Asset Tracking Systems

What Makes Up an Asset Tracking System

![]() The GAO RFID Asset Tracking System is a fully integrated asset locating solution that tracks and monitors assets in real-time. The system is powered by three key components:

The GAO RFID Asset Tracking System is a fully integrated asset locating solution that tracks and monitors assets in real-time. The system is powered by three key components:

- GAO Asset Tracking Software

- GAO RFID Tags

- GAO RFID Readers

These three components work together to track assets globally or locally, and can be customized to address the needs of any business environment. In three simple steps, the GAO Asset Tracking System empowers you to know exactly where your assets are on demand. Here’s how:

STEP 1:

Specific GAO RFID Tags are physically placed on your valuable assets.

STEP 2:

GAO RFID Readers are tailor-fit to your business environment and installed at strategic points so that they can “read” the signals being broadcasted by the GAO RFID Tags.

STEP 3:

The GAO RFID Tags assigned to your assets are imported into our GAO Asset Tracking Software. Through an intuitive interface, you can track and locate specific assets on-site from a laptop, remotely on your web browser, or even while on the go using your mobile device.

![]()

Improved Loss Prevention

Full Asset Visibility

Increased Efficiency for Production & Shipping

RFID Asset Tracking System Details

Click on any item below to learn more

If you’re in charge of a business or a particular unit within an organization, chances are you’ve wanted to know about which assets are owned, who they’re being used by, or where they may be located.

You’re not alone.

This need is shared by decision makers around the world and is the reason why Asset Tracking Systems have emerged as a must-have technology in today’s competitive business landscape.

Here are some common questions Asset Tracking can solve for businesses:

- How can we keep track of our laptops, tablets, and other electronic devices?

- Is it possible to help our nurses find wheelchairs and infusion pumps quickly?

- How can we minimize misplaced parts and tools in our factory?

- How can we track our armored vehicles and specialized equipment?

- How do we reduce expendable packing costs?

- We need to track which trailers are entering or exiting our yard. Is it possible?

- How can we track our pallets?

- How can we track our returnable containers?

- Is it possible for us to tag and track individual livestock?

Asset Tracking using Radio Frequency Identification (RFID) is the answer to these mission critical problems. By using GAO RFID Asset Tracking, you are deploying state-of-the-art equipment to locate the whereabouts of your company’s valuables. Knowing where they are means you can show accountability in your business units and have an extremely clear grasp of your asset utilization.

At GAO RFID, we are serious about helping our customers track and monitor the location of assets with customized solutions, below are the Asset Tracking Systems we have developed and deployed for our customers:

- Learn about our IT Asset Tracking System

- Learn about our Pallet & Returnable Transport Item Asset Tracking System

- Learn about our Tool & Industrial Equipment Asset Tracking System

- Learn about our WIP Asset Tracking System

Many companies are not familiar with the existence of Asset Tracking systems and often struggle with determining the cost/benefit of this technology. The following questions will help you decide whether your business is ready for Asset Tracking:

Do you have long-term physical assets that are moveable?

If you have expensive mobile or portable assets that can be misplaced or stolen, then being able to track and locate these items might be what you need.

How many of these items do you own?

The more mobile and portable assets you own, the greater the need you have for Asset Tracking. While sometimes the thought of losing one small asset is trivial, imagine how in a shipping yard that is charged with maintaining thousands of containers, one small loss can quickly multiply if left unmonitored.

Once lost, what are the chances for these assets to be located again?

If you feel it is virtually impossible to locate valuable company resources once they go missing, an Asset Tracking system will provide you with a greater potential return on your investment.

What are the consequences if you cannot locate these assets?

For many industries, the loss of certain assets may result in consequences more severe than financial losses: legal, safety, health, security, and privacy can all be greater concerns to your company when an asset is lost. This is where an Asset Tracking System can become an integral part of your operations.

How much can you potentially save by being able to track these assets?

While every company calculates potential savings differently, a general approach is to accept that the savings for a company can be significant due to gains in labour, productivity, and the prevention of theft.

If any of the questions above touched on issues you are currently experiencing, then GAO Asset Tracking can help you better manage your business.

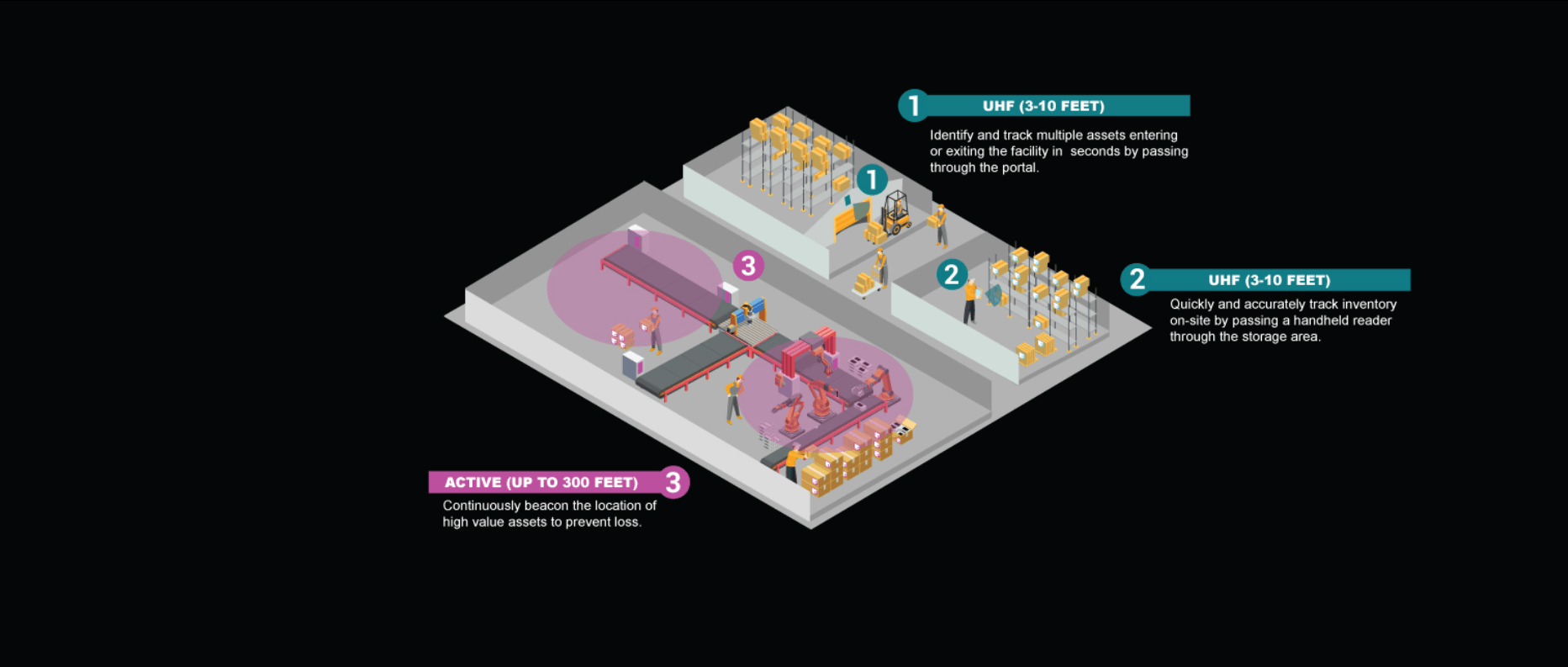

How RFID Applies to an Asset Tracking System

Click on any item below to learn more

Asset Tracking uses Radio Frequency Identification (RFID) technology to locate assets. RFID tags take the guesswork out of Asset Tracking. These tags are attached to the things that matter most to your business, anything from computers to livestock. In turn, the RFID Tags broadcast the locations of these items. This gives you real-time information on the status, movement, and position of every asset.

As an example, in the Automobile Manufacturing industry, suppliers struggle with locating returnable containers. By using RFID Asset Tracking, an enhanced visibility of the containers is provided, giving you the ability to locate them within the expanse of your supply chain. This ultimately reduces your cost of ownership for returnable containers and puts knowledge in your hands.

The GAO Short Range Asset Tracking System is one of two Passive RFID versions available for our Asset Tracking System that uses two distinct radio frequencies: low frequency and high frequency. Low frequency systems cover frequencies from 125 to 134.2 KHz, while high frequency systems cover 13.56 MHz.

Because ultra-high frequency radio waves bounce off metal and are absorbed by water, low and high frequencies are the ideal choice for tracking products that involve these properties. The GAO Short Range Asset Tracking System is designed to excel in environments where tracking metal products or items with water content are required.

Bottom Line

The GAO Short Range Asset Tracking System offers:

- An economical solution

- Controlled access to assets

- A perfect solution for metal or liquid products

The GAO Mid-Range Asset Tracking System is one of two Passive RFID versions of our Asset Tracking System. In this system, the RFID Reader sends signals to the Tags assigned to your assets. The Tag uses this transmitted signal to power on and reflects information back to the Receiver; thereby making the asset locatable. The GAO Mid-Range Asset Tracking System uses the Ultra-High Frequency (UHF) radio band, a band covering the range of 860 MHz to 960 MHz. UHF operates on a worldwide standard and has 20 times the range and speed of the High Frequency (HF) radio band. This makes it optimal for applications where the scanning of many items at once is required, such as boxes as they pass through a door or an electronic toll collector.

The GAO Mid-Range Asset Tracking System is ideal for in-building asset tracking applications, whether in the office or in manufacturing environments.

Bottom Line

The GAO Mid-Range Asset Tracking System enables you to:

- Maintain a chain of custody

- Control access to assets

- Manage inventory of tool and equipment

The GAO Long Range Asset Tracking System is the Active RFID version of our Asset Tracking System that uses the 433 MHz and 2.45 GHz bands. Because it uses Active RFID technology, the Tags which are assigned to your assets have their own transmitter and power source. This means they broadcast their signal and transmit their information actively, making real-time locating possible. Active tags are especially useful for large objects such as containers and rail cars that need to be tracked over long distances.

Bottom Line

The GAO Long Range Asset Tracking System helps you to:

- Improve security and alerting

- Protect intellectual property

- Locate assets in real-time on a map

- Improve asset utilization

The GAO Asset Tracking System is available as a cloud-computing solution. Using our Cloud or SaaS solution, you won’t need to make costly investments in servers and other infrastructure. Instead, our services-based Cloud system allows you to pay for applications only when you need them.

Benefits of the Cloud-based GAO Asset Tracking System:

- Lower initial investment by avoiding costly infrastructure expenses

- Faster roll out for a quicker ROI

- Ongoing software updates

- Highly scalable

- Access anywhere through a web browser

- Always-on and secure with the option of hosting on our servers or your own private network

Asset Tracking System: Applications

The GAO Asset Tracking System has been successfully applied to the industries world-wide:

Oil & Gas Industry

Asset tracking is a cornerstone of operational efficiency and safety in the oil and gas industry. Given the capital-intensive and often hazardous nature of this sector, having real-time visibility and control over physical assets is crucial. From drilling rigs and pipelines to storage tanks and transport equipment, RFID (Radio Frequency Identification) technology enables precise tracking, ensuring that assets are optimally utilized and well-maintained.

RFID Asset Tracking in the Oil & Gas Industry

The oil and gas industry operates in challenging environments, demanding robust and reliable asset management solutions. From sprawling drilling rigs and intricate pipelines to critical equipment and valuable inventory, tracking physical assets is paramount for operational efficiency, safety, and cost control.

Key Applications of Asset Tracking in the Oil & Gas Industry:

Equipment Tracking:

- Drilling Rigs: Tracking drilling rigs and associated equipment, such as pumps, generators, and mud tanks, is crucial. RFID enables real-time monitoring of their location and movement, facilitating efficient mobilization and demobilization across various sites. This minimizes equipment loss, reduces downtime, and optimizes resource allocation.

- Production Equipment: Monitoring the location and usage of production equipment, including compressors, separators, and tanks, is vital for optimizing production schedules and identifying underutilized assets. RFID technology allows for continuous tracking, enabling predictive maintenance and minimizing costly equipment failures.

- Maintenance Equipment: Tracking the location and service history of maintenance equipment, such as repair tools, spare parts, and welding equipment, ensures timely maintenance and reduces downtime. By tracking usage patterns and identifying wear and tear, proactive maintenance schedules can be implemented, improving overall equipment lifespan and reducing operational costs.

Pipeline Tracking:

- Pipeline Integrity: Tracking the location and condition of pipelines, including valves, fittings, and joints, is critical for ensuring pipeline integrity and safety. RFID technology can be integrated with sensors to monitor pressure, temperature, and other critical parameters, enabling early detection of potential leaks, corrosion, or other anomalies. This proactive approach minimizes environmental risks and prevents costly disruptions to operations.

- Asset Management: Tracking the installation and maintenance of pipeline components ensures compliance with industry regulations and improves the overall efficiency of pipeline operations. RFID technology can be used to track the history of each component, including installation dates, maintenance records, and inspection results, providing valuable data for asset management and regulatory compliance.

Inventory Management:

- Supply Chain: Tracking the movement of inventory, such as drilling fluids, chemicals, and spare parts, throughout the supply chain is essential for optimizing logistics and minimizing stockouts. RFID technology enables real-time visibility into inventory levels, allowing for just-in-time deliveries, reducing inventory holding costs, and improving overall supply chain efficiency.

- Warehouse Management: Monitoring the location and usage of inventory within warehouses and storage facilities ensures accurate inventory counts, prevents stockpiling, and improves overall warehouse efficiency. RFID technology can automate inventory tracking processes, reducing manual data entry errors and minimizing the risk of inventory loss or theft.

Benefits of RFID Asset Tracking in the Oil & Gas Industry:

- Improved Operational Efficiency: Streamlines operations by optimizing asset utilization, minimizing downtime, and reducing manual data entry.

- Enhanced Safety: Improves worker safety by tracking personnel in hazardous locations and identifying potential safety hazards.

- Reduced Costs: Minimizes inventory losses, improves maintenance planning, and optimizes resource allocation, leading to significant cost savings.

- Increased Productivity: Enhances productivity by improving the efficiency of asset management processes, reducing downtime, and optimizing resource utilization.

- Improved Decision Making: Provides valuable insights into asset usage, performance, and maintenance needs, enabling data-driven decision making and proactive maintenance strategies.

By leveraging RFID technology, oil and gas companies can significantly enhance their operational efficiency, improve safety, and reduce costs across the entire value chain. RFID provides a powerful tool for managing assets effectively, optimizing operations, and ensuring the long-term success of their businesses.

Discover GAO Asset Tracking System solutions for the Oil & Gas Industry

Manufacturing Industry

Asset tracking in the manufacturing industry is vital for ensuring operational efficiency, reducing costs, and improving asset utilization. It is essential for tracking physical assets, such as machinery, equipment, tools, raw materials, and finished goods, throughout their lifecycle in the production environment. By leveraging RFID (Radio Frequency Identification) technology, manufacturers can gain real-time visibility into their assets, ensuring that they are properly managed and optimized for maximum productivity.

Key Applications of Asset Tracking in the Manufacturing Industry

Equipment Tracking

Monitoring Machinery:

- Why it matters: Expensive machinery like CNC machines, robots, and assembly lines are crucial to the manufacturing process. Downtime due to malfunction or maintenance issues can significantly impact production.

- How asset tracking helps: By tracking the location and usage of these machines, manufacturers can:

- Schedule preventive maintenance proactively, minimizing unexpected downtime.

- Monitor machine performance and identify potential issues early on.

- Optimize machine utilization by identifying underutilized equipment and reallocating resources.

IT Asset Management:

- Why it matters: IT assets like laptops, desktops, and tablets are essential for modern manufacturing operations. Tracking these assets is crucial to prevent theft, ensure proper utilization, and maintain IT security.

- How asset tracking helps:

- Track the location of IT assets within the facility.

- Monitor asset usage and identify unauthorized use.

- Streamline IT support by quickly locating and troubleshooting equipment.

- Reduce the risk of data breaches by tracking the location of sensitive company data.

Inventory Management

Work-in-Process Tracking:

- Why it matters: Efficiently tracking work-in-process inventory is essential for optimizing production flow and minimizing bottlenecks.

- How asset tracking helps:

- Monitor the movement of raw materials, components, and finished goods through each stage of the production process.

- Identify and address bottlenecks in the production line.

- Improve production planning and scheduling.

Supply Chain Visibility:

- Why it matters: Understanding the location and movement of goods throughout the supply chain is crucial for timely delivery and cost-effective operations.

- How asset tracking helps:

- Track goods from suppliers to the manufacturing facility and throughout the distribution chain.

- Identify potential delays or disruptions in the supply chain.

- Improve inventory management and reduce the risk of stockouts or overstocking.

Tool and Equipment Tracking

- Why it matters: Tools and equipment are essential for manufacturing operations, but they can be easily misplaced or stolen.

- How asset tracking helps:

- Prevent the loss or theft of valuable tools and equipment.

- Ensure proper tool usage and maintenance by tracking check-out and check-in times.

- Reduce downtime caused by missing or misplaced tools.

- How asset tracking helps:

Quality Control

- Why it matters: Maintaining high product quality is critical for customer satisfaction and brand reputation.

- How asset tracking helps:

- Track the movement of specific components through the production process.

- Identify potential quality issues by tracing the origin of defective parts.

- Improve product traceability and compliance with regulatory requirements.

- How asset tracking helps:

Benefits of RFID Asset Tracking in the Manufacturing Industry

Increased Efficiency:

- Streamlined production processes by minimizing downtime and optimizing workflow.

- Reduced labor costs associated with manual tracking and inventory counts.

Improved Productivity:

- Real-time visibility into asset location and usage enables better resource allocation and faster response times.

Reduced Costs:

- Minimize equipment loss and theft.

- Optimize inventory levels and reduce carrying costs.

- Lower maintenance costs through proactive maintenance scheduling.

Enhanced Accuracy:

- Eliminate manual data entry errors and improve the accuracy of inventory records.

Improved Security:

- Enhanced visibility into asset movement and usage reduces the risk of theft or unauthorized access.

Better Compliance:

- Ensure compliance with industry regulations and traceability requirements.

Data-Driven Decision Making:

- Generate valuable data on asset utilization, production bottlenecks, and other key performance indicators to inform strategic decisions.

RFID-based asset tracking provides manufacturing companies with a competitive advantage by offering real-time visibility, lowering operational costs, and boosting efficiency. It supports the tracking of various assets, such as machinery, inventory, tools, and IT assets, making it a scalable solution for managing assets throughout their lifecycle. RFID’s ability to improve productivity, enhance security, and streamline operations helps manufacturers optimize asset utilization, reducing inefficiencies and staying competitive in a fast-paced industry.

Discover GAO Asset Tracking System solutions for the Manufacturing Industry

Construction Industry

Asset tracking plays a vital role in managing the diverse range of physical assets used across residential, non-residential, and engineering projects. These assets, including heavy machinery, construction materials, tools, and equipment, are essential for project success and require accurate tracking to optimize their utilization and reduce costs.

RFID Asset Tracking in the Construction Industry

The construction industry, known for its dynamic and fast-paced nature, faces unique challenges in managing a vast array of assets. From heavy machinery and equipment to smaller tools and materials, effective asset tracking is critical for optimizing costs, enhancing productivity, and ensuring the success of projects. RFID technology offers a reliable solution to streamline asset management, providing real-time visibility and reducing inefficiencies.

How it Works:

RFID (Radio-Frequency Identification) technology revolutionizes asset tracking within the construction sector. It involves attaching small, electronic tags to various assets. These tags contain unique identifiers that can be read by RFID readers at a distance. This wireless communication enables real-time tracking and monitoring of assets throughout the construction site and beyond.

Key Applications of Asset Tracking in the Construction Industry

Equipment Tracking:

- Heavy Machinery: Monitor the location and usage of large equipment like excavators, cranes, bulldozers, and dump trucks. This helps prevent theft, optimize equipment utilization, and schedule maintenance effectively.

- Small Tools & Equipment: Track the whereabouts of smaller tools like drills, saws, and ladders to minimize loss, improve inventory control, and ensure their availability when needed.

Material Tracking:

- Inventory Management: Track the movement of building materials, from raw materials to finished components, throughout the construction site. This ensures timely delivery, prevents theft or loss, and optimizes material ordering.

- Waste Reduction: Monitor material usage to identify and minimize waste, improving project efficiency and reducing environmental impact.

Rental Equipment Management:

- Usage Monitoring: Track the usage of rented equipment to optimize rental costs and ensure timely returns.

- Damage Prevention: Monitor equipment condition to identify potential damage and reduce repair costs.

- Billing Accuracy: Accurately track rental periods for accurate billing and invoicing.

Maintenance Management:

- Preventative Maintenance: Track equipment usage to schedule timely maintenance, prevent costly breakdowns and ensure optimal equipment performance.

- Predictive Maintenance: Analyze equipment data to predict potential failures and schedule maintenance proactively.

Benefits of Asset Tracking in the Construction Industry

- Reduced Theft & Loss: Real-time tracking significantly minimizes the risk of theft or unauthorized use of valuable equipment and materials.

- Improved Inventory Management: Accurate inventory data leads to better material ordering, reduced waste, and optimized resource allocation.

- Enhanced Equipment Utilization: By monitoring equipment usage, companies can identify underutilized assets and optimize their deployment.

- Increased Efficiency: Streamlined processes, such as tool management and material tracking, lead to improved operational efficiency and faster project completion.

- Cost Savings: Reduced equipment loss, improved inventory control, and optimized resource allocation translate into significant cost savings for construction projects.

- Enhanced Safety: Real-time location tracking of personnel and equipment can enhance safety on the construction site.

- Improved Project Planning & Scheduling: Accurate data on asset availability and usage enables better project planning and scheduling, minimizing delays and ensuring projects stay on budget.

- Better Data-Driven Decisions: Asset tracking data provides valuable insights into project performance, allowing for data-driven decision-making and continuous improvement.

By implementing effective asset tracking systems, construction companies can gain a significant competitive advantage by improving efficiency, reducing costs, and enhancing overall project success.

Discover GAO Asset Tracking System solutions for the Construction Industry

Food & Beverage Industry

Food & Beverage Industry

The food and beverage industry operates within a complex and highly regulated environment. Prioritizing product safety, maintaining consistent quality, and optimizing operational efficiency are paramount for businesses in this sector.

Leveraging RFID for Enhanced Control

RFID (Radio-Frequency Identification) technology offers a powerful solution for addressing these critical challenges. By implementing RFID systems, businesses can gain real-time visibility and enhanced control over key assets throughout the entire production and distribution chain.

Key Applications of Asset Tracking in the Food & Beverage Industry:

Equipment Tracking:

- Predictive Maintenance: Track the usage and performance of critical equipment (e.g., processing lines, packaging machines, refrigeration units). This data enables proactive maintenance scheduling, minimizing downtime and optimizing equipment lifespan.

- Calibration & Inspections: Ensure timely and accurate calibration and inspection of equipment, ensuring compliance with industry regulations and maintaining product quality.

Inventory Management:

- Raw Material Tracking: Monitor the movement of raw materials (e.g., ingredients, packaging) from receiving to production, ensuring accurate inventory levels and preventing spoilage.

- Finished Goods Tracking: Track the location and movement of finished goods throughout the warehouse, distribution center, and transportation network.

- Traceability: Enhance product traceability by tracking ingredients and raw materials from source to consumer, enabling rapid response to potential contamination issues and facilitating recalls.

Supply Chain Visibility:

- Transportation Tracking: Monitor the location and movement of pallets, crates, and other transport units throughout the supply chain.

- Logistics Optimization: Identify bottlenecks and optimize transportation routes, reducing delivery times and minimizing transportation costs.

Benefits of RFID Asset Tracking in the Food & Beverage Industry:

- Enhanced Efficiency: Streamlined inventory management, reduced search times for misplaced equipment, and optimized maintenance schedules contribute to increased operational efficiency.

- Improved Quality Control: Real-time monitoring of temperature-sensitive items and accurate traceability of ingredients ensure product safety and quality.

- Reduced Costs: Minimized equipment downtime, reduced waste, and optimized inventory levels translate into significant cost savings.

- Increased Productivity: Automated data collection frees up personnel for more value-added tasks, improving overall productivity.

- Enhanced Compliance: Enhanced traceability and accurate record-keeping help ensure compliance with food safety regulations and industry standards.

- Reduced Risk: Minimize the risk of product recalls and contamination by quickly identifying and addressing potential issues.

By implementing RFID-based asset tracking solutions, food and beverage manufacturers can gain a competitive edge by improving operational efficiency, enhancing product quality, and ensuring the safety and integrity of their products throughout the entire supply chain.

Discover GAO Asset Tracking System solutions for the Food & Beverage Industry

Healthcare Industry

Healthcare Industry

The healthcare industry is a dynamic and multifaceted domain where effective management of physical assets is essential for operational efficiency and delivering high-quality patient care. RFID-based asset tracking systems provide healthcare facilities with real-time visibility into their assets, enabling better resource utilization, minimizing losses, and significantly improving overall efficiency.

RFID Asset Tracking in the Healthcare Industry

RFID (Radio Frequency Identification) technology has revolutionized asset management across industries, particularly in healthcare. By leveraging RFID tags and readers, healthcare organizations can streamline operations, enhance safety, and reduce costs.

Key Applications in Healthcare:

Medical Equipment Tracking:

- High-Value Assets: Tracking costly equipment like MRI machines, CT scanners, and surgical robots is paramount. RFID helps prevent theft, loss, and ensures their availability when urgently needed.

- Preventative Maintenance: By monitoring equipment usage, scheduled maintenance can be optimized, reducing downtime and ensuring patient safety.

Surgical Instrument Tracking:

- Patient Safety: A critical application, RFID tags on surgical instruments minimize the risk of “foreign bodies” – leaving instruments inside patients during procedures. This significantly enhances patient safety.

- Inventory Management: Accurate tracking ensures the availability of the right instruments for each surgery, streamlining surgical workflows.

Pharmaceutical Tracking:

- Medication Safety: Tracking pharmaceuticals throughout the supply chain helps prevent medication errors, counterfeiting, and ensures proper storage conditions.

- Inventory Control: Real-time visibility into medication inventory helps optimize stock levels and prevent shortages, minimizing waste and ensuring timely patient care.

Wheelchair and Bed Tracking:

- Improved Patient Flow: Tracking the location of these essential items reduces wait times and ensures their availability when needed, improving patient experience and overall hospital efficiency.

Inventory Management:

- Supply Chain Optimization: Tracking medical supplies, consumables, and other inventory items helps optimize stock levels, reduce waste, and minimize the risk of stockouts.

Benefits of RFID Asset Tracking in Healthcare:

Enhanced Patient Safety

- Reduces medical errors, such as misplaced surgical tools or medication mistakes.

- Ensures the availability of critical equipment, minimizing delays in patient care.

Improved Operational Efficiency

- Saves time by eliminating the need to search for lost or misplaced equipment.

- Optimizes inventory management, reducing overstocking or shortages.

- Facilitates better maintenance schedules, maximizing equipment uptime.

Cost Reduction

- Minimizes equipment loss or theft, reducing financial burdens.

- Lowers costs associated with replacing lost or damaged items.

- Optimizes inventory, reducing excess stock and associated holding costs.

Revenue Growth

- Improves asset utilization, allowing healthcare facilities to provide timely care to more patients.

- Reduces downtime, leading to higher revenue generation opportunities.

Regulatory Compliance

- Supports compliance with healthcare regulations regarding medical device tracking, medication safety, and patient data management.

GAO RFID offers state-of-the-art asset tracking solutions tailored to meet the unique needs of healthcare organizations. Our solutions ensure efficient resource utilization, enhanced patient care, and compliance with industry regulations.

By implementing GAO RFID systems, healthcare facilities can transform their asset management practices, leading to better patient outcomes, streamlined workflows, and significant cost savings.

Discover GAO Asset Tracking System solutions for the Healthcare Industry

Retail Trade & Rental Industry

Retail Trade & Rental Industry

In the fast-paced world of retail and rental, managing physical assets is a critical yet complex undertaking. From tracking inventory across multiple locations to monitoring the whereabouts of valuable equipment, businesses face the constant challenge of maintaining accurate records while ensuring smooth operations. Radio Frequency Identification (RFID) technology has emerged as a powerful solution, offering real-time visibility and control over assets, transforming the way businesses operate.

Key Applications of RFID in Retail and Rental:

Inventory Management:

- Real-time Visibility: RFID enables instant tracking of inventory levels across all locations, from warehouses to individual stores. This real-time data empowers businesses to make informed decisions regarding ordering, pricing, and promotions. For example, a retailer can quickly identify low stock levels and initiate immediate replenishment orders, preventing stockouts and ensuring customer satisfaction.

- Minimized Shrinkage: By tracking item movements with RFID, businesses can significantly reduce inventory shrinkage due to theft, damage, or misplaced items. This not only protects the company’s bottom line but also enhances customer trust.

- Automated Reordering: RFID systems can be integrated with inventory management software to trigger automatic reorders when stock levels fall below predetermined thresholds. This proactive approach ensures timely replenishment, minimizes the risk of stockouts, and optimizes inventory levels.

- Streamlined Checkouts: RFID technology revolutionizes the checkout process by enabling the rapid scanning of multiple items simultaneously. This significantly reduces wait times, improves customer satisfaction, and enhances the overall shopping experience.

Equipment Tracking:

- Rental Equipment Management: In the rental industry, RFID plays a crucial role in tracking the location and usage of equipment such as tools, vehicles, and machinery. This real-time tracking facilitates efficient utilization, prevents unauthorized use, and enables proactive maintenance scheduling, minimizing downtime and repair costs.

- Preventative Maintenance: By analyzing equipment usage data captured by RFID tags, businesses can schedule preventative maintenance based on actual usage rather than arbitrary timelines. This proactive approach extends the equipment’s lifespan, reduces the risk of unexpected breakdowns, and minimizes costly repairs.

Supply Chain Optimization:

- Streamlined Logistics: RFID enables real-time tracking of shipments throughout the entire supply chain, from the point of origin to the final destination. This provides valuable insights into shipment status, identifies potential delays, and facilitates proactive measures to ensure timely delivery.

- Reduced Inventory Holding Costs: By optimizing inventory levels across the supply chain, businesses can minimize storage costs, reduce the risk of stockouts, and improve overall supply chain efficiency.

Benefits of RFID Asset Tracking Retail Trade & Rental Industry:

- Increased Efficiency: RFID streamlines operations by automating manual tasks, reducing labor costs, and improving overall productivity.

- Reduced Costs: By minimizing inventory losses, optimizing stock levels, and streamlining operations, businesses can significantly reduce operational expenses.

- Improved Accuracy: RFID technology enhances inventory accuracy, minimizing discrepancies between physical stock and recorded data. This leads to better financial reporting, improved decision-making, and increased profitability.

- Enhanced Security: RFID systems deter theft and facilitate the rapid recovery of lost or stolen assets through real-time tracking and monitoring capabilities.

- Data-Driven Decisions: The wealth of data collected by RFID systems provides valuable insights into inventory trends, customer behavior, and operational performance. This data-driven approach empowers businesses to make informed decisions that drive growth and profitability.

In today’s competitive landscape, businesses that embrace RFID technology gain a significant competitive advantage. By enhancing operational efficiency, reducing costs, and improving customer satisfaction, RFID asset tracking empowers businesses in the retail and rental industries to thrive and achieve sustainable growth.

Discover GAO Asset Tracking System solutions for the Retail Trade & Rental Industry

Passenger Transport Industry

Passenger Transport Industry

The Passenger Transport Industry encompasses a diverse range of sectors, including airlines, railways, ports, and bus services. These organizations rely heavily on a vast array of physical assets, from aircraft and trains to baggage handling equipment, ground support vehicles, and even specialized tools. Efficiently managing these assets is paramount for ensuring safety, optimizing operational efficiency, and ultimately, driving profitability.

RFID Asset Tracking in the Passenger Transport Industry

Radio Frequency Identification (RFID) technology offers a powerful solution for enhancing asset tracking within this dynamic industry. RFID utilizes small, electronic tags attached to assets that emit unique identification signals. These signals are then read by RFID readers, enabling real-time tracking and monitoring of asset movements throughout the entire transportation journey.

Key Applications of Asset Tracking in the Passenger Transport Industry:

Aircraft Maintenance:

- Tracking aircraft engines, landing gear components, and other critical parts throughout the maintenance process.

- Monitoring the location and usage of ground support equipment, such as baggage carts, tow tractors, and catering trucks.

Railway Operations:

- Tracking locomotives, rolling stock (wagons, carriages), and maintenance equipment.

- Monitoring the location and movement of rail infrastructure components, including switches, signals, and track sections.

Port & Harbor Operations:

- Tracking containers, cargo handling equipment (cranes, forklifts), and ground support vehicles within the port environment.

- Monitoring the location and movement of shipping containers throughout the supply chain.

Bus & Coach Operations:

- Tracking buses, spare parts, and maintenance equipment.

- Monitoring the location and usage of passenger amenities, such as on-board entertainment systems and wheelchair lifts.

Ground Transportation:

- Tracking taxis, ride-sharing vehicles, and rental cars within urban environments.

Benefits of RFID Asset Tracking in the Passenger Transport Industry:

Enhanced Asset Visibility: Real-time location tracking provides unparalleled visibility into the whereabouts of assets, minimizing the risk of theft, loss, or misuse. This significantly improves inventory accuracy and enables swift recovery of misplaced or stolen items.

Streamlined Maintenance:

- Automated data collection on equipment usage and maintenance history allows for more proactive maintenance scheduling, reducing downtime and optimizing maintenance costs.

- Predictive maintenance can be implemented by analyzing equipment usage patterns to identify potential failures before they occur, minimizing costly and unexpected repairs.

Improved Inventory Management:

- RFID technology significantly improves inventory accuracy, reducing the time and resources spent on manual inventory checks.

- Real-time inventory data enables better stock management, minimizing stockouts and optimizing procurement processes.

Increased Operational Efficiency:

- Tracking asset movement and utilization helps identify bottlenecks and optimize workflows, leading to improved operational efficiency and reduced labor costs.

Reduced Costs:

- By minimizing asset loss, optimizing maintenance schedules, and streamlining inventory management, RFID asset tracking can deliver significant cost savings across various departments.

Enhanced Safety:

- Real-time tracking of critical equipment can improve safety by ensuring timely maintenance and identifying potential hazards, such as malfunctioning ground support equipment or delayed maintenance on critical components.

By leveraging RFID technology, passenger transport companies can gain a significant competitive advantage through improved asset management, enhanced operational efficiency, and reduced costs.

Discover GAO Asset Tracking System solutions for the Passenger Transport Industry

Supply Chain & Logistics Industry

Supply Chain & Logistics Industry

Asset tracking is a vital element in the supply chain and logistics industry, ensuring smooth movement and management of physical assets across various touchpoints. RFID technology in asset tracking provides real-time visibility and control over items, ranging from warehouse equipment to shipping containers, optimizing operations and reducing inefficiencies.

Asset Tracking in the Supply Chain & Logistics Industry

The Supply Chain & Logistics industry consists of a complex network of interconnected processes, spanning from raw material sourcing to final product delivery. Efficient asset tracking is essential for optimizing these processes, minimizing losses, and ensuring cost-effective and timely operations.

Key Areas of Asset Tracking in Supply Chain & Logistics:

Warehouse & Storage:

- Tracking inventory: RFID tags attached to pallets, containers, and individual items provide real-time visibility of inventory levels, locations, and movements within the warehouse. This enhances stock accuracy, speeds up order fulfillment, and improves space utilization.

- Equipment tracking: RFID enables the tracking of warehouse equipment such as forklifts and pallet jacks, helping prevent theft, misuse, and ensuring timely maintenance.

Freight Trucking:

- Trailer tracking: RFID tags on trailers enable real-time location tracking, improving dispatch efficiency, route optimization, and reducing delivery times.

- Cargo tracking: RFID tags on cargo within trailers ensure security during transit and help prevent losses.

- Equipment maintenance: Tracking critical components like tires, brakes, and engines in freight trucks enables proactive maintenance, reducing downtime and extending vehicle lifespan.

Vessel Transportation:

- Container tracking: RFID tags attached to shipping containers enable real-time tracking of cargo movement across the shipping journey. This enhances visibility, minimizes delays, and reduces the risk of theft or loss.

- Vessel tracking: RFID tracking of vessels provides data on their location, speed, and arrival times, aiding in port operation optimization and improving overall logistics efficiency.

Rail Transportation:

- Rolling stock tracking: Tracking locomotives, freight wagons, and other rail assets allows for efficient maintenance, better asset management, and optimal usage.

- Cargo tracking: RFID tags on rail cargo enable secure and timely delivery while providing data for optimizing train schedules and improving operational performance.

Postal Services:

- Mail tracking: RFID tags on packages allow real-time tracking from origin to destination, providing customers with accurate delivery updates and enhancing satisfaction.

- Equipment tracking: RFID enables tracking of postal equipment such as sorting machines and delivery vehicles, helping optimize usage, prevent losses, and schedule maintenance.

Benefits of Asset Tracking in Supply Chain & Logistics:

- Reduced losses: Minimize the risk of asset theft, misplacement, or damage.

- Improved efficiency: Streamline operations, optimize routes, and reduce delivery time.

- Enhanced visibility: Gain real-time insights into asset locations and status across the supply chain.

- Better inventory management: Improve inventory accuracy, reduce stockouts, and streamline order fulfillment.

- Increased productivity: Improve asset utilization and reduce downtime.

- Improved customer satisfaction: Provide customers with precise delivery information, enhancing service quality.

By leveraging RFID technology, businesses in the Supply Chain & Logistics sector can significantly enhance operations, boost efficiency, and deliver exceptional service, gaining a competitive edge in the marketplace.

Discover GAO Asset Tracking System solutions for the Supply Chain & Logistics

Utilities Industry

Utilities Industry

The Utilities Industry encompasses companies providing essential services like electricity, gas, water, and sewage. These services are crucial for modern life but require significant investments in infrastructure and are heavily regulated. Challenges include aging infrastructure, environmental concerns, cybersecurity threats, and natural disasters.

RFID Asset Tracking in the Utilities Industry

The utilities industry, encompassing sectors like electric power generation, water supply, and sewage treatment, faces the critical challenge of managing vast and often geographically dispersed assets. From critical infrastructure like power transformers and water pumps to smaller but essential equipment like tools and meters, efficient asset management is paramount for ensuring reliable service delivery and minimizing operational disruptions.

Key Applications of RFID Asset Tracking

Critical Infrastructure Tracking:

- Transformers: Track location, health, and maintenance schedules to ensure reliable power delivery and minimize outages. RFID tags can be affixed to transformers to monitor their real-time location, operating temperature, and voltage levels. This data can be used to predict potential failures and schedule preventative maintenance, reducing costly emergency repairs.

- Substations: Monitor the status of equipment within substations, detect anomalies, and optimize maintenance operations. RFID tags can be used to track the location and status of circuit breakers, switches, and other critical components. This enables real-time monitoring of equipment health, early detection of potential problems, and efficient scheduling of maintenance activities.

- Power Lines: Track the location of poles, wires, and other components for maintenance and repair. RFID tags can be attached to poles, wires, and other infrastructure elements, enabling utilities to accurately map their network and efficiently locate and repair faults. This improves response times to outages and reduces repair costs.

Inventory Management:

- Spare Parts: Track stock levels, optimize inventory, and ensure timely delivery to field crews. RFID tags can be attached to spare parts, allowing for real-time tracking of inventory levels across warehouses and distribution centers. This helps optimize inventory levels, reduce stockouts, and ensure that necessary parts are available when needed for repairs, minimizing equipment downtime.

- Consumables: Monitor the usage and availability of consumables like fuel, lubricants, and safety equipment. RFID tags can be used to track the consumption of fuel, lubricants, and other consumables, allowing for better inventory planning and cost control. This also helps ensure that essential safety equipment is always readily available to field crews.

Equipment Maintenance:

- Predictive Maintenance: Integrate sensor data with location tracking to predict equipment failures and schedule proactive maintenance. While RFID plays a role in tracking asset location and movements, predictive maintenance often involves additional sensors and technologies like IoT to assess the condition and predict failures. This integration helps minimize downtime, reduces repair costs, and extends asset lifespan.

- Work Order Management: Track the location and movement of maintenance crews and equipment to optimize work orders and improve efficiency. RFID tags can be attached to maintenance vehicles and equipment, allowing for real-time tracking of their location and movement. This helps optimize work order scheduling, improve resource allocation, and ensure that maintenance crews are dispatched to the right location with the necessary equipment.

Meter Management:

- Smart Meter Tracking: Track the location and status of smart meters, optimize meter reading routes, and detect tampering. RFID tags can be embedded in smart meters, allowing for real-time tracking of their location and status. This enables utilities to optimize meter reading routes, improve data collection accuracy, and detect potential tampering or theft.

- Meter Data Management: Collect and analyze meter readings for accurate billing and demand forecasting. RFID technology can facilitate the collection and analysis of meter reading data, enabling utilities to improve billing accuracy, identify trends in energy consumption, and optimize their grid operations. However, real-time data transmission often requires other technologies like wireless communication or IoT.

Construction and Maintenance:

- Equipment Tracking: Track the location and usage of construction and maintenance equipment, such as excavators, cranes, and generators. RFID tags can be attached to construction and maintenance equipment, allowing for real-time tracking of their location and usage. This helps prevent equipment theft, optimize equipment utilization, and improve the efficiency of construction and maintenance operations.

- Material Tracking: Track the movement of construction materials to ensure timely delivery and prevent loss or theft. RFID tags can be attached to construction materials, allowing for real-time tracking of their movement from suppliers to the construction site. This helps ensure the timely delivery of materials, prevents theft or loss, and improves the overall efficiency of construction projects.

Benefits of RFID Asset Tracking

- Improved Operational Efficiency: Reduced downtime and faster response times to equipment failures. Optimized inventory management, leading to cost savings and reduced stockouts. Increased productivity of maintenance crews.

- Enhanced Asset Visibility: Real-time location tracking of critical assets across the entire network. Improved asset utilization and reduced equipment loss or theft.

- Improved Safety: Enhanced visibility of hazardous materials and equipment. Improved worker safety through real-time location tracking of personnel and equipment in hazardous areas.

- Reduced Costs: Lower maintenance costs through predictive maintenance (often integrated with other technologies like IoT). Reduced inventory costs through optimized stock levels. Improved operational efficiency leading to overall cost savings.

- Improved Customer Service: Faster response times to customer service requests. Improved service reliability and customer satisfaction.

By leveraging RFID technology for asset tracking, utilities can significantly enhance their operational efficiency, improve service reliability, and reduce costs while ensuring the safety of their workforce and the public.

Discover GAO Asset Tracking System solutions for the Utilities