The Power Generation Construction industry is a sector that involves the planning, design, procurement, construction, and commissioning of power plants that generate electricity for industrial, commercial, and residential use. These power plants can be fueled by a variety of sources, including fossil fuels, nuclear energy, hydro, wind, and solar. GAO RFID Inc., a global top 10 RFID leader based in the cities of New York and Toronto, has served many companies in the power generation construction industry.

GAO RFID Systems & Hardware for the Power Generation Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the power generation construction industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

- IP67 Rated BLE 2.45GHz Active RFID Wristband Tag w/ Panic Button

- BLE 2.45GHz Ultra Rugged Active RFID Pallet Tag/Beacon

- BLE 2.45GHz Active RFID Asset Tag/Beacon

GAO’s BLE technology is suitable for all kinds of industries, including the power generation construction industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the power generation construction industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the power generation construction industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the power generation construction industry:

- 134.2KHz ISO11784/5 FDX RFID Plug and Play Portable Reader

- 134.2 kHz LF Long Range Fixed RFID Reader

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the power generation construction industry:

and antennas:

GAO also offers RFID printers, Digital I/O adapters, relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the power generation construction industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

- GAO RFID Heavy Duty Machinery Asset Management System

- Tool & Industrial Equipment Tracking System

- Asset Tracking Software

- GAO RFID Construction and Industrial Machinery Rental Asset Management System

Personnel or people access control system:

Parking or vehicle control system:

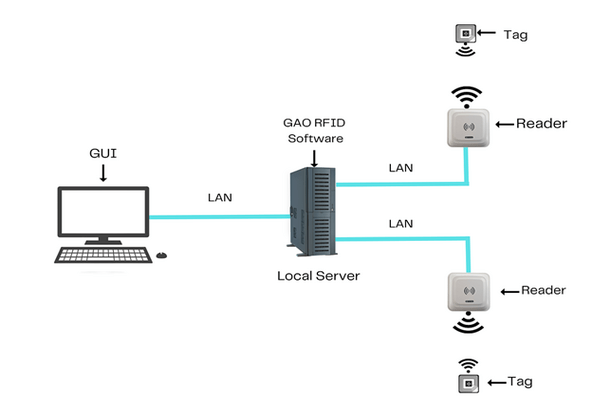

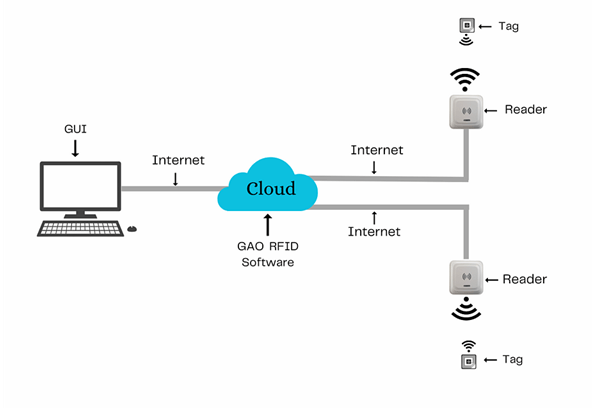

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

Benefits of GAO’s RFID, BLE, IoT & Drones for the Power Generation Construction

RFID, BLE, IoT and drones technologies from GAO RFID Inc. offer many benefits for the power generation construction industry:

Benefits of applying RFID to the power generation construction industry:

- Improved efficiency: GAO RFID tags can be used to quickly and easily track the location of fireproofing material, cranes, power generators, concrete mixers, and tools like saws, hammers, and grinders, reducing the time spent searching for these items.

- Increased accuracy: Our RFID solutions can provide more accurate data by minimizing errors and enhancing the accuracy of data.

- Improved inventory management: By providing real-time data on inventory levels and locations, Our RFID solutions prevent both overstocking and stock shortages. GAO RFID solutions can be utilized to monitor the inventory of materials like metals, fuel storage tanks, pumps, drivers, and fireproofing material available on-site.

Benefits of applying BLE technology to the power generation construction industry:

- Long-range tracking: GAO BLE products have a much longer range of up to 300 meters, making it ideal for tracking cranes, power generators, concrete mixers, tools like saws, hammers, and workers, labors, and engineers over a large construction site.

- Real-time tracking: Due to the relatively small size of GAO’s BLE solutions it can enable real-time tracking of pumps, backhoes, pavers, power generators, and tools like saws, hammers, drills, grinders which can prevent theft, and reduce the time required to locate missing items.

- Access Control: Our BLE beacons wirelessly transit credentials so that workers can be granted/restricted access by our gateways.

Benefits of applying combination of RFID and drones to the power generation construction industry:

- Rapid data collection: Drones equipped with GAO RFID solutions can quickly and easily collect data from a large area, including areas that are difficult to access by foot or by vehicle.

- Improved safety: By using drones to collect RFID data, workers do not have to enter hazardous or hard-to-reach areas, reducing the risk of accidents and injuries.

- Surveillance: Drones can also be equipped with cameras to provide a bird’s eye view of the site, allowing managers to identify potential safety hazards before they become a problem.

- Automation: Drones equipped with GAO RFID products can be less expensive than hiring a large team of workers to manually track equipment and components.

Benefits of applying combination of RFID and IoT to the power generation construction industry:

- Monitoring real-time environmental factors: IoT sensors can be used to monitor a wide range of environmental factors, including temperature, humidity, and vibrations. By combining IoT with GAO’s RFID products, managers can receive real-time alerts if there are any abnormalities in the environment, allowing them to take corrective action quickly.

- Prevent hazards: IoT sensors can be used with our GAO RFID products to detect overheating or high humidity levels, which can be indicative of a potential electrical hazard.

- Predictive maintenance: IoT sensors in the RFID tags can detect vibrations or other hazardous conditions, alerting managers to potential safety issues before they cause an accident or injury.

GAO Helps Customers Comply with Standards, Mandates & Regulations

GAO RFID Inc. has helped many companies in the power generation construction industry to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

- ASTM E2273-10: This is a standard for active RFID systems used in tracking and locating personnel and equipment in hazardous environments, such as power plants and construction sites.

- ASTM F3077: This is a standard which provide guidelines for the use of RFID technology in power generation construction projects, including best practices for data management and privacy protection.

- OSHA 29 CFR 1926.952: This is a mandate from the Occupational Safety and Health Administration in the United States that requires the use of RFID technology for tracking and managing workers in confined spaces, such as power plant boilers and tunnels.

- NERC CIP-014: This is a mandate from the North American Electric Reliability Corporation that requires power generation facilities to implement physical security measures, including the use of RFID technology, to protect against physical and cyber-attacks. This mandate applies to all power generation facilities in the United States and Canada.

- Clean Air Act (CAA) and Clean Water Act (CWA): These are enacted by the Environmental Protection Agency (EPA), sets air quality standards and limits for pollutants that can be emitted by power plants. CWA sets water quality standards and limits for pollutants, such as arsenic and mercury, that can be discharged by power plants.

- National Environmental Policy Act (NEPA): This regulation requires federal agencies to assess the potential environmental impacts of proposed projects, including power generation construction projects before they can proceed.

- Federal Energy Regulatory Commission (FERC) Regulations: This regulatory agency regulates the transmission and wholesale sale of electricity and natural gas in the U.S. It oversees the construction of new power generation facilities and transmission lines.

- Canadian Environmental Protection Act (CEPA): This regulation, enacted by Environment and Climate Change Canada, sets air and water quality standards and limits for pollutants, that can be emitted by power plants. The regulation aims to reduce the negative impact of power generation on the environment and public health.

- Canadian Energy Regulator Act (CERA): This regulation, enacted by the Canadian Energy Regulator, regulates the construction, operation, and abandonment of pipelines and power transmission lines that cross international or provincial borders.

Case Studies of RFID Applications

Here are two cases of applying RFID in the power generation industry:

Skanska USA construction company has used RFID technologies during the construction of a power plant in the United States. The RFID system was used to track the location and status of construction materials and turbines, hammers, saws, graders, and heavy equipment like bulldozers, concrete mixers, and power generators, which helped to improve efficiency, reduce costs, and improve safety. The RFID tags were attached to each piece of construction material and equipment, and readers were installed at various locations throughout the construction site. The RFID system was integrated with the company’s construction management software, which allowed real-time tracking and monitoring of the materials and equipment. The deployment of the RFID system helped Skanska USA to improve efficiency, reduce costs, and improve safety during the construction of the power plant.

Bechtel Corporation has utilized RFID systems in the power generation construction project in the USA, which involved the construction of a new power plant. The project required the management of a large number of assets, including turbines, hammers, saws, graders, and heavy equipment like pavers, cranes, and power generators, and vehicles, across a vast construction site. Bechtel Corporation implemented an RFID-based asset tracking system to address the challenges of managing assets on the construction site. The solution involved the use of RFID tags attached to assets, and readers installed at various locations across the site. The tags emitted a radio frequency signal that was picked up by the readers, and the data was transmitted to a central database, where it could be accessed by authorized personnel. The use of RFID technology has enabled Bechtel Corporation to improve its construction processes and deliver projects more efficiently, leading to increased customer satisfaction and a competitive advantage in the industry.

GAO Has Served the Power Generation Construction Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the power generation construction industry, including its various divisions such as

- Fossil fuel power generation: It involves the construction of power plants that use fossil fuels such as coal, oil, or gas to generate electricity.

- Renewable energy power generation: It involves the construction of power plants that use renewable energy sources such as wind, solar, hydro, or geothermal.

- Transmission and distribution: It involves the construction of infrastructure such as transmission lines and distribution networks.

- Energy storage: It involves the construction of facilities that store energy for later use, such as batteries or pumped hydro storage.

- Energy efficiency: It involves the construction of buildings and infrastructure that are designed to use energy more efficiently.

Some of the leading companies in the power generation construction industry in the US:

Some of the leading companies in the power generation construction industry in Canada: