Painting and finishing in construction refer to the application of paint and other coatings to surfaces such as walls, ceilings, floors, and furniture, to enhance their appearance, protect them from damage, and add durability. This involves preparing surfaces, selecting appropriate paints or coatings, applying them with techniques such as brushing, rolling, or spraying, and ensuring a smooth, even, and professional finish.

GAO RFID Inc. a global top 10 leader in RFID technology based in the cities of New York and Toronto, has extensive experience serving companies in Painting and Finishing.

GAO RFID Systems & Hardware for Painting and Finishing

GAO RFID technology can help in the painting and finishing projects by providing real-time tracking and monitoring of assets and resources, enhancing safety and security measures, and streamlining project workflows.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

- IP67 Rated BLE 2.45GHz Active RFID Wristband Tag w/ Panic Button

- BLE 2.45GHz Ultra Rugged Active RFID Pallet Tag/Beacon

- BLE 2.45GHz Active RFID Asset Tag/Beacon

GAO’s BLE technology is suitable for all kinds of industries, including the power generation construction industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the power generation construction industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the power generation construction industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the power generation construction industry:

- 134.2KHz ISO11784/5 FDX RFID Plug and Play Portable Reader

- 134.2 kHz LF Long Range Fixed RFID Reader

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the power generation construction industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the power generation construction industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

- GAO RFID Heavy Duty Machinery Asset Management System

- Tool & Industrial Equipment Tracking System

- Asset Tracking Software

- GAO RFID Construction and Industrial Machinery Rental Asset Management System

Personnel or people access control system:

Parking or vehicle control system:

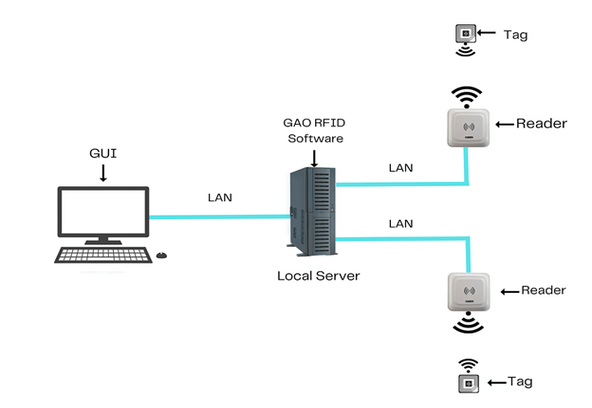

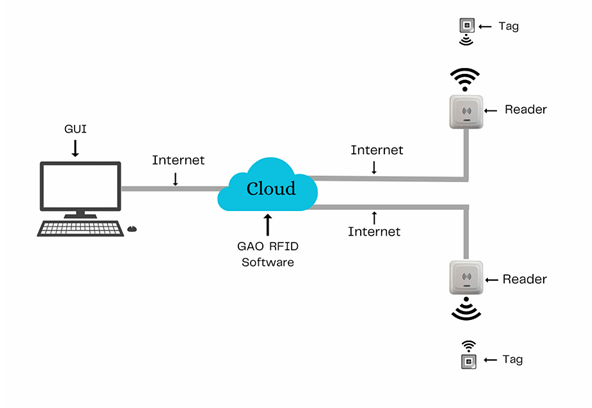

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO offers free samples of its RFID tags, labels, badges, and wristbands

GAO offers a free trial for all of its software available.

Application and Benefits of GAO’s RFID, BLE, IOT & Drone for the Painting and Finishing

GAO’s RFID, Bluetooth Low Energy (BLE) and drone Painting and Finishing all have unique benefits that can help to enhance different aspects of modern life. Here are some of the benefits of each technology:

Application and Benefits of applying RFID

- Improved inventory management: GAO RFID can be used to track and manage the use of paint and other finishing materials. By using RFID tags and readers, it’s possible to automatically track the quantity of materials used, which helps prevent waste and ensures that the necessary supplies are always on hand.

- Enhanced quality control: GAO RFID can also be used to ensure that the right materials are used in the right way during painting and finishing processes. By tagging paint cans and other materials.

- Increased Accomplishment: GAO RFID to automate and streamline various aspects of the painting and finishing process, it’s possible to increase overall efficiency. This can include everything from automating inventory management to using RFID-enabled tools and equipment that help speed up the application process. The result is a more efficient, cost-effective, and consistent process that delivers high-quality results.

Application and Benefits of applying Bluetooth Low Energy (BLE)

- Wireless Control: GAO BLE can be used to create a wireless control system for painting and finishing tools, such as sprayers, sanders, or brushes. This allows workers to control the tools from a distance, which can improve safety and ergonomics.

- Real-time Monitoring: GAO BLE can also be used to monitor various aspects of the painting and finishing process in real-time, such as temperature, humidity, or pressure. This allows workers to make adjustments or corrections as needed, which can help ensure a high-quality finish and reduce the risk of errors or defects.

Application and Benefits of applying Drones

- Improved Safety: GAO Drones can be used to perform painting and finishing tasks in hard-to-reach or dangerous areas, such as high ceilings, tall buildings, or bridges. This eliminates the need for workers to perform these tasks at heights or in hazardous conditions

- Enhanced Efficiency: GAO Drones can cover large areas quickly and efficiently, which can help reduce the time and effort required to complete painting and finishing tasks. This can also help increase productivity and reduce costs, as fewer workers and resources may be needed to complete the work. Drones can also be equipped with sensors and cameras that can provide real-time data on the progress of the work.

- Better Viewing Angle: The use of GAO drones in painting and finishing in construction offers several viewing angle benefits. Drones equipped with high-resolution cameras can capture images and videos from various angles and heights, providing a unique perspective that is otherwise difficult to achieve. This allows for thorough inspections of large or hard-to-reach areas, identification of surface imperfections or coating inconsistencies, and precise planning of painting and finishing tasks

Application and Benefits of applying IOT with RFID

- Real-time Asset Tracking and Inventory Management: By combining IoT (Internet of Things) with RFID technology in painting and finishing processes, businesses can gain real-time visibility into the location and status of assets, such as raw materials, work-in-progress (WIP) items, and finished goods. This allows for accurate tracking and management of assets throughout the painting and finishing processes, reducing inventory errors, improving process efficiency, and minimizing production delays.

- Automated Process Monitoring and Control: IoT-enabled RFID systems can provide automated monitoring and control of painting and finishing processes, ensuring consistent quality and reducing human error. Sensors embedded in assets or equipment can collect data, such as temperature, humidity, and air quality, and transmit it to a central system for analysis. This data can be used to optimize process parameters, trigger alerts for deviations, and enable timely corrective actions, resulting in improved process control and product quality.

- Enhanced Product Traceability and Compliance: IoT-enabled RFID systems can enhance product traceability and compliance in painting and finishing processes. RFID tags with unique identifiers can be attached to products, allowing them to be tracked and traced throughout the supply chain and production process. This can help businesses meet regulatory requirements, such as product labeling, authentication, and recall management. Additionally, IoT-enabled RFID systems can provide automated documentation and reporting, reducing paperwork and ensuring compliance with industry standards and customer requirements.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Painting and Finishing

GAO RFID Inc. has helped many companies in the Painting and Finishing to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

- OSHA Standard 1926.62: This standard regulates worker exposure to hazardous materials, including lead, which is commonly found in old paint.

- EPA Renovation, Repair, and Painting (RRP) Rule: This rule requires contractors who work on pre-1978 homes and child-occupied facilities to follow lead-safe work practices.

- ASTM International Standards: ASTM International sets standards for a variety of construction materials, including paint and coatings. Standards related to painting and finishing include ASTM D3273, which tests mold resistance of paints, and ASTM D3730, which establishes standards for evaluating the durability and performance of coatings.

- National Institute of Standards and Technology (NIST): NIST publishes standards related to construction materials, including paint and coatings. These standards cover areas such as adhesion, abrasion resistance, and color stability.

- International Building Code (IBC): The IBC sets minimum requirements for building safety and performance. It includes requirements related to fire resistance of coatings and finishes.

- American Disabilities Act (ADA): The ADA requires that certain areas of buildings be accessible to people with disabilities. This includes requirements related to the color and texture of floor finishes to help people with visual impairments navigate.

GAO’s Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking. access control, parking system control offers a free trial and offers an API to each of the common software in the Painting and Finishing.

-

Personnel Management:

- Employee Information

- Time and Attendance

- Payroll Management

- Performance Management

Equipment Management:

- Equipment Inventory

- Equipment Maintenance

- Equipment Utilization

- Equipment Tracking

Supply Chain Management:

- Supplier Management

- Logistics Management

- Purchase Management

- Inventory Management

Other Application for insulation construction:

- Color matching and recommendation

- Surface preparation and treatment

- Paint calculation

- Quality control

Case Studies of RFID Applications

Here are two cases of applying RFID in the power generation industry:

A company that produces specialty coatings for the aerospace industry implemented an RFID-based solution for automated paint mixing. The system consisted of RFID tags on paint containers and a reader at the mixing station. When a paint container was placed on the mixing station, the RFID reader automatically identified the paint type and provided the correct mixing ratios and instructions to the operator. The system ensured accurate mixing, reduced waste, and improved inventory management.

A manufacturer of automotive parts implemented an RFID-based solution for quality control in its painting and finishing process. The system consisted of RFID tags on parts and readers at various points in the process. As a part moved through the process, the RFID readers recorded data on its location, the type of coating applied, and other relevant information. The data was collected and analyzed in real-time to identify any defects or issues with the process. The system helped improve quality control, reduce waste, and increase efficiency.

GAO Has Served the Painting and Finishing Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the Painting and Finishing, including its various divisions such as GAO has applied its RFID, BLE, drone and IOT technologies to help its clients in the Painting and Finishing.

-

- Residential Painting: This includes painting and finishing services for single-family homes, apartments, and other residential properties.

- Industrial Painting: This includes painting and finishing services for industrial facilities, such as factories, warehouses, and refineries.

- Marine Painting: This includes painting and finishing services for boats, ships, and other marine vessels.

- Surface Coatings: This includes the application of coatings to various surfaces for protection, durability, and aesthetic purposes, such as epoxy coatings, anti-corrosion coatings, and other specialized coatings.

- Aerospace Painting: This includes painting and finishing services for aircraft, spacecraft, and other aerospace vehicles.

Some of the leading companies in Painting and Finishing in the US:

Some of the leading companies in the Painting and Finishing in Canada: