Related Products & Systems on Other Pages on This Website

Tool & Industrial Equipment Tracking System

GAO RFID Industrial Sand Mining Asset Management System

GAO RFID Peat Extraction RFID Solutions

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

High-Temperature Tolerant RFID Tags

Hazardous Environment (ATEX) RFID Tags

On Metal RFID Tags – All Types

Overview

The coal mining industry is a sector involved in the extraction and processing of coal from underground mines or surface mines. It plays a crucial role in providing energy resources for various industries and power generation. Coal mining involves the exploration, extraction, and transportation of coal deposits, which are then used for electricity production, steel manufacturing, and other industrial applications.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the coal mining industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as excavators, bulldozers, loaders, haul trucks, conveyor belts, drill rigs, roof bolters, longwall shearers, continuous miners, shuttle cars and rock dusters.

Ranked as a top 10 global GAO’s RFID supplier and based in New York City and Toronto, GAO RFID Inc. offers a wide choice of RFID (radio frequency identification) readers and tags at ultra-high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in coal mining

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Coal Mining

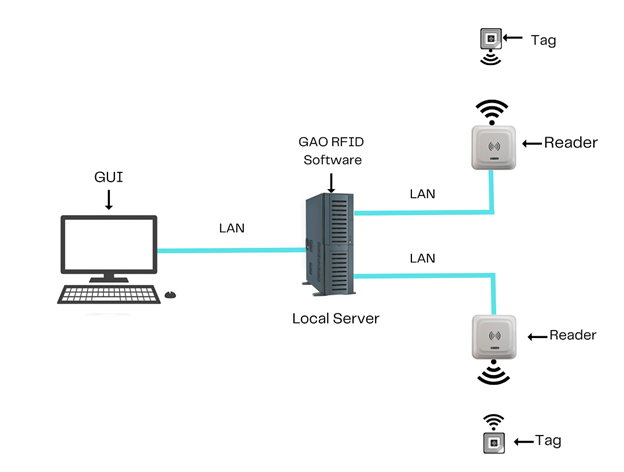

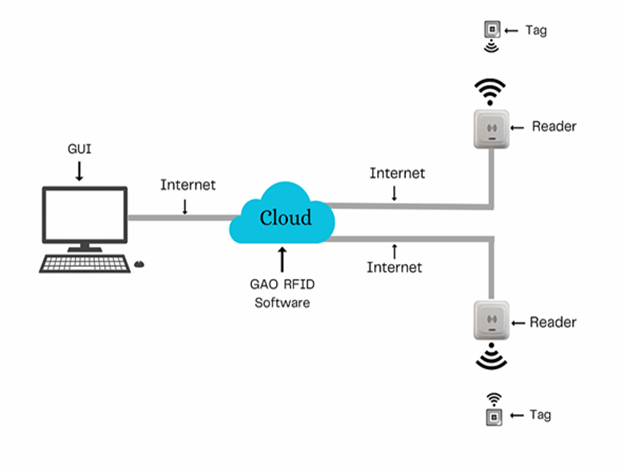

To satisfy its customers, GAO’s RFID or RFID Systems for coal mining are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for coal mining with its software running on a local server.

The above illustrates GAO system for coal mining with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of GAO’s RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in coal mining:

- Personnel Tracking: GAO’s RFID tags can be attached to the helmets or clothing of coal miners to monitor their locations in real-time. This helps ensure their safety and allows for quick response in case of emergencies or evacuations.

- Vehicle and Equipment Tracking: GAO’s RFID tags can be installed on mining vehicles, trucks, and equipment to monitor their movements and usage. This enables better management of the fleet, preventive maintenance scheduling, and reduces the risk of theft.

- Asset Management: GAO’s RFID technology allows for easy tracking and management of various assets used in mining operations, such as tools, safety equipment, and machinery components. This reduces downtime and increases overall productivity.

- Conveyor Belt Monitoring: GAO’s RFID tags attached to coal containers or containers carrying materials can help in automating the tracking process and provide real-time updates on conveyor belt positions and the movement of materials.

- Coal Quality Monitoring: GAO’s RFID tags can be used to identify and track specific batches of coal, making it easier to monitor the quality and origin of the coal throughout the mining process.

- Mine Safety Compliance: GAO’s RFID technology can be utilized to ensure that personnel are following safety protocols and entering restricted areas only when authorized. This helps maintain compliance with safety regulations.

- Inventory Management: GAO’s RFID tags can be applied to stockpiles of coal to automate inventory tracking. This ensures accurate records and helps prevent stockouts or excess inventory.

- Environmental Monitoring: GAO’s RFID sensors can be deployed to monitor environmental parameters, such as air quality, water levels, and ground stability, to help identify potential hazards and mitigate environmental impacts.

- Emergency Response and Evacuation: GAO’s RFID technology can play a crucial role in emergency scenarios by providing real-time information about the location of personnel, equipment, and materials. This helps in executing timely and efficient evacuation procedures.

- Workforce Management: GAO’s RFID badges worn by personnel can be used for time and attendance tracking, enabling more accurate payroll calculations and ensuring adherence to work schedules.

- Dust Control: GAO’s RFID technology can be integrated into dust suppression systems to optimize their usage based on real-time data, helping to reduce airborne dust levels in the mine.

- Access Control: GAO’s RFID-enabled access control systems can be implemented at entry points, ensuring that only authorized personnel can access specific areas of the mine.

GAO’s drone technologies find the following applications in the coal mining industry:

- Surveying and Mapping: GAO’s Drones equipped with high-resolution cameras or LiDAR (Light Detection and Ranging) sensors can quickly survey large areas of the mine, creating detailed topographic maps and 3D models. This data helps in mine planning, optimizing extraction processes, and identifying potential hazards.

- Stockpile Monitoring: GAO’s Drones can be used to measure and monitor the volume of coal stockpiles accurately. Regular monitoring helps ensure efficient inventory management and minimizes the risk of stockpile instability.

- Inspection of Highwalls and Pit Walls: GAO’s Drones can access areas that might be dangerous for human inspectors, such as highwalls and pit walls. They can capture high-resolution imagery, allowing geotechnical engineers to assess the stability of these critical structures.

- Environmental Monitoring: GAO’s Drones equipped with specialized sensors can assess the impact of mining operations on the surrounding environment. They can monitor air quality, water bodies, and vegetation, helping companies comply with environmental regulations and implement mitigation measures.

- Safety Inspections: GAO’s Drones can perform routine safety inspections of equipment and infrastructure, including conveyor belts, access roads, and facilities. Early detection of defects or potential issues improves safety and reduces downtime.

- Emergency Response: GAO’s in the event of an emergency, such as a mine collapse or fire, drones can be deployed to assess the situation and provide real-time information to emergency responders. This aids in making informed decisions and organizing rescue operations more effectively.

- Monitoring Mining Operations: GAO’s Drones equipped with thermal cameras can monitor coal extraction, processing, and transportation activities. They can identify equipment malfunctions, detect hotspots, and optimize the flow of materials.

- Security and Surveillance: GAO’s Drones can be used for security purposes to monitor the mine’s perimeter and deter unauthorized access or illegal activities.

- Tailings Dam Inspections: GAO’s Drones can inspect tailings dams, providing crucial data on their structural integrity, erosion, and environmental impact. Regular inspections contribute to safe dam management and help prevent potential disasters.

- Communication and Coordination: GAO’s Drones equipped with communication systems can serve as relays, enhancing communication in remote mining areas with limited network coverage.

- Gas Monitoring: GAO’s Drones can be equipped with gas sensors to monitor the concentration of harmful gases within the mine, helping ensure the safety of personnel and optimizing ventilation systems.

- Search and Rescue: In emergency situations involving missing personnel, GAO’s drones with thermal imaging cameras can assist in search and rescue operations, increasing the chances of locating individuals more quickly.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the coal mining industry:

- Safety Monitoring: GAO’s IoT sensors can be deployed to monitor hazardous conditions in mines, such as gas concentrations, air quality, temperature, and humidity. These sensors can provide real-time data to miners and central control systems, enabling timely evacuation and alerting of potential dangers.

- Asset Tracking and Management: GAO’s IoT can be used to track the location and status of mining equipment and vehicles. This helps optimize equipment utilization, prevent theft, and schedule maintenance proactively.

- Predictive Maintenance: GAO’s IoT sensors can collect data on the health and performance of machinery and equipment. Analyzing this data can help predict maintenance needs, reduce downtime, and extend the lifespan of expensive mining equipment.

- Remote Monitoring and Control: GAO’s IoT enables remote monitoring and control of critical operations in the mine, reducing the need for human intervention in hazardous areas. It allows operators to adjust and optimize processes in real-time, leading to increased efficiency.

- Worker Safety: GAO’s IoT wearables, such as smart helmets or vests, can be equipped with sensors to monitor the health and safety of miners. These devices can track vital signs, fatigue levels, and location, ensuring timely assistance in case of emergencies.

- Environmental Monitoring: GAO’s IoT devices can monitor the impact of mining operations on the environment, such as water quality, soil erosion, and air pollution. This information can help mining companies adhere to environmental regulations and implement sustainable practices.

- Geological Data Collection: GAO’s IoT sensors can be installed to gather geological data, providing valuable insights into the composition and characteristics of coal deposits. This data can aid in optimizing mining techniques and resource planning.

- Energy Management: GAO’s IoT can be used to optimize energy consumption in the mining process, reducing overall operational costs and carbon footprint.

- Fleet Management: GAO’s IoT-enabled fleet management systems can help optimize the movement of vehicles within the mine, reduce fuel consumption, and improve overall logistics.

- Real-Time Communication and Collaboration: GAO’s IoT-based communication systems can enhance connectivity between miners, supervisors, and control centers, enabling quick response to emergencies and better coordination during day-to-day operations.

- Mine Planning and Optimization: GAO’s IoT data can be integrated with advanced analytics and AI systems to optimize mine planning, extraction techniques, and resource allocation.

- Supply Chain Management: GAO’s IoT can be used to track the transportation and delivery of coal from the mine to its final destination, ensuring efficient supply chain management.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Coal Mining

GAO RFID Inc. has helped many companies in the coal mining to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates, and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- IEC ISO 18000

- ISO/IEC 14443

- ISO/IEC 18092

- Bluetooth SIG

- Bluetooth Core

- IEEE 802.15.4

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- ASTM F38

- ISO 21384

US. Government Regulations for Coal Mining Industry

- Surface Mining Control and Reclamation Act (SMCRA)

- Mine Safety and Health Act (Mine Act)

- Clean Water Act (CWA)

- Clean Air Act (CAA)

- National Environmental Policy Act (NEPA)

- Federal Mine Safety and Health Administration (MSHA) Regulations

- Office of Surface Mining Reclamation and Enforcement (OSMRE) Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- S. Environmental Protection Agency (EPA) Regulations

- State Mining Regulations (varies by state)

Canadian Government Regulations for Coal Mining Industry

- Canadian Environmental Protection Act (CEPA)

- Fisheries Act

- Canadian Environmental Quality Guidelines (CEQGs)

- Canadian Labour Code

- Explosives Act and Regulations

- Provincial and Territorial Mining Regulations

- Mine Safety Regulations

- Water Management Regulations

- Environmental Assessment Regulations

U.S. Environmental Protection Agency

U.S. Environmental Protection Agency

Mine Safety and Health Administration

Mine Safety and Health Administration

Federal Aviation Administration

Federal Aviation Administration

Office of Surface Mining Reclamation and Enforcement

Office of Surface Mining Reclamation and Enforcement

Unmanned Aircraft Systems

Unmanned Aircraft Systems

Unified Architecture

Unified Architecture

Canadian Energy Regulator

Canadian Energy Regulator

Canadian Environmental Assessment

Canadian Environmental Assessment

Constrained Application Protocol

Constrained Application Protocol

Fisheries Act

Fisheries Act

Message Queuing Telemetry Transport

Message Queuing Telemetry Transport

WirelessHART

WirelessHART

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the coal mining such as:

Personnel Management Applications in Coal Mining:

- Time and Attendance Tracking

- Training and Certification Management

- Health and Safety Compliance

- Emergency Response and Evacuation Planning

Equipment Management Applications in Coal Mining:

- Preventive Maintenance Scheduling

- Asset Tracking and Monitoring

- Condition Monitoring

- Equipment Calibration and Certification

Access Control Applications in Coal Mining:

- Personnel Access Control

- Vehicle and Equipment Access Control

- Visitor Management

Warehouse Management Applications in Coal Mining:

- Inventory Control

- Real-Time Stock Monitoring

Supply Chain Management Applications in Coal Mining:

- Supplier and Vendor Management

- Logistics and Transportation Optimization

- Demand Forecasting

Other Applications for Coal Mining:

- Environmental Monitoring

- Waste Management

- Community Relations

- Data Analytics and Reporting

- Sustainability Initiatives

GAO has enabled its customers to make use of some of leading software and cloud services in Coal Mining industry. Below are some of popular software and cloud services in coal mining industry.

SAP SuccessFactors, Workday Human Capital Management (HCM), ADP Workforce Now, Kronos Workforce Central, Oracle Human Capital Management (HCM) Cloud, SAP SuccessFactors, Oracle HCM Cloud, BambooHR, Microsoft Azure IoT Hub, AWS IoT Core, IBM Maximo Asset Management on Cloud, ABB Ability™ Asset Health for Mining, Wenco Fleet Awareness, Honeywell Pro-Watch, LenelS2 OnGuard, Genetec Security CenterSAP Extended Warehouse Management (EWM), Manhattan Associates Warehouse Management System (WMS), Blue Yonder (formerly JDA Software) Warehouse Management Blue Yonder (formerly JDA Software) Supply Chain Management, Infor Supply Chain Management, Kinaxis RapidResponse, Honeywell Pro-Watch Cloud Edition, LenelS2 Cloud Access Control, Genetec Security Center Cloud, RPMGlobal XPAC Solutions, Datamine Studio,Carlson Mining, Oracle Cloud .

ADP Workforce Now

ADP Workforce Now

Amazon Web Services

Amazon Web Services

Google Cloud Platform

Google Cloud Platform

Honeywell Pro Watch

Honeywell Pro Watch

IBM Maximo

IBM Maximo

Infor EAM

Infor EAM

Microsoft azure

Microsoft azure

MineSight

MineSight

Minex

Minex

Oracle

Oracle

SAP Success

SAP Success

Vulcan

Vulcan

GAO has worked with some of the leading technology companies in sub-industry in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in coal mining industry:

Microsoft, Hexagon AB, Trimble Inc., Schneider Electric, Siemens AG, Rockwell Automation, Komatsu Ltd., Caterpillar Inc., Joy Global Inc. (now part of Komatsu), ABB, Wenco International Mining Systems (A subsidiary of Hitachi Construction Machinery), MST Global, RPMGlobal Holdings Limited.

ASEA Brown Boveri

ASEA Brown Boveri

Caterpillar

Caterpillar

General Electric

General Electric

Hexagon Mining

Hexagon Mining

Komatsu

Komatsu

Maptek

Maptek

Microsoft

Microsoft

Minemax

Minemax

MineWare

MineWare

Rockwell Automation

Rockwell Automation

RPMGlobal

RPMGlobal

Siemens Digital

Siemens Digital

Case Studies of RFID Applications

Below are some GAO’s RFID application cases in the coal mining industry.

Arch Coal Inc., one of the largest coal producers in the United States, implemented an RFID tracking system to improve the efficiency and safety of coal transportation. The implementation of RFID technology resulted in significant improvements in operational efficiency and cost savings for Arch Coal Inc. The real-time tracking and visibility of coal transportation allowed for better planning and coordination, reducing idle time and fuel consumption

Teck Resources Limited, a leading mining company in Canada, implemented an RFID-based asset management system to track and manage critical equipment in their coal mining operations. The RFID-based asset management system provided Teck Resources with valuable data and analytics to make informed decisions about equipment utilization and maintenance. This resulted in increased operational efficiency, reduced costs, and improved overall productivity in their coal mining operations.

Peabody Energy Corporation, a leading coal mining company in the United States, implemented a UFH RFID asset tracking system to improve inventory management and optimize the utilization of equipment and resources. With the UFH RFID system, Peabody Energy gained real-time visibility into the location and status of each asset. This allowed them to track the movement of equipment within the mining site, monitor usage patterns, and schedule maintenance tasks more efficiently.

Teck Resources Limited, a prominent mining company in Canada, implemented a UFH RFID personnel tracking system to enhance safety and security in their coal mining operations. The UFH RFID system enabled Teck Resources to track and manage personnel movements, ensuring that individuals were in authorized areas and complying with safety protocols. In the event of an emergency, the system provided accurate and up-to-date information about the location of personnel, facilitating timely evacuation and rescue operations.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in coal mining industry.

Using IoT sensors to monitor air quality, water levels, and other environmental parameters in and around mining sites to ensure compliance with regulations and promote sustainable practices.

Deploying the IoT sensors on mining equipment to track their condition, performance, and health in real-time, enabling predictive maintenance and reducing downtime. Using wearable IoT devices and sensors to monitor the health and safety of workers in hazardous environments, such as underground coal mines.

Employing IoT solutions to track and manage mining vehicles and equipment, optimizing their usage, and improving operational efficiency. Implementing IoT-based asset tracking systems to monitor the location and movement of critical assets, such as coal trucks and conveyor belts, in the mining process.

Leveraging IoT technologies to enable remote monitoring and control of mining operations, allowing for efficient management of multiple sites from a central location. Utilizing IoT sensors and analytics to optimize energy consumption and reduce waste in mining operations.

Case Studies of Drone Applications

Below are some drone application cases in coal mining industry.

Drones equipped with high-resolution cameras and LiDAR sensors can perform aerial surveys of mining sites, providing detailed topographic maps and 3D models for better planning and analysis. It can be used to monitor coal stockpiles, providing accurate volume measurements and real-time data on inventory levels.

Drones equipped with sensors can monitor environmental parameters such as air quality, water quality, and vegetation health in and around mining sites. It can conduct visual inspections of mining equipment, infrastructure, and structures, identifying potential issues and reducing the need for manual inspections in hazardous areas. Drones can be deployed for search and rescue missions in case of accidents or emergencies in mining sites.

GAO RFID Systems & Hardware for the Coal Mining

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including coal mining.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration, and panic button:

GAO’s BLE technology is suitable for many industries, including coal mining.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including coal mining:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including coal mining:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including coal mining:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including coal mining:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

The RFID systems by GAO are highly popular for clients in the coal mining:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Continuous Miners: Continuous miners are large machines used to extract coal from the mining face. They have rotating cutting heads that break up the coal and load it onto a conveyor belt for transport.

- Longwall Shearers: Longwall shearers are advanced machines used in longwall mining, which is a highly efficient method of underground coal extraction. These machines have rotating cutting drums that shave coal from the coal seam, allowing it to be collected and transported away.

- Roof Bolters: Roof bolters are specialized machines used to install roof support bolts in underground coal mines. They ensure the stability and safety of the mine by securing the roof and preventing collapses.

- Shuttle Cars: Shuttle cars, also known as shuttle cars or coal haulers, are used to transport coal from the mining face to the conveyor belt or storage area. They are designed to navigate the narrow underground tunnels and carry large volumes of coal.

- Conveyor Systems: Conveyor systems are essential in coal mining operations for efficient transportation of coal. These systems consist of belts and pulleys that move coal from one location to another, such as from the mining face to the processing plant or storage area.

- Draglines: Draglines are large excavating machines used in surface mining to remove overburden and expose coal seams. They have a long boom with a bucket that can dig and remove massive amounts of soil and rock.

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Coal Mining Extensively

GAO’s products and technologies have helped its customers in the coal mining industry to achieve success in automation, digitalization, sustainable mining, renewable energy integration, remote monitoring and control, predictive maintenance, artificial intelligence, big data analytics, robotics, virtual reality, augmented reality, internet of things (IoT), block chain technology, mine safety and health, mine reclamation and rehabilitation, energy efficiency, green mining, carbon capture and storage, mine electrification and mine optimization.

GAO RFID Inc. has served many customers in the coal mining, including its various divisions such as

- Underground Mining: this division involves the extraction of coal from underground mines using methods such as room and pillar mining, longwall mining, or retreat mining.

- Surface Mining: surface mining division involves the extraction of coal from near-surface deposits through methods like strip mining, open-pit mining, and mountaintop removal mining.

- Coal Processing: this division includes the processing and preparation of coal after it has been extracted from the mines. it involves activities like coal crushing, screening, washing, and blending to meet the specific quality and size requirements.

- Coal Transportation: this division focuses on the transportation of coal from mines to processing plants, power plants, or other destinations. it includes activities such as coal hauling, trucking, rail transportation, and shipping.

- Coal Trading: this division involves the buying and selling of coal as a commodity. it includes activities like coal marketing, pricing, negotiation, and contract management.

- Coal Power Generation: this division focuses on the use of coal as a fuel for power generation. it includes coal-fired power plants, boiler operations, and related activities.

- Coal Research and Development: this division involves the research, development, and innovation in coal mining technologies, safety practices, environmental sustainability, and alternative uses of coal.

- Coal Regulatory and Compliance: this division deals with regulatory and compliance aspects related to coal mining operations. it includes government agencies, regulatory bodies, and organizations involved in ensuring compliance with safety, environmental, and labor regulations.

Here are some of the leading companies in the coal mining industry:

- Microsoft: Microsoft provides a wide array of technological solutions for the coal mining industry. Their offerings include cloud computing services, data analytics, machine learning, and collaboration tools. Microsoft’s solutions help coal mining companies streamline their operations, automate processes, and enable real-time decision-making through advanced data analytics and visualization.

- Hexagon Mining: Hexagon Mining specializes in providing technology solutions specifically designed for the mining industry, including coal mining. Their solutions encompass mine planning and design, fleet management, safety monitoring, and geological modeling.

- Caterpillar: Caterpillar is a renowned electronic technology company that provides a wide range of equipment and solutions for the coal mining industry.

- Komatsu: Komatsu is a leading provider of electronic technology solutions for the coal mining industry. They specialize in manufacturing heavy machinery and equipment, such as excavators, bulldozers, and haul trucks, integrated with advanced electronic control systems.

- Siemens: Siemens is a global leader in electronic technology, offering comprehensive solutions for the coal mining industry. Their portfolio includes automation and control systems, electric drives, and communication systems tailored for mining applications.

- ABB: ABB provides a wide range of electronic technology solutions for the coal mining industry. They offer automation and control systems, electrical equipment, and power distribution solutions designed to optimize coal mining operations.

- Rockwell Automation: Rockwell Automation specializes in providing electronic technology solutions for the coal mining industry.

- RPMGlobal: RPMGlobal provides system technology solutions for the coal mining industry, focusing on mine planning and scheduling software. Their solutions include advanced tools for mine design, production scheduling, and equipment optimization.

- MineWare: MineWare is a system technology company that specializes in advanced monitoring and optimization solutions for the coal mining industry. They offer real-time monitoring systems for equipment performance, payload management, and operator guidance.

- Minemax: Minemax provides system technology solutions for strategic mine planning and scheduling in the coal mining industry. Their software platforms enable coal mining companies to optimize mine design, production scheduling, and supply chain management.

- Maptek: Maptek offers system technology solutions for the coal mining industry, focusing on geological modeling, mine planning, and data management. Their software platforms enable accurate geological modeling, mine design, and resource estimation.

- General Electric (GE): GE provides electronic technology solutions for the coal mining industry, focusing on areas such as electrical power distribution, automation, and control systems.

Alliance Resource Partners

Alliance Resource Partners

Alpha Natural Resources

Alpha Natural Resources

Arch Resources

Arch Resources

Atrum Coal

Atrum Coal

Booth Energy Group

Booth Energy Group

Cardero Resource

Cardero Resource

Cloud Peak Energy

Cloud Peak Energy

Coalspur Mines

Coalspur Mines

CONSOL Energy

CONSOL Energy

Contura Energy

Contura Energy

Conuma Coal Resources

Conuma Coal Resources

Coronado Global Resources

Coronado Global Resources

Corsa Coal

Corsa Coal

Foresight Energy

Foresight Energy

Hallador Energy Company

Hallador Energy Company

Paringa Resources

Paringa Resources

Peabody Energy Corporation

Peabody Energy Corporation

Ramaco Carbon

Ramaco Carbon

Ramaco Resources

Ramaco Resources

Rhino Resource Partners

Rhino Resource Partners

Riversdale Resources

Riversdale Resources

SunCoke Energy

SunCoke Energy

Teck Resources

Teck Resources

Warrior Met Coal

Warrior Met Coal