Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Biochemical Manufacturing Industry

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Biochemical Manufacturing Industry

GAO Makes Efforts to Satisfy Customers

Overview

The Biochemicals Manufacturing Industry is a sector within the chemical industry that specializes in producing a diverse range of chemicals and substances derived from biological sources or processes. These bio-based chemicals find applications in pharmaceuticals, agriculture, food processing, cosmetics, and environmental solutions. Utilizing biotechnological methods and emphasizing sustainability, the industry plays a pivotal role in providing innovative, eco-friendly, and versatile ingredients for various products and processes across multiple sectors, while also addressing regulatory and quality control requirements to ensure safety and efficacy.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the biochemical manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as storage tanks and containers for bulk chemicals, chemical pumps and transfer equipment, specialized handling equipment like forklifts and pallet jacks, safety equipment such as protective clothing, gloves, and respirators, labeling and packaging machinery, quality control and testing equipment for product verification, computer systems for inventory management and order processing, as well as transportation vehicles like trucks and tankers equipped for the safe transport of hazardous materials. Additionally, modern facilities often include climate-controlled warehouses to store sensitive chemicals and ensure product integrity. Properly maintained equipment is crucial for the safe and effective operations of chemical wholesalers in this industry.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for Chemical and Allied Products Merchant Wholesalers Industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Biochemical Manufacturing Industry

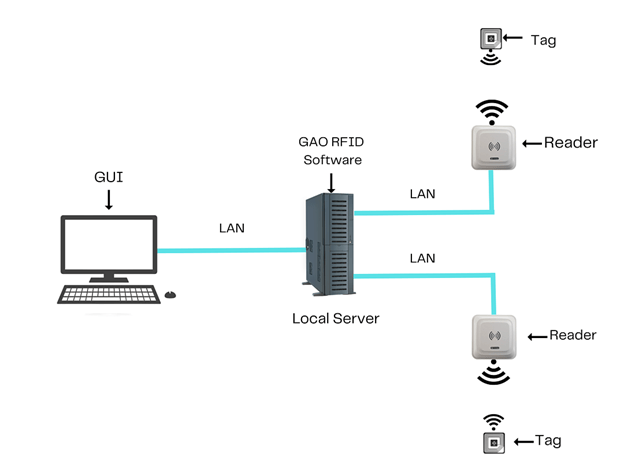

To satisfy its customers, GAO’s RFID or RFID Systems for biochemical manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for sub-industry biochemical manufacturing industry software running on a local server.

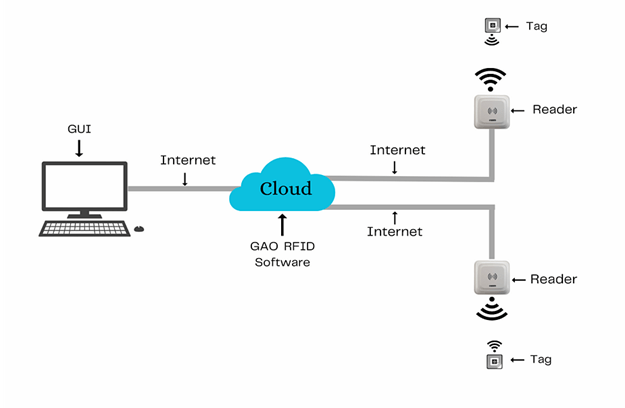

To satisfy its customers, GAO’s RFID or RFID Systems for biochemical manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for sub-industry biochemical manufacturing industry software running on a local server.

The above illustrates GAO system for biochemical manufacturing industry with its software running in cloud

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in biochemical manufacturing industry:

- Inventory Management: GAO RFID tags can be attached to raw materials, chemicals, and equipment, allowing for real-time tracking and management of inventory levels. This helps in maintaining adequate stock, reducing wastage, and optimizing procurement processes.

- Quality Control: GAO RFID tags can be used to track batches and lots of products throughout the manufacturing process. This enables real-time quality control checks and helps identify and address any deviations or issues promptly.

- Asset Tracking: GAO RFID tags can be attached to equipment, machinery, and tools. This ensures that assets are properly maintained, calibrated, and available when needed, reducing downtime and maintenance costs.

- Product Authentication: GAO RFID tags with unique identifiers can be applied to finished products, enabling easy authentication and counterfeit prevention. This is particularly crucial in the pharmaceutical and biotechnology sectors.

- Supply Chain Visibility: GAO RFID technology provides real-time visibility into the movement of materials and products within the supply chain. This enhances logistics management, reduces lead times, and minimizes the risk of stockouts.

- Temperature and Environmental Monitoring: For temperature-sensitive biochemicals, GAO RFID tags equipped with sensors can monitor temperature and environmental conditions during storage and transportation, ensuring product integrity.

- Laboratory Sample Tracking: GAO RFID tags help track samples and specimens in laboratories, reducing the risk of mislabeling or misplacement, and ensuring accurate test results.

- Compliance and Documentation: GAO RFID can assist in automating compliance documentation by tracking the history and documentation of each batch or lot, simplifying regulatory reporting and audits.

- Waste Management: GAO RFID technology can be used to track and manage hazardous waste disposal. It ensures that waste is properly labeled, stored, and disposed of in compliance with regulations.

- Personnel Safety: GAO RFID badges or wearables can enhance safety by monitoring the location of personnel within manufacturing facilities and ensuring they are not in restricted or hazardous areas.

- Maintenance Scheduling: GAO RFID-enabled maintenance management systems can automatically schedule and track equipment maintenance, reducing unplanned downtime and optimizing maintenance schedules.

- Validation and Verification: GAO RFID technology can be used to validate and verify processes and procedures at various stages of production, ensuring that all steps are executed correctly.

- Document and Data Management: GAO RFID tags can be attached to documents and data storage systems, making it easier to locate and manage critical documentation and records.

- Security and Access Control: GAO RFID-based access control systems can restrict access to sensitive areas, ensuring that only authorized personnel have access to certain parts of the manufacturing facility.

- Raw Material Authentication: GAO RFID tags can be used to verify the authenticity of incoming raw materials, reducing the risk of using counterfeit or substandard materials in production.

GAO’s drone technologies find the following applications in the biochemical manufacturing industry:

- Site Surveillance: GAO Drones can perform routine aerial surveillance of manufacturing facilities, helping to monitor for unauthorized access, security breaches, or other potential risks.

- Environmental Monitoring: GAO Drones equipped with sensors can monitor air and water quality, emissions, and environmental conditions, ensuring compliance with environmental regulations and early detection of issues.

- Inventory Management: GAO Drones can be used to perform aerial scans of inventory, ensuring accurate and up-to-date records of raw materials and finished products.

- Transportation and Logistics: GAO Drones can transport small, high-value items within manufacturing facilities, improving efficiency in material handling and reducing the need for manual labor.

- Safety Inspections: GAO Drones can access hard-to-reach or hazardous areas within manufacturing plants, conducting safety inspections and identifying potential safety hazards.

- Maintenance Inspections: GAO Drones equipped with cameras and sensors can inspect machinery and equipment for signs of wear and tear, corrosion, or damage, facilitating predictive maintenance.

- Pipeline and Infrastructure Inspection: In the biochemical industry, pipelines and other infrastructure components can be inspected by drones for leaks, corrosion, or structural issues.

- Crop Monitoring (Agricultural Biochemicals): For bio-based agricultural products, drones can monitor crop health, identify pests, and optimize the application of pesticides and fertilizers.

- Data Collection for Research and Development: GAO Drones can collect data for research purposes, such as studying the impact of biochemical products on the environment or conducting field trials.

- Security and Surveillance: GAO Drones equipped with advanced cameras and sensors can enhance security measures by monitoring the perimeter of manufacturing facilities for intruders or security breaches.

- Emergency Response: GAO Drones can be deployed in emergency situations, such as chemical spills or accidents, to assess the extent of the incident without putting human responders at risk.

- Quality Control and Sampling: GAO Drones can assist in the sampling and quality control process by collecting samples from different areas of a manufacturing facility, ensuring product uniformity.

- Remote Sensing for Agriculture: In the case of bio-based agricultural products, GAO drones can use remote sensing technology to gather data on soil conditions, crop health, and yield predictions.

- Mapping and Surveying: GAO Drones equipped with mapping and surveying tools can create accurate 3D models of manufacturing sites, aiding in facility planning and expansion.

- Transport of Lab Samples: GAO Drones can be used to transport lab samples quickly and safely within large manufacturing campuses, reducing transportation times.

- Compliance Documentation: GAO Drones can capture visual data and images required for compliance documentation, streamlining regulatory reporting processes.

- Training and Simulation: GAO Drones can be used for training purposes, such as simulating emergency response scenarios or conducting safety drills.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the biochemical manufacturing industry:

- Real-time Monitoring: GAO IoT sensors and devices can continuously monitor various parameters such as temperature, humidity, pressure, and pH levels in manufacturing processes, ensuring optimal conditions for biochemical production.

- Quality Control: GAO IoT sensors can track the quality of raw materials, intermediate products, and finished goods, providing real-time data for quality control and early detection of defects.

- Predictive Maintenance: GAO IoT-enabled equipment can predict when machinery and equipment need maintenance based on usage patterns and sensor data, reducing downtime and unplanned shutdowns.

- Inventory Management: GAO IoT devices can monitor inventory levels in real-time, automatically triggering orders for raw materials or notifying when stock needs replenishment.

- Supply Chain Visibility: GAO IoT provides end-to-end visibility in the supply chain by tracking the movement and conditions of materials and products during transportation, reducing the risk of spoilage or damage.

- Energy Management: GAO IoT sensors can optimize energy consumption by monitoring and controlling lighting, HVAC systems, and other utilities based on real-time data and demand.

- Safety Monitoring: GAO IoT sensors can monitor for hazardous conditions, gas leaks, and other safety risks, triggering alerts and emergency response when necessary.

- Environmental Compliance: GAO IoT can track and report on environmental factors, helping companies adhere to regulatory requirements and reduce their environmental footprint.

- Batch Traceability: GAO IoT systems can track the entire production process, allowing for precise batch traceability to ensure product quality and facilitate recalls if necessary.

- Laboratory Equipment Monitoring: GAO IoT sensors can monitor laboratory equipment, ensuring precise and consistent conditions for experiments and sample storage.

- Remote Control: GAO IoT enables remote monitoring and control of equipment and processes, allowing for adjustments and troubleshooting without physical presence.

- Data Analytics: GAO IoT generates vast amounts of data that can be analyzed for process optimization, trend analysis, and predictive modeling to improve overall efficiency and product quality.

- Worker Safety: GAO IoT wearables and sensors can monitor worker health and safety, ensuring compliance with safety protocols and providing immediate assistance in emergencies.

- Water and Wastewater Management: GAO IoT systems can monitor water usage and wastewater treatment processes, optimizing resource utilization and reducing environmental impact.

- Compliance Documentation: GAO IoT devices can automatically record and store data required for compliance documentation, reducing manual record-keeping and paperwork errors.

- Remote Diagnostics: GAO IoT-enabled equipment can be diagnosed remotely, reducing the need for on-site maintenance and minimizing downtime.

- Asset Tracking: GAO IoT can track the location and condition of assets, such as containers, vehicles, and equipment, enhancing supply chain visibility and security.

- Customer Insights: GAO IoT can collect data on product usage and customer behavior, providing insights for product development and marketing strategies.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Biochemical Manufacturing Industry

GAO RFID Inc. has helped many companies in biochemical manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 14443/ISO 15693

- ISO 18000

- EPCglobal

- ISO 21041

- ISO 19845

- GS1 Standards

- Bluetooth Core Specification

- GATT (Generic Attribute Profile)

- Bluetooth 5

- Regulatory Compliance

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- DDS (Data Distribution Service)

- Sigfox

- NIST Cybersecurity Framework

- FAA Part 107 (United States)

- EU UAS Regulations (European Union)

- ICAO Annex 2 (International)

- Industry-Specific Guidelines

- Drug Supply Chain Security Act (DSCSA) in the United States

- Customs and Border Protection (CBP) Regulations

- EPCglobal Standards

- Wireless Communication Regulations

- Data Privacy and Security Regulations

- Cybersecurity Regulations

- Supply Chain and Traceability Standards

- Data Privacy and Security Regulations

- Occupational Safety and Health Regulations

- ISO Standards

- Environmental Regulations

- Aviation Regulations

- Remote Pilot Certification (United States)

- Visual Line of Sight (VLOS) Rules

- Payload Regulations

- Data Protection and Security

US Government Regulations

- FDA Regulations (Food and Drug Administration)

- cGMP Regulations (Current Good Manufacturing Practices)

- EPA Regulations (Environmental Protection Agency)

- OSHA Regulations (Occupational Safety and Health Administration)

- USDA Regulations (United States Department of Agriculture)

- PSM Regulations (Process Safety Management)

- FIFRA Regulations (Federal Insecticide, Fungicide, and Rodenticide Act)

- NRC Regulations (Nuclear Regulatory Commission)

- DOT Regulations (Department of Transportation)

- Hazardous Materials Regulations (HMR)

- TSCA Regulations (Toxic Substances Control Act)

- CDC Regulations (Centers for Disease Control and Prevention)

Canadian Government Regulations

- GMP Regulations (Good Manufacturing Practices)

- WHMIS Regulations (Workplace Hazardous Materials Information System)

- Transport of Dangerous Goods (TDG) Regulations

- Pest Control Products Regulations

- Food and Drugs Act Regulations

- Canadian Environmental Assessment Act (CEAA) Regulations

- Agriculture and Agri-Food Canada (AAFC) Regulations

- Fisheries and Oceans Canada (DFO) Regulations

- Canadian Transportation Agency (CTA) Regulations

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in biochemical manufacturing industry such as:

Personnel Management:

- SAP SuccessFactors

- Workday

- BambooHR

- Ultimate Software UltiPro

- ADP Workforce Now

- Oracle HCM Cloud

- Kronos Workforce Ready

Equipment Management:

- CMMS (Computerized Maintenance Management System) Software

- IoT-Enabled Asset Management Platforms

- Maintenance 4.0 Software

- PTC ThingWorx

- Asset Panda

- LabWare LIMS

- Enterprise Asset Management (EAM) Software

- ERP (Enterprise Resource Planning) Software

- Asset Tracking and Inventory Management Software

- GIS (Geographic Information System) Software

- Asset Tracking and Inventory Management

- Equipment Health Monitoring (e.g., sensors for temperature, pressure)

- Calibration and Certification Tracking

Access Control:

- HID Global (HID)

- LenelS2 (LenelS2)

- Genetec Security Center (Genetec)

- Honeywell Access Control (Honeywell)

- Tyco Software House (Johnson Controls)

- Brivo Access Control

- Kisi

- Proxyclick

- Openpath Access

Warehouse Management:

- SAP Extended Warehouse Management (SAP EWM)

- Oracle Warehouse Management (Oracle WMS Cloud)

- JDA Warehouse Management (Blue Yonder)

- Manhattan Warehouse Management System (Manhattan Associates)

- HighJump Warehouse Advantage (Körber Supply Chain)

Supply Chain Management:

- SAP Integrated Business Planning (SAP IBP)

- Oracle Supply Chain Management Cloud (Oracle SCM Cloud)

- Kinaxis RapidResponse (Kinaxis)

- JDA Supply Chain Management (Blue Yonder)

- Logility Voyager Solutions (Logility)

- GEP SMART

Other Applications:

- AspenTech’s Aspen Plus

- SoftMax Pro by Molecular Devices

- EnviroSuite

- MasterControl

- SIMCA by Umetrics (a part of Sartorius Group)

- Amazon Web Services (AWS)

- Oracle Cloud

- 3D EXPERIENCE Platform by Dassault Systèmes

GAO has enabled its customers to make use of some of the leading software and cloud services in the Chemical and Allied Products Merchant Wholesalers industry. Below are some of the popular software and cloud services in biochemical manufacturing industry such as SAP, IBM, Oracle, Microsoft, Dassault Systèmes, Benchling, LabWare, Thermo Fisher Scientific, Waters Corporation, PerkinElmer, Bio-Rad Laboratories, MilliporeSigma, Biovia (Dassault Systèmes), Veeva Systems, BIOVIA (Dassault Systèmes), Agilent Technologies, Mettler-Toledo, Illumina, Shimadzu Corporation, Zeiss, Bruker Corporation, Erlab, Anton Paar, GE Healthcare, Siemens, Emerson, Rockwell Automation, ABB, Honeywell Process Solutions, Yokogawa Electric Corporation, Wonderware (Schneider Electric), ICONICS, AVEVA, KISTERS, TIBCO Software, OSIsoft (now part of Aveva), Werum IT Solutions, Lighthouse Info Systems.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in biochemical manufacturing industry.

Inventory Management: GAO RFID tags can be used to track the movement and usage of raw materials, chemicals, and biological reagents within a manufacturing facility. This helps in maintaining accurate inventory levels and reducing the risk of stockouts or overstocking.

Equipment and Asset Tracking: GAO RFID can be used to monitor the location and status of equipment, such as bioreactors, centrifuges, and analytical instruments. This ensures that equipment is properly maintained and calibrated, reducing downtime and improving efficiency.

Supply Chain Visibility: RFID can be used to track the movement of materials and products as they move through the supply chain, from suppliers to manufacturers to distributors. This provides better visibility and control over the entire supply chain.

Academic Databases: Search academic databases like PubMed, IEEE Xplore, and Google Scholar for research papers, case studies, and articles related to RFID applications in biochemical manufacturing in Canada. Use specific search terms to narrow down your results.

Networking: Connect with professionals and experts in the field of biochemical manufacturing in Canada through industry events, associations, and networking platforms. They may be aware of or have access to relevant case studies.

Personnel and Access Control: UHF RFID badges can be issued to employees and contractors for access control purposes, ensuring that only authorized personnel enter specific manufacturing areas.

Product Traceability: GAO UHF RFID tags can be used to track individual product batches or containers, providing complete traceability throughout the manufacturing process. This is crucial for product recalls and quality assurance.

Consult RFID Solution Providers: GAO RFID technology companies that specialize in manufacturing solutions often have case studies on their websites or can provide you with relevant examples.

Networking: Attend industry conferences, trade shows, and events related to biochemical manufacturing and GAO RFID technology in Canada. Networking with professionals in the field can lead to valuable case study information.

Many applications of RFID by GAO can be found here.

https://gaorfid.com/healthcare-rfid-solutions/

Case Studies of IoT Applications

Below are some IoT application cases in the biochemical manufacturing industry.

Online Search: Conduct online searches using specific keywords related to IoT applications in biochemical manufacturing in the USA. For example, use phrases like “IoT in biochemical manufacturing case study USA.”

Industry Publications: Look for case studies in industry-specific publications, journals, and magazines related to biotechnology, pharmaceuticals, and manufacturing.

Contact Industry Associations: Reach out to industry associations and organizations related to biochemical manufacturing in the USA. They may have resources or case studies available.

Networking: Attend industry conferences, trade shows, and events related to biochemical manufacturing and IoT technology in the USA. Networking with professionals in the field can lead to valuable case study information.

Consult IoT Solution Providers: IoT technology companies that specialize in manufacturing solutions often have case studies on their websites or can provide you with relevant examples.

Academic Research: Explore academic research databases for publications and case studies related to IoT applications in biochemical manufacturing.

Environmental Monitoring: IoT sensors can monitor and control environmental conditions within manufacturing facilities, ensuring that temperature, humidity, and air quality are maintained at optimal levels for biochemical processes.

Equipment Monitoring and Maintenance: IoT devices can track the performance and maintenance needs of manufacturing equipment, reducing downtime and ensuring efficient operations.

Case Studies of Drone Applications

Below are some drone application cases in the biochemical manufacturing industry.

Remote Sensing: Drones with specialized sensors can gather data on air quality, water quality, and other environmental factors that may affect biochemical manufacturing processes.

Emergency Response: Drones can be deployed during emergencies or accidents to assess the situation, identify hazards, and assist in the coordination of response efforts.

Site Inspection: Drones can conduct site inspections, including checking for leaks, spills, or other safety hazards, without putting human workers at risk.

GAO RFID Systems & Hardware for Biochemical Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including biochemical manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, biochemical manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including biochemical manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including biochemical manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including biochemical manufacturing industry:

- high-frequency-13-56-mhz-rfid-readers

- high-frequency-134-khz-rfid-readers

- low-frequency-125-khz-rfid-readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including biochemical manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- uhf-860-960-mhz-rfid-modules

- 13-56-mhz-high-frequency-rfid-modules

- 125-khz-low-frequency-rfid-modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in biochemical manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include storage tanks and containers, chemical pumps and transfer equipment, forklifts and pallet jacks, safety equipment (e.g., protective clothing, gloves, respirators), labeling and packaging machinery, quality control and testing equipment, computer systems for inventory management, transportation vehicles (e.g., trucks, tankers), climate-controlled storage warehouses, and specialized handling equipment for hazardous materials.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for biochemical manufacturing industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in biochemical manufacturing industry.

we have worked with to serve our joint customers:

- Accenture

- Deloitte

- Capgemini

- Cognizant

- IBM Global Business Services

- PricewaterhouseCoopers (PwC)

- Wipro

- Ernst & Young (EY)

- Infosys

- DXC Technology

- HCL Technologies

- Tata Consultancy Services (TCS)

- Atos

- NTT Data

- CGI Group

- Compugen Inc.

- Long View Systems

- Scalar Decisions

- CDW Canada

- Softchoice

- OnX Enterprise Solutions

- Sierra Systems (an NTT Data Company)

- Bell Canada

- Insight Canada

- TeraMach Technologies

- Cogeco Peer 1

- Scalar Decisions

- OnX Enterprise Solutions

- Compufix Solutions

- PCL Constructors Canada Inc. (PCL)

- Sopra Steria

- TietoEVRY

GAO Has Biochemical Manufacturing Industry

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in biochemical manufacturing industry to achieve success in sustainability, digital transformation, supply chain optimization, e-commerce, regulatory compliance, blockchain, data analytics, IoT (Internet of Things), chemical safety, chemical traceability, environmental responsibility, predictive maintenance, inventory management, and green chemistry.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in biochemical manufacturing industry, including many in its various divisions such as:

- Industrial Chemicals: Wholesalers in this sub-industry distribute a wide range of chemicals used in various industrial processes, such as manufacturing, construction, and agriculture.

- Pharmaceutical Wholesalers: These wholesalers specialize in the distribution of pharmaceutical products, including prescription and over-the-counter medications, to pharmacies, healthcare facilities, and retailers.

- Agricultural Chemicals: This sub-industry focuses on the distribution of chemicals and products used in agriculture, such as fertilizers, pesticides, herbicides, and animal feed.

- Specialty Chemicals: Wholesalers in this segment deal with specialized chemicals used in industries like electronics, aerospace, and automotive manufacturing.

- Plastics and Resins: Wholesalers in this category distribute plastics, resins, and related products used in the production of consumer goods, packaging materials, and industrial components.

- Petroleum Products: Some wholesalers specialize in the distribution of petroleum-based products, including fuels, lubricants, and chemicals used in the energy sector.

- Cleaning and Janitorial Supplies: Wholesalers in this sub-industry supply cleaning and janitorial products, including chemicals, cleaning equipment, and sanitation supplies, to businesses and institutions.

- Paint and Coatings: This segment focuses on the distribution of paints, coatings, and related products used in construction, automotive, and industrial applications.

- Adhesives and Sealants: Wholesalers in this category distribute adhesives, sealants, and bonding solutions used in various industries, including construction and manufacturing.

- Laboratory and Scientific Equipment: Some wholesalers specialize in laboratory supplies, equipment, and chemicals used in research, healthcare, and educational institutions.

GAO’s technologies enable its customers in biochemical manufacturing industry to effectively track their workforces such as sales representatives, product specialists, warehouse managers, logistics coordinators, chemical engineers, safety officers, quality control analysts, procurement specialists, inventory managers, customer service representatives, compliance officers, and supply chain managers effectively track operational assets such as storage tanks, chemical pumps, drum handling equipment, forklifts, pallet jacks, labeling machines, packaging machinery, conveyor systems, quality control and testing equipment, temperature and humidity sensors, RFID systems, inventory management software, safety showers and eyewash stations, hazmat storage cabinets, spill containment pallets, and transportation vehicles such as trucks and tankers.

Here are some of the leading companies in biochemical manufacturing industry. GAO has served:

- Univar Solutions

- Brenntag North America

- Nexeo Solutions

- Basic Chemical Solutions, L.L.C.

- PVS Chemicals, Inc.

- Ravago Chemicals

- ChemGroup, Inc.

- Hawkins, Inc.

- Palmer Holland

- com

- Hubbard-Hall Inc.

- Superior Solvents & Chemicals

- Lorama Group Inc.

- Chemical Associates, Inc.

- Ashland Canada Corp.

- Superior Plus LP

- Can-Am Chemicals Ltd.

- Chemtrade Logistics Income Fund

- Quadra Chemicals Ltd.

- Sigma-Aldrich Corporation

- Lonza Group

- Avantor

- MilliporeSigma

- Bio-Rad Laboratories, Inc.

- Waters Corporation

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com