The avionics manufacturing industry is a sector that produces electronic systems and components used in aircraft, spacecraft, and other aerospace vehicles. These components and systems can include navigation systems, communication systems, flight control systems, and more. Avionics manufacturing companies may also produce components such as sensors, antennas, and displays that are used in various aviation applications.

GAO RFID Inc., a global top 10 RFID leader based in the cities of New York and Toronto, has served many companies in avionics manufacturing.

GAO RFID Systems & Hardware for the Avionics Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the avionics manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

- 3G/4G/LTE/Wi-Fi/Ethernet BLE Active RFID Outdoor Gateway

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

- IP67 Rated BLE 2.45GHz Active RFID Wristband Tag w/ Panic Button

- BLE 2.45GHz Ultra Rugged Active RFID Pallet Tag/Beacon

- BLE 2.45GHz Active RFID Asset Tag/Beacon

GAO’s BLE technology is suitable for all kinds of industries, including the avionics manufacturing industry

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the avionics manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the avionics manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the avionics manufacturing industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the avionics manufacturing industry

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the avionics manufacturing industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

- GAO RFID Heavy Duty Machinery Asset Management System

- GAO RFID Construction and Industrial Machinery Rental Asset Management System

- Tools and industrial equipment tracking system

- asset tracking software

Personnel or people access control system:

Parking or vehicle control system:

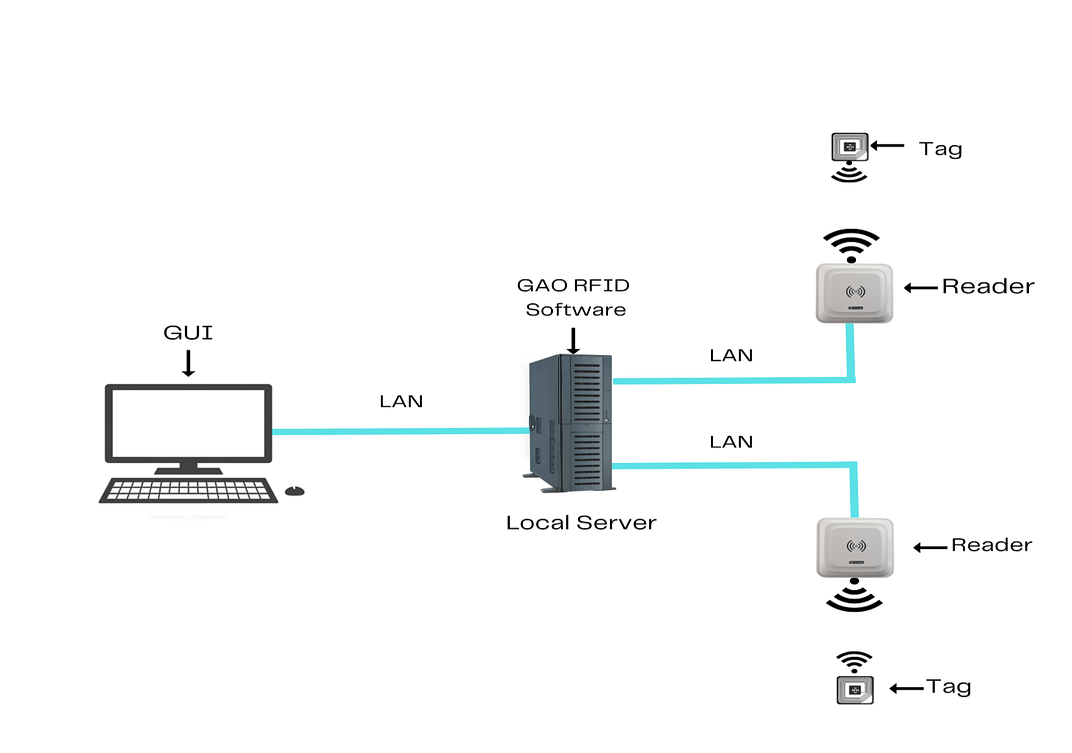

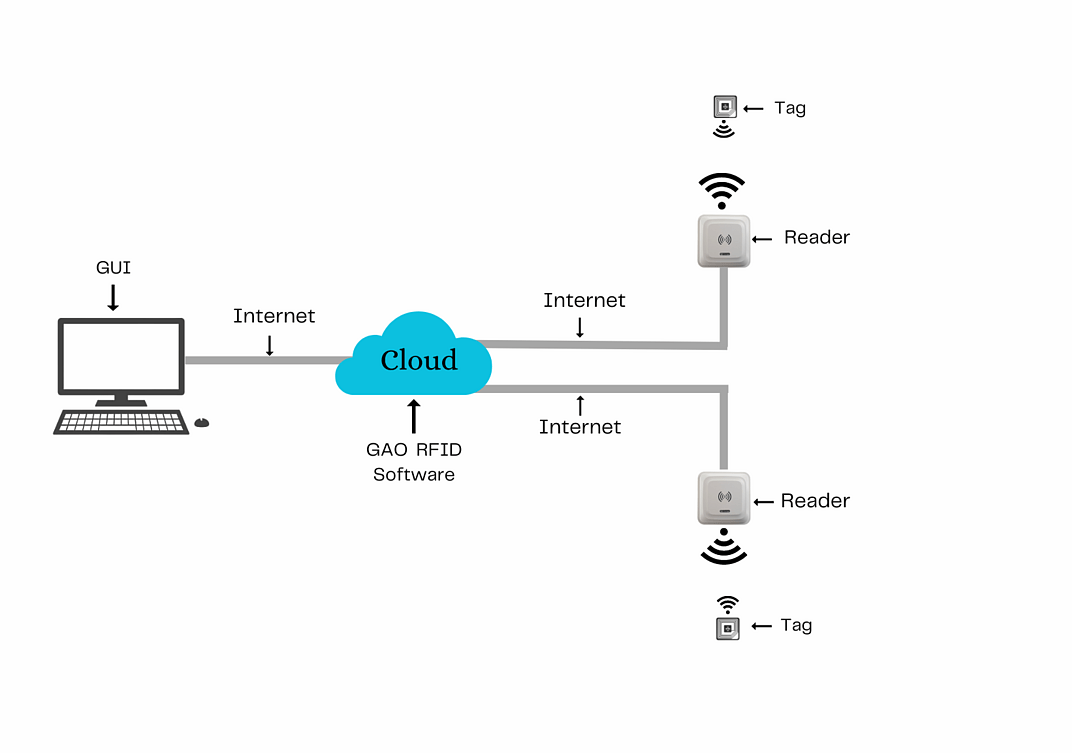

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO’s software runs on a local server.

GAO’s software runs on a local server.

GAO’s software runs in the cloud.

GAO’s software runs in the cloud.

Application & Benefits of GAO’s RFID, BLE, IoT & Drone for Avionics Manufacturing

GAO’s RFID, BLE, IoT, and drones technologies provide many benefits for avionics manufacturing:

Applications & Benefits of applying RFID to avionics manufacturing

- Asset tracking: GAO RFID tags can be used to track components, tools, and equipment like turbojet, turbofan, turboprop, seats etc. throughout the manufacturing process, making it easier to locate and manage these items.

- Inventory management: Our RFID can help track inventory levels like raw materials, work-in-progress, finished goods, JIT etc. allowing manufacturers to automate, reduce manual errors, and optimize the use of resources.

- Improved quality control: GAO’s RFID can be used to track and monitor the production process, enabling manufacturers to identify potential defects and quality issues in real-time, thereby reducing errors and improving product quality.

Applications & Benefits of applying BLE to avionics manufacturing

- Indoor positioning: GAO’s BLE technology can be used to create an indoor positioning system, enabling manufacturers to track the location of personnel and assets like flight simulators, test benches, assembly lines, robots etc. in real-time.

- Enhanced productivity: Our BLE can help streamline and automate various manufacturing processes, leading to increased productivity and efficiency in the manufacturing process.

- Supply chain visibility: GAO BLE can help manufacturers gain visibility into their supply chain by providing real-time tracking of materials from suppliers to the manufacturing facility, enabling them to identify potential delays and take appropriate action.

Applications & Benefits of applying a combination of RFID and drones to avionics manufacturing

- Reduced downtime: Drones equipped with GAO RFID readers can be used to quickly locate components and tools like screws, bolts, nuts, and rivets, hence reducing the time and effort required to find these items.

- Safety: The use of drones equipped with our RFID tags can reduce the risk of injury associated with manual inventory management which includes physical counts, stock rotation, material handling and storage, stockroom organization and labelling, etc. and quality control checks.

Applications & Benefits of applying a combination of RFID and IoT to avionics manufacturing

- Improved sustainability: The use of IoT sensors with GAO RFID can help to monitor and optimize energy usage and reduce waste, promoting sustainability and reducing costs.

- Increased security: IoT sensors that employ our RFID technology can be used to track the movement of anyone inside the production facility, including mechanical, electrical, and aeronautical engineers, boosting security and lowering the danger of theft or unauthorized entry. GAO RFID-enabled IoT sensors can monitor environmental variables and spot hazards like fires and gas leaks.

- Predictive maintenance: IoT sensors can be used to monitor the condition of production equipment like CNC machines, testing, soldering, welding, inspection, and calibration equipment, etc. and predict when maintenance is required, reducing downtime and maintenance costs.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Avionics Manufacturing

GAO RFID Inc. has helped many companies in avionics manufacturing to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates, and regulations:

- Federal Aviation Administration (FAA) regulations: The FAA is responsible for regulating the aviation industry, including avionics manufacturing for airworthiness, certification, and safety to ensure that their products meet minimum requirements.

- Radio Technical Commission for Aeronautics (RTCA) standards: The RTCA develops and recommends standards for avionics systems, and customers may choose to comply with these standards.

- International Civil Aviation Organization (ICAO) regulations: The ICAO is a specialized agency of the United Nations that develops and recommends standards and practices for international civil aviation.

- National Institute of Standards and Technology (NIST) cybersecurity guidelines: NIST develops and recommends guidelines for protecting information systems and reducing cyberattacks, including those used in avionics manufacturing.

- Export Administration Regulations (EAR): Customers in the avionics manufacturing industry must comply with EAR regulations related to the export of sensitive technologies to foreign countries to ensure that they are not used for military or other unauthorized purposes.

- Federal Trade Commission (FTC) regulations: The FTC enforces regulations related to consumer protection, including those related to advertising and marketing.

- U.S. Customs and Border Protection (CBP) regulations: Customers in the avionics manufacturing industry must comply with CBP regulations related to the import and export of goods, including customs clearance and documentation requirements.

- Federal Communications Commission (FCC) regulations: The FCC regulates the use of radio frequency devices, and customers in the avionics manufacturing industry must comply with FCC regulations.

- National Aeronautics and Space Administration (NASA) regulations: Customers in the avionics manufacturing industry may need to comply with NASA regulations related to the development and testing of avionics systems for space applications.

Export Administration Regulations

Export Administration Regulations

Federal Trade Commission

Federal Trade Commission

Federal Communications Commission

Federal Communications Commission

Radio Technical Commission for Aeronautics

Radio Technical Commission for Aeronautics

Federal Aviation Administration

Federal Aviation Administration

U.S. Customs and Border Protection

U.S. Customs and Border Protection

GAO’s Software Provides API

GAO’s popular RFID software such as personnel tracking, and asset tracking. access control, parking system control offers a free trial and offers an API to each of the common software in avionics manufacturing:

Personnel Management

- Hiring Process: Recruitment and training of skilled workers, including engineers, technicians, and assemblers.

- Performance management and evaluation: Performance management, including goal setting, feedback, and rewards.

- Succession planning: Ensures continuity of key roles and expertise.

Equipment Management

- Maintenance and repair of machinery and equipment: Maintenance and calibration of production equipment, including CNC machines, test benches, and inspection equipment.

- Replacement of obsolete equipment: Procurement and replacement of equipment to ensure production efficiency and quality.

- Acquisition of new machinery and equipment: Integration of Industry 4.0 technologies such as IoT and AI to improve equipment performance and reliability.

Supply Chain Management

- Raw materials procurement: This involves identifying and sourcing high-quality raw materials from suppliers, negotiating prices, and managing supplier relationships.

- Logistics management and optimization: Logistics management, including transportation and distribution, to ensure timely delivery of products and materials.

- Supplier selection and relationship management: Collaboration with suppliers to optimize supply chain performance and mitigate risks.

Other Applications

- Quality Control: Quality management, including the implementation of quality control and assurance processes to ensure product quality and reliability.

- Research and development of new materials and production techniques: Research and development to create innovative products and technologies that meet customer needs and industry standards.

- Environmental issues: Environmental management to ensure compliance with regulations and reduce the environmental impact of production processes.

Case Studies of RFID Applications

A case study of RFID Application in avionics manufacturing

Gulfstream, a manufacturer of business jets and a subsidiary of General Dynamics, implemented an RFID system to track the movement and inventory of parts and materials in its manufacturing facilities in Savannah, Georgia. The RFID system was integrated with Gulfstream’s manufacturing execution system (MES) to provide real-time visibility into the location and status of parts and materials throughout the production process. The RFID system improved inventory accuracy and reduced the risk of stockouts or overstocking. It also provided data for process improvement and helped to streamline production processes. Gulfstream reported that the RFID system resulted in a 30% reduction in inventory and a 99.9% inventory accuracy rate.

Another case study of RFID application in avionics manufacturing

The company L-3 Communications uses RFID technology in its manufacturing operations to improve inventory management and reduce production time. L-3 Communications produces a variety of avionics components, including communication systems, navigation equipment, and cockpit displays. It has implemented an RFID-based solution to track the movement of parts and tools throughout the manufacturing process. RFID tags are attached to each part, and they contain important information such as the part number, supplier, and manufacturing location. This real-time visibility into inventory levels allowed us to quickly locate parts and tools, reducing production time and increasing efficiency. The company has also reduced inventory costs by minimizing excess stock and ensuring that the right parts are available when needed.

GAO Has Served Avionics Manufacturing Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in avionics manufacturing, including its various divisions such as:

- Avionics Component Manufacturing: RFID technology can be used to track the movement of individual avionics components throughout the manufacturing process, ensuring that the right parts are available when needed.

- Wiring Harness Manufacturing: RFID can be used to track the location of wiring harnesses on the assembly line, helping to improve efficiency and reduce errors.

- Landing Gear Manufacturing: RFID can be used to track the movement of landing gear components and ensure that they are assembled correctly.

- Engine Manufacturing: RFID technology can be used to track the movement of engine components and ensure that they are assembled correctly.

- Aircraft Engine Manufacturing: RFID can be used to track the movement of engine components throughout the manufacturing process, improving quality control and reducing production time.

- Aircraft Interiors Manufacturing: RFID can be used to track the movement of interior components such as seats, lighting, and entertainment systems throughout the manufacturing process, improving inventory management and production efficiency.

- Aircraft Composite Manufacturing: RFID can be used to track the movement of composite materials throughout the manufacturing process, ensuring that the right materials are available when needed and improving production efficiency.

List of the leading companies in the avionics manufacturing industry in the US:

Curtiss-Wright Corporation

Curtiss-Wright Corporation

Thales Avionics Group

Thales Avionics Group

Texas Instruments Incorporated

Texas Instruments Incorporated

Micron Technology, Inc.

Micron Technology, Inc.

Applied Materials, Inc.

Applied Materials, Inc.

Intel Corporation

Intel Corporation

Pratt & Whitney Company Inc.

Pratt & Whitney Company Inc.

Eaton Corporation

Eaton Corporation

Moog Inc.

Moog Inc.

Woodward, Inc.

Woodward, Inc.

Parker-Hannifin Corporation

Parker-Hannifin Corporation

Lockheed Martin Global, Inc.

Lockheed Martin Global, Inc.

General Electric Aviation Inc.

General Electric Aviation Inc.

Northrop Grumman Corporation

Northrop Grumman Corporation

Honeywell International Inc.

Honeywell International Inc.

Collins Aerospace Corporation

Collins Aerospace Corporation

Esterline Technologies Corporation

Esterline Technologies Corporation

List of the leading companies in the avionics manufacturing industry in Canada:

Bombardier Inc.

Bombardier Inc.

Magellan Aerospace Corporation

Magellan Aerospace Corporation

IMP Aerospace & Defence Corporation

IMP Aerospace & Defence Corporation

CAE Inc.

CAE Inc.

FLYHT Aerospace solutions

FLYHT Aerospace solutions

Avcorp Industries Inc.

Avcorp Industries Inc.