Overview

This segment involves the production of various clay-based products, including bricks, tiles, ceramics, pottery, and clay pipes. The primary raw material is clay, which is shaped and fired at high temperatures to create durable and often decorative products. Clay products are used in construction (bricks, tiles), art and design (ceramics, pottery), and sanitation (clay pipes for sewer systems. Refractories are specialized materials designed to withstand high temperatures, extreme pressure, and chemical exposure. They include bricks, castables, and coatings. Refractory materials are typically made from minerals such as alumina, silica, and magnesia. They are engineered to provide thermal insulation, resist corrosion, and maintain structural integrity in high-heat environments. Refractories are crucial in industries where extreme temperatures are involved, such as steel manufacturing, cement production, glassmaking, and petrochemical processing. They line furnaces, kilns, and other high-temperature equipment to protect them from damage and ensure efficiency.

The industry’s demand is closely tied to construction activity, industrial manufacturing, and infrastructure development. Economic growth and expansion in these sectors drive demand for both clay products and refractories. The industry serves a global market because refractory materials are essential in various heavy industries worldwide. Ongoing research and development efforts aim to improve the performance and longevity of refractory materials, reducing downtime and maintenance costs for industries that rely on them. Sustainability is becoming increasingly important, and the industry is exploring ways to reduce energy consumption and emissions associated with manufacturing processes.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in clay product and refractory manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as: Clay Mixing Equipment, Pug Mills, Extruders, Clay Forming Machines, Kilns, Drying Chambers, Glazing Machines, Pottery Wheels, Ceramic Printing Equipment, Brick Molding Machines, Refractory Presses, Refractory Mixers, Refractory Vibrating Screens, Mold Making Equipment, Firing Furnaces, Clay Cutting Machines, Refractory Casting Machines, Glaze Sprayers, Clay Extrusion Dies, Clay Sieving Equipment, Refractory Brick Cutting Tools, Refractory Drying Ovens, Pottery Kiln Furniture, Clay Grinding Mills, Refractory Insulation Materials, Clay Blungers, Refractory Fiber Manufacturing Equipment, Palletizers (for brick and tile handling), Dust Collectors, Material Handling Conveyors.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for clay product and refractory manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications &Benefits of GAO’s RFID, BLE, IoT & Drones for Clay Product and Refractory Manufacturing Industry

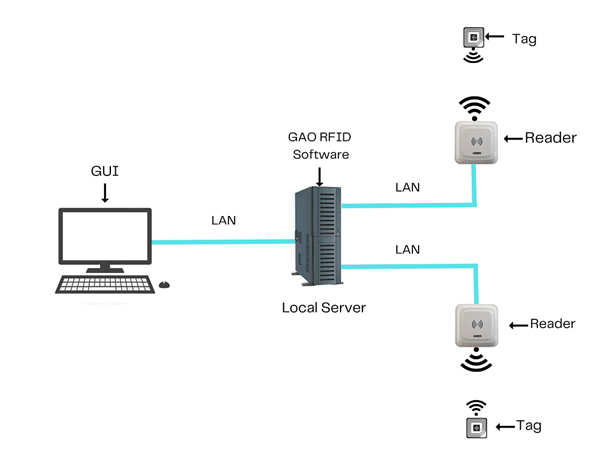

To satisfy its customers, GAO’s RFID or RFID Systems for clay product and refractory manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace.The above illustrates GAO system for clay product and refractory manufacturing industry with its software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for clay product and refractory manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace.The above illustrates GAO system for clay product and refractory manufacturing industry with its software running on a local server.

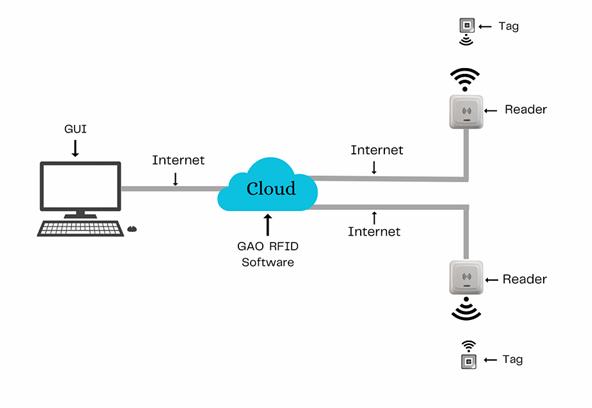

The above illustrates GAO system for clay product and refractory manufacturing industry with its software running in cloud.

The above illustrates GAO system for clay product and refractory manufacturing industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in clay product and refractory manufacturing industry:

- Inventory Management: GAO’s RFID tags are attached to raw materials, intermediate products, and finished goods, allowing for real-time tracking of inventory levels. This helps prevent stockouts and overstock situations.

- Asset Tracking: GAO’s RFID is used to track and manage critical assets such as kilns, molds, machinery, and specialized tools. It aids in maintenance scheduling and reduces equipment downtime.

- Quality Control: GAO’s RFID tags can be used to associate digital records with specific batches or lots of clay products or refractories. This assists in quality control by providing a digital history of each item’s production process.

- Work-in-Progress Tracking: GAO’s RFID tags on products in various stages of production provide visibility into work-in-progress (WIP) inventory. This helps in managing production flow and optimizing production schedules.

- Traceability: GAO’s RFID enables precise tracking of each clay product or refractory from raw materials to finished product, making it easier to trace the source of any defects or quality issues.

- Maintenance and Servicing: GAO’s RFID tags on machinery and equipment can store maintenance schedules and records. This ensures timely maintenance, reducing unexpected downtime.

- Batch Management: GAO’s RFID helps in managing and tracking different batches of clay products or refractories. It aids in ensuring consistency in product quality and properties.

- Process Monitoring: GAO’s RFID sensors can be used to monitor temperature, humidity, and other environmental conditions during the firing and curing processes. This data helps maintain product quality.

- Security and Access Control: GAO’s RFID cards or badges are used for access control and security measures to restrict unauthorized access to manufacturing facilities.

- Shipping and Logistics: GAO’s RFID tags on finished products facilitate efficient shipping and logistics operations, including automating the creation of shipping manifests and tracking the location of shipments in real-time.

- Energy Efficiency: GAO’s RFID technology can be used to monitor energy consumption in manufacturing processes and identify areas for optimization.

- Supply Chain Visibility: GAO’s RFID provides supply chain visibility by allowing manufacturers to track the movement of materials and products from suppliers to the end customers.

- Material Authentication: GAO’s RFID tags can be used to authenticate the source and quality of raw materials, ensuring that only approved materials are used in production.

- Labor Tracking: GAO’s RFID badges worn by employees can help track their movements and activities within the manufacturing facility, aiding in workforce management and safety.

- Regulatory Compliance: GAO’s RFID data can be used to demonstrate compliance with industry regulations and quality standards by providing a complete digital record of production processes.

GAO’s drone technologies find the following applications in the clay product and refractory manufacturing industry:

- Inventory Management: GAO’s Drones equipped with cameras or LiDAR sensors can conduct aerial surveys of stockpiles of raw materials (e.g., clay, sand, refractory materials). This enables accurate volume calculations and efficient inventory management.

- Site Surveying and Mapping: GAO’s Drones can create high-resolution aerial maps of manufacturing facilities, including kilns, production areas, and storage yards. These maps help in facility planning, design, and layout optimization.

- Inspecting High Structures: GAO’s Drones can access and inspect tall structures such as chimneys, smokestacks, and kilns. They provide visual data and enable close-up inspections without the need for scaffolding or cranes.

- Environmental Monitoring: GAO’s Drones can monitor emissions from manufacturing processes and ensure compliance with environmental regulations. They can also survey nearby ecosystems for any impact.

- Safety Inspections: GAO’s Drones can conduct safety inspections of manufacturing sites, identifying potential hazards and safety violations, ensuring compliance with safety standards.

- Infrastructure Maintenance: GAO’s Drones can inspect and assess the condition of infrastructure such as conveyor belts, storage tanks, and piping systems. This helps in identifying maintenance needs and reducing downtime.

- Site Security: GAO’s Drones equipped with cameras and motion sensors can be used for security surveillance to prevent unauthorized access and monitor critical areas.

- Aerial Photography and Videography: GAO’s Drones capture high-quality aerial photographs and videos for marketing, project documentation, and reporting purposes.

- Material Tracking: GAO’s Drones with RFID or GPS technology can track the movement of materials within the facility, ensuring efficient material handling and reducing errors.

- Surveillance During Production: GAO’s Drones can monitor production processes, helping operators identify issues or inefficiencies in real-time.

- Transport and Logistics: GAO’s Drones can be used to transport small, high-value items within a manufacturing facility, increasing efficiency in material handling.

- Training and Simulation: GAO’s Drones can be used for training purposes, simulating various manufacturing scenarios and emergency response drills.

- Regulatory Compliance: GAO’s Drones can assist in compliance with environmental regulations by providing data and visual evidence of adherence to standards.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the clay product and refractory manufacturing industry:

- Asset Tracking: GAO’s IoT sensors can be attached to manufacturing equipment, machinery, and tools to monitor their location, status, and usage in real-time. This helps in optimizing asset utilization and scheduling maintenance.

- Energy Management: GAO’s IoT sensors and meters can track energy consumption in various stages of production, helping manufacturers identify energy-saving opportunities and reduce operational costs.

- Inventory Management: GAO’s IoT-enabled RFID tags and sensors track the movement of raw materials and finished products throughout the manufacturing process. This improves inventory accuracy and streamlines supply chain operations.

- Quality Control: GAO’s IoT devices can monitor and record parameters during the production process, ensuring that clay products and refractories meet quality standards. Any deviations can trigger alerts for corrective action.

- Process Optimization: GAO’s IoT systems use data analytics to optimize manufacturing processes, identifying inefficiencies and suggesting improvements to increase productivity and reduce waste.

- Supply Chain Visibility: GAO’s IoT devices provide real-time visibility into the supply chain, enabling manufacturers to track the movement of materials and products from suppliers to customers.

- Equipment Utilization: GAO’s IoT systems can analyze equipment utilization data to determine which machines are underutilized or overburdened, allowing for better resource allocation.

- Material Handling: GAO’s IoT-enabled forklifts, conveyors, and AGVs (Automated Guided Vehicles) can optimize material handling processes, reducing errors and delays.

- Quality Assurance: GAO’s IoT devices can measure and record product dimensions, weight, and other quality-related metrics, ensuring consistency and compliance with specifications.

- Waste Reduction: GAO’s IoT helps identify areas where waste can be reduced, such as in the use of raw materials, energy, or water.

- Supply Chain Planning: GAO’s IoT data can be used for demand forecasting, production planning, and inventory optimization to streamline operations and reduce costs.

- Product Traceability: GAO’s IoT systems enable end-to-end traceability of products, making it easier to identify the source of defects or quality issues and initiate recalls if necessary.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Clay Product and Refractory Manufacturing Industry

GAO RFID Inc. has helped many companies in clay product and refractory manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 Series

- Bluetooth SIG

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- OneM2M

- OPC UA (Unified Architecture)

- ASTM F38 Committee

- ISO 21384 Series

- ANSI/CTA-2063

- FAA Regulations

- EASA Regulations

US.Government Regulations

- Clean Air Act (CAA)

- Clean Water Act (CWA)

- Resource Conservation and Recovery Act (RCRA)

- Occupational Safety and Health Administration (OSHA) Regulations

- National Emissions Standards for Hazardous Air Pollutants (NESHAPs)

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- Emergency Planning and Community Right-to-Know Act (EPCRA)

- Toxic Substances Control Act (TSCA)

- Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)

- Department of Transportation (DOT) Hazardous Materials Regulations

- National Fire Protection Association (NFPA) Standards

- Consumer Product Safety Commission (CPSC) Regulations

- Mine Safety and Health Administration (MSHA) Regulations

- Department of Labor Wage and Hour Division Regulations

- Environmental Protection Agency (EPA) Reporting and Recordkeeping Requirements

- Department of Transportation (DOT) Pipeline and Hazardous Materials Safety Administration (PHMSA) Regulations

- Federal Trade Commission (FTC) Regulations

- S. Department of Agriculture (USDA) Regulations for Biomass and Agricultural Products

- Federal Motor Carrier Safety Administration (FMCSA) Regulations

- National Institute for Occupational Safety and Health (NIOSH) Guidelines for Occupational Safety and Health in Manufacturing Industries

Canadian Government Regulations

- Canadian Environmental Protection Act, 1999 (CEPA)

- Canadian Environmental Assessment Act, 2012 (CEAA 2012)

- Fisheries Act

- Transportation of Dangerous Goods Act, 1992 (TDGA)

- Canada Labour Code

- Canada Occupational Health and Safety Regulations (COHSR)

- Canadian Standards Association (CSA) Standards

- Hazardous Products Regulations

- Pest Control Products Act

- Explosives Act

- Food and Drugs Act

- Canada Consumer Product Safety Act (CCPSA)

- Transportation of Dangerous Goods Regulations (TDGR)

- Canadian Nuclear Safety Commission (CNSC) Regulations

- Transportation Safety Board (TSB) Regulations

- Canadian Transportation Agency (CTA) Regulations

- Canadian Food Inspection Agency (CFIA) Regulations

- Natural Resources Canada (NRCan) Regulations

- Fisheries and Oceans Canada (DFO) Regulations

- Health Canada Regulations

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in clay product and refractory manufacturing industry such as:

Personnel Management:

- Human Resource Information System (HRIS)

- Payroll and Benefits Management Software

- Employee Time and Attendance Tracking

- Performance Management Systems

- Training and Development Management

- Health and Safety Compliance Software

- Employee Scheduling and Shift Planning

- Recruitment and Applicant Tracking Systems (ATS)

- Labor Management Systems (LMS)

- Employee Self-Service Portals

Equipment Management:

- Computerized Maintenance Management System (CMMS)

- Asset Tracking and Management Software

- Predictive Maintenance Tools

- Equipment Health Monitoring Systems

- Calibration and Testing Equipment Software

- Fleet Management Solutions

- Telematics and GPS Tracking

- RFID-Based Equipment Tracking

- Inventory Management for Spare Parts

Access Control:

- Access Control Systems (ACS)

- Biometric Access Control (e.g., fingerprint or facial recognition)

- Card-Based Access Control

- Visitor Management Systems

- Video Surveillance and Monitoring

- Intrusion Detection Systems (IDS)

- Electronic Locking Systems

- Alarm and Notification Systems

Warehouse Management:

- Warehouse Management Systems (WMS)

- Inventory Control and Tracking Software

- RFID-Based Warehouse Management

- Barcode Scanning and Labeling

- Order Management Systems (OMS)

- Picking and Packing Automation

- Dock Scheduling and Management

- Warehouse Optimization Software

- Material Handling Equipment Control

Supply Chain Management:

- Supply Chain Planning and Optimization Software

- Demand Forecasting and Planning

- Supplier Relationship Management (SRM)

- Transportation Management Systems (TMS)

- Inventory Optimization Solutions

- Order Fulfillment and Distribution Management

- Supplier Collaboration and Integration

- EDI (Electronic Data Interchange) for Supply Chain

- Sustainability and Compliance Tracking

Other Applications:

- Quality Control and Assurance Software

- Environmental Management and Compliance Tools

- Customer Relationship Management (CRM)

- Financial Management and Accounting Software

- Product Lifecycle Management (PLM)

- Energy Management and Monitoring

- Regulatory Compliance Management

- Business Intelligence and Analytics

- IoT and Sensor Integration for Data Collection

- Document Management and Digital Archiving

GAO has enabled its customers to make use of some of the leading software and cloud services in clay product and refractory manufacturing industry. Below are some of popular software and cloud services in clay product and refractory manufacturing industry Workday, SAP SuccessFactors, Oracle HCM Cloud, ADP Workforce Now, BambooHR, Kronos Workforce Ready, Zenefits, UltiPro, Gusto, Namely, Fiix, UpKeep, eMaint CMMS, Asset Panda, Maintenance Connection, ManagerPlus, Limble CMMS, Asset Essentials, Maintenance Care, Hippo CMMS, HID Global, Genetec, Brivo, Gallagher, S2 Security, LenelS2, AMAG Technology, Openpath, Avigilon, Identiv, Oracle NetSuite WMS, HighJump WMS, Manhattan Associates WMS, SAP Extended Warehouse Management (EWM), Fishbowl Inventory, Snapfulfil WMS, 3PL W, rehouse Manager, Logiwa WMS, Warehouse Anywhere, Softeon WMS, SAP Integrated Business Planning (IBP), Kinaxis RapidResponse, JDA Software, Oracle Supply Chain Cloud, Blue Yonder (formerly JDA Software), Llamasoft Supply Chain Guru, GEP SMART, E2open, Saviom Software, Logility Voyager Solutions.

GAO has worked with some of the leading technology companies in clay product and refractory manufacturing industry to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in clay product and refractory manufacturing industry such as IBM, SAP, Oracle, Microsoft, Salesforce, Infor, Epicor, Plex Systems, IQMS, SYSPRO, Siemens, ABB, Schneider Electric, Rockwell Automation, Emerson Electric, Honeywell, Yokogawa Electric Corporation, Mitsubishi Electric, Omron Corporation, Beckhoff Automation, Wonderware (Schneider Electric), GE Digital, Inductive Automation, ICONICS, Canary Labs, OSIsoft, PTC, eRPortal Software, Lighthouse Systems, InfinityQS International.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in some RFID application cases in clay product and refractory manufacturing industry:

A refractory manufacturing company in the USA implemented RFID tags on critical equipment and molds used in the production of refractory products. This allowed them to track the location and maintenance history of these assets in real-time, improving equipment utilization and reducing downtime.

A brick manufacturing facility in the USA deployed RFID technology to manage their inventory of clay, sand, and other raw materials. RFID tags on material containers helped automate inventory tracking and reorder processes, ensuring that raw materials were always available for production.

A refractory manufacturer in Canada used RFID tags on individual refractory products to track their journey through the production process. This included monitoring temperature and other environmental conditions during curing and firing to ensure product quality and consistency.

A ceramic tile manufacturer in Canada implemented RFID-enabled pallets and conveyor systems to track the movement of tiles through different production stages. This allowed for real-time monitoring of WIP inventory and production bottlenecks.

A clay product manufacturer in Mexico employed RFID tags on pallets of finished products. This enabled them to track shipments from their manufacturing facility to distribution centers, providing real-time visibility into the supply chain and helping optimize logistics operations.

A refractory manufacturing plant in Mexico utilized RFID tags on containers of hazardous materials. This ensured that these materials were stored, handled, and transported in compliance with environmental regulations, with automated reporting for regulatory purposes.

A European clay product manufacturer embedded RFID tags in clay blocks at the production stage. These tags contained information about the clay’s origin and quality, assisting in material authentication and traceability throughout the supply chain.

A refractory manufacturer in Europe implemented RFID sensors on critical machinery and kilns. These sensors monitored equipment conditions and automatically generated maintenance alerts, reducing unplanned downtime and improving overall equipment efficiency.

Many applications of RFID by GAO can be found here.

Manufacturing Industry | RFID Solutions

Case Studies of IoT Applications

Below are some IoT application cases in clay product and refractory manufacturing industry.

A refractory manufacturing plant in the USA deployed IoT sensors on critical machinery, such as kilns and conveyor belts. These sensors monitored equipment conditions in real-time, analyzing data for signs of wear or impending failures. Predictive maintenance alerts were generated to schedule maintenance proactively, reducing downtime and maintenance costs.

A clay product manufacturing facility in the USA used IoT sensors to monitor energy consumption across various production processes. The data collected was analyzed to identify areas where energy efficiency improvements could be made, ultimately reducing operational costs and environmental impact.

A refractory manufacturer in Canada implemented IoT sensors to continuously monitor emissions and air quality within their facility. The data collected was reported to regulatory authorities in real-time to ensure compliance with environmental regulations.

A Canadian ceramic tile manufacturer employed IoT sensors on production lines to monitor variables such as temperature and humidity during the firing process. This data helped maintain consistent product quality and ensured that products met industry standards.

A clay product manufacturer in Mexico integrated IoT-enabled tracking devices into pallets of finished goods. These devices provided real-time location data during transportation to distribution centers, improving supply chain visibility and helping optimize logistics routes.

A refractory manufacturing plant in Mexico used IoT wearable devices for workers. These devices monitored environmental conditions and worker health, sending alerts in cases of extreme conditions or accidents, thus enhancing safety on the shop floor.

A European refractory manufacturer implemented IoT sensors and RFID tags on raw materials. This allowed them to track the source and quality of materials throughout the production process, ensuring that only approved materials were used and enhancing product traceability.

A European clay product manufacturer used IoT sensors to monitor variables like temperature, pressure, and humidity in real-time during the production process. The data collected was used to optimize manufacturing processes, reduce waste, and improve product consistency.

Case Studies of Drone Applications

Below are some drone application cases in clay product and refractory manufacturing industry.

A refractory manufacturing plant in the USA used drones equipped with high-resolution cameras to conduct regular aerial inspections of their facility. This allowed them to identify structural issues, leaks, and potential hazards in hard-to-reach areas, ensuring timely maintenance and compliance with safety regulations.

A brick manufacturing company in the USA employed drones for aerial surveys of their outdoor stockpiles of clay and finished products. The drone’s data, combined with photogrammetry software, allowed for accurate volume calculations of raw materials and inventory, optimizing supply chain management.

A refractory manufacturer in Canada utilized drones to monitor emissions and environmental conditions around their facility. Drones equipped with environmental sensors collected data on air quality and pollutant levels, aiding in regulatory compliance and demonstrating a commitment to environmental responsibility.

Canadian ceramic tile manufacturers have used drones to inspect the condition of kilns, conveyor systems, and other high structures within their manufacturing plants. This aerial inspection helps identify maintenance needs, ensuring the safe and efficient operation of equipment.

A clay product manufacturing facility in Mexico implemented drones for safety surveillance. Drones equipped with cameras and thermal imaging sensors were used to monitor large areas and identify potential safety hazards, ensuring a safe working environment for employees.

Mexican refractory manufacturers employed drones with high-resolution cameras to capture aerial images of their production processes. This allowed for the visual inspection of product quality and consistency, enabling real-time adjustments when necessary.

A refractory manufacturer in Europe used drones to inspect the internal conditions of kilns and furnaces. Equipped with heat-resistant cameras and sensors, the drones provided visual data on refractory linings and structural integrity, helping extend equipment lifespan.

European clay product manufacturers employed drones to monitor the stockpiles of raw materials, ensuring accurate inventory tracking. Drones provided aerial imagery and volume measurements, aiding in demand forecasting and supply chain optimization.

GAO RFID Systems & Hardware for Clay Product and Refractory Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the air transportation industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including air transportation industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including air transportation industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including air transportation industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including air transportation industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including air transportation industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in air transportation industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

Air Traffic Control (ATC) Systems, Airport Security Screening Equipment, Baggage Handling Systems, Aircraft De-icing Equipment, Aircraft Ground Power Units (GPUs), Aircraft Tugs and Towbars, Passenger Boarding Bridges (Jetways), Runway Snow Removal Equipment, Aircraft Maintenance Tooling and Equipment, Flight Simulators, Avionics Test Equipment, Aircraft Fueling and Refueling Equipment, In-Flight Entertainment Systems, Aircraft Lavatory Servicing Carts, Aircraft Cabin Emergency Evacuation Slides, Ground Control Stations for Drones, Aircraft Rescue and Firefighting (ARFF) Vehicles, Airport Snow Blowers, Weather Radar Systems.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for air transportation industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customer’s premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in clay product and refractory manufacturing industry we have worked with to serve our joint customers:

- Accenture

- Deloitte

- Capgemini

- Cognizant

- IBM Global Business Services

- PwC (PricewaterhouseCoopers)

- Wipro

- HCL Technologies

- Tata Consultancy Services (TCS)

- Infosys

- CGI Group

- TELUS International

- Sierra Systems (a NTT Data Company)

- KPMG Canada

- Accenture Canada

- Deloitte Canada

- Capgemini Canada

- Cognizant Canada

- Fujitsu Canada

- PwC Canada

- Softtek

- Neoris

- Tata Consultancy Services (TCS Mexico)

- Accenture Mexico

- Deloitte Mexico

- Capgemini Mexico

- Cognizant Mexico

- KIO Networks

- Wizeline

- Indra Mexico

- Atos

- Cognizant Europe

- DXC Technology

- HCL Technologies Europe

- IBM Global Business Services (Europe)

- Tata Consultancy Services (TCS Europe)

GAO Has Served Clay Product and Refractory Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in clay product and refractory manufacturing industry to achieve success in such as Sustainability, Digital Transformation, Circular Economy, Advanced Materials, Energy Efficiency, Safety Culture, Customization, Regulatory Compliance, Lean Manufacturing, IoT (Internet of Things), Industry 4.0, Smart Manufacturing, Digital Twin, Predictive Maintenance, Blockchain, Green Manufacturing, Energy Management, Additive Manufacturing (3D Printing), Resilience, Ceramic Matrix Composites, Supply Chain Visibility, Quality Assurance, Refactory Anchors, Alumina-Zirconia-Silica (AZS), High Alumina Refractories, Rheology, Sintering, Slip Casting, Kiln Automation.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in clay product and refractory manufacturing industry, including many in its various divisions such as:

- Brick and Structural Clay Product Manufacturing: This division includes the production of various types of bricks, clay tiles, and other structural clay products used in construction and masonry applications.

- Ceramic Tile and Sanitary Ware Manufacturing: This segment focuses on the production of ceramic tiles for flooring and wall coverings, as well as sanitary ware products like toilets and sinks.

- Refractory Manufacturing: Refractories are specialized materials designed to withstand high temperatures and harsh conditions. This division involves the manufacturing of refractory bricks, monolithic refractories, and other products used in industries such as steel, cement, and petrochemicals.

- Clay Building Material and Refractory Manufacturing: This broader division encompasses the production of a wide range of clay-based products, including bricks, tiles, refractories, and other construction materials.

- Art and Ceramic Product Manufacturing: Some manufacturers in this industry focus on creating artistic and decorative clay and ceramic products, such as pottery, sculptures, and decorative tiles.

- Advanced Ceramic Manufacturing: This segment deals with the production of advanced ceramics used in specialized applications like electronics, aerospace, and medical devices. These ceramics often have unique properties such as high heat resistance or electrical conductivity.

- Clay and Ceramic Mining: This division involves the extraction of clay and ceramic raw materials from mines and quarries, which are then used in the manufacturing of clay products and refractories.

- Research and Development: Many companies in this industry have dedicated R&D divisions focused on developing new materials, improving production processes, and exploring innovative applications for clay and ceramic products.

GAO’s technologies enable its customers in clay product and refractory manufacturing industry to effectively track their workforces such as Plant Manager, Production Supervisor, Quality Control Inspector, Kiln Operator, Machine Operator, Maintenance Technician, Process Engineer, Materials Handler, Clay Mixer, Glaze Technician, Refractory Technician, Bricklayer, Ceramic Engineer, R&D Scientist, Safety Coordinator, Environmental Compliance Specialist, Logistics Coordinator, Sales Representative, Warehouse Manager, Electrical Technician, Mechanical Engineer, CNC Machinist, Laboratory Technician, Packaging Operator, Customer Service Representative, Purchasing Manager, Human Resources Manager, IT Support Specialist, Shipping and Receiving Clerk, Marketing Coordinator and effectively track operational assets such as Extruders, Pug Mills, Kilns, Drying Chambers, Mold Making Equipment, Pottery Wheels, Clay Cutting Machines, Glazing Machines, Brick Molding Machines, Refractory Presses, Refractory Mixers, Refractory Vibrating Screens, Clay Extrusion Dies, Clay Sieving Equipment, Refractory Brick Cutting Tools, Refractory Casting Machines, Pottery Kiln Furniture, Clay Blungers, Clay Grinding Mills, Palletizers, Dust Collectors, Material Handling Conveyors, Ceramic Printing Equipment, Ceramic Decal Machines, Refractory Forming Dies, Pottery Clay Extruders, Refractory Fiber Manufacturing Equipment.

Here are some of the leading companies in clay product and refractory manufacturing industry GAO has served:

- HarbisonWalker International

- Morgan Advanced Materials

- Resco Products

- Riverside Refractories

- Empire Refractory Sales

- Universal Refractories

- Allied Mineral Products Canada

- MinMet Refractories

- Intin Refractories

- Thermoclad Company

- Unifrax Canada

- Thermal Ceramics Canada

- The Kiln Room

- Intertechne Refractarios

- MTC Matercon

- VEL Refractarios

- Foseco de Mexico

- Ladrillos Refractarios y Aislantes

- RHI Magnesita

- Vesuvius

- Saint-Gobain SEFPRO

- Calderys (France)

- KROSAKI HARIMA

- RATH Group

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com