Overview:

Bluetooth Low Energy (BLE) is transforming the manufacturing industry by enabling real-time tracking, condition monitoring, and automation across factory floors. GAO RFID Inc., headquartered in New York City and Toronto, is among the top 10 global suppliers of RFID and BLE, renowned for its significant investments in R&D and stringent quality assurance. Our BLE solutions streamline manufacturing processes, enhance equipment monitoring, and ensure workplace safety, helping manufacturers across the U.S. and Canada, including numerous Fortune 500 companies, achieve operational excellence. With our expert support available both remotely and onsite, GAO RFID empowers manufacturers to harness BLE technology for increased efficiency, data-driven decision-making, and reduced downtime.

Applications of BLE in Manufacturing:

- Real-Time Asset Tracking: BLE beacons enable manufacturers to monitor tools, equipment, and raw materials in real-time, minimizing asset loss and improving workflow management. GAO RFID’s BLE asset tracking solutions provide real-time location data, helping manufacturers enhance inventory management and reduce search time for essential items.

- Predictive Maintenance and Equipment Health Monitoring: BLE sensors continuously monitor equipment health indicators like temperature, vibration, and runtime, allowing for predictive maintenance. GAO RFID’s BLE technology supports maintenance teams by alerting them to potential issues before they escalate, reducing unplanned downtime and extending equipment lifespan.

- Production Line Automation: BLE technology facilitates automation by communicating with machines and systems along the production line. GAO RFID’s BLE solutions allow seamless data exchange between devices, optimizing process flows, and enabling more efficient manufacturing operations.

- Worker Safety and Location Tracking: BLE tags can track personnel in high-risk environments, ensuring worker safety by monitoring access to restricted areas and alerting management in case of emergency. GAO RFID’s BLE solutions help manufacturers enhance safety protocols, reducing risks and ensuring regulatory compliance.

- Tool and Equipment Tracking: BLE tags affixed to tools allow manufacturers to monitor tool usage, manage access, and prevent loss or misplacement. With GAO RFID’s BLE tool tracking systems, production teams can ensure that the right tools are available at the right time, reducing delays and optimizing tool utilization.

- Quality Control and Process Monitoring: BLE-enabled sensors monitor environmental conditions, such as temperature and humidity, essential for maintaining quality standards in sensitive manufacturing processes. GAO RFID’s BLE solutions help maintain product quality by ensuring environmental parameters are within specified ranges.

- Supply Chain and Inventory Management: BLE beacons provide real-time data on stock levels and inventory movement, supporting better supply chain management and minimizing stockouts. GAO RFID’s BLE systems offer manufacturers insights into material flow, improving inventory control and helping maintain lean manufacturing processes.

- Energy Monitoring and Efficiency Tracking: BLE sensors measure energy consumption and equipment performance, helping manufacturers track energy usage and identify inefficiencies. GAO RFID’s BLE energy monitoring solutions support manufacturers in reducing energy costs and improving sustainability efforts.

- Workforce Management and Productivity Tracking: BLE technology enables manufacturers to monitor workforce activity and productivity, optimizing labor allocation and enhancing overall efficiency. GAO RFID’s BLE solutions provide real-time insights into worker activity, helping management allocate resources effectively and maintain smooth operations.

- Automated Materials Handling: BLE tags on materials allow for automated tracking in materials handling processes, reducing manual intervention and human error. GAO RFID’s BLE solutions support streamlined material flows, improving handling efficiency, and reducing bottlenecks.

- Environmental Monitoring in Hazardous Areas: BLE sensors can monitor hazardous environments, such as detecting gas leaks or tracking air quality. GAO RFID’s BLE solutions provide continuous environmental monitoring, ensuring safety and compliance in regulated manufacturing settings.

- Security and Access Control: BLE technology can restrict access to sensitive areas by tracking personnel and controlling door access. GAO RFID’s BLE solutions allow manufacturers to enhance security measures, preventing unauthorized entry and ensuring secure facility operations.

GAO RFID Inc. offers tailored BLE solutions to help manufacturers achieve precise asset tracking, efficient maintenance, and optimized workflows, driving productivity and cost savings across manufacturing facilities.

Navigation Menu for BLE:

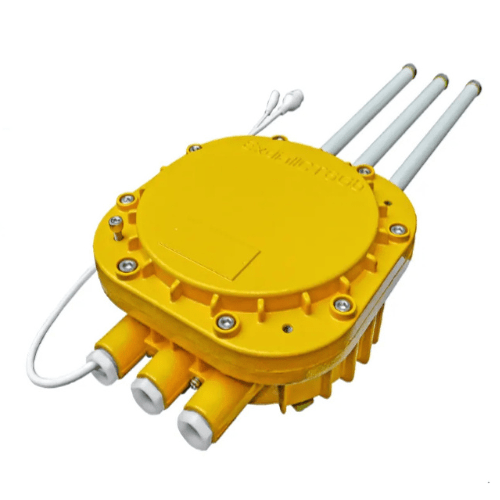

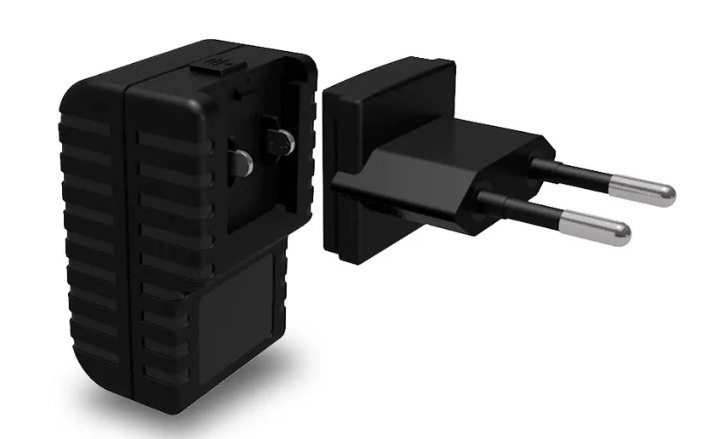

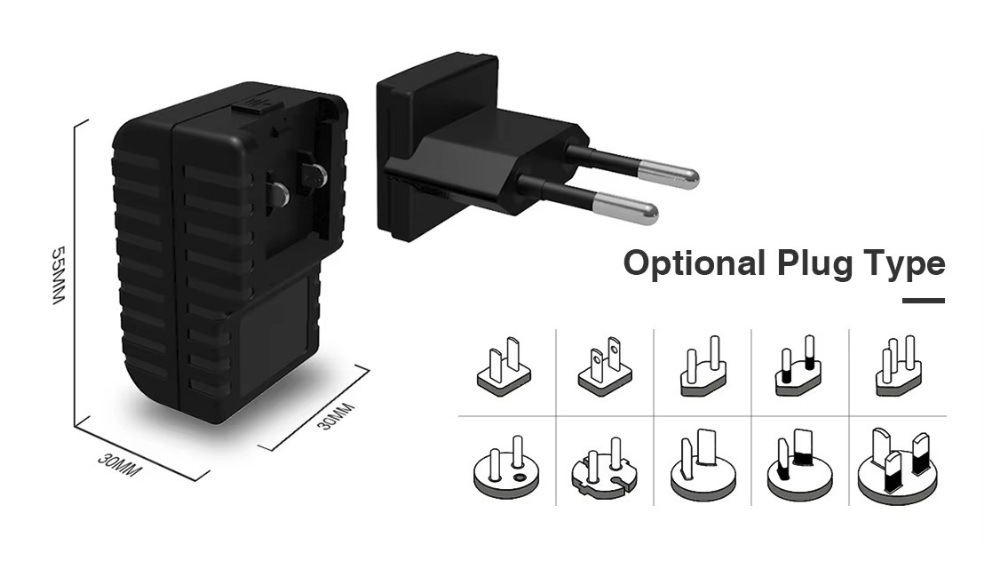

Here are BLE gateways offered by GAO:

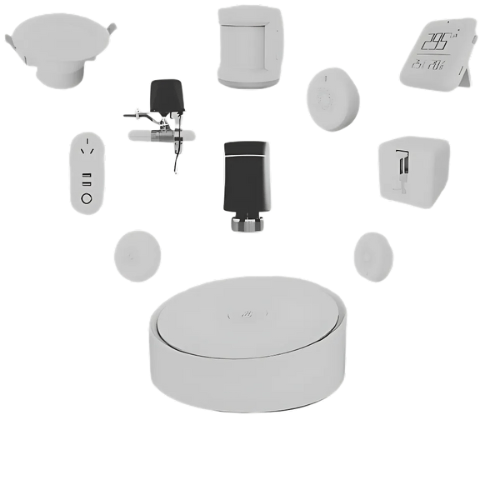

Here are BLE beacons offered by GAO:

Here are lists of BLE gateways offered by GAO:

Here are lists of BLE beacons offered by GAO:

Our products are in stock and can be shipped to anywhere in continental U.S. or Canada from our local warehouse. For any further information, please fill out this form or email us.