Typical Electronic, Mechanical, and Software Design of High-Frequency RFID Tags

High-frequency RFID tags are crucial components in various applications like inventory management, contactless payments, and asset tracking. Operating at 13.56 MHz, these tags consist of several integrated components that work together to store and communicate data wirelessly.

Electronic Components

Integrated Circuit (IC):

The IC is the core of the high-frequency RFID tag. It stores data, manages power, and handles communication with RFID readers. The IC typically has a small memory capacity, ranging from 96 bits to several kilobytes, and can be used for either read-only or read-write purposes.

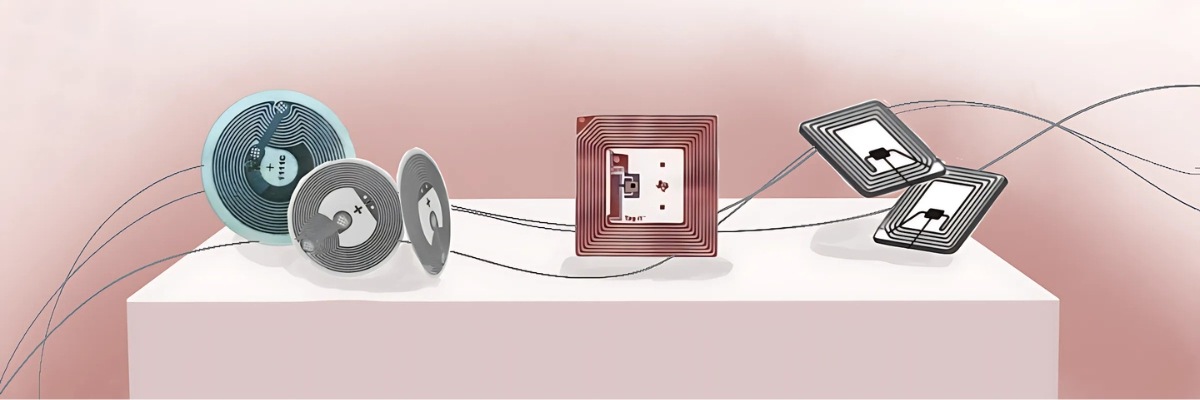

Antenna:

The antenna in a high-frequency RFID tag is designed to capture electromagnetic signals from an RFID reader. These antennas are usually coil-based, allowing the tag to effectively harvest energy and transmit information over short distances.

Mechanical Components

Substrate:

The antenna and IC are mounted on a substrate, which provides structural integrity. Depending on the application, this substrate can be made from materials such as paper, plastic, or even flexible materials that allow the tag to conform to various surfaces.

Encapsulation:

To protect the internal components, high-frequency RFID tags are often encapsulated in durable materials like epoxy or plastic, making them resistant to environmental factors such as moisture, dust, and heat. This encapsulation is particularly important in industrial settings where the tags may be exposed to harsh conditions.

Form Factor:

The mechanical design of the tag can vary significantly depending on its intended application. For example, some tags are designed as small stickers or labels for retail products, while others are embedded in ruggedized casings for asset tracking in industrial environments.

Software Components

Data Encoding:

The data stored on a high-frequency RFID tag must be encoded in a standardized format, such as ISO/IEC 14443 or ISO/IEC 15693. These standards ensure that the tag can be read by a wide range of compatible RFID readers. The encoding process involves converting binary data into a format that can be interpreted by the RFID reader.

Data Transmission Protocols:

High-frequency RFID tags typically use either amplitude shift keying (ASK) or frequency shift keying (FSK) modulation to communicate with the reader. The tag receives power and data requests from the reader via inductive coupling, then responds by modulating the reader’s signal with its stored data.

Anti-Collision Algorithms:

In environments where multiple RFID tags are present, anti-collision algorithms are employed to ensure that the RFID reader can accurately identify and communicate with individual tags without interference. This is particularly important in high-density applications such as inventory tracking.

Working Principles

High-frequency RFID tags operate on the principle of inductive coupling. The tag’s antenna captures the electromagnetic field emitted by an RFID reader and converts it into electrical energy to power the IC. The IC processes the reader’s request and responds by modulating the electromagnetic field to transmit the stored data. Passive RFID tags do not have an internal power source and rely entirely on the reader’s signal for activation.

Connections, Ports, and Interfaces

High-frequency RFID tags are typically passive and do not require direct physical connections to other devices. However, they interact with RFID readers via a wireless connection, using the 13.56 MHz frequency. The following interfaces are common for these tags:

ISO/IEC 14443 Interface:

This standard is widely used for contactless smart cards and payment systems. RFID tags adhering to this standard are compatible with most high-frequency RFID readers used in access control and transit applications.

ISO/IEC 15693 Interface:

This standard is used for applications that require longer read ranges and higher data transfer rates. Tags compliant with ISO/IEC 15693 are commonly used in logistics and supply chain management.

Industry Standards and Regulations

High-frequency RFID tags must comply with a range of industry standards to ensure interoperability and safety.

U.S. Regulations:

- FCC Part 15: The Federal Communications Commission (FCC) regulates RFID devices under Part 15 of its rules, which govern unlicensed radio frequency transmissions. High-frequency RFID tags must comply with these rules to avoid interference with other devices operating in the same frequency band.

Canadian Regulations:

- ISED Compliance: In Canada, high-frequency RFID tags are regulated by Innovation, Science and Economic Development (ISED) Canada. These regulations set limits on the emissions from RFID tags to ensure they do not interfere with other wireless devices.

- Global Standards: High-frequency RFID tags must also adhere to international standards such as ISO/IEC 14443, ISO/IEC 15693, and NFC (Near Field Communication) standards. These ensure that the tags can be read by a wide range of compatible devices, regardless of the manufacturer.

Quality Assurance and Testing

Functional Testing:

Before deployment, high-frequency RFID tags undergo rigorous functional testing to ensure they can be read at the intended distances and angles. This testing also ensures that the tags are durable enough to withstand their operating environment, whether that be a retail store or an industrial facility.

Environmental Testing:

High-frequency RFID tags are tested under various environmental conditions, including extreme temperatures, humidity, and physical stress. These tests are essential to ensure the tags will perform reliably throughout their lifecycle.

Data Integrity Testing:

To ensure data integrity, high-frequency RFID tags undergo read/write tests to verify that data can be stored and retrieved without errors. These tests are critical for applications such as access control and asset tracking, where accurate data is essential.

Our products are in stock and can be shipped overnight to Continental U.S. and Canada from one of our local warehouses. If you have any questions, our technical experts can help you. Please fill out this form or email us.