Overview

Bridge construction involves building a structure that spans a physical obstacle, such as a river, canyon, or highway. It involves a combination of engineering, planning, design, and construction techniques and materials, such as concrete, and steel. Bridge construction depends on various factors, such as the terrain, load carrying capacity, and budget. This process can take years to complete and involves stages such as site investigation, design, construction, and inspection.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the bridge construction industry to improve their work processes, their operations and productivity by better management of their staff, materials, and operational equipment such as tractors, concrete, excavator, cranes, telescopic handler, skid-steer loader, and steel.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the bridge construction industry.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Bridge Construction

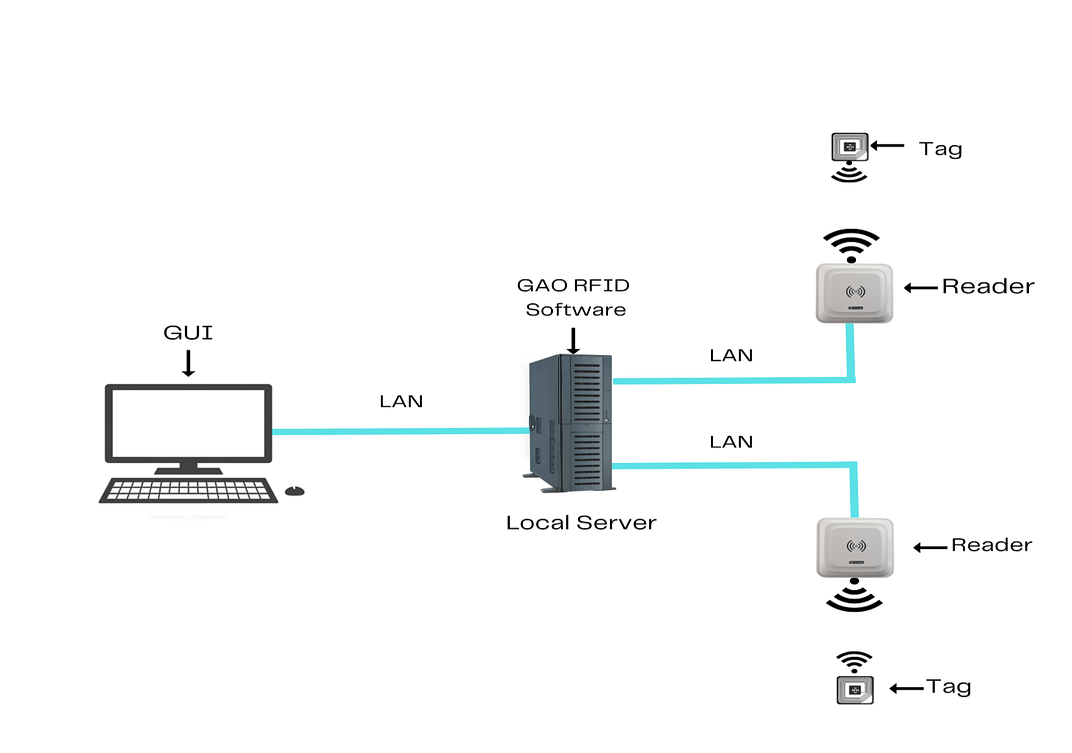

To satisfy its customers, GAO’s RFID or RFID Systems for the bridge construction are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates the GAO system for bridge construction with its software running on a local server.

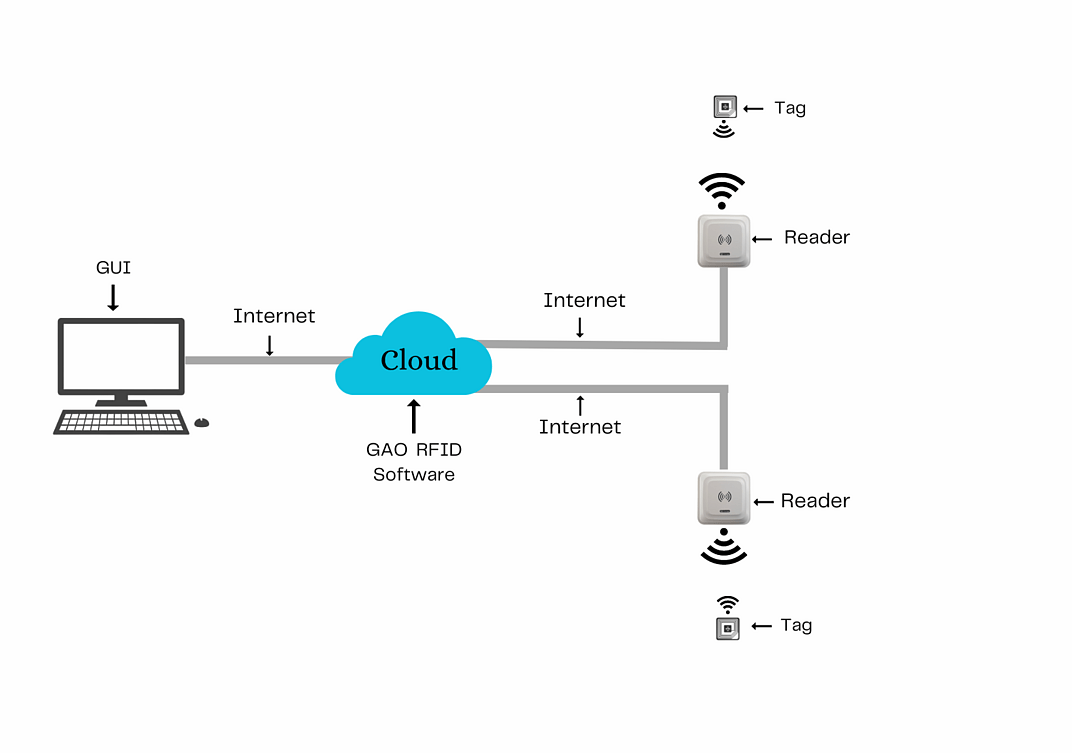

The above illustrates the GAO system for the bridge construction with its software running in cloud.

GAO’s RFID technologies bring the many benefits to the bridge construction industry:

- Workforce Management: GAO’s RFID badges can be issued to workers, enabling automated attendance tracking and access control. This provides accurate records of the workforce presence and improves security by restricting access to authorized personnel only.

- Documentation and Recordkeeping: GAO’s RFID technology can streamline the documentation process by automatically recording and organizing data related to construction materials such as cement, tractors, and steel, equipment such as excavator, backhoe, and skid-steer loader, and inspections.

- Asset Tracking: GAO’s RFID tags can be used to track and manage construction equipment such as skid loaders and telehendlers, tools such rubber, aluminum and iron, and machinery such as dragline excator, graders and wheel tractor scraper.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger workspaces within the bridge construction industry:

- Accuracy and precision: By using GAO’s BLE technology to track materials and equipment such as piles, graders, and bulldozers, construction companies can achieve greater accuracy and precision in project planning and execution.

- Better project management: GAO’s BLE technology can help to streamline project management and coordination, by enabling construction companies to track the progress of work more closely and identify potential delays or problems early on.

- Improved safety: By implementing GAO’s BLE technology, construction site managers can track the location of workers such as engineers, drivers and welders, and equipment like graders and steel ensure that everyone is in the right place at the right time. This can help to prevent accidents and injuries on the job site.

GAO’s RFID and drone technologies are often combined, and such solutions offer the following benefits to the bridge construction industry:

- Enhanced safety: Drones and GAO’s RFID technology can help monitor site activity and detect potential safety violations.

- Communication and collaboration: Drones and GAO’s RFID technology can provide real-time data sharing, allowing all project stakeholders to work in sync and make informed decisions.

- Project documentation: GAO’s RFID and drones can provide high-resolution imagery and data that can be used to create 3D models and maps, providing detailed documentation of the entire project lifecycle.

Here are benefits of IoT technologies to the bridge construction industry:

- Real-time monitoring: IoT devices can be embedded in bridge components, such as sensors for structural health monitoring, to collect real-time data on factors like vibrations, temperature, and stress.

- Efficient resource management: IoT devices can optimize resource utilization by monitoring and managing the consumption of energy, water, and other resources on the construction site.

- Network management: IoT technology allows for monitoring and control of various bridge systems and equipment such as aerial lifts and light towers.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Bridge Construction

GAO RFID Inc. has helped many companies in the bridge construction to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates, and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- EPC global Gen2: This standard defines the air interface protocol for GAO’s RFID tags operating in the ultra-high frequency (UHF) range. It ensures interoperability between different GAO’s RFID systems and facilitates global supply chain management.

- ASTM E2567: This standard provides guidelines for the selection and application of passive GAO’s RFID tags used for tracking and managing construction materials and equipment.

- Bluetooth SIG: Bluetooth Special Interest Group (SIG) is responsible for developing and maintaining Bluetooth standards. These standards define the specifications for Bluetooth technology, including GAO’s BLE, ensuring compatibility and interoperability between devices.

- Transport Canada RPAS Regulations: In Canada, Transport Canada regulates the use of drones under the Remotely Piloted Aircraft Systems (RPAS) regulations. These regulations cover certification, flight restrictions, operational limitations, and safety guidelines for drone operations.

- IEEE 802.15.4: This standard specifies the physical and media access control (MAC) layers for low-rate wireless personal area networks (LR-WPANs). It forms the foundation for various IoT communication protocols.

US. Government Regulations

- Federal-Aid Highway Act: This legislation provides the framework for the federal funding of highways, including bridges. It establishes guidelines and requirements for the design, construction, and maintenance of bridges that receive federal funding.

- National Bridge Inspection Standards (NBIS): Administered by the Federal Highway Administration (FHWA), NBIS sets the standards for the inspection, evaluation, and rating of all highway bridges. It establishes the frequency of inspections, qualifications for bridge inspectors, and reporting requirements.

- AASHTO LRFD Bridge Design Specifications: Published by the American Association of State Highway and Transportation Officials (AASHTO), these specifications provide guidelines for the design, analysis, and construction of highway bridges. They cover various aspects, including loads, materials, structural elements, and design methodologies.

- FHWA Bridge Construction and Rehabilitation Program: The FHWA oversees federal funding and provides guidance for bridge construction and rehabilitation projects. This program ensures compliance with federal regulations and promotes best practices in bridge construction, safety, and sustainability.

- Environmental Protection Agency (EPA) Regulations: The EPA enforces regulations related to environmental impact assessments, pollution control, and resource protection during bridge construction.

- U.S. Army Corps of Engineers (USACE) Permitting: For bridges that may impact navigable waters or wetlands, a permit from the USACE may be required under the Clean Water Act Section 404.

- National Environmental Policy Act (NEPA): NEPA requires federal agencies, including those involved in bridge construction, to assess and consider the environmental impacts of their actions.

- Federal Emergency Management Agency (FEMA) Requirements: FEMA provides guidelines and requirements for designing and constructing bridges in areas prone to natural disasters, such as floods and earthquakes.

Canadian Government Regulations

- Canadian Environmental Protection Act (CEPA): CEPA addresses environmental protection, pollution prevention, and the management of toxic substances. It regulates the use, release, and disposal of substances that may be harmful to the environment during bridge construction.

- Transportation Association of Canada (TAC) Guidelines: TAC publishes guidelines and best practices for transportation infrastructure, including bridges.

- Fisheries Act: Administered by Fisheries and Oceans Canada, the Fisheries Act protects fish and fish habitats in Canada. It regulates activities that may cause harm to fish and requires authorization or permits for projects that may impact fisheries, including bridge construction near water bodies.

- Canadian Environmental Assessment Act (CEAA): CEAA sets the framework for conducting environmental assessments of projects, including bridge construction, that may have significant environmental impacts.

- Canadian Highway Bridge Design Code (CHBDC): Published by the Canadian Standards Association (CSA), the CHBDC provides guidelines and requirements for the design, evaluation, and load rating of highway bridges.

- National Building Code of Canada (NBCC): The NBCC establishes minimum requirements for the design and construction of buildings, including bridges. It covers structural design, materials, fire protection, accessibility, and other aspects related to the safety and performance of bridges.

- Occupational Health and Safety Regulations: Provinces and territories in Canada have their own occupational health and safety regulations that apply to bridge construction sites. These regulations, which are enforced by provincial or territorial authorities, cover aspects such as worker safety, equipment operation, and hazard management.

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the bridge construction such as:

Personal management

- Emergency mustering

- Real-time attendance tracking

- Access control

Equipment management

- Inventory management

- Automated maintenance alerts

Supply chain management

- Supply chain visibility

- Real-time inventory tracking

Other applications

- Material tracking

- Documentation management

GAO has enabled its customers to make use of some of leading software and cloud services in the bridge construction industry. Below are some of the popular software and cloud services in the bridge construction industry.

- Oracle PeopleSoft: is an enterprise software suite that offers comprehensive solutions for personnel management, including workforce scheduling, time and attendance tracking, performance evaluation, and employee skill management.

- SAP SuccessFactors: is a cloud-based human capital management software that provides tools for personnel management, such as workforce planning, performance management, learning and development, and employee engagement.

- IBM Maximo: is an enterprise asset management software that helps manage and optimize equipment and maintenance operations. It provides features for equipment tracking maintenance scheduling, asset lifecycle management, and inventory control.

- Trimble PULSE: is a connected field service management solution that enables equipment management. It offers features for asset tracking, remote monitoring, maintenance planning, and equipment performance analysis.

- Infor Warehouse Management: is a comprehensive software solution that optimizes warehouse operations. It provides features for inventory tracking, order fulfilment, labour management, and warehouse analytics.

- Oracle NetSuite WMS: is a cloud-based solution that helps streamline warehouse operations. It offers features for inventory control, order management, pick and pack processes, and shipping management.

- Blue Yonder: formerly known as JDA Software, is a leading supply chain management platform. It provides capabilities for demand planning, inventory optimization, transportation management, and supply chain visibility.

- Manhattan Associates: is a supply chain and omnichannel commerce software provider. Its solutions include supply chain planning, order management, warehouse management, transportation management, and omnichannel fulfilment.

- SAP Ariba: is a cloud-based procurement platform that facilitates supply chain management. It offers features for supplier management, sourcing, contract management, and procurement automation.

- Microsoft Dynamics 365 Supply Chain Management: is an integrated solution that helps manage supply chain operations.

- Amazon Web Services (AWS): AWS is a popular cloud service provider that offers a range of infrastructure and platform services. It can be utilized in the bridge construction industry for cloud-based storage, computing, and data analytics, enabling scalable and cost-effective solutions.

- Bluebeam Revu: Bluebeam Revu is a cloud-based collaboration platform that allows teams to share, review, and mark up construction drawings and documents. It is often used in bridge construction projects for document management and collaboration purposes.

GAO has worked with some of the leading technology companies in the bridge construction in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the bridge construction industry

- Siemens: is a global technology company that offers a wide range of solutions for various industries, including infrastructure and construction. Their offerings include engineering software, automation systems, electrical components such as the lights, and road cameras, and building technologies that can be applied to bridge construction projects.

- Trimble: provides advanced technology solutions for various industries, including construction. They offer solutions for surveying, geospatial data collection, and construction project management that can be utilized in bridge construction projects.

- Autodesk: is a leading software company specializing in computer-aided design (CAD) and building information modelling (BIM). Their software, such as AutoCAD and Revit, is widely used in the construction industry, including bridge design and modelling.

- ABB: is a multinational corporation specializing in robotics, power, and automation technologies. They provide solutions for electrical systems, control systems, and automation equipment that can be integrated into bridge construction projects.

- Huawei: is a global provider of telecommunications equipment and services. They offer solutions for network infrastructure, including communication systems and data transmission technologies that can be utilized in bridge construction projects.

- Schneider Electric: is a multinational corporation specializing in energy management and automation solutions. They provide products and software for electrical distribution, energy monitoring, and control systems that can be applied in bridge construction projects.

- Intel: is a leading technology company specializing in semiconductor chips and advanced computing solutions. Their technologies, such as processors and IoT platforms, can be used to enhance connectivity, data processing, and automation in bridge construction projects.

- IBM: is a multinational technology company that offers a wide range of solutions and services. They provide data analytics, artificial intelligence, and cloud computing platforms that can be utilized for efficient project management and decision-making in bridge construction.

- Cisco Systems: is a global leader in networking and communication technologies. Their solutions for network infrastructure, connectivity, and cybersecurity can be applied to ensure reliable and secure communication systems during bridge construction projects.

- Rockwell Automation: is a provider of industrial automation and information solutions. They offer control systems, software, and monitoring technologies that can be used for efficient and safe operation of bridge construction equipment and processes.

- Bentley Systems: is a software development company specializing in infrastructure design, construction, and operation. Their software solutions, such as Open-Bridge and MicroStation, are widely used for bridge design, analysis, and asset management.

- Honeywell: is a multinational conglomerate that provides technology solutions for various industries, including construction. They offer solutions for building automation, safety systems, and control technologies that can be applied in bridge construction projects.

Case Studies of RFID Applications

Below are some RFID application cases in the bridge construction industry.

The Woodrow Wilson Bridge Reconstruction Project in Washington, D.C., implemented RFID technology to enhance construction efficiency. RFID tags were attached to construction process. This enabled real-time tracking of inventory, automated equipment identification such as identifying tractors, and trucks, and improved worker safety through access control. The RFID system facilitated streamlined logistics, reduced material loss, and minimized manual recordkeeping. The project successfully utilized RFID applications to optimize construction operations, resulting in cost savings and timely completion. This company implemented RFID systems to improve efficiency, enhance safety, and streamline processes in the construction of the bridge.

The Port Mann Bridge Expansion Project in the US incorporated RFID technology for efficient bridge construction management. RFID tags were used to monitor the movement of prefabricated bridge components, ensuring accurate inventory control and precise tracking throughout the assembly process. The RFID system enabled seamless coordination between suppliers, contractors, and transportation teams, minimizing delays and enhancing project scheduling. By leveraging RFID applications, the Port Mann Bridge project achieved improved supply chain management, reduced construction time, and enhanced overall productivity. By leveraging RFID technology, this construction project aimed to improve project efficiency, enhance inventory management, and ensure accurate documentation throughout the construction process. The Port Mann Bridge Expansion Project recognized the challenges involved in tracking and managing construction process.

UHF RFID Technology for Steel Girder Tracking in Bridge Construction” – This case study was conducted by Clemson University’s Department of Civil Engineering in collaboration with the South Carolina Department of Transportation (SCDOT) and Alpha 2 Omega Solutions. The study focused on implementing UHF RFID technology to track the movement and placement of steel girders during bridge construction projects. This was in in collaboration with the Texas Department of Transportation (TxDOT) and Topcon Positioning Systems. The study aimed to improve construction efficiency and safety by utilizing UHF RFID technology for material tracking, asset management, and worker monitoring in bridge construction.

Xylem Inc. is a global construction company that provides innovative solutions for the construction and maintenance of bridge construction. The company uses UHF RFID technology to track and manage their inventory of steels, concrete, asphalt and other materials used in the construction process. The UHF RFID tags are attached to each item, and the information is stored in a cloud-based database accessible to Xylem’s employees and contractors. UHF RFID technology also helps Xylem improve their supply chain management by providing real-time visibility into the availability of equipment such as excavators and tele-handlers, enabling them to quickly identify any potential delays or shortages in the construction process.

GAO RFID Systems & Hardware for the Bridge Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the bridge construction.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the bridge construction industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the bridge construction:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the bridge construction:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the bridge construction:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the bridge construction:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the bridge construction:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Formwork: Used to create temporary molds for shaping and supporting concrete during the casting process.

- Pile Driver: Used to drive piles into the ground to create foundation support for the bridge.

- Excavator: Used for digging and earthmoving activities, such as excavating foundations and removing soil.

- Tower Crane: A tall crane used for lifting heavy materials and equipment to great heights during bridge construction.

- Barge: Used for constructing bridges over water bodies, providing a stable platform for equipment and materials

- Vibratory Pile Hammer: Used to drive steel or concrete piles into the ground by applying high-frequency vibrations.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Bridge Construction Extensively

GAO’s products and technologies have helped its customers in the bridge construction industry to achieve success in artificial intelligence (AI), 3D printing, augmented reality (AR), Internet of Things (IoT), blockchain technology, predictive analytics, digital twins, cloud computing, last-mile delivery optimization, autonomous vehicles and drones, mobile technologies & apps, collaborative robots, predictive maintenance, voice picking and automation & robotics.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the bridge construction, including many in its various divisions such as:

- Modular Bridges: Building bridges using pre-engineered modules that can be easily transported and assembled, allowing for rapid construction and enhanced flexibility.

- Intelligent Infrastructure: Utilizing smart technologies, such as sensors, IoT (Internet of Things), and data analytics, to monitor bridge health, optimize maintenance, and enhance safety.

- Adaptive Reuse: Repurposing existing bridge structures or elements for new construction projects, promoting sustainability and resource conservation.

- Lightweight Materials: Employing advanced materials, such as carbon fiber composites, high-strength alloys, and innovative polymers, to reduce weight while maintaining structural integrity.

- Cable-Stayed Bridges: Bridges supported by cables anchored to towers, known for their aesthetic appeal, long spans, and efficient use of materials like concrete, steel, and masonry.

- 3D Printing: Using additive manufacturing techniques to construct bridge components such as the bridge tower, pile cap and the beam, enabling complex designs.

Here are the leading companies in the bridge construction industry in the U.S. and Canada