The railway construction industry is a vital sector that builds and maintains railway infrastructure, including tracks, bridges, tunnels, and signal systems. It also includes the manufacturing and maintenance of locomotives and railcars. This industry plays a crucial role in the transportation of goods and people across countries and continents. The industry is constantly evolving with new technologies and innovations, and it is committed to implementing sustainable solutions to reduce its environmental impact.

GAO RFID Inc., a global top 10 leader in RFID, has extensive experiences in the railway construction industry.

GAO RFID Systems & Hardware for Railway Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including railway construction industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for all kinds of industries, including railway construction.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including railway construction:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including railway construction:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including railway construction:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including railway construction:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in railway construction:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

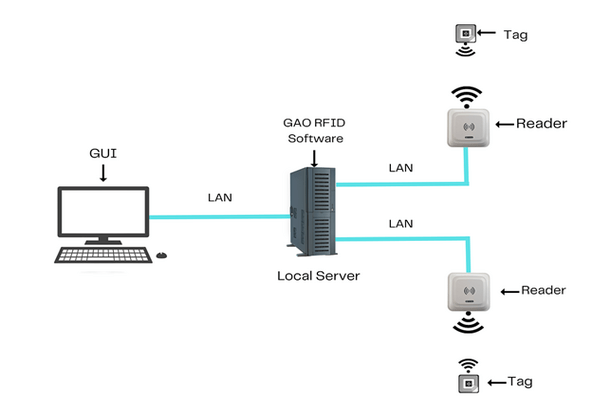

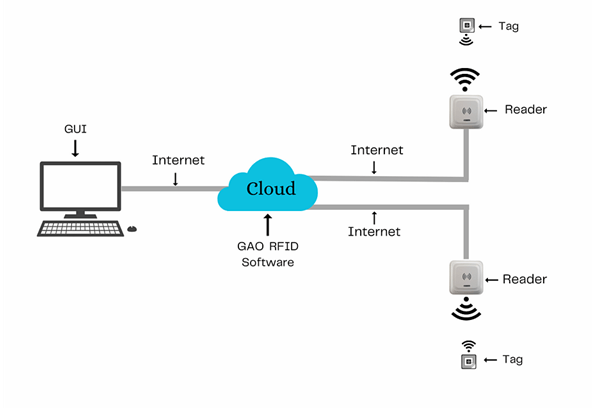

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO offers free samples of its RFID tags, labels, badges, and wristbands.

GAO offers a free trial for all of its software available.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Railway Construction

RFID, BLE, IoT and drones technologies from GAO RFID Inc. offer many benefits for the railway construction:

Applications & benefits of applying RFID to the railway construction

- Enhanced Asset Tracking: Our RFID solutions improves tracking of construction materials, reducing the risk of loss or theft, and provides real-time information about the location and status of assets.

- Improved Inventory Management: GAO RFID tags enable accurate and timely inventory management, reducing the need for manual inventory counts and minimizing waste.

- Enhanced Safety: Our RFID solutions improves safety by tracking the movement of workers and alerting supervisors if they are in hazardous areas. It can also monitor worker fatigue to prevent accidents.

- Better project management: RFID can be integrated with project management software to provide us real-time updates on project progress, which helps to ensure that the project is completed on time and within budget.

Applications & benefits of applying BLE solutions to the railway construction

- Real-time tracking and monitoring: GAO BLE solutions can be used to track and monitor railway assets such as trains, wagons, and cargo in real-time. This can improve the efficiency of railway operations and reduce the risk of accidents.

- Reduced maintenance costs: BLE solutions can be used to monitor the health of railway infrastructure such as tracks, bridges, and tunnels. This can help identify potential issues early on, allowing for timely maintenance and reducing overall maintenance costs.

- Energy efficiency: GAO BLE solutions can be used to optimize the use of energy in railway operations, such as by controlling the lighting and air conditioning systems in railway stations.

- Optimize workflows: Our GAO BLE sensors can be used to monitor the status of tie inserters and materials, providing real-time data that can help improve decision-making and optimize workflows.

Applications & benefits of applying combination of RFID and drones to the railway construction

- Improved asset tracking and management: GAO RFID solutions can be used to track and manage railway assets such as trains, wagons, and cargo. By combining this technology with drones, it is possible to track assets in real-time and detect any anomalies.

- Reduced maintenance costs: GAO RFID solutions can be used to monitor the health of railway infrastructure such as tracks, bridges, and tunnels. Drones can be used to conduct inspections of these assets, allowing for early identification of potential issues and reducing overall maintenance costs.

- Increased productivity: By combining GAO RFID solutions with drones, it is possible to automate many tasks that would otherwise require manual labor in railway construction industry. This can increase productivity and reduce the risk of human error.

Applications & benefits of applying combination of RFID and IoT to the railway construction

- Enhanced safety: GAO RFID with IoT sensors can be used to detect potential hazards on railway tracks, such as debris or animals on the tracks, and alert the appropriate personnel in real-time. This can help prevent accidents and improve overall safety.

- Enhanced passenger experience: By combining GAO RFID technology and IoT sensors, it is possible to provide passengers with real-time information on train schedules, delays, and other important information. This can enhance the overall passenger experience and improve customer satisfaction.

- Improved visibility and tracking: Our GAO RFID tags can be attached to construction materials, cranes, track jacks and assets, allowing them to be easily tracked and monitored throughout the construction process. With IoT sensors, the location, condition, and status of assets can be remotely monitored.

GAO Helps Customers Comply with Standards, Mandates & Regulations

GAO RFID Inc. has helped many companies in the Railway Construction to deploy GAO RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

- AAR RFID Tag Data Standard: This standard is developed by the Association of American Railroads (AAR) and specifies the requirements for RFID tags used in the railway industry. It is used for tracking and managing railway assets such as rolling stock, locomotives, and track components.

- UIC 918-3: This standard provides guidelines for the use of RFID technology in the railway industry, including the use of RFID tags and readers for asset management and train identification.

- Surface Transportation Board (STB) Regulations: The STB is responsible for regulating the economic aspects of railway operations, including rates, services, and competition.

- Federal Railroad Administration (FRA) regulations: The FRA is an agency within the U.S. Department of Transportation (DOT) that regulates the safety of railroad operations and equipment.

- Americans with Disabilities Act (ADA): Regulations on accessibility for people with disabilities in railway construction.

- Transport Canada regulations: Safety, construction, and operations regulations for railways.

- Canadian Environmental Assessment Act (CEAA): This law requires federal agencies to consider the environmental impacts of their actions, including those related to railway construction projects.

- Canada Labour Code (CLC): It sets out the minimum standards for working conditions in federally regulated workplaces, including those in the railway construction sub-industry. Its regulations cover issues such as hours of work, overtime pay, vacation pay, and workplace health and safety.

GAO’s Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking, access control, parking system control, are work in progress, offer a free trial and offers an API to each of the common software in the railway construction:

Personnel management

- Human Resource Management (HRM) software: This can help in managing the recruitment process, tracking employee attendance, handling payroll, and providing training and development opportunities.

- Time and Attendance Management System: This can be used to manage the attendance of employees, and automate the tracking of overtime, leave, and other time-off requests.

- Performance Management: This can be used to manage employee performance, set goals and objectives, and track progress towards achieving these goals.

Equipment Management

- Equipment Maintenance Management: This can help in tracking maintenance schedules, ensuring timely repairs, and managing the inventory of spare parts.

- Asset Tracking: This can be used to track the location of equipment, monitor usage, and prevent theft.

- Equipment Rental Management: This can help in managing the rental of equipment, including scheduling, billing, and inventory management.

Supply Chain Management

- Procurement Management: This can be used to manage the procurement of materials, supplies, and services, including vendor selection, contract management, and purchase order processing.

- Inventory Management: This can help in managing inventory levels, ensuring that there is enough stock on hand to meet demand, and reducing excess inventory.

- Logistics Management: This can be used to manage the transportation of materials and supplies, including scheduling, routing, and tracking shipments.

Other applications

- Project Management: This can help in managing the overall project, including scheduling, budgeting, and resource allocation.

- Safety Management: This can be used to manage safety policies and procedures, conduct safety audits, and ensure compliance with safety regulations.

- Quality Management: This can help in managing quality control processes, including inspections, testing, and certification.

Case Studies of RFID Applications

The Port of Long Beach in California underwent a major rail yard modernization project, and one of the technologies implemented was RFID. The RFID system was used to track the location and status of rail cars, equipment, and materials throughout the construction process. Each piece of equipment and material was tagged with an RFID tag, and readers were placed throughout the site. This allowed the construction team to quickly and accurately locate and track items, which improved efficiency and reduced delays. The RFID system also provided real-time information on the status of each item, which helped the team to manage inventory levels and reduce waste.

The Central Corridor Light Rail Transit Project in Minnesota used RFID technology to track the location and status of construction equipment and materials. The RFID system was used to monitor the movement of equipment and materials throughout the construction site, as well as to ensure that the correct equipment and materials were used in each stage of the project. The RFID system was integrated with the project management software, which allowed the team to monitor progress in real-time and make adjustments as needed. The use of RFID helped to reduce waste, improve efficiency, and ensure that the project was completed on time and within budget.

GAO Has Served the Railway Construction Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the railway construction, including its various divisions such as:

- Track construction and maintenance: This sub-industry is responsible for building and maintaining the track infrastructure, including the ties, ballast, and other components that make up the railway track.

- Signaling and train control: This sub-industry is responsible for designing, installing, and maintaining the signaling and train control systems that ensure the safe and efficient operation of trains.

- Railroad bridge and tunnel construction: This sub-industry is responsible for building and maintaining the bridges and tunnels that are necessary for the railway to cross over or pass under obstacles such as waterways, mountains, and highways.

- Railway maintenance and repair: This sub-industry is responsible for maintaining and repairing the various components of the railway system, including track, signaling systems, locomotives, and rolling stock.

Here are some leading companies in railway construction industry in US:

Here are some leading companies in railway construction industry in Canada: