An Accurate and Efficient Asset Management Solution For Manufacturers

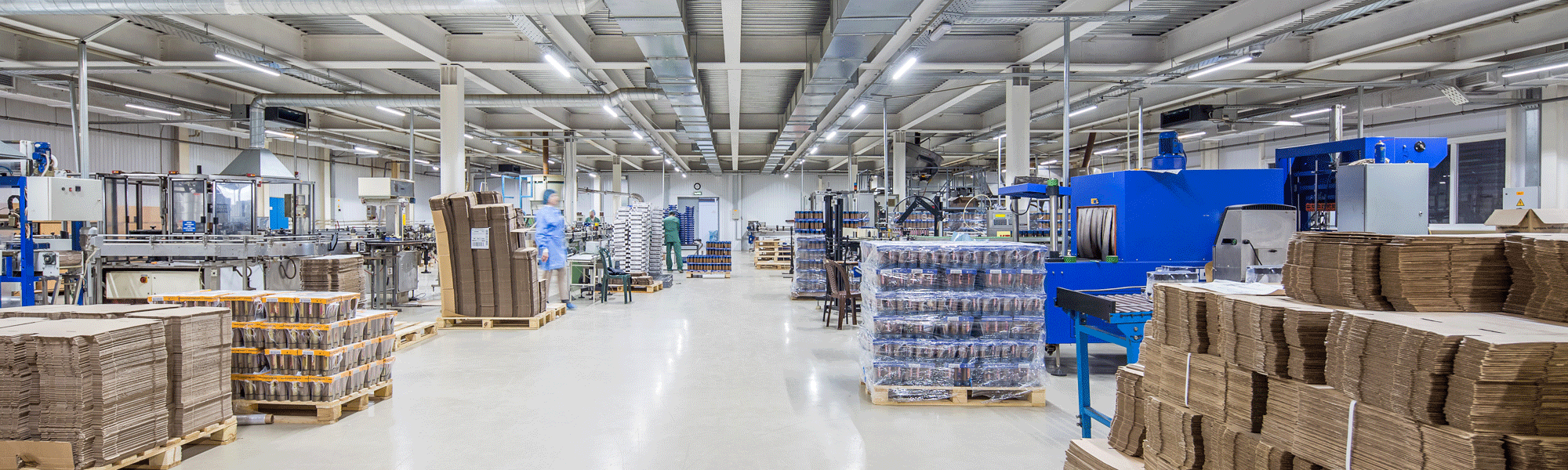

With this RFID solution, the asset management of your fruit and vegetable canning, pickling and drying business can be done simply by having an employee walk through the facility while holding a handheld computer with an RFID reader, which tracks the tagged assets.

For more technical details, please visit the GAO RFID Fruit and Vegetable Canning, Pickling and Drying Asset Management System page on our website.

What the GAO RFID Fruit and Vegetable Canning, Pickling and Drying Asset Management System Tracks

Our RFID system can track:

- Screw grader, roller grader

- Steam washing machines

- Peeling machines

- Can-filling machines

- Steam or machine vacuum

- Exhausting

- Sealing machines

- Microwave heated driers

Applications of the GAO RFID Fruit and Vegetable Canning, Pickling and Drying Asset Management System

This system can adapt to all sizes of processing factories. There are all kinds of canning, pickling and drying factories, including those that specialize in:

- Canned juices

- Canned baby food

- Canned soups

- Canned tomato sauce or paste

- Salsa

- Chilli

- Jellies

- Jams

- Relishes

- Bullions

This system is well suited to manage assets in all factory specialities and sizes.

LEARN MORE ABOUT THIS SYSTEM!

Click here to get detailed specifics of how this system will work.

Request a quote or speak to one of our RFID experts

to see how this system WILL save you time & money

The Canning, Pickling and Drying Industry

Canned, pickled or dried food can easily be found on shelves in all stores and supermarkets. Whether consumers need food that fits their budget, need something quick to make, or simply want preserves like pickles or jams, canned food has become a great alternative to fresh food.

Overall, canning, pickling, and drying refer to the process of preserving a large variety of foods in sealed cans to prevent it from being spoiled. The first step in canning is choosing fresh, ripe or mature fruits and vegetables. After that, they are graded and washed to remove the dirt, dust or any potential pesticides. The following steps are peeling, cutting, blanching and cooling the fruits and vegetables. After the cans have been washed and sterilized, they are filled with fruits or vegetables, as well as syrup or brine. After lidding the cans, they undergo the important process of exhausting, which is when the air is removed from the cans. This helps the fruits preserve numerous vitamins and reduces the corrosion, strain or oxidation of the cans.

Pickling requires a more complex process, as the vegetables go through brining and fermenting for around three to five weeks. Unlike canning, pickling is more suitable for younger fruits and vegetables, as the mature ones are already losing their texture and color. On the other hand, mature fruits sometimes undergo pickling, as is the case when producing jams.

Drying or dehydrating is known as the oldest method of preserving food. It is done by removing the water inside fruits or vegetables through sun drying or artificial dehydration. Usually, the fruits or vegetables go through pre-drying treatments, artificial or natural drying and post-dehydration treatments.

The global fruit and vegetable canning, pickling and drying market was estimated to be worth $200 billion in 2017. This year, the largest region in the canning and pickling industry was North America, with a market share of 31%. The USA played an important role constituted 24% of the market. Over the past three years, the US has been amongst the leading countries in the canning, pickling and drying industry, reaching $39.7 billion in revenue.

The leading companies to produce canned, pickled and dried fruits and vegetables are Kraft Heinz Company, Campbell Soup Co, JM Smucker Company, Tropicana Products Inc, TreeHouse Foods Inc, Dole Food Company Inc, Newman’s Own Inc, Chiquita Brands International Inc, and Del Monte Foods Inc.

Lately, more and more companies are increasingly outsourcing production operations to contract manufacturing companies. These companies are performing different operations like fruit and vegetable procurement, product development, production and packaging. This trend allows companies to focus on marketing and other core operations.

Based on the 2011 market forecast, the canning, pickling and drying industry was ‘back in trend’, because of the significant increase in demand. In 2021, the industry is expected to reach $234 billion, due to the fast urbanization and rapidly growing number of restaurants globally.

There are some debates about the lack of vitamins and nutrients in canned, pickled and dried fruits or vegetables. We can agree that some vitamins are lost during the manufacturing process, but the fruits or vegetables are still very healthy for consumption. Eating healthier has become a trend, so whether consuming the fruits and vegetables from cans, fresh, pickled or dried, it still going to give consumers enough nutrients to support their lifestyle.