Index

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Cement and concrete product manufacturing industry

GAO Makes Efforts to Satisfy Customers

GAO Has Served Cement and concrete product manufacturing industry Extensively

Overview

The cement and concrete product manufacturing industry produces key construction materials like cement and concrete. These materials are essential for building infrastructure and structures. It’s capital-intensive, dependent on construction activity, faces environmental challenges, operates in a global market, and seeks innovations for sustainability.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in cement and concrete product manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Kilns, Crushers, Mixers, Cement mills, Silos, Conveyors, Batch plants, Pavers, Block-making machines, Pipe-making machines, Precast concrete molds, Vibrators, Grout pumps, Concrete testing equipment, Batching and weighing systems, Curing chambers, Rebar processing machinery, Dust collectors, Material handling equipment, Packaging and palletizing machines.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for cement and concrete product manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Cement and Concrete Product Manufacturing Industry

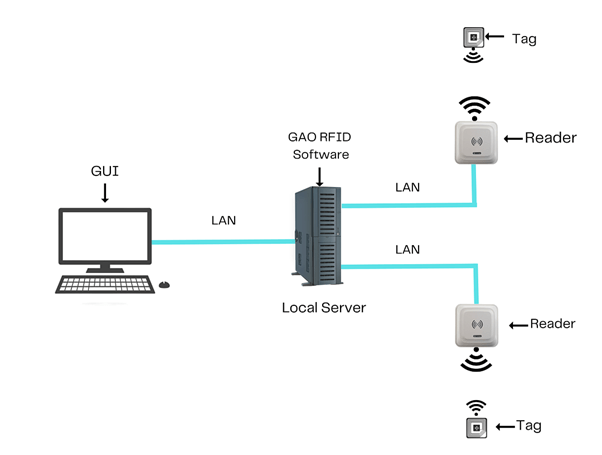

To satisfy its customers, GAO’s RFID or RFID Systems for cement and concrete product manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, Cloudflare and Rackspace. The above illustrates GAO system for cement and concrete product manufacturing industry software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for cement and concrete product manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, Cloudflare and Rackspace. The above illustrates GAO system for cement and concrete product manufacturing industry software running on a local server.

The above illustrates GAO system for cement and concrete product manufacturing industry with its software running in cloud.

The above illustrates GAO system for cement and concrete product manufacturing industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in cement and concrete product manufacturing industry:

- Inventory Management: GAO’s RFID tags can be attached to raw materials, cement bags, concrete mix components, and finished products, enabling real-time tracking and accurate inventory management.

- Quality Control: GAO’s RFID can be used to track the quality of raw materials and components, ensuring that only suitable materials are used in the manufacturing process.

- Equipment Tracking: GAO’s RFID tags on machinery and equipment help monitor their usage, maintenance schedules, and location, optimizing equipment utilization and maintenance.

- Asset Management: GAO’s RFID technology can track the location and condition of assets like vehicles, forklifts, and tools, reducing loss and improving asset utilization.

- Batch and Production Control: GAO’s RFID tags can be used to identify and trace batches of cement or concrete mixes throughout the production process, ensuring consistency and quality control.

- Supply Chain Visibility: GAO’s RFID allows for real-time tracking of shipments, enabling better supply chain visibility and coordination with suppliers and distributors.

- Worker Safety: GAO’s RFID-enabled identification badges or wearables can enhance worker safety by monitoring their location in hazardous areas and providing access control.

- Maintenance and Repairs: GAO’s RFID can assist in tracking the maintenance history of equipment and scheduling timely repairs, reducing downtime.

- Quality Assurance: GAO’s RFID can be used to trace the manufacturing process of concrete products, ensuring compliance with industry standards and quality control protocols.

- Security: GAO’s RFID access control systems can enhance security at manufacturing facilities, preventing unauthorized access to critical areas.

GAO’s drone technologies find the following applications in the cement and concrete product manufacturing industry:

- Site Surveying and Mapping: GAO’s drones can quickly survey and map construction sites, providing high-resolution aerial imagery and topographic data. This helps in site planning and design.

- Stockpile Measurement: GAO’s drones equipped with LiDAR or photogrammetry technology can accurately measure stockpiles of raw materials, such as sand, gravel, and aggregates, helping with inventory management.

- Site Inspection and Safety: GAO’s drones can conduct aerial inspections of construction sites, ensuring safety compliance, identifying potential hazards, and monitoring work progress.

- Quality Control: Aerial imagery from GAO’s drones can be used to assess the quality of concrete pours and surface finishes, ensuring compliance with project specifications.

- Progress Monitoring: GAO’s drones provide a bird’s-eye view of construction progress, enabling project managers to track milestones and identify delays or discrepancies.

- Environmental Monitoring: GAO’s drones can monitor environmental factors like dust emissions, noise levels, and erosion, helping to ensure compliance with environmental regulations.

- Infrastructure Inspection: GAO’s drones equipped with specialized cameras and sensors can inspect infrastructure elements like bridges, dams, and pipelines for signs of wear, corrosion, or damage.

- Thermal Imaging: Thermal cameras on GAO’s drones can detect anomalies in concrete structures, such as areas with reduced insulation or potential leaks.

- Safety and Security: GAO’s drones can be used for security surveillance at construction sites, helping to deter theft and vandalism.

- Delivery of Materials: In some cases, GAO’s drones can transport small construction materials or tools to remote or inaccessible areas within the construction site.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the cement and concrete product manufacturing industry:

- Asset Tracking and Management: GAO’s IoT sensors can track the location and condition of equipment, machinery, and vehicles, optimizing asset utilization and scheduling maintenance.

- Predictive Maintenance: GAO’s IoT sensors can monitor the health of critical machinery, predicting maintenance needs and preventing unexpected breakdowns.

- Quality Control: GAO’s IoT sensors can continuously monitor parameters like temperature, humidity, and curing conditions to ensure the quality and integrity of concrete products.

- Inventory Management: GAO’s IoT can provide real-time data on inventory levels of raw materials, enabling efficient procurement and reducing stockouts or excess inventory.

- Energy Management: GAO’s IoT systems can optimize energy consumption in manufacturing processes by monitoring and controlling equipment and lighting based on real-time demand.

- Supply Chain Visibility: GAO’s IoT enables real-time tracking of shipments, ensuring that materials and products are delivered on time and minimizing delays.

- Environmental Monitoring: GAO’s IoT sensors can track environmental factors like dust levels, emissions, and noise pollution, ensuring compliance with environmental regulations.

- Production Efficiency: GAO’s IoT can optimize production processes by monitoring and adjusting parameters such as mixing ratios and curing times to minimize waste and improve product consistency.

- Worker Safety: GAO’s wearable IoT devices can monitor worker safety by tracking location, detecting falls, and ensuring compliance with safety protocols.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Cement and Concrete Product Manufacturing Industry

GAO RFID Inc. has helped many companies in cement and concrete product manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 series

- Bluetooth SIG (Special Interest Group)

- IEEE 802.11 (Wi-Fi)

- OPC UA (Unified Architecture)

- ISA-95

- ASTM International F38 Committee

US. Government Regulations

- Clean Air Act (CAA)

- Clean Water Act (CWA)

- Resource Conservation and Recovery Act (RCRA)

- Occupational Safety and Health Administration (OSHA) regulations

- National Emissions Standards for Hazardous Air Pollutants (NESHAP)

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- Toxic Substances Control Act (TSCA)

- National Ambient Air Quality Standards (NAAQS)

- Federal Water Pollution Control Act (FWPCA)

- Environmental Protection Agency (EPA) regulations

Canadian Government Regulations

- Canadian Environmental Protection Act, 1999 (CEPA)

- Canadian Environmental Assessment Act (CEAA)

- Canadian Environmental Assessment Agency (CEAA) Regulations

- Canadian Environmental Assessment Agency (CEAA) Inclusion List Regulations

- Canadian Environmental Assessment Agency (CEAA) Administrative Monetary Penalties Regulations

- Canadian Environmental Assessment Agency (CEAA) Cost Recovery Regulations

- Canadian Environmental Assessment Agency (CEAA) Self-Assessment Regulations

GAO Software Provides Easy Integration With API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in cement and concrete product manufacturing industry such as:

Personnel Management:

- Employee Attendance Tracking

- Workforce Scheduling and Shift Management

- Health and Safety Compliance Monitoring

- Training and Certification Tracking

- Employee Performance Evaluation

- Payroll and Compensation Management

- Human Resources Information System (HRIS)

- Labor Union and Collective Bargaining Management

Equipment Management:

- Predictive Maintenance

- Equipment Health Monitoring

- Equipment Utilization Optimization

- Equipment Calibration Management

- Equipment Rental and Leasing Management

Access Control:

- Visitor Management

- Security Surveillance

- Restricted Area Monitoring

- Time and Attendance Control

Warehouse Management:

- Stockpile Measurement

- Raw Material and Finished Product Storage

- Barcode and RFID Inventory Scanning

- Order Fulfillment and Dispatching

- Warehouse Layout Optimization

- Demand Forecasting and Inventory Replenishment

Supply Chain Management:

- Procurement and Purchase Order Management

- Transportation and Logistics Optimization

- Demand Planning and Forecasting

- Production Planning and Scheduling

- Vendor Compliance Monitoring

- Just-in-Time (JIT) Inventory Management

- Cold Chain Management for Concrete Additives

Other Applications:

- Batch Control and Recipe Management

- Customer Relationship Management (CRM)

- Financial Management and Cost Control

- Sustainability and Carbon Footprint Monitoring

- Regulatory Compliance (Safety, Environmental, Building Codes)

GAO has enabled its customers to make use of some of the leading software and cloud services in the cement and concrete product manufacturing industry. Below are some of popular software and cloud services in cement and concrete product manufacturing industry SAP SuccessFactors, Oracle HCM Cloud, ADP Workforce Now, Kronos Workforce Central, IBM Maximo, Infor EAM, eMaint CMMS, Fiix, UpKeep, Maintenance Connection, Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), IBM Cloud, Oracle Cloud, SAP Cloud Platform, Salesforce Platform, ServiceNow, Workday, ADP Workforce Cloud, Warehouse Management Cloud, Manhattan Associates Warehouse Management, SAP Extended Warehouse Management (EWM), Blue Yonder (formerly JDA Software) Warehouse Management, Zebra Technologies (for barcode and RFID solutions), Honeywell Intelligrated (for warehouse automation), Microsoft Dynamics 365 Supply Chain Management, Kinaxis RapidResponse, Descartes Systems Group (for logistics and supply chain solutions), Infor Supply Chain Management.

GAO has worked with some of the leading technology companies in the cement and concrete product manufacturing industry to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in cement and concrete product manufacturing industry IBM, SAP, Oracle, Microsoft, Infor, Salesforce, Siemens PLM Software, Trimble, Rockwell Automation, Hexagon PPM, Siemens, Schneider Electric, ABB, Honeywell, Mitsubishi Electric, Eaton Corporation, Emerson Electric, Omron Corporation, Yokogawa Electric Corporation, Telemecanique (Schneider Electric), Rockwell Automation, Siemens, Emerson Electric, Schneider Electric, ABB, Honeywell, GE Digital, Johnson Controls, Wonderware (Schneider Electric), Invensys (Schneider Electric)

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in the cement and concrete product manufacturing industry.

A large cement manufacturer in the USA implements an RFID-based inventory management system. RFID tags are affixed to raw materials such as aggregates, cement, and additives. RFID readers installed at various storage locations automatically record inventory levels and notify the inventory manager when it’s time to reorder. This reduces stockouts, prevents overstocking, and minimizes manual tracking efforts.

A concrete precast plant in the USA uses RFID sensors embedded in concrete molds. These sensors monitor curing temperatures and humidity levels during the concrete curing process. RFID data is transmitted to a central system, ensuring that each concrete product meets precise quality specifications. Any deviations trigger immediate alerts for corrective action.

A concrete block manufacturing facility in Canada equips workers with RFID-enabled safety vests. These vests incorporate RFID tags that communicate with fixed RFID readers installed in dangerous areas of the plant. If a worker enters a restricted zone without proper authorization or safety equipment, the system sends instant alerts to plant supervisors, ensuring a rapid response to potential hazards.

A concrete pipe manufacturer in Canada employs RFID tags on heavy machinery and equipment. These tags store maintenance schedules and usage data. When equipment needs servicing or is approaching its maintenance interval, RFID sensors trigger automated maintenance requests. This proactive approach reduces downtime and extends equipment lifespan.

A European cement production facility integrates RFID technology into its energy management system. RFID sensors monitor energy consumption across different production processes. The data collected allows for real-time analysis and optimization of energy usage, leading to significant energy savings and reduced environmental impact.

A concrete products manufacturer in Europe embeds RFID sensors in concrete blocks and pipes during production. These sensors continuously monitor structural integrity and performance characteristics in real-time. Data collected from RFID sensors help in early detection of potential issues, reducing product defects and ensuring compliance with industry standards.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in the cement and concrete product manufacturing industry.

A cement manufacturing plant in the USA implements an IoT-based environmental monitoring system. IoT sensors are deployed to continuously measure air quality, dust emissions, and noise levels in and around the facility. The data is transmitted to a central control center in real-time, allowing the plant to proactively address environmental compliance issues and minimize environmental impact.

A concrete batching plant in the USA adopts IoT sensors on critical machinery, such as mixers and conveyors. These sensors collect real-time data on equipment performance, including temperature, vibration, and power consumption. Advanced analytics and machine learning algorithms predict when equipment maintenance is needed, reducing unexpected breakdowns and improving operational efficiency.

A concrete block manufacturing facility in Canada integrates IoT devices into its energy management strategy. Smart meters and sensors are installed to monitor electricity and natural gas consumption across the plant. Real-time data is analyzed to identify energy-saving opportunities and implement load-shifting strategies to reduce energy costs.

A precast concrete products manufacturer in Canada leverages IoT-enabled tracking devices on trucks delivering concrete elements to construction sites. These devices provide real-time location data, estimated arrival times, and traffic updates. This information helps optimize delivery schedules, improve customer service, and reduce transportation costs.

A European concrete pipe manufacturer deploys IoT sensors within molds during the curing process. These sensors monitor temperature, humidity, and curing time. Data is collected and analyzed in real-time, ensuring that each concrete product meets strict quality standards. Any deviations trigger alerts for immediate corrective action.

A cement production facility in Europe implements IoT-enabled silos and inventory management systems. Sensors track the level and quality of raw materials and finished products in real-time. IoT data is used for precise batching control, reducing waste and improving product consistency.

Case Studies of Drone Applications

Below are some drone application cases in cement and concrete product manufacturing industry.

A large cement manufacturing plant in the USA employs drones for regular site inspections and monitoring. Drones equipped with high-resolution cameras and thermal imaging sensors are used to assess the condition of storage silos, kilns, and other critical infrastructure. This proactive approach helps identify potential issues such as cracks, leaks, or wear and tear early on, allowing for timely maintenance and preventing costly breakdowns.

A concrete products manufacturer in the USA utilizes drones for stockpile management. Drones equipped with LiDAR technology and GPS mapping capabilities conduct regular aerial surveys of raw material stockpiles. This data is then used to calculate precise volume measurements and monitor stockpile changes over time, optimizing inventory levels and reducing waste.

A Canadian cement production facility employs drones to monitor environmental compliance. Drones equipped with air quality sensors and cameras conduct routine flights over the facility to collect data on emissions and dust levels. This data is transmitted to regulatory authorities in real-time, ensuring compliance with environmental regulations and minimizing environmental impact.

Concrete block manufacturing plant in Canada deploys drones for site safety and security. Drones equipped with high-resolution cameras and thermal imaging technology patrol the facility perimeter during off-hours. They can detect unauthorized access, monitor for potential security breaches, and provide real-time alerts to security personnel.

A European precast concrete manufacturer offers drone services to construction companies. Drones equipped with cameras and 3D mapping technology capture aerial imagery of construction sites where their products are being used. This data is shared with construction project managers, enabling them to monitor progress, verify the correct placement of precast elements, and ensure adherence to project timelines.

A European cement plant in a remote location employs drones for remote inspection and maintenance. Drones equipped with high-resolution cameras and sensors are used to inspect equipment and infrastructure in challenging or hard-to-reach areas of the plant. Maintenance teams can then prioritize repairs and maintenance activities based on the drone inspection findings, improving overall plant efficiency.

GAO RFID Systems & Hardware for Cement and Concrete Product Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including cement and concrete product manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including cement and concrete product manufacturing industry.

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including cement and concrete product manufacturing industry:

and an array of antennas to address different applications:

cement and concrete product manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Module

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones are offered:

The RFID systems by GAO are highly popular for clients in cement and concrete product manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including cement and concrete product manufacturing industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including cement and concrete product manufacturing industry:

and antennas:

The RFID systems by GAO are highly popular for clients in cement and concrete product manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

Batching Plants, Concrete Mixers, Cement Silos, Concrete Pumps, Concrete Block Machines, Concrete Forms, Concrete Finishing Equipment, Precast Concrete Molds, Rebar Cutters and Benders, Concrete Testing Equipment, Curing Chambers, Concrete Recycling Equipment, Shotcrete Machines, Concrete Vibrators, Mortar Mixers, Pipe Making Machines, Concrete Surface Preparation Equipment, Trowels and Floats, Concrete Cutting Equipment, Concrete Transport Trucks (Ready-Mix Trucks).

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for cement and concrete product manufacturing industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in cement and concrete product manufacturing industry we have worked with to serve our joint customers:

- Accenture

- Deloitte

- Capgemini

- Cognizant

- IBM Global Business Services

- DXC Technology

- HCL Technologies

- Infosys

- Wipro

- Tata Consultancy Services (TCS)

- CGI

- Sierra Systems (a NTT Data Company)

- WSP Canada

- BDO IT Solutions

- T4G Limited

- SNC-Lavalin Group Inc.

- Atos

- T-Systems

GAO Has Served Cement and Concrete Product Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in cement and concrete product manufacturing industry to achieve success in Sustainable Construction, Carbon Capture, Digital Twin, Industry 4.0, Smart Concrete, Green Building, IoT (Internet of Things), BIM (Building Information Modeling), Precast Concrete, 3D Printing, Self-Healing Concrete, Circular Economy, Lightweight Concrete, Modular Construction, Automation, Augmented Reality (AR), Robotics, Energy Efficiency, Resilient Infrastructure, Nanotechnology.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in cement and concrete product manufacturing industry, including many in its various divisions such as:

- Cement Manufacturing: This division focuses on the production of cement, which is a key ingredient in concrete. It involves processes such as quarrying raw materials, crushing, grinding, blending, and clinker production.

- Ready-Mix Concrete Manufacturing: Ready-mix concrete companies prepare concrete mixtures off-site and deliver them to construction sites. They specialize in producing concrete with specific mix designs and deliver it in a ready-to-use form.

- Concrete Block and Brick Manufacturing: This sub-industry produces concrete blocks, bricks, and other masonry products used in construction. It involves molding, curing, and finishing concrete blocks and bricks.

- Precast Concrete Product Manufacturing: Precast concrete manufacturers produce pre-made concrete components and structures, such as beams, columns, walls, and architectural elements, which are transported to construction sites for assembly.

- Concrete Pipe and Block Manufacturing: This division focuses on the production of concrete pipes, culverts, and blocks used in infrastructure projects like drainage systems and wastewater management.

- Concrete Product Repair and Restoration: Companies specializing in concrete repair and restoration work to maintain and extend the life of existing concrete structures.

- Concrete Admixtures Manufacturing: This sub-industry produces chemical additives used in concrete to improve its performance, durability, and workability.

- Concrete Sealer and Coating Manufacturing: Manufacturers in this division produce sealants and coatings used to protect and enhance the appearance of concrete surfaces.

- Concrete Equipment Manufacturing: Companies in this category produce machinery and equipment used in concrete production and construction, including mixers, pumps, and batch plants.

- Concrete Testing and Inspection Services: This sub-industry provides testing and inspection services to ensure the quality and compliance of concrete products and structures with industry standards and regulations.

GAO’s technologies enable its customers in cement and concrete product manufacturing industry to effectively track their workforces such as Mixer Operator, Batch Plant Operator, Concrete Finisher, Precast Production Worker, Mason, Quarry Worker, Quality Control Inspector, Form Setter, Heavy Equipment Operator, Cement Mason, Reinforcing Ironworker, Production Supervisor, Maintenance Technician, Mold Maker, Safety Coordinator, Environmental Compliance Specialist, Concrete Pump Operator, Batch Technician, Electrician, Welder and effectively track operational assets such as Mixer, Batch Plant, Conveyor, Kiln, Crusher, Silo, Paver, Formwork, Trowel, Vibrator, Rebar Cutter, Mold, Pump, Compactor, Saw, Loader, Crane, Excavator, Bulldozer, Rolle.

Here are some of the leading companies in cement and concrete product manufacturing industry GAO has served:

- Lehigh Hanson, Inc. (HeidelbergCement Group)

- LafargeHolcim (U.S.)

- CRH (Oldcastle)

- Argos USA

- Buzzi Unicem USA

- The QUIKRETE Companies

- CEMEX USA

- Martin Marietta

- Ash Grove Cement Company

- Boral North America

- CalPortland Company

- GCC (Grupo Cementos de Chihuahua)

- CalPortland Company

- U.S. Concrete, Inc.

- Eagle Materials, Inc.

- Titan America

- Lehigh Southwest Cement Company

- National Cement Company

- Lafarge Canada Inc.

- CRH Canada Group Inc. (Oldcastle)

- Lehigh Hanson Materials Limited

- Béton Provincial Ltd.

- St. Marys Cement (Votorantim Cimentos)

- Ciment Quebec Inc.

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com