Overview

The Aftermarket Manufacturing and Services industry focuses on supplying replacement parts, maintenance, repair services, and product customization for existing equipment and products. It serves various sectors, including automotive, electronics, industrial machinery, and more, with a strong emphasis on sustainability and technology integration.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in Aftermarket Manufacturing and Services Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as machine tools, diagnostic tools, welding and fabrication equipment, testing and measurement instruments, 3D printers, computer-aided design (CAD) software, lifting and handling equipment, comprehensive toolsets, diagnostic software, environmental control equipment, test benches, cleaning equipment, safety equipment, material handling equipment, vehicle lifts and hoists, packaging and shipping equipment, computer systems, power tools.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for Aftermarket Manufacturing and Services Industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications &Benefits of GAO’s RFID, BLE, IoT& Drones for Aftermarket Manufacturing and Services Industry

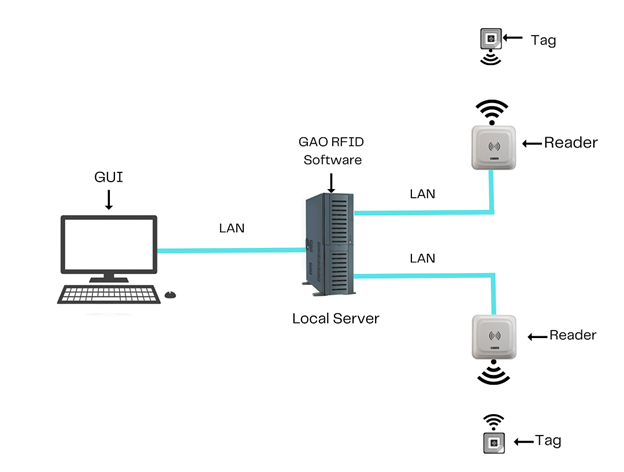

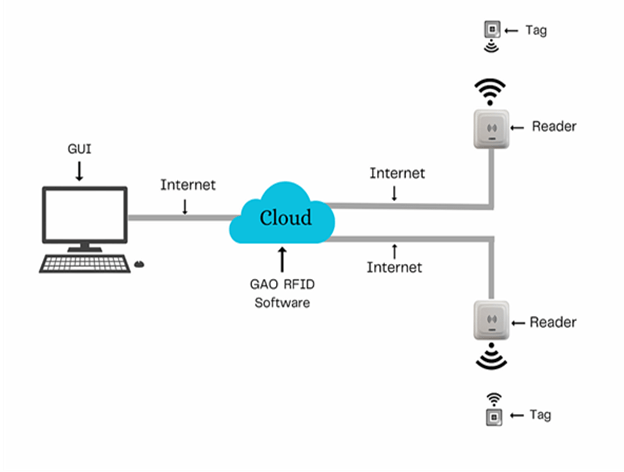

To satisfy its customers, GAO’s RFID or RFID Systems for Aftermarket Manufacturing and Services Industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for residential building construction software running on a local server.

Above illustrates GAO system for Aftermarket Manufacturing and Services Industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Aftermarket Manufacturing and Services Industry:

- Inventory Management: RFID tags can be attached to replacement parts and components, allowing for automated tracking of inventory levels. This helps businesses maintain optimal stock levels, reduce overstocking, and streamline procurement processes.

- Asset Tracking: RFID can be used to track the location and status of valuable assets, such as tools, equipment, and machinery. This reduces the risk of loss or theft and ensures assets are readily available for maintenance or repair tasks.

- Product Authentication: RFID tags can be integrated into replacement parts to verify their authenticity. This helps prevent the use of counterfeit or substandard components, ensuring the quality and reliability of repairs.

- Warranty Management: RFID technology can store warranty information on products and components. This simplifies warranty tracking, making it easier to identify eligible items for repair or replacement.

- Service History Tracking: By attaching RFID tags to equipment or products, service providers can easily access and update service histories. This information is valuable for diagnosing issues and performing timely maintenance.

- Tool and Equipment Management: RFID tags on tools and equipment enable easy monitoring of their usage, maintenance schedules, and location. This reduces downtime caused by misplaced or poorly maintained tools.

- Customer Engagement: RFID-enabled loyalty programs and customer portals can provide customers with real-time updates on service progress and product information. This enhances customer satisfaction and loyalty.

- Supply Chain Visibility: RFID can be employed to track the movement of aftermarket parts and components within the supply chain, from manufacturers to service centers. This ensures timely deliveries and efficient logistics.

- Anti-Theft Measures: RFID tags can act as anti-theft devices, triggering alarms or notifications when unauthorized removal of components or equipment is detected.

- Quality Control: RFID can assist in quality control processes by recording data about the manufacturing and testing of replacement parts, helping ensure consistency and reliability.

GAO’s drone technologies find the following applications in the Aftermarket Manufacturing and Services Industry:

- Asset Inspection: Drones can be used to inspect assets such as industrial machinery, infrastructure, and buildings. They can capture high-resolution images and videos, allowing for detailed visual inspections without the need for manual climbing or scaffolding.

- Inventory Management: Drones equipped with RFID or barcode scanners can quickly and accurately inventory replacement parts, helping businesses track stock levels and reduce manual counting errors.

- Site Surveys and Mapping: Drones can create accurate 3D maps and models of manufacturing facilities, construction sites, and other locations. These maps are valuable for facility planning, maintenance, and troubleshooting.

- Equipment Maintenance: Drones can reach inaccessible or hazardous areas to inspect and maintain equipment. They can identify wear and tear, loose components, or potential issues, facilitating timely repairs.

- Environmental Monitoring: Drones equipped with sensors can monitor environmental conditions in manufacturing plants, warehouses, or outdoor facilities, ensuring compliance with safety and regulatory standards.

- Security Surveillance: Drones can provide real-time surveillance of manufacturing plants and storage areas, enhancing security and helping to deter theft or vandalism.

- Supply Chain Tracking: Drones can track the movement of replacement parts, components, and products within the supply chain, improving logistics efficiency and reducing the risk of delays.

- Emergency Response: In the event of accidents, fires, or other emergencies, drones can be used to assess the situation quickly, providing critical information to first responders and aiding in decision-making.

- Site Safety Inspections: Drones can be used to inspect construction sites, manufacturing facilities, and warehouses for safety compliance, identifying potential hazards and reducing the risk of accidents.

- Customization and Prototyping: Drones equipped with 3D printing capabilities can create rapid prototypes and customized components, speeding up product development and customization processes.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the Aftermarket Manufacturing and Services Industry:

- Predictive Maintenance: IoT sensors on equipment and machinery monitor performance data in real time. This data is analyzed to predict maintenance needs accurately, reducing downtime and preventing costly breakdowns.

- Remote Equipment Monitoring: IoT allows for remote monitoring of equipment and assets, providing insights into their condition and performance from anywhere with an internet connection.

- Asset Tracking: IoT-enabled devices and tags are used to track the location, status, and usage of assets, including replacement parts and components, improving inventory management and reducing losses.

- Supply Chain Visibility: IoT sensors and RFID technology offer real-time visibility into the movement of replacement parts, products, and components throughout the supply chain, optimizing logistics and reducing delays.

- Energy Management: IoT systems can monitor and control energy consumption in manufacturing plants and facilities, helping to reduce energy costs and minimize environmental impact.

- Quality Control: IoT sensors and cameras can be used for quality control during the manufacturing process, ensuring that replacement parts meet specifications and quality standards.

- Environmental Monitoring: IoT devices can monitor environmental conditions in manufacturing plants and warehouses, ensuring compliance with safety and regulatory standards.

- Fleet Management: IoT-equipped vehicles and machinery enable efficient fleet management, with real-time tracking, route optimization, and maintenance scheduling.

- Customer Engagement: IoT devices can provide customers with real-time updates on service progress, maintenance schedules, and product information, enhancing customer satisfaction and loyalty.

- Inventory Optimization: IoT helps in optimizing inventory levels by providing accurate, real-time data on stock levels, demand patterns, and shelf life of replacement parts and components.

- Remote Diagnostics: IoT sensors and data analysis tools allow for remote diagnostics of equipment issues, enabling technicians to identify and resolve problems without being physically present.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Aftermarket Manufacturing and Services Industry

GAO RFID Inc. has helped many companies in Aftermarket Manufacturing and Services Industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations.

RFID, BLE, IoT, & Drone Standards & Mandates

- EPCglobal UHF Gen2

- MQTT

- CoAP

- HTTP/HTTPS

- AMQP

- OPC UA

- DDS

- LoRaWAN

- Zigbee

- 6LoWPAN

- ASTM F38

- ISO 21384-3:2019

- ISO 23665:2011

- ANSI/ASSE A10.48-2016

- Part 107

- EU UAS Regulations

- CAA CAP 722

U.S Government Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- Environmental Protection Agency (EPA) Regulations

- Federal Trade Commission (FTC) Regulations

- Food and Drug Administration (FDA) Regulations (if applicable)

- Federal Communications Commission (FCC) Regulations (if applicable)

- Federal Aviation Administration (FAA) Regulations (if applicable)

- Consumer Product Safety Commission (CPSC) Regulations (if applicable)

- National Highway Traffic Safety Administration (NHTSA) Regulations (if applicable

Canadian Government Regulations

- Canadian Standards Association (CSA) Regulations

- Health Canada Regulations (if applicable)

- Environment and Climate Change Canada (ECCC) Regulations

- Transport Canada Regulations (if applicable)

- Competition Bureau Regulations

- Canada Revenue Agency (CRA) Tax Regulations (if applicable)

- Customs and Border Protection Canada (CBSA) Regulations (if applicable)

- Canadian Food Inspection Agency (CFIA) Regulations (if applicable)

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Aftermarket Manufacturing and Services Industry such as:

Personnel Management:

- Employee Scheduling and Shift Management

- Human Resource Information Systems (HRIS)

- Workforce Analytics and Performance Management

- Training and Skills Development Tracking

- Health and Safety Compliance Tracking

- Employee Benefits Management

- Payroll and Compensation Systems

- Employee Onboarding and Offboarding

Equipment Management:

- Asset Tracking and Inventory Management

- Predictive Maintenance and Equipment Health Monitoring

- Equipment Calibration and Testing

- Equipment Utilization and Efficiency Analysis

- Equipment Lifecycle Management

- Remote Equipment Monitoring and Control

Access Control:

- Physical Access Control Systems (PACS)

- Visitor Management and Authentication

- Identity and Credential Management

- Biometric Access Control

- Security Surveillance and Monitoring

- Lockdown and Emergency Access Protocols

Warehouse Management:

- Inventory Control and Optimization

- Order Fulfillment and Pick-Pack-Ship Processes

- Warehouse Layout and Slotting Optimization

- Real-time Location Tracking (RTLS)

- Cross-Docking and Dock Scheduling

- Returns Management and Reverse Logistics

Supply Chain Management:

- Demand Forecasting and Inventory Planning

- Supplier Relationship Management (SRM)

- Procurement and Vendor Management

- Transportation Management and Route Optimization

- Supplier Collaboration and Communication

- Sustainability and Ethical Supply Chain Management

Other Applications:

- Customer Relationship Management (CRM)

- Sales and Order Management

- Product Lifecycle Management (PLM)

- Warranty and Service Contract Management

- Regulatory Compliance and Reporting

- Quality Assurance and Control

GAO has enabled its customers to make use of some of the leading software and cloud services in the residential building construction industry.

Below are some of popular software and cloud services in Aftermarket Manufacturing and Services: Oracle HCM Cloud, Workday, ADP Workforce Now, IBM Maximo, Fiix, Maintenance Connection, and eMaint CMMS, Infor CloudSuite EAM, Fiix CMMS Cloud, eMaint X3 CMMS, LenelS2, Avigilon Control Center, HighJump (now part of Korber), Infor WMS, Blue Yonder (formerly JDA Software), and Zebra Warehouse Solutions. Supply chain management software encompasses SAP Integrated Business Planning (IBP), Oracle SCM Cloud, Blue Yonder Luminate Control Tower, Logiwa WMS, Fishbowl Warehouse (integrates with various cloud services), 3PL Central, Blue Yonder Luminate Control Tower, E2open Supply Chain Operating Network, and Llamasoft (now part of Coupa), Syncron Inventory Management, IFS Field Service Management, and PTC Servigistics. For cloud services supporting Aftermarket Manufacturing and Services, consider Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), IBM Cloud, and Oracle Cloud.

GAO has worked with some of the leading technology companies in residential building construction to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in Aftermarket Manufacturing and Services:

SAP, Oracle, IBM, Microsoft, Salesforce, Infor, Workday, PTC, ServiceNow, Epicor, Siemens, Rockwell Automation, ABB, Schneider Electric, Emerson Electric, Honeywell, Mitsubishi Electric, Omron Corporation, Eaton Corporation, Yokogawa Electric Corporation, Siemens PLM Software, PTC (Parametric Technology Corporation), Autodesk, Bentley Systems, Hexagon AB, ANSYS, Altair Engineering, National Instruments (NI), Trimble.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in Aftermarket Manufacturing and Services Industry.

American Nuts Manufacturing Embraces Cutting-Edge RFID ERC Solution to Control Inventory, Operations and Profitability: This case study shows how a nut processor company used an RFID enabled Enterprise Resource Control (ERC) system from Senitron and Avery Dennison to improve their inventory accuracy, production scheduling, quality control, and data analytics. The company reported a reduction in inventory levels by at least 25%, an improvement in contribution margins by at least 3-5%, and an increase in customer satisfaction and retention.

Avery Dennison Helps EY Capture the Advantages of RFID for Grupo Boticário: This case study demonstrates how a beauty industry leader in Brazil used RFID tags from Avery Dennison to achieve end-to-end traceability across its complex supply chain. The company hired EY to help test RFID tagging for six months in 2018. The results reduced stockouts by 97%, decreased labor by 14%, and increased revenue.

Aftermarket Services: The Digital Differentiator: This case study explores how digital technologies such as RFID can help manufacturers enhance their aftermarket services and create new revenue streams. The study highlights the benefits of using RFID for asset tracking, predictive maintenance, remote diagnostics, and customer engagement. The study also provides some best practices and recommendations for implementing RFID solutions in the aftermarket service domain.

Siemens provides a white paper on how UHF RFID can improve manufacturing visibility and control, with examples of applications such as tool identification, work-in-process tracking, asset management, and quality control. The paper also gives guidelines for deploying a UHF RFID system, with insights on the RF engineering challenges and best practices.

Baysquare Technologies is a company that offers RFID solutions for manufacturing, logistics, and retail. They have implemented UHF RFID projects for clients such as Ford Motor Company, General Motors, Toyota, Honda, and Nissan. Some of their applications include parts tracking, inventory management, warranty verification, and recall management.

Case Studies of IoT Applications

Below are some IoT application cases in Aftermarket Manufacturing and Services Industry.

Siemens, a German-based engineering company, used Deloitte’s IoT solutions to create a digital service platform that connects its industrial equipment with its service technicians and customers. The platform provides real-time data and insights on equipment performance, health, and usage. Siemens has improved customer satisfaction, reduced service costs, and increased service revenue with this platform.

Caterpillar, a US-based manufacturer of construction and mining equipment, used Deloitte’s IoT solutions to enhance its aftermarket service offerings. Caterpillar has deployed over 500,000 connected assets across the world that provides data on location, health, utilization, and fuel consumption. Caterpillar has used this data to optimize maintenance schedules, reduce downtime, increase uptime, and create new service models such as equipment-as-a-service.

Schindler, a Swiss-based manufacturer of elevators and escalators, used Deloitte’s IoT solutions to transform its service operations. Schindler has connected over 100,000 elevators and escalators with sensors that monitor their status and performance. Schindler has used this data to predict failures, prevent breakdowns, dispatch technicians, and improve safety. Schindler has reduced service costs by 10%, increased availability by 15%, and enhanced customer loyalty with this solution.

GE Healthcare, a US-based provider of medical equipment and services, used Cognizant’s IoT solutions to improve its service delivery and customer satisfaction. GE Healthcare has connected over 500,000 medical devices with sensors that collect data on performance, usage, and errors. GE Healthcare has used this data to enable remote monitoring, diagnostics, repair, and optimization of its devices. GE Healthcare has reduced service costs by 30%, increased uptime by 20%, and improved customer retention by 15% with this solution.

Philips Lighting, a Dutch-based provider of lighting products and services, used Cognizant’s IoT solutions to create a smart lighting platform that connects its LED lamps with its customers and partners. The platform provides data on lamp status, energy consumption, location, and preferences. Philips Lighting has used this data to offer value-added services such as lighting-as-a-service, energy management, asset tracking, and personalization. Philips Lighting has increased customer loyalty, reduced energy costs, and generated new revenue streams with this platform.

Case Studies of Drone Applications

Below are some drone application cases in Aftermarket Manufacturing and Services Industry.

In the USA, a company called PrecisionHawk provides drone-based inspection and data analysis services for various industries, including manufacturing. One of their clients is John Deere, a leading manufacturer of agricultural equipment. PrecisionHawk helps John Deere monitor the quality and performance of their products in the field, as well as provide predictive maintenance and warranty support. PrecisionHawk uses advanced sensors and artificial intelligence to collect and process data from drones, which can detect issues such as crop health, soil moisture, pest infestation, and equipment wear and tear.

In Canada, a company called Drone Delivery Canada offers drone-based logistics solutions for remote and rural areas. They have partnered with Air Canada, the largest airline in Canada, to provide cargo delivery services using drones. Drone Delivery Canada has developed a proprietary system that integrates drones, software, hardware, and cloud-based infrastructure to enable safe and reliable delivery of goods. The drones can carry up to 180 kg of payload and fly up to 150 km.

In Europe, a company called Flyability specializes in drone-based inspection and exploration of confined and complex spaces. They have developed a unique drone called Elios, which is protected by a spherical cage that allows it to bounce off obstacles and access hard-to-reach areas. Flyability has served clients in various industries, such as power generation, oil and gas, mining, and chemical. One of their projects was inspecting the interior of the Chernobyl nuclear power plant, which was severely damaged by a meltdown in 1986. Flyability’s drones helped assess the radiation levels and structural integrity of the plant without exposing humans to danger.

In Mexico, a company called [Verity Studios] creates drone-based entertainment shows for live events. They have designed drones that can perform synchronized movements, create dynamic shapes, and interact with music and lights. Verity Studios has collaborated with artists such as [Cirque du Soleil], [Metallica], and [Drake] to create stunning aerial performances. Verity Studios’ drones are equipped with fail-safe algorithms and backup systems to ensure safety and reliability.

GAO RFID Systems & Hardware for Aftermarket Manufacturing and Services Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Aftermarket Manufacturing and Services Industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including Aftermarket Manufacturing and Services Industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Aftermarket Manufacturing and Services Industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Aftermarket Manufacturing and Services Industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Aftermarket Manufacturing and Services Industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Aftermarket Manufacturing and Services Industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in Aftermarket Manufacturing and Services Industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

Computerized Maintenance Management Systems (CMMS), Diagnostic Equipment, 3D Printing and Additive Manufacturing Equipment, CNC Machines, Hydraulic Presses, Welding and Fabrication Equipment, Industrial Balancing Equipment, Alignment Tools, Pneumatic and Hydraulic Tools, Testing and Measurement Equipment, Material Handling Equipment, Asset Tracking and RFID Systems, Scanning and Barcode Equipment, Lubrication Systems, Electrical Testing Equipment, Safety Equipment, Fluid Handling Equipment, Condition Monitoring Sensors, Cleaning and Surface Treatment Equipment, Robotic Automation Systems.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Aftermarket Manufacturing and Services Industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Aftermarket Manufacturing and Services Industry we have worked with to serve our joint customers:

- Deloitte

- Cognizant

- McKinsey

- Accenture

- IBM

- Infosys

GAO Has Served Aftermarket Manufacturing and Services Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in Aftermarket Manufacturing and Services Industry to achieve success in Digital Transformation, Predictive Maintenance, Remote Monitoring, Augmented Reality (AR) and Virtual Reality (VR), 3D Printing and Additive Manufacturing, Data Analytics, E-commerce and Online Parts Ordering, Sustainability, Circular Economy, Blockchain. IoT (Internet of Things), Industry 4.0, Servitization, Customer-Centric, Cloud Computing, Big Data, Edge Computing, Supply Chain Visibility, Cybersecurity, Customer Experience (CX).

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in Aftermarket Manufacturing and Services Industry, including many in its various divisions such as:

- Automotive Aftermarket: This includes the manufacturing and services related to replacement parts, accessories, maintenance, and repair for vehicles, including cars, trucks, motorcycles, and commercial vehicles.

- Aerospace Aftermarket: Focusing on the aftermarket needs of the aerospace and aviation industry, including maintenance, repair, and the supply of spare parts for aircraft and related equipment.

- Industrial Machinery Aftermarket: This division covers the aftermarket services for industrial machinery and equipment, including heavy machinery, manufacturing equipment, and factory automation systems.

- Electronics Aftermarket: Involves the maintenance, repair, and servicing of electronic devices and equipment, such as consumer electronics, industrial automation systems, and telecommunications equipment.

- Medical Equipment Aftermarket: Focusing on the maintenance, repair, and servicing of medical devices and equipment, including diagnostic tools, imaging equipment, and healthcare technology.

- Construction Equipment Aftermarket: Includes services related to the maintenance, repair, and supply of parts for construction machinery and equipment.

- Power Generation and Energy Aftermarket: Encompasses the servicing of power generation equipment, including turbines, generators, and renewable energy systems.

- Marine and Maritime Aftermarket: Addresses the needs of the marine industry, including ship repair, maintenance, and the supply of marine equipment and parts.

- Railway Aftermarket: Involves the maintenance, repair, and supply of parts for railway systems, locomotives, and rolling stock.

- Oil and Gas Aftermarket: Covers the aftermarket services for the oil and gas industry, including maintenance, repair, and supply chain management for equipment and components.

- HVAC (Heating, Ventilation, and Air Conditioning) Aftermarket: Focusing on the maintenance and repair of HVAC systems and equipment used in buildings and industrial facilities.

GAO’s technologies enable its customers in “Aftermarket Manufacturing and Services Industry” to effectively track their workforces such as Technician, Mechanic, Engineer, Field Service Technician, Electrician, Parts Specialist, Inventory Manager, Quality Control Inspector, Customer Support Representative, Sales Representative, Project Manager, Logistics Coordinator, Safety Coordinator, Service Manager, Product Support Specialist, Training Instructor, Machine Operator, Warehouse Worker, Diagnostic Technician and effectively track operational assets such as CNC Machine, Lathe, Milling Machine, Welding Machine, Diagnostic Equipment, Material Handling Equipment, Testing and Measurement Equipment, Hydraulic Press, Pneumatic Tools, 3D Printer, Laser Cutting Machine, Surface Treatment Equipment, Robotic Automation System, Crane and Hoist, HVAC Equipment, Electric Testing Equipment, Ultrasonic Testing Equipment, Vibration Analyzers, Computerized Maintenance Management Systems (CMMS), Augmented Reality (AR) Devices, Precision Tools, Safety Equipment.

Here are some of the leading companies in Aftermarket Manufacturing and Services Industry GAO has served:

- General Electric (GE)

- Raytheon Technologies

- UTC Aerospace Systems

- Honeywell International

- Siemens Industry

- IBM Global Business Services

- Caterpillar Inc.

- Deere & Company (John Deere)

- Cummins Inc.

- Emerson Electric Co.

- Harley-Davidson, Inc.

- Oshkosh Corporation

- Boeing

- Northrop Grumman Corporation

- Tesla, Inc.

- Intel Corporation

- Applied Materials, Inc.

- NVIDIA Corporation

- Exxon Mobil Corporation

- Chevron Corporation

- Halliburton Company

- The Coca-Cola Company

- Gulfstream Aerospace Corporation

- Baker Hughes Company

- Linamar Corporation

- Magna International

- Wajax Corporation

- Finning International

- Toromont Industries

- Brandt Group of Companies

- Nemak

- Metalsa

- Rassini

- Industrias Bachoco

- Industrias CH SAB de CV

- Grupo Bimbo

- Bosch Group

- Siemens AG

- SKF Group

- ABB Group

- Schneider Electric SE

- Daimler AG

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com