Chemical and petrochemical construction refers to the process of designing, building and commissioning facilities that produce chemicals and petrochemicals such as plastics, fertilizers and pharmaceuticals, as well as refineries, processing plants and storage facilities that produce petrochemicals. It requires technical expertise, compliance with regulations, and collaboration with various stakeholders.

Many companies in the chemical and petrochemical industry have been served by GAO RFID Inc., a top 10 global leader in RFID with headquarters in both New York and Toronto.

GAO RFID Systems & Hardware for the Chemical and Petrochemical Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the chemical and petrochemical construction.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for all kinds of industries, including the chemical and petrochemical construction.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the chemical and petrochemical construction:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the chemical and petrochemical construction:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the chemical and petrochemical construction:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the chemical and petrochemical construction:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the chemical and petrochemical construction:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

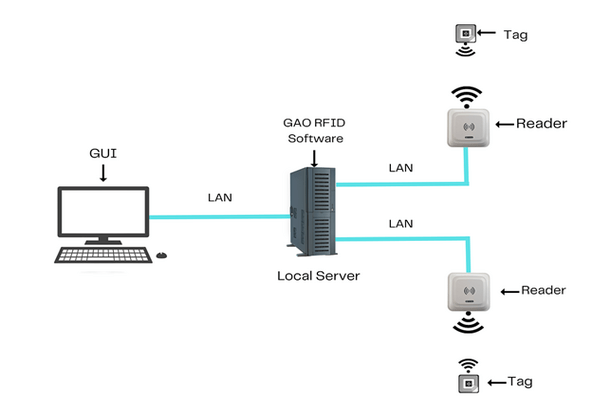

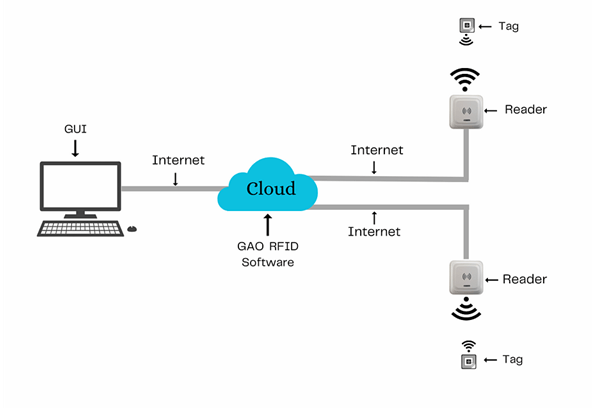

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO offers free samples of its RFID tags, labels, badges, and wristbands.

GAO offers a free trial for all of its software available.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Chemical and Petrochemical Construction

RFID, BLE, IoT and drone technologies from GAO RFID Inc. offer many benefits for the chemical and petrochemical construction Industry:

Applications and benefits of applying RFID to the chemical and petrochemical construction:

- Asset tracking and management: GAO RFID tags can be used to track and manage assets such as crane, pump, tanks, compressors, wrenches and pliers, hammers and mallets, and materials by affixing an RFID tag to an asset, it can be easily located and monitored.

- Inventory management: Our RFID products can be used to improve inventory management by enabling real-time monitoring of inventory levels and automatic replenishment of stock.

- Better data management: Our RFID can provide accurate, real-time data that can be used for analytics and reporting, enabling better decision-making and process optimization.

Applications & benefits of applying BLE technology to the chemical and petrochemical construction:

- Indoor positioning and navigation: GAO BLE beacons can be used to enable indoor positioning and navigation, which can be useful in large and complex construction sites

- Increased Efficiency: Our BLE products can be used to track the location and status of crane, pump, tanks, compressors, and personnel, which can help to improve workflow, reduce downtime, and increase productivity.

- Enhanced Supply Chain Visibility: GAO BLE can be used to track the movement of materials and equipment throughout the supply chain, which can help to improve inventory management, reduce errors, and increase transparency.

Applications & benefits of applying combination of RFID and drones to the chemical and petrochemical construction:

- Site surveying and mapping: Drones can be equipped with RFID technology to map and survey construction sites more efficiently. This can help identify potential hazards or inefficiencies in the construction process and improve overall safety and productivity.

- Quality control and traceability: Drones equipped with RFID readers can be used to track materials and components through the manufacturing process, enabling better quality control and traceability.

- Safety monitoring: Drones equipped with cameras and sensors can be used to monitor safety hazards on construction sites, such as gas leaks, chemical spills, or unsafe working conditions.

Applications & benefits of applying combination of RFID and IoT to chemical and petrochemical construction:

- Increased efficiency: Our RFID and IoT can automate processes such as inventory management, asset tracking, and equipment maintenance, leading to increased productivity and efficiency.

- Real-time data and analytics: RFID and IoT can provide real-time data and analytics on supply chain performance, equipment utilization, and other key metrics.

GAO Helps Customers Comply with Standards, Mandates & Regulations

GAO RFID Inc. has helped many companies in the chemical and petrochemical construction industry to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

- API RP 781: American Petroleum Institute provides guidance on the use of RFID technology in the upstream oil and gas industry, including drilling, production, and transportation.

- Canadian Environmental Assessment Act, 2012: This act requires federal environmental assessments for designated projects that may have significant adverse environmental effects, including some chemical and petrochemical construction activities.

- The U.S. Department of Defense (DoD) RFID Mandate: This mandate requires DoD suppliers to use RFID technology to track and identify goods and assets shipped to DoD facilities.

- Occupational Safety and Health Administration (OSHA) standards: OSHA sets and enforces standards for workplace safety and health, including regulations related to hazardous chemicals and process safety management.

- Environmental Protection Agency (EPA) regulations: The EPA regulates the release of hazardous substances into the environment, including air emissions, wastewater discharges, and hazardous waste management.

- Chemical Facility Anti-Terrorism Standards (CFATS): This program, administered by the Department of Homeland Security, sets security standards for high-risk chemical facilities to prevent and mitigate the consequences of terrorist attacks.

- Clean Air Act (CAA) and Clean Water Act (CWA): These acts are important tools for protecting the environment and public health, and they have been successful in reducing pollution levels and improving air and water quality.

GAO’s Software Provides API

GAO’s popular RFID software, such as personnel tracking, asset tracking, access control, and parking control system, are work-in-progress, offer a free trial and offer an API to each of the software in the chemical and petrochemical construction:

Personnel Management:

- Workforce Planning: This involves forecasting the required workforce needed for the project and planning for their recruitment, training, and retention.

- Safety Management: This application ensures that all workers follow safety protocols and procedures to minimize accidents and injuries in the workplace.

- Performance Management: This involves monitoring and evaluating employee performance, providing feedback and training to improve their skills, and recognizing exceptional performance.

Equipment Management:

- Asset Tracking: This application involves keeping track of equipment location, status, and maintenance records to optimize their use and minimize the risk of loss or theft.

- Maintenance Management: This involves monitoring and scheduling routine maintenance and repairs of equipment to prevent unexpected breakdowns, reduce downtime, and increase productivity.

- Calibration Management: This application ensures that instruments and equipment are accurately calibrated and maintained to ensure that they produce accurate and reliable measurements.

Supply Chain Management:

- Material Planning and Procurement: This application involves forecasting material requirements and sourcing the necessary materials from suppliers at the right price, quality, and quantity.

- Inventory Management: This involves monitoring inventory levels, tracking usage, and forecasting demand to optimize inventory levels and minimize waste.

- Logistics Management: This application involves planning and coordinating the transportation, storage, and distribution of materials and products to ensure timely delivery and minimize transportation costs.

Other Applications:

- Project Management: This involves planning, organizing, and controlling all aspects of a project, including cost, schedule, and quality, to ensure successful project completion.

- Quality Management: This application involves developing and implementing quality control measures and procedures to ensure that products meet or exceed customer expectations.

- Environmental Health and Safety Management: This involves managing environmental and occupational health and safety risks associated with chemical and petrochemical industrial construction to protect workers, the public, and the environment.

Case Studies of RFID Applications

Here’s a brief case study of an RFID application in the chemical and petrochemical construction:

Dow Chemical Company implemented an RFID system for inventory management in its Texas plant construction project. The RFID tags were attached to materials and equipment and were tracked using handheld readers and a centralized database. This system helped Dow Chemical Company to increase productivity, reduce labor costs, and improve supply chain visibility.

Another case study is Fluor Corporation implemented an RFID system for materials management in its construction project for a petrochemical plant in Louisiana. The system involved tagging materials with RFID tags and using handheld readers and fixed readers to track their location, status, and movement. This system helped Fluor Corporation to reduce errors, increase productivity, and improve supply chain visibility.

GAO Has Served the Chemical and Petrochemical Construction Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the chemical and petrochemical construction, including its various divisions such as

- Basic Chemicals Manufacturing: This division involves the production of basic chemicals such as acids, alkalis, and salts, which are used as raw materials for other chemical products.

- Specialty Chemicals Manufacturing: This division involves the production of specialty chemicals such as coatings, adhesives, and specialty polymers, which have specific applications in various industries.

- Petrochemical Manufacturing: This division involves the production of chemicals and products derived from petroleum, such as plastics, synthetic fibers, and synthetic rubber.

- Refining: This division involves the processing of crude oil and other feedstocks to produce gasoline, diesel, and other fuels.

- EPC (Engineering, Procurement, and Construction): This division involves the design, procurement, and construction of chemical and petrochemical plants.

Some of the leading companies in the chemical and petrochemical construction in the US:

Some of the leading companies in the chemical and petrochemical construction in Canada: