RFID tracks machinery, managing assets, and maintenance schedules to prevent losses and downtime.

Transparent Supply Chain: RFID provides insights into material and product movement, improving coordination and planning.

Regulatory Compliance: RFID automates data collection, aiding in adhering to regulations and maintaining accurate records.

Security Enhancement: RFID secures areas, prevents unauthorized access, and deters theft in paper product facilities.

Data-Driven Insights: RFID data analysis identifies trends, production bottlenecks, and supports informed decisions.

Sustainable Practices: RFID tracks waste and recycling, promoting environmentally friendly approaches in paper manufacturing.

GAO’s technologies empower businesses in the “Paper Manufacturing” sector to efficiently monitor and manage their workforce. By utilizing RFID and BLE solutions, companies can accurately track worker locations, ensuring adherence to safety protocols and optimized task distribution. These technologies facilitate attendance tracking, enhance health and safety compliance, and streamline emergency response efforts. Real-time data from RFID and BLE devices aids in analyzing work patterns, optimizing workflows, and improving overall operational efficiency. Furthermore, GAO’s systems enable customized alerts, contact tracing during health crises, and integration with HR systems for seamless attendance and payroll management. Ultimately, GAO’s workforce tracking technologies contribute to safer working environments, regulatory compliance, and enhanced workforce management practices

Here are some of the leading companies in the Paper Manufacturing Industry:

- International Paper Company

- Georgia-Pacific LLC

- Kimberly-Clark Corporation

- WestRock Company

- Stora Enso Oyj

- UPM-Kymmene Corporation

- Sappi Limited

- Mondi Group

- Nippon Paper Industries Co., Ltd.

- Neenah, Inc.

- Boise Cascade Company

- Orchids Paper Products Company

- Glatfelter Corporation

- Pixelle Specialty Solutions

- Monadnock Paper Mills, Inc.

- Appleton Coated LLC

- Finch Paper LLC

- SWM International

- Cascades Inc. (US operations)

- Norpac Holdings LLC

- Resolute Forest Products Inc.

- Clearwater Paper Corporation

- Domtar Corporation

- Rengo Co., Ltd.

- Canfor Pulp Products Inc.

- Catalyst Paper Corporation

- Kruger Inc.

- Mercer International Inc.

You Are Invited to Contact Us!

If you interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

https://gaorfid.com/ask-the-experts/

or email us at sales@gaorfid.com