RFID technology is a vital tool to tracking your parts, equipment, tools and so much more. Whether you are a automotive assembly line, parts manufacturer, automotive repair garage or dealer / used car dealer, RFID can track assets, inventory, permit access throughout your facility, permit parking and even track your employees onsite in your premises.

What Can RFID Do?

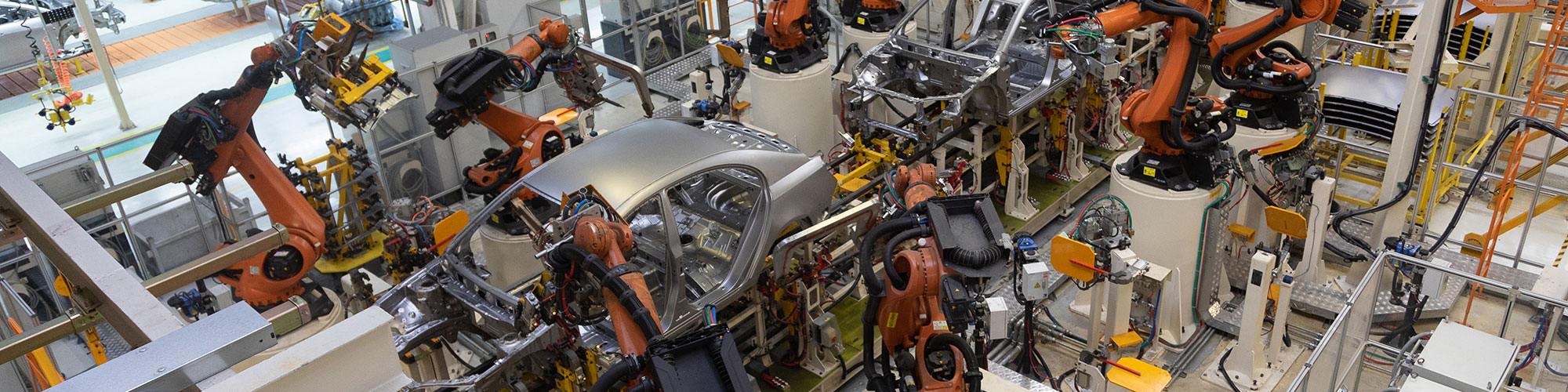

In large manufacturing facilities you can track every part, every tool and with WIP RFID your items as they go down the assembly line. Tracking is simple and is completed simply by an employee moving about the premises with a handheld RFID reader which reads the tags that are mounted on every item you wish to tag. It reads it simply by being in proximity to the tag and does not have to read the tag directly like barcodes do. It sends that information to cloud based software that then automatically records which item is where and how many items are there. It can also track employees through out the facility and provide access to only the areas they should have access to. This helps improve safety and security.

In car dealers and automotive sales lots you can track your inventory in the same was as someone goes through the parking lot with a handheld RFID reader. It can also provide parking access into the lot and employee access to the parts of the building they should have access to. It can also track the other important assets to the company such as promotional materials, office equipment, computer and POS equipment and more.

For automotive repair / repair garages, it can track all your tools, parts, equipment and other assets that are important to everyday work. It can also provide employee access and ensure only those with permission can access certain parts of the garage.