Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Adhesives and Sealants Manufacturing

GAO’s Assists Clients with Standards, Mandates & Regulations of Adhesives and Sealants Manufacturing

Case Studies of RFID Applications

GAO RFID Systems & Hardware for Adhesives and Sealants Manufacturing

GAO Has Served Adhesives and Sealants Manufacturing Extensively

Overview

Adhesive and sealants manufacturing industry produces a wide range of products used for bonding and sealing applications in various sectors. Adhesives are substances used to join two or more surfaces together, while sealants are used to create a barrier or fill gaps to prevent leakage or the ingress of air, water, or contaminants.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in adhesives and sealants manufacturing to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as reactors, mixers and agitators, dispensing Systems, filtration systems, heating and cooling Systems, storage tanks.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for adhesives and sealants manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Adhesives and Sealants Manufacturing

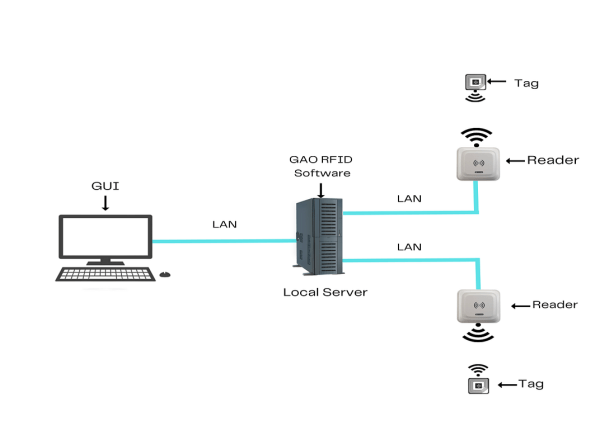

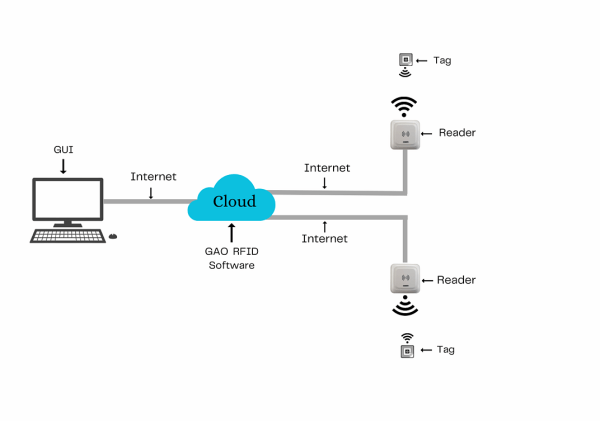

To satisfy its customers, GAO’s RFID or RFID Systems for adhesives and sealants manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for adhesives and sealants manufacturing with its software running on a local server.

The above illustrates GAO system for adhesives and sealants manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in adhesives and sealants manufacturing industry:

- Raw Material Tracking: GAO RFID solutions enable the tracking of raw materials used in the production of adhesives and sealants. By affixing RFID tags to material containers, drums, or tanks, manufacturers can automate the identification and tracking of incoming raw materials, ensuring accurate inventory control and streamlining the material handling process.

- Batch Production Control: Our RFID technology facilitates precise batch production control in the adhesives and sealants manufacturing industry. RFID tags can be integrated into batches or containers to record essential data, such as production dates, chemical compositions, and manufacturing processes. This enables automated batch identification and helps ensure consistent product quality.

- Equipment Maintenance and Calibration: GAO RFID’s solutions assist in tracking the maintenance and calibration schedules of unique equipment used in the adhesives and sealants manufacturing process. RFID tags attached to machinery and tools help record maintenance history, usage data, and calibration status, optimizing equipment performance and minimizing downtime.

- Worker Safety and Compliance: RFID technology enhances worker safety in the adhesives and sealants manufacturing industry. RFID-enabled identification badges can be issued to workers, allowing automated access control and ensuring that only authorized personnel can access certain hazardous areas or equipment.

- Quality Assurance and Traceability: RFID tags applied to finished products enable seamless quality assurance and traceability throughout the adhesives and sealants manufacturing process. RFID technology allows for real-time tracking of products, recording production data, and facilitating easy access to product information for quality control inspections and regulatory compliance.

- Inventory Management and Replenishment: GAO RFID’s inventory management solutions optimize stock control in the adhesives and sealants manufacturing industry. RFID tags on finished products or containers allow manufacturers to monitor inventory levels accurately and trigger automated replenishment processes, ensuring timely restocking and preventing stockouts.

GAO’s drone technologies find the following applications in the adhesives and sealants manufacturing industry:

- Facility Inspection and Maintenance: GAO’s drones can be deployed for facility inspections in adhesives and sealants manufacturing plants. Drones equipped with cameras and sensors can perform aerial inspections of roofs, chimneys, and other hard-to-reach areas, identifying potential maintenance needs and ensuring the structural integrity of the facility.

- Inventory Management and Warehouse Surveillance: Drones can aid in inventory management within the adhesives and sealants manufacturing industry. By using drones equipped with RFID readers from GAO RFID, manufacturers can perform aerial scans of warehouse shelves and storage areas, ensuring accurate stock levels and reducing the need for manual inventory checks.

- Environmental Monitoring: In the adhesives and sealants manufacturing process, environmental monitoring is crucial. Drones can be used to monitor air quality, water sources, and other environmental factors around manufacturing facilities. GAO’s drones can carry specialized sensors to detect and analyze pollutants, ensuring compliance with environmental regulations.

- Equipment and Machinery Inspection: Drones equipped with visual and thermal imaging cameras can be utilized to inspect equipment and machinery in the adhesives and sealants manufacturing industry. This can help identify potential defects, overheating, or malfunctions, allowing for proactive maintenance and minimizing downtime.

- Safety Compliance and Emergency Response: GAO’s drones can support safety compliance efforts in adhesives and sealants manufacturing plants. Aerial surveillance of work areas can be used to detect safety hazards and ensure adherence to safety protocols. In case of emergencies, drones equipped with emergency supplies can quickly reach workers in need, improving emergency response times.

- Quality Control and Product Testing: Drones can be employed to assess product quality in adhesives and sealants manufacturing. Drones equipped with sensors can scan and analyze finished products, ensuring conformity to specifications and identifying any defects or irregularities.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the adhesives and sealants manufacturing industry:

- Condition Monitoring of Mixing Equipment: GAO’s IoT solutions can be applied to monitor and collect real-time data from mixing equipment used in the adhesives and sealants manufacturing process. Sensors attached to mixers can track parameters such as temperature, pressure, and RPM, ensuring optimal mixing conditions and early detection of equipment malfunctions or maintenance needs.

- Smart Sensors for Quality Control: IoT-enabled smart sensors can be integrated into the production line of adhesives and sealants. These sensors can measure viscosity, density, and curing rates, providing valuable data to maintain consistent product quality. GAO’s IoT technology ensures continuous monitoring and instant adjustments during production.

- Predictive Maintenance of Production Machinery: GAO’s IoT solutions enable predictive maintenance of critical production machinery used in the adhesives and sealants manufacturing industry. By analyzing sensor data from equipment, manufacturers can identify patterns of wear and predict maintenance requirements, minimizing unexpected breakdowns and optimizing equipment uptime.

- Remote Monitoring of Production Facilities: In the adhesives and sealants manufacturing industry, remote production facilities may require continuous monitoring. GAO’s IoT systems enable remote monitoring of equipment, environmental conditions, and product quality. This provides real-time insights, allowing manufacturers to make data-driven decisions and ensure consistent production outcomes.

- Supply Chain Visibility: Implementing IoT in the adhesives and sealants manufacturing industry provides end-to-end visibility in the supply chain. IoT-enabled sensors can track the movement of raw materials, intermediate products, and finished goods from suppliers to production facilities and distribution centers. This ensures efficient inventory management and timely replenishment.

- Environmental and Safety Compliance: IoT-based environmental sensors can be used to monitor air quality, temperature, and humidity within manufacturing facilities. GAO’s IoT solutions enable manufacturers to maintain compliance with environmental regulations and ensure a safe working environment for employees.

GAO’s Assists Clients with Standards, Mandates & Regulations of Adhesives and Sealants Manufacturing

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in adhesives and sealants manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- ASTM F3322

- ISO 22927-1

- ISO 22927-2

- MQTT

- CoAP

- OPC UA

- Bluetooth SIG Specification v5.2

- Bluetooth SIG Profile for Adhesives and Sealants Manufacturing

- ISO 18000-6C

- ISO 18000-6B

- EPCglobal Class 1 Generation 2

US Government Regulations

- Environmental Protection Agency (EPA) Regulations

- Federal Trade Commission (FTC) Regulations

- Hazard Communication Standard (HCS)

Canadian Government Regulations

- Canadian Environmental Protection Act, 1999 (CEPA)

- Transportation of Dangerous Goods Act, 1992 (TDGA

- Workplace Hazardous Materials Information System (WHMIS)

- Health Canada’s Consumer Chemicals and Containers Regulations (CCCR)

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in adhesives and sealants manufacturing such as:

Personnel Management:

-

- Employee scheduling and shift management

- Time and attendance tracking

- Performance management and appraisal

- Training and development management

- Workforce planning and optimization

- Payroll management

Equipment Management:

-

- Asset tracking and maintenance

- Equipment calibration and certification

- Predictive maintenance and condition monitoring

- Equipment utilization and downtime analysis

- Spare parts inventory management

- Energy management and optimization

Access Control:

-

- Visitor management and access control systems

- Identity verification and authentication

- Security surveillance and monitoring

- Access rights and permissions management

- Intrusion detection and alarm systems

- Emergency response and evacuation planning

Warehouse Management:

-

- Inventory tracking and control

- Receiving and putaway management

- Order picking and packing optimization

- Storage space optimization

- Cross-docking and transportation management

- Real-time visibility and reporting

Supply Chain Management:

-

- Demand forecasting and planning

- Supplier relationship management

- Procurement and purchase order management

- Production scheduling and optimization

- Distribution and logistics management

- Supply chain analytics and performance measurement

Other Applications:

-

- Quality management and control

- Regulatory compliance and documentation

- Batch and lot tracking

- Environmental health and safety management

- Research and development management

- Sales and customer relationship management

GAO has enabled its customers to make use of some of leading software and cloud services in adhesives and sealants manufacturing. Below are some of popular software and cloud services in adhesives and sealants manufacturing SAP ERP, Oracle E-Business Suite, Microsoft Dynamics 365, IBM Maximo, Infor EAM, Fiix CMMS, Plex Supply Chain Management, 3PL Warehouse Manager, Ramco Supply Chain Management, Alibaba Cloud, Cisco Meraki, and JDA Software.

GAO has worked with some of the leading technology companies in adhesives and sealants manufacturing industry to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in adhesives and sealants manufacturing industry Amazon Web Services (AWS), Microsoft Azure, Minitab, Siemens Opcenter Execution, Dassault Systèmes DELMIA, DigitalOcean, Siemens MindSphere, ProcessPro ERP, Epicor ERP, IQMS MES, ABB Ability Manufacturing Operations Management (MOM), and Sage X3.

Case Studies of RFID Applications

Below are some RFID application cases in adhesives and sealants manufacturing:

Reynolds decided to evaluate how UHF RFID could solve this problem. As a result, Avery Dennison integrated an automatic tracking system including UHF RFID labels and an overhead UHF RFID reader placed at exit and entry points, providing a solution. The main goal was to increase inventory accuracy. This was achieved by providing each tray with an UHF RFID tag as an identifier, which is then read by Reynolds when it leaves for a delivery, and is then read again when it is returned empty.

The case study shows that RFID technology holds many promises for improving manufacturing processes while also exhibiting new challenges. The automation of object identification processes through RFID can help to increase the efficiency by reducing scan times and manual work, reduce errors due to manual data entry and analysis, and improve product tracking and tracing. Detailed data tracks can help increasing product quality and narrowing the extent of necessary product recalls.

RFID systems have proved to optimize logistics, warehousing and transportation activities. Conventionally, all these activities involved a certain amount of time in inspection, identification and documentation which was carried out by human force. All this causes a hindrance into the flow of goods and services in terms of time. RFID can greatly eliminate these hindrances by automating the entire manual process involved. It provides benefits such as reduced time and labor involvement and increased visibility.

In this study, an RFID system was developed to share real-time inventory information and to prevent sequencing errors, which are a type of wrong delivery: they are tremendously important issues in the automotive supply chain process. An RFID system was developed based on an RFID standard information infrastructure called the EPCglobal network, and the standard system helps flexible information sharing between companies, fast system extension, and flexible responses to vendor replacements.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in adhesives and sealants manufacturing industry.

3M is a multinational conglomerate that has utilized IoT technology in its adhesives and sealants manufacturing processes. They have implemented IoT sensors to monitor production equipment and collect real-time data for predictive maintenance, improving equipment reliability and reducing downtime.

Henkel Corporation, a global leader in adhesives technologies, has incorporated IoT solutions to enhance their adhesive manufacturing operations. They have implemented smart sensors to monitor critical process variables, enabling real-time adjustments and ensuring consistent product quality.

Sika Canada Inc. is a major player in the adhesives and sealants industry, and they have integrated IoT technology in their Canadian manufacturing facilities. They use IoT-enabled sensors to monitor equipment performance, energy consumption, and environmental conditions, optimizing production efficiency and sustainability.

DAP Products Inc., a leading manufacturer of sealants and adhesives, has implemented IoT solutions in their Canadian manufacturing plants. By using IoT sensors, they can remotely monitor their production facilities, track inventory movement, and ensure compliance with safety and quality standards.

Case Studies of Drone Applications

Below are some drone application cases in adhesives and sealants manufacturing industry.

ABC Adhesives, a major manufacturer in the USA, implemented drones equipped with thermal imaging cameras for facility inspections. The drones performed routine inspections of their production facilities, identifying heat anomalies in machinery and potential leaks in storage tanks. This proactive approach to maintenance helped prevent costly breakdowns and ensured optimal equipment performance.

XYZ Sealants, a leading sealants manufacturer, employed drones to assist with inventory management. Drones equipped with RFID readers conducted aerial scans of their warehouse to track and monitor pallets of finished products. The real-time data collected by the drones enabled XYZ Sealants to optimize their inventory levels, reducing excess stock and minimizing inventory carrying costs.

Canadian Adhesive Technologies used drones equipped with high-resolution cameras to inspect their large outdoor storage areas. By regularly flying the drones over their outdoor chemical storage yards, they could detect and address any signs of product degradation or potential environmental risks. This helped maintain product quality and ensured compliance with environmental regulations.

Maple Sealants utilized drones with LIDAR technology to perform aerial surveys of their manufacturing facilities. The LIDAR-equipped drones captured detailed 3D maps of the production site, enabling Maple Sealants to optimize their layout and identify potential areas for process improvement. This data-driven approach resulted in increased operational efficiency and reduced production bottlenecks.

GAO RFID Systems & Hardware for Adhesives and Sealants Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including adhesives and sealants manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the adhesives and sealants manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including adhesives and sealants manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including adhesives and sealants manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including adhesives and sealants manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including adhesives and sealants manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

The RFID systems by GAO are highly popular for clients in adhesives and sealants manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Mixing Tanks: Large containers used for blending raw materials together to form adhesive or sealant formulations.

- Reactors: Specialized vessels designed for chemical reactions required during the production of certain adhesives and sealants.

- Dispensing Systems: Equipment used to accurately measure and dispense adhesive or sealant formulations.

- High-Speed Mixers: Powerful mixers that provide thorough mixing and dispersion of raw materials, additives, and fillers.

- Extruders: Machinery used to process adhesive or sealant formulations into desired shapes.

- Vacuum Chambers: Used for degassing or removing air bubbles from adhesive or sealant formulations.

- Filling Machines: Equipment designed for filling adhesive or sealant products into containers, such as tubes, cartridges, bottles, or drums.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served Adhesives and Sealants Manufacturing Extensively

GAO’s products and technologies have helped its customers in adhesives and sealants manufacturing industry to achieve success in green adhesives, high-performance bonding, hybrid adhesives, lightweight materials bonding, miniaturization and microelectronics, bio-based adhesives, smart adhesives.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in adhesives and sealants manufacturing, including many in its various divisions such as:

- Acrylic Adhesives and Sealants: This division focuses on the production of adhesives and sealants based on acrylic polymers.

- Epoxy Adhesives and Sealants: Epoxy-based products are widely used in construction, automotive, aerospace, and other industries where strong and durable bonds are required.

- Polyurethane Adhesives and Sealants: Polyurethane-based products are known for their excellent adhesion, flexibility, and resistance to moisture and chemicals.

- Silicone Adhesives and Sealants: Silicone-based adhesives and sealants are widely used in applications that require high-temperature resistance, electrical insulation, and excellent weatherability.

- Hot Melt Adhesives: Hot melt adhesives are solid at room temperature but become liquid when heated.

- Pressure-Sensitive Adhesives: Pressure-sensitive adhesives (PSAs) are tacky at room temperature and adhere to surfaces upon application of slight pressure.

- Construction Adhesives and Sealants: This division specializes in the production of adhesives and sealants specifically designed for construction applications.

- Henkel AG & Co. KGaA: A multinational chemical and consumer goods company based in Germany. Henkel operates in three main business areas: Adhesive Technologies, Beauty Care, and Laundry & Home Care. They provide a wide range of adhesive products for various industries, including construction, automotive, and electronics.

- 3M Company: An American multinational conglomerate known for its innovation in various industries. 3M manufactures a wide array of products, including adhesives, abrasives, and consumer goods. They offer adhesives and tapes for construction, electronics, and healthcare applications.

- B. Fuller Company: A global adhesives provider headquartered in the United States. H.B. Fuller offers adhesives, sealants, and other specialty chemicals for packaging, construction, woodworking, and other industries.

- Dow Chemical Company: An American multinational chemical corporation that produces a wide range of chemical products, including adhesives and coatings for construction, automotive, and industrial applications.

- Avery Dennison Corporation: An American company specializing in materials science and manufacturing. Avery Dennison produces adhesive materials and labels used in various industries, including construction, packaging, and graphics.

- Sika AG Group: A Swiss multinational specialty chemicals company that produces adhesives, sealants, and coatings for construction and industrial applications.

- Ashland Inc.: An American specialty chemicals company that offers a variety of products, including adhesives and coatings used in construction, transportation, and other industries.

- Bostik SA Group: A global adhesives company headquartered in France. Bostik provides adhesive solutions for the construction, automotive, aerospace, and consumer goods industries.

- RPM International Inc.: An American multinational holding company that owns subsidiaries specializing in various coatings, sealants, and adhesives products.

- Huntsman Corporation: An American multinational manufacturer and marketer of chemical products, including adhesives and sealants used in construction, aerospace, and automotive industries.

- Illinois Tool Works Inc. (ITW): An American multinational industrial company that manufactures a wide range of products, including adhesives and sealants for the construction and automotive sectors.

- LORD Corporation: An American company that develops and manufactures adhesives, coatings, and vibration control technologies for various industries, including aerospace, automotive, and construction.

- PPG Industries, Inc.: An American global supplier of paints, coatings, and specialty materials, including adhesives for automotive, construction, and industrial applications.

- Wacker Chemie AG Group: A German chemical company that produces adhesives, silicones, and sealants used in construction, electronics, and medical applications.

- Mapei Corporation: An Italian multinational company specializing in adhesives, sealants, and chemical products for the construction industry.

- Franklin International Corporation: An American manufacturer of adhesives, sealants, and coatings used in woodworking, construction, and other industries.

- DAP Products Inc.: An American company that manufactures and distributes adhesives, sealants, and related products for various construction and repair applications.

- Chemtech Inc.: A Canadian company that offers industrial adhesives, sealants, and specialty chemicals for the automotive, construction, and manufacturing sectors.

- The Gluefast Company, Inc.: An American manufacturer of adhesive application equipment and glue products for various industries, including packaging and construction.

- Parson Adhesives Canada Inc.: A Canadian company specializing in the development and distribution of adhesives and sealants for the construction and industrial sectors.

- Permabond Engineering Adhesives Inc.: A Canadian company that manufactures and supplies engineering adhesives and sealants for industrial applications, including construction and manufacturing.

- Canrep Inc.: A Canadian company that provides adhesives, tapes, and other specialty products for the automotive, construction, and industrial markets.

- RS Industrial Canada Inc.: A Canadian supplier of industrial adhesives, sealants, and tapes used in various industries, including construction and automotive.

- Master Bond Inc.: An American manufacturer of high-performance adhesives, sealants, and coatings for aerospace, electronics, and other advanced industries.

Here are some of the leading companies in adhesives and sealants manufacturing:

HenkelAG & Co.KGaA

3M Company

H.B.FullerCompany

Dow Chemical Company

Avery Dennison Corporation

Sika AG Group

Ashland Inc.

Bostik SA Group

RPM International Inc.

Huntsman Corporation

Illinois Tool Works Inc.

LORD Corporation

PPG Industries, Inc.

Wacker Chemie AG Group

Mapei Corporation

Franklin International Corporation

DAP Products Inc.

Chemtech Inc.

The Gluefast Company, Inc.

The Gluefast Company, Inc.

Parson Adhesives Canada Inc.

Permabond Engineering Adhesives Inc.

Canrep Inc.

RS Industrial Canada Inc.

Master Bond Inc.