Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Basic Chemical Manufacturing

GAO’s Assists Clients with Standards, Mandates & Regulations of Basic Chemical Manufacturing

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drones Applications

GAO RFID Systems & Hardware for Basic Chemical Manufacturing

Overview

The Basic Chemical Manufacturing industry produces a wide range of chemicals used as raw materials in various sectors. It encompasses the production of inorganic and organic chemicals, petrochemicals, agrochemicals, specialty chemicals, and industrial gases. This industry is essential for supplying the fundamental materials required for manufacturing and is closely regulated due to safety and environmental concerns.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in Basic Chemical Manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Reactors, Distillation Columns, Heat Exchangers, Pumps, Compressors, Mixers, Storage Tanks, Filters, Valves, Pipes and Tubing, Cooling Towers, Pressure Vessels, Crystallizers, Dryers, Centrifuges, Evaporators, Instrumentation and Control Systems, Safety Equipment (e.g., Relief Valves, Emergency Shutdown Systems), Analytical Instruments.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in Basic Chemical Manufacturing. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Basic Chemical Manufacturing

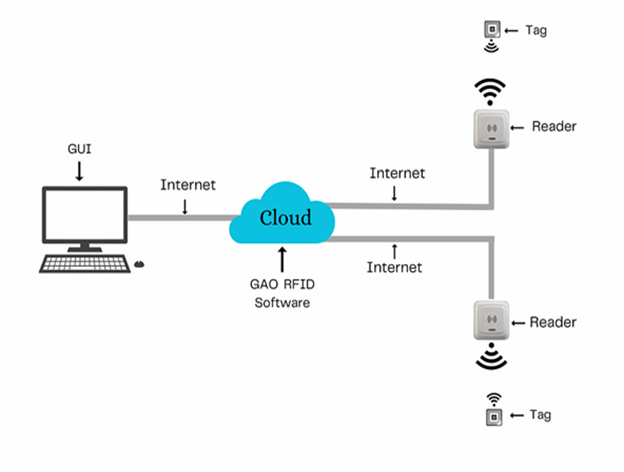

To satisfy its customers, GAO’s RFID or RFID Systems for Basic Chemical Manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for sub-industryBasic Chemical Manufacturingftware running on a local server.

The above illustrates GAO system for Carpet and Rug Manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Basic Chemical Manufacturing industry:

- Inventory Management: RFID tags can be attached to chemical containers and equipment to monitor inventory levels in real-time, allowing for better supply chain management and preventing stock outs or overstocking.

- Asset Tracking: RFID can help track the movement and location of critical assets, such as tanks, reactors, and machinery, improving asset utilization and reducing the risk of loss or theft.

- Quality Control: RFID can be used to track and trace raw materials and products, ensuring that quality standards are met throughout the manufacturing process.

- Batch and Lot Tracking: RFID technology can provide accurate data on the origin and history of chemical batches, aiding in product recalls and quality assurance.

- Maintenance and Servicing: RFID tags on equipment can facilitate maintenance scheduling and record equipment history, helping to optimize maintenance processes and minimize downtime.

- Safety Compliance: RFID can be used to monitor the movement and handling of hazardous materials, ensuring that safety protocols are followed and providing a digital record of compliance.

- Personnel and Access Control: RFID badges or cards can control access to restricted areas within chemical manufacturing facilities, enhancing security and safety measures.

- Process Automation: RFID technology can be integrated into automated systems to streamline processes, such as the automatic tracking of chemical reactions or the management of filling and packaging lines.

- Environmental Monitoring: RFID sensors can be employed to monitor environmental conditions, such as temperature and humidity, in storage areas to ensure chemical stability and safety.

- Shipping and Logistics: RFID tags on containers and shipments enable real-time tracking of chemical products in transit, improving logistics and reducing the risk of theft or tampering.

- Regulatory Compliance: RFID data can assist in maintaining compliance with industry regulations and reporting requirements, providing a transparent and auditable record of activities.

GAO’s drone technologies find the following applications in the Basic Chemical Manufacturing industry:

- Asset Inspection: Drones equipped with cameras and sensors can inspect chemical manufacturing equipment, tanks, and structures for signs of wear, damage, or corrosion, helping to identify maintenance needs and prevent accidents.

- Tank Level Monitoring: Drones can be used to check and monitor chemical storage tank levels, ensuring accurate inventory management and preventing overflows or shortages.

- Environmental Monitoring: Drones equipped with sensors can monitor air and water qualities, helping chemical plants comply with environmental regulations and detect any emissions or spills.

- Security and Surveillance: Drones can provide real-time surveillance of chemical manufacturing facilities, helping to prevent unauthorized access, theft, or vandalism.

- Emergency Response: Drones can quickly assess and document chemical spills or accidents, providing valuable information for emergency responders and minimizing the risk to human operators.

- Mapping and Surveying: Drones can create accurate 3D maps of manufacturing sites, helping with site planning, construction, and maintenance.

- Inventory Management: Drones can be used to automate inventory checks by scanning RFID tags or barcodes on chemical containers, reducing manual labor and improving accuracy.

- Routine Inspections: Drones can conduct routine inspections of pipelines, infrastructure, and hard-to-reach areas, reducing the need for manual inspections that can be time-consuming and hazardous.

- Safety Audits: Drones can assist in safety audits by providing aerial views and data on potential safety hazards, allowing for proactive safety measures.

- Transport and Delivery: Drones can transport small packages or samples within a manufacturing facility, improving logistics and reducing the need for manual transport.

- Monitoring of Remote Facilities: For chemical plants with remote or difficult-to-access facilities, drones can provide cost-effective monitoring and inspection solutions.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the Basic Chemical Manufacturing industry:

- Remote Equipment Monitoring: IoT sensors can continuously monitor the condition and performance of manufacturing equipment, providing real-time data on factors like temperature, pressure, and vibration. This data helps identify maintenance needs and prevent unexpected breakdowns.

- Predictive Maintenance: IoT analytics can predict when equipment is likely to fail based on historical data and real-time sensor information. This enables proactive maintenance, reducing downtime and production disruptions.

- Energy Management: IoT devices can monitor energy usage within the facility, allowing for the optimization of energy consumption, which can lead to cost savings and reduced environmental impact.

- Inventory Control: IoT-enabled sensors can track the levels of raw materials, chemicals, and finished products in real-time, helping with inventory management and preventing shortages or overstocking.

- Quality Control: Sensors can continuously monitor the quality of chemical products during the manufacturing process, ensuring that they meet quality standards and allowing for real-time adjustments if necessary.

- Process Optimization: IoT data can be used to optimize chemical processes, improve yields, reduce waste, and enhance overall production efficiency.

- Safety Monitoring: IoT sensors can detect hazardous conditions, such as leaks, spills, or abnormal temperature and pressure levels, triggering immediate alerts and safety protocols.

- Environmental Compliance: IoT sensors can monitor emissions, wastewater, and other environmental parameters, helping chemical plants adhere to environmental regulations and minimize their ecological footprint.

- Supply Chain Visibility: IoT technology provides real-time visibility into the movement of raw materials and finished products throughout the supply chain, improving logistics and reducing lead times.

GAO’s Assists Clients with Standards, Mandates & Regulations of Basic Chemical Manufacturing

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in Basic Chemical Manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 series (including ISO 18000-6 for RFID air interface standards)

- ISO 15693 (for vicinity card systems)

- EPCglobal UHF Gen2 (for Electronic Product Code RFID tags)

- ISO 28560 (for RFID in libraries)

- ASTM E2919 (for chemical sector applications)

- Bluetooth SIG specifications for Bluetooth Low Energy (BLE) devices

- IEEE 802.15.1 (Bluetooth technology standard)

- IEEE 802.15.4 (Low-Rate Wireless Personal Area Networks)

- ISO/IEC 30141 (IoT Reference Architecture)

- IEEE P2413 (Standard for an Architectural Framework for the Internet of Things)

- IETF RFC 7228 (Terminology for Constrained-Node Networks)

- Open Connectivity Foundation (OCF) IoTivity (IoT standard for device interoperability)

- ASTM F38 (Unmanned Aircraft Systems)

- ISO 21384 (UAS operational procedures)

- IEEE 802.11 (Wireless LAN standards that drones might use for communication)

- FAA Part 107 (U.S. drone regulations for commercial use)

Government Regulations

- Clean Air Act (CAA)

- Clean Water Act (CWA)

- Resource Conservation and Recovery Act (RCRA)

- Occupational Safety and Health Administration (OSHA) Regulations

- Hazardous Waste Generator Improvements Rule

- Chemical Facility Anti-Terrorism Standards (CFATS)

- Toxic Substances Control Act (TSCA)

- Emergency Planning and Community Right-to-Know Act (EPCRA)

- Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)

- National Emission Standards for Hazardous Air Pollutants (NESHAPs)

- Risk Management Program (RMP) Rule

- Food and Drug Administration (FDA) Regulations (if applicable)

- Department of Transportation (DOT) Hazardous Materials Regulations (if applicable)

Canadian Government Regulations

- Canadian Environmental Protection Act, 1999 (CEPA)

- Transportation of Dangerous Goods Act and Regulations (TDG)

- Canadian Occupational Health and Safety Regulations (COHSR)

- Canada Labour Code, Part II – Occupational Health and Safety

- Hazardous Products Regulations (WHMIS)

- Canadian Environmental Assessment Act, 2012 (CEAA 2012)

- Fisheries Act (Canada)

- Food and Drugs Act and Regulations (if applicable)

- Pest Control Products Act and Regulations (if applicable)

- Natural Health Products Regulations (if applicable)

- Explosives Act and Regulations (if applicable)

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Basic Chemical Manufacturing such as:

- Workforce Scheduling

- Training and Certification Tracking

- Health and Safety Monitoring

- Laboratory Management

- Employee Records

- Maintenance Scheduling

- Asset Tracking

- Equipment Performance Monitoring

- Energy Management

- Equipment Calibration

- Access Control Systems

- Visitor Management

- Biometric Authentication

- Security Cameras

- Inventory Tracking

- Storage Optimization

- Order Fulfillment

- Temperature and Humidity Monitoring

- Barcode Scanning

- Supplier Management

GAO has enabled its customers to make use of some of the leading software and cloud services in Basic Chemical Manufacturing industry. Below are some of popular software and cloud services in Basic Chemical Manufacturing:

Human Resource Management Systems (HRMS), Enterprise Resource Planning (ERP) systems with HR modules, Talent Management Software, Workforce Management Software, Computerized Maintenance Management System (CMMS), Enterprise Asset Management (EAM) Software, Equipment Tracking and Maintenance Software, IoT-based Equipment Monitoring Solutions, Access Control Systems, Visitor Management Systems, Biometric Access Control Systems, Security Information and Event Management (SIEM) System, Warehouse Management Systems (WMS), Inventory Management Software, Barcode Scanning and RFID Solutions, Temperature and Humidity Monitoring Systems, Supply Chain Management (SCM) Software, Demand Forecasting and Planning Software, Transportation Management Systems (TMS).

GAO has worked with some of the leading technology companies in Basic Chemical Manufacturing in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in sub-industryBasic Chemical Manufacturing:

SAP, Oracle, Microsoft, IBM, Siemens, Wonderware (Schneider Electric), Aspen Technology, PTC, Emerson, AVEVA, Honeywell, Rockwell Automation, Yokogawa Electric, Mitsubishi Electric, Omron, Eaton, Beckhoff Automation, ABB, Siemens, Schneider Electric, GE Digital, OSIsoft, Dassault Systèmes, Invensys (Schneider Electric), L&T Technology Services, Yokogawa Electric, Aspen Technology, Emerson, OSI (Open Systems International).

Case Studies of RFID, IoT & Drones Applications

Case Studies of RFID Applications

Below are some RFID application cases in Basic Chemical Manufacturing industry:

A Basic Chemical Manufacturing company in the USA implemented RFID technology to track and manage its extensive inventory of chemical raw materials and finished products. RFID tags were attached to containers and equipment, allowing for real-time monitoring, reducing manual counting errors, and improving traceability throughout the supply chain.

In Canada, a chemical manufacturer utilized RFID for tracking and managing hazardous materials within its production facility. RFID tags on chemical containers enabled quick identification and monitoring of chemical contents, contributing to safety compliance and rapid response in emergencies.

A European chemical manufacturer enhanced supply chain visibility by deploying RFID tags on chemical shipments. This allowed them to monitor the location and status of products during transit, optimize logistics, and ensure timely deliveries to customers.

A chemical manufacturing company in Europe implemented RFID tags on product packaging to maintain quality control and prevent counterfeit products. Customers could verify product authenticity by scanning RFID tags, enhancing brand trust and product integrity.

A chemical manufacturing plant in Mexico used RFID access control systems to enhance security. Employees were issued RFID cards for secure access to specific areas within the facility, ensuring that only authorized personnel could enter restricted zones.

Several chemical manufacturers across North America adopted RFID technology to comply with various regulatory requirements. This included RFID-based labeling and reporting solutions to meet regulatory mandates and streamline compliance processes.

In Europe, RFID sensors were deployed in chemical manufacturing plants to monitor environmental conditions. These sensors tracked factors such as temperature, humidity, and emissions to ensure compliance with strict environmental regulations and reduce environmental impact.

RFID technology was integrated into emergency response systems at chemical manufacturing facilities in different regions. RFID tags on hazardous material containers facilitated rapid identification and response in case of chemical spills or accidents, ensuring the safety of employees and the environment.

Case Studies of IoT Applications

Below are some IoT application cases in Basic Chemical Manufacturing industry:

IoT sensors are installed on critical machinery and equipment in a chemical manufacturing facility. These sensors continuously monitor parameters such as temperature, pressure, and vibration, sending real-time data to a central control system. This allows for predictive maintenance, reducing downtime and improving equipment reliability.

IoT sensors are deployed to monitor environmental conditions within and around the manufacturing plant. This includes tracking emissions, air quality, water quality, and noise levels. The data collected helps the company comply with environmental regulations and proactively address any issues.

IoT devices are used to optimize energy consumption within the manufacturing process. Sensors collect data on energy usage, and advanced analytics are applied to identify opportunities for energy efficiency improvements, reducing operational costs and environmental impact.

RFID tags and IoT sensors are used to track the location and status of chemical containers, equipment, and assets throughout the manufacturing facility. This ensures efficient asset utilization and minimizes the risk of loss or theft.

IoT is employed to provide real-time visibility into the supply chain. Sensors on shipping containers and vehicles transmit data on the location, temperature, and condition of chemical products during transit. This enhances supply chain management, reduces losses due to spoilage, and ensures on-time deliveries.

IoT sensors are integrated into safety equipment, such as gas detectors and personal protective gear, to monitor the well-being of employees. Data from these sensors can trigger alarms in the event of hazardous conditions and ensure compliance with safety regulations.

IoT sensors are used to monitor the quality of chemical processes and products in real time. Any deviations from established quality parameters trigger immediate corrective actions, ensuring consistent product quality.

IoT devices collect data from various stages of the manufacturing process. This data is analyzed to identify process inefficiencies, optimize production parameters, and reduce waste.

Case Studies of Drone Applications

Below are some drone application cases in Basic Chemical Manufacturing industry:

Drones equipped with cameras and sensors are used to conduct routine inspections of chemical manufacturing facilities. They can identify structural issues, equipment wear and tear, and potential hazards. This proactive approach helps prevent costly breakdowns and ensures regulatory compliance.

Drones are employed to inspect chemical storage tanks, both aboveground and underground. They can capture images and data to assess the condition of tanks, detect leaks, and monitor corrosion levels. This enhances safety and reduces the risk of environmental incidents.

Drones equipped with specialized sensors are used for environmental monitoring around chemical manufacturing plants. They can detect air and water pollution, emissions, and chemical leaks, providing real-time data to help maintain compliance with environmental regulations.

Drones with RFID or barcode scanning capabilities are used to perform rapid inventory counts of chemical products stored in large warehouses or yards. This improves inventory accuracy and reduces the time and labor required for manual counts.

In the event of a chemical spill or emergency, drones equipped with cameras and sensors can be quickly deployed to assess the situation from a safe distance. They provide critical information to emergency responders, enabling faster and more informed decision-making.

Drones equipped with thermal imaging and surveillance cameras are used for perimeter security and monitoring of chemical manufacturing facilities. They can detect unauthorized access, intruders, or unusual activities, enhancing overall security.

Drones equipped with high-resolution cameras and LiDAR (Light Detection and Ranging) technology are used for land surveying and mapping. They provide accurate topographical data for construction, expansion, or land management purposes.

Drones are employed to inspect pipelines, bridges, and other critical infrastructure components. They can identify issues like corrosion, structural damage, or leaks in pipelines, ensuring the integrity of chemical transportation systems.

GAO RFID Systems & Hardware for Basic Chemical Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Basic Chemical Manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including Basic Chemical Manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Basic Chemical Manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Basic Chemical Manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Basic Chemical Manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Basic Chemical Manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selectioon of high quality drones are offered:

The RFID systems by GAO are highly popular for clients in Basic Chemical Manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

Reactors, Distillation Columns, Mixers and Blenders, Pumps and Compressors, Heat Exchangers, Storage Tanks, Pressure Vessels, Filtration Equipment, Centrifuges, Dryers, Evaporators, Crystallizers, Extruders, Analytical Instruments, Safety Equipment, Instrumentation and Control Systems, Dust Collectors and Scrubbers, Laboratory Equipment, Materials Handling Equipment, Environmental Control Systems.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Basic Chemical Manufacturing and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Basic Chemical Manufacturing we have worked with to serve our joint customers:

- Accenture

- Deloitte

- IBM Global Business Services

- Capgemini

- Cognizant

- Wipro

- Infosys

- Tata Consultancy Services (TCS)

- HCL Technologies

- Atos

GAO Has Served Basic Chemical Manufacturing Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in Basic Chemical Manufacturing Industry to achieve success in Digital Transformation, Sustainability, Industry 4.0, Circular Economy, Advanced Materials, Bio-Based Chemicals, Safety and Compliance, Supply Chain Resilience, IoT (Internet of Things), AI (Artificial Intelligence), Blockchain, Predictive Maintenance, Green Chemistry, Chemical Recycling, Smart Manufacturing, Digital Twin, Regenerative Medicine, Chemical Safety Culture.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in Basic Chemical Manufacturing, including many in its various divisions such as:

- Petrochemicals: This division involves the production of chemicals derived from petroleum and natural gas, such as ethylene, propylene, and various plastics.

- Inorganic Chemicals: This sub-industry deals with the manufacturing of inorganic compounds like acids, salts, and chemicals used in various industrial processes.

- Organic Chemicals: Organic chemical manufacturing involves the production of a wide range of carbon-based compounds, including solvents, synthetic resins, and specialty chemicals.

- Agrochemicals: Agrochemical manufacturing focuses on the production of chemicals used in agriculture, including fertilizers, pesticides, and herbicides.

- Specialty Chemicals: Specialty chemicals are unique and high-value chemicals designed for specific applications, such as electronic chemicals, water treatment chemicals, and additives.

- Pharmaceutical Chemicals: This division is responsible for producing chemicals used in pharmaceuticals and healthcare products, including active pharmaceutical ingredients (APIs).

- Fine Chemicals: Fine chemicals are high-purity, often custom-made chemicals used in various industries, including pharmaceuticals, agrochemicals, and electronics.

- Dyes and Pigments: This sub-industry involves the manufacturing of dyes, pigments, and colorants used in textiles, paints, and coatings.

- Explosives and Propellants: Manufacturers in this division produce explosives and propellants used in military, mining, and other applications.

- Industrial Gases: Industrial gas companies produce gases like oxygen, nitrogen, and helium, used in various industrial processes and applications.

- Catalysts: Catalyst manufacturers produce substances that accelerate chemical reactions without being consumed in the process. Catalysts are essential in many chemical processes.

GAO’s technologies enable its customers in “Basic Chemical Manufacturing” to effectively track their workforces such as Chemical Operator, Chemical Technician, Process Engineer, Plant Manager, Safety Coordinator, Quality Control Inspector, Maintenance Technician, Environmental Specialist, Logistics Coordinator, Warehouse Supervisor, Chemist, Production Supervisor, Automation Engineer, Materials Handler, Packaging Technician and effectively track operational assets such as Reactors, Distillation Columns, Mixers and Blenders, Pumps, Compressors, Heat Exchangers, Storage Tanks, Pressure Vessels, Filtration Equipment, Centrifuges, Dryers, Evaporators, Crystallizers, Extruders, Analytical Instruments, Safety Equipment, Instrumentation and Control Systems, Dust Collectors, Scrubbers.

Here are some of the leading companies in Basic Chemical Manufacturing industry GAO has served:

- International Flavors & Fragrances Inc.

- Union Carbide Corporation

- BASF Corporation.

- Cabot Corporation

- R. Grace Holdings LLC

- MPM Holdings Inc.

- CF Industries Holdings Inc.

- The Andersons Inc.

- Praxair Inc.

- LyondellBasell Industries N.V.

- Huntsman Corporation

- Olin Corporation

- Air Products and Chemicals Inc.

- Chevron Phillips Chemical Company LLC

- ExxonMobil Chemical Company

- Shell Chemical LP

- Westlake Chemical Corporation

- Phillips 66

- The Mosaic Company

- Linde Inc.

- Eastman Chemical Company

- Suncor Energy Inc.

- Imperial Oil Limited

- Methanex Corporation

- Chemtrade Logistics Inc.

- NOVA Chemicals Corporation

- Air Liquide Canada Inc.

- Braskem-Idesa

- Mexichem

- Alpek

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com