Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Component Manufacturing industry

GAO’s Assists Clients with Standards, Mandates & Regulations of Component Manufacturing industry

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Component Manufacturing industry

Overview

The Component Manufacturing industry is a vital sector within manufacturing that specializes in crafting individual parts, components, or sub-assemblies essential for a wide array of products and systems. These components vary from straightforward, standardized elements like screws and connectors to highly intricate and specialized pieces such as microprocessors, intricate gears, or aerospace-grade components. One hallmark of this industry is an unwavering commitment to precision and quality control, recognizing that even the tiniest imperfections in components can result in safety hazards or product failures. To achieve these high standards, manufacturers often employ cutting-edge machining and fabrication techniques. Component manufacturers are frequently integrated into the supply chains of larger product manufacturers, functioning as tiered suppliers, and providing their components to original equipment manufacturers (OEMs) or other manufacturers further up the production chain. Some component manufacturers specialize in crafting bespoke or tailored parts, while others concentrate on producing standardized components for versatile applications. This sector is marked by its embrace of advanced technologies, including computer-aided design (CAD), computer-aided manufacturing (CAM), automation, and robotics, which enhance efficiency, precision, and productivity. With a global presence, component manufacturers operate on a worldwide scale, serving diverse industries with distinct needs. Due to the critical nature of many components, adherence to stringent quality and safety standards and regulations is imperative, particularly in sectors such as healthcare, aerospace, and automotive.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in Component Manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as

CNC Machines, Injection Molding Machines, Presses, Lathes, Milling Machines, Grinding Machines, Welding Machines, Die-Casting Machines, 3D Printers, Heat Treatment Furnaces, Surface Treatment Equipment, Quality Control Equipment, Material Handling Equipment, Tooling and Fixtures, Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) Software, Dust and Fume Extraction Systems, Safety Equipment, Material Handling and Storage Systems, Cooling and Lubrication Systems, Electrical and Electronics Testing Equipment.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra-high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in Aftermarket Manufacturing and Services. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Component Manufacturing industry

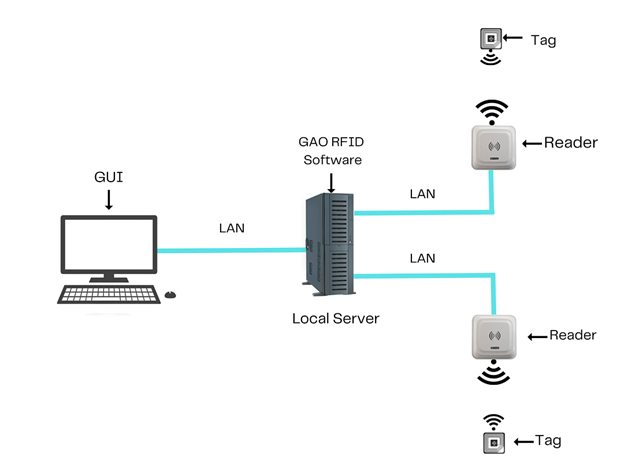

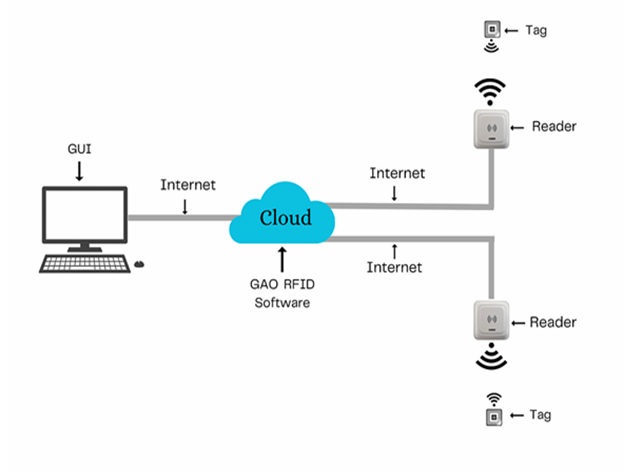

To satisfy its customers, GAO’s RFID or RFID Systems for Component Manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for Component Manufacturing industry running on a local server.

The above illustrates GAO system for Component Manufacturing industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Component Manufacturing industry:

- Inventory Management: In the Component Manufacturing industry, GAO RFID systems can be used to track and manage raw materials, work-in-progress components, and finished products. This helps optimize stock levels, reduce overstocking or stockouts, and streamline the production process.

- Tool Tracking: GAO RFID solutions can be employed to monitor and locate specialized equipment and tools used by machinists, technicians, and engineers. This ensures that the right tools are available when needed, minimizing downtime and enhancing worker efficiency.

- Work-in-Progress (WIP) Tracking: By attaching RFID tags to components at various stages of production, we can monitor the progress of each component as it moves through different manufacturing processes and workstations. This enables real-time visibility into production status and helps identify bottlenecks or quality issues.

- Quality Control: GAO RFID technology can assist in quality control processes by tracking components’ manufacturing history and specifications. It ensures that each component meets the required standards and helps trace any defects back to their source.

- Asset Management: The Component Manufacturing industry relies on a range of specialized equipment, including CNC machines, presses, and injection molding machines. RFID tags can be affixed to these assets, enabling efficient maintenance scheduling, preventing equipment loss, and optimizing resource allocation.

- Worker Safety: GAO RFID systems can be integrated with worker safety equipment, such as RFID-enabled safety vests or helmets. This allows for real-time tracking of workers’ locations within the manufacturing facility, enhancing safety and emergency response.

- Supplier and Vendor Management: RFID tags can be used to track incoming shipments of raw materials and components from suppliers. This ensures that the right materials are received on time and helps manage supplier relationships effectively.

- Process Automation: In Component Manufacturing, GAO RFID technology can be integrated with automated manufacturing systems, enabling seamless coordination between machines and workers. This enhances production efficiency and reduces manual intervention.

- Traceability and Compliance: The Component Manufacturing industry often requires strict traceability and compliance with regulations. GAO’s RFID solutions provide detailed tracking records for components, making it easier to demonstrate compliance with industry standards and regulations.

- Maintenance and Repairs: RFID tags on components can store maintenance and repair history, making it easier to schedule preventive maintenance and address equipment breakdowns promptly. This minimizes production downtime and extends the lifespan of equipment.

GAO’s drone technologies find the following applications in the Component Manufacturing industry.

- Inventory Management: In the Component Manufacturing industry, GAO’s drones can be employed to conduct aerial surveys of raw material storage areas, warehouses, and production facilities. This allows us to monitor inventory levels, track the movement of components, and ensure that adequate stock is available for production.

- Facility Inspections: GAO’s drones can perform routine inspections of manufacturing facilities, including the inspection of roofs, structures, and equipment. This helps identify maintenance needs, potential safety hazards, and ensures the optimal functioning of specialized equipment like CNC machines.

- Security Surveillance: Our drones equipped with advanced cameras and sensors can enhance security surveillance in Component Manufacturing facilities. They can monitor access points, perimeters, and critical equipment, providing real-time alerts to security personnel or specialized workers.

- Environmental Monitoring: Drones can be used for environmental monitoring, such as tracking emissions, air quality, and waste disposal practices. This is particularly important in Component Manufacturing, where compliance with environmental regulations is crucial.

- Supply Chain Optimization: GAO’s drones can be integrated into the supply chain by monitoring the transportation of components from suppliers to manufacturing plants. This ensures that deliveries are on schedule and helps in route optimization.

- Emergency Response: In the event of emergencies or accidents in Component Manufacturing facilities, our drones can quickly assess the situation and relay critical information to emergency response teams. This aids in timely and efficient responses to incidents.

- Quality Control: Drones equipped with cameras and sensors can be used to inspect components during the manufacturing process. This provides a bird’s-eye view of production lines, enabling real-time quality control checks and ensuring components meet specifications.

- Worker Safety: GAO’s drones can assist in enhancing worker safety by monitoring the workplace for potential hazards, such as spills or equipment malfunctions. They can also be used to locate and assist workers in distress, such as those working on elevated platforms or in confined spaces.

- Infrastructure Planning: When expanding or upgrading manufacturing facilities, drones can help with site surveys, assessing the suitability of new locations, and planning for the installation of specialized equipment like injection molding machines.

- Training and Education: Drones can be used for training workers in Component Manufacturing by simulating real-world scenarios, such as equipment operation and safety protocols. This aids in the development of skilled workers, including CNC machine operators and quality control technicians.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the Component Manufacturing industry

- Machine Monitoring and Maintenance: In the Component Manufacturing industry, GAO’s IoT devices can be integrated with specialized equipment such as CNC machines and presses. These devices collect real-time data on machine performance, including temperature, vibration, and energy consumption. This data helps us predict maintenance needs, reducing downtime and optimizing machine lifespan.

- Quality Control and Assurance: IoT sensors can be installed on production lines to monitor the dimensions, tolerances, and other critical parameters of components as they are being manufactured. This ensures that components meet the required specifications and standards, enhancing product quality.

- Inventory and Material Tracking: GAO’s IoT technology can be used to track the movement of raw materials, work-in-progress components, and finished products within the Component Manufacturing facility. This ensures accurate inventory management, minimizes material waste, and streamlines production processes.

- Energy Efficiency: IoT sensors can monitor energy usage in the manufacturing facility, including lighting, HVAC systems, and machinery. By analyzing this data, we can identify opportunities to reduce energy consumption, lower operating costs, and improve sustainability.

- Worker Safety: IoT devices, such as wearable sensors and smart helmets, can be used to enhance worker safety in Component Manufacturing. These devices can monitor vital signs, detect hazardous conditions, and provide real-time alerts to workers and supervisors.

- Supply Chain Optimization: IoT-enabled tracking devices can be attached to shipments of components from suppliers. This provides real-time visibility into the supply chain, allowing us to track the location and condition of components during transit and ensuring on-time deliveries.

- Predictive Analytics: By collecting and analyzing data from various IoT sensors and devices, we can use predictive analytics to forecast demand, optimize production schedules, and improve resource allocation in Component Manufacturing.

- Environmental Monitoring: IoT sensors can monitor environmental conditions within the manufacturing facility, including air quality, temperature, and humidity. This data helps ensure compliance with environmental regulations and provides a safe and comfortable working environment for employees.

- Remote Monitoring and Control: GAO’s IoT solutions allow us to remotely monitor and control equipment and processes. This is especially valuable for Component Manufacturing facilities with multiple locations or when specialized workers, such as CNC machine operators, need to adjust settings remotely.

- Product Lifecycle Management: IoT data can be used to track the entire lifecycle of components, from production to end-of-life disposal. This helps with warranty tracking, recalls, and sustainability initiatives.

GAO’s Assists Clients with Standards, Mandates & Regulations of Component Manufacturing industry

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in Component Manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- EPC Gen2 (Electronic Product Code Generation 2)

- ISO 18000

- ISO 15693

- ISO 14443

- ISO 21481

- ISO 29143

- AIT (Automatic Identification Technology) Standard

- AIM (Association for Automatic Identification and Mobility) Standards

- Bluetooth 4.0 and later versions (BLE)

- Bluetooth SIG (Special Interest Group)

- GATT (Generic Attribute Profile)

- GAP (Generic Access Profile)

- Bluetooth Mesh

- iBeacon and Eddystone

- ISO/IEC 20907 (Bluetooth Low Energy)

- IEEE 802.15.1 (Bluetooth) and IEEE 802.15.4 (related standard)

- BLE 5.0 and subsequent versions

- Bluetooth Certification Programs

- Here are the headings for a list of IoT (Internet of Things) standards related to the Component Manufacturing industry:

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- OPC UA (Open Platform Communications Unified Architecture)

- Thread

- Zigbee

- LoRaWAN (Long Range Wide Area Network)

- DDS (Data Distribution Service)

- AllJoyn

- BACnet (Building Automation and Control Networks)

- Modbus

- IEEE 802.15.4

- OCF (Open Connectivity Foundation)

- OneM2M

- AMQP (Advanced Message Queuing Protocol)

- Lightweight M2M (LwM2M)

- OPC Foundation Standards

- ISO/IEC JTC 1/SC 41 IoT Standards

- Industrial Internet Consortium (IIC) Frameworks

- IEC 62443 (Industrial Network and System Security)

- ISA-95 (Enterprise-Control System Integration)

- ASTM F2910 – Standard Specification for Unmanned Aircraft System (UAS) Parachutes

- ASTM F3322 – Standard Specification for Drive Train Fatigue Testing for Small Unmanned Aircraft Systems (sUAS)

- ASTM F3322 – Standard Specification for Drive Train Fatigue Testing for Small Unmanned Aircraft Systems (sUAS)

- ISO 21384 – Unmanned Aircraft Systems (UAS) – Vocabulary

- ISO 21385 – Unmanned Aircraft Systems (UAS) – Flight Termination Systems

- ISO 21384 – Unmanned Aircraft Systems (UAS) – General Specification for Batteries

- ANSI/UL 3030 – Standard for Safety for Unmanned Aircraft Systems

- ANSI/UL 8400 – Standard for Safety for Unmanned Aircraft Systems (UAS)

- ASTM F3322 – Standard Specification for Drive Train Fatigue Testing for Small Unmanned Aircraft Systems (sUAS)

- ASTM F3332 – Standard Specification for Unmanned Aircraft Systems (UAS) to Predict Flight Time

- General RFID Mandates for Manufacturing

- Supply Chain and Inventory Management Mandates

- Food Safety and Traceability Regulations

- Pharmaceutical and Healthcare Compliance Requirements

- Aerospace and Defense RFID Regulations

- Automotive and Component Traceability Standards

- RFID Regulations for Electronics Manufacturing

- Government and Defense RFID Mandates

- Environmental and Sustainability Reporting

- Regional and National RFID Initiatives

- General BLE Mandates and Regulations

- Wireless Communication Standards

- IoT Connectivity and Interoperability Mandates

- Indoor Navigation and Location-Based Services

- Asset Tracking and Inventory Management Requirements

- Energy Efficiency and Sustainability Standards

- Data Privacy and Security Regulations

- Healthcare and Medical Device Compliance (if applicable)

- Smart Building and Facility Management Mandates

- Environmental and Emission Reporting (if applicable)

- General IoT Mandates and Regulations

- Data Privacy and Security Requirements

- Wireless Communication Standards

- Industrial IoT (IIoT) and Manufacturing Compliance

- Environmental and Sustainability Reporting

- IoT Device Certification and Testing

- Industry 4.0 and Smart Manufacturing Initiatives

- Supply Chain and Inventory Management Mandates

- Energy Efficiency and Sustainability Standards

- IoT Connectivity and Interoperability Mandates

- General Drone Regulations

- Aviation Authority Requirements

- Drone Registration and Licensing

- Operational Safety Guidelines

- Airspace Access and Permissions

- Privacy and Data Security Regulations

- Environmental Impact and Sustainability Reporting

- Use of Drones in Industrial Facilities

- Safety Training and Certification for Drone Operators

- Remote Pilot Licensing (if applicable)

- Compliance with National and International Aviation Standards

US. Government Regulations

- OSHA Regulations

- EPA Regulations

- FDA Regulations

- S. Department of Commerce Export Controls

- NIOSH Guidelines

- FCC Regulations

- CPSC Regulations

- FTC Regulations

- S. Customs and Border Protection Regulations

- Intellectual Property Regulations

- NLRB Regulations

- Taxation and Financial Regulations

Canadian Government Regulations

- Canadian Environmental Protection Act, 1999

- Canadian Occupational Health and Safety Regulations

- Canadian Environmental Assessment Act, 2012

- Hazardous Products Regulations

- Controlled Products Regulations

- Export and Import of Hazardous Waste and Hazardous Recyclable Material Regulations

- Food and Drugs Act

- Canadian Standards Association (CSA) Standards

- Competition Act

- Canadian Intellectual Property Office (CIPO) Regulations

- Transportation of Dangerous Goods Regulations

- Canadian Customs Regulations

- Investment Canada Act

- Income Tax Act

- Canada Business Corporations Act (CBCA)

- Consumer Packaging and Labelling Regulations

- Pest Control Products Act

- Canadian Transportation Agency (CTA) Regulations

- Excise Tax Act

- Import Control List (ICL) Regulations

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Component Manufacturing industry as:

Personnel Management:

- Workforce Scheduling and Shift Planning

- Employee Training and Certification Tracking

- Labor and Productivity Monitoring

- Safety Training and Compliance

- Health and Safety Incident Reporting

- Employee Records Management

Equipment Management:

- Preventive Maintenance Scheduling

- Asset Tracking and Utilization

- Equipment Health Monitoring

- Equipment Calibration and Testing

- Energy Management and Efficiency

- Predictive Maintenance

Access Control:

- Facility Access Control

- Restricted Area Monitoring

- Visitor Management

- Identity Verification

- Compliance with Security Regulations

- Audit Trails and Access Logs

Warehouse Management:

- Inventory Tracking and Control

- Goods Receipt and Putaway

- Order Picking and Packing

- Shipping and Dispatch Management

- Space Optimization

- Stock Rotation and FIFO/LIFO Control

Supply Chain Management:

- Supplier Relationship Management (SRM)

- Demand Forecasting and Planning

- Procurement and Purchase Order Management

- Supplier Performance Monitoring

- Transportation and Logistics Management

- Vendor Managed Inventory (VMI)

Other Applications:

- Inspection and Testing

- Non-Conformance Reporting

- Statistical Process Control (SPC)

- Corrective and Preventive Actions (CAPA)

- Quality Audits and Compliance

- Product Traceability

- Data-driven Decision Making

- Key Performance Indicator (KPI) Tracking

- Real-time Dashboards and Reporting

- Root Cause Analysis

- Performance Benchmarking

- Regulatory Compliance Reporting

- Production Order Management

- Capacity Planning

- Job Scheduling

- Work-in-Progress Tracking

- Lean Manufacturing Practices

- Batch Management

- Waste Management and Recycling

- Energy Consumption Monitoring

- Carbon Footprint Reduction

- Sustainability Reporting

- Compliance with Environmental Regulations

- Green Manufacturing Initiatives

- Occupational Health and Safety (OHS) Compliance

- Product Safety and Compliance

- Regulatory Reporting

- Documentation and Record Keeping

- Safety Training and Certification

- Hazardous Materials Handling

GAO has enabled its customers to make use of some of the leading software and cloud services in Component Manufacturing industry. Below are some of popular software and cloud services in Component Manufacturing industry as:

SAP SuccessFactors, Workday HCM, Oracle Human Capital Management Cloud, ADP Workforce Now, BambooHR, eMaint CMMS, Fiix, Maintenance Connection, Infor EAM, UpKeep, LenelS2 OnGuard, Honeywell Access Control, Avigilon Access Control Manager, Genetec Security Center, Open Options DNA Fusion, Manhattan Associates WMS, HighJump Warehouse Advantage, Infor Warehouse Management, Blue Yonder WMS (formerly JDA WMS), Oracle Warehouse Management Cloud, SAP Integrated Business Planning, Oracle SCM Cloud, Kinaxis RapidResponse, Blue Yonder Luminate Control Tower, GEP SMART, Epicor ERP, Infor CloudSuite Industrial (SyteLine), Microsoft Dynamics 365 for Finance and Operations, Plex Manufacturing Cloud, IQMS EnterpriseIQ (now part of Dassault Systèmes), Amazon Web Services (AWS), Microsoft Azure, Google Cloud Platform (GCP), IBM Cloud, Oracle Cloud.

GAO has worked with some of the leading technology companies in Component Manufacturing industry in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in Component Manufacturing industry

IBM, Cisco Systems, Siemens, Schneider Electric, HP Inc. (Hewlett-Packard), Dell Technologies, Panasonic Corporation, Emerson Electric Co., Rockwell Automation, ABB Group, Siemens, General Electric (GE), Honeywell International Inc., Mitsubishi Electric Corporation, Advantech Co., Ltd., Texas Instruments, STMicroelectronics, TE Connectivity, Keysight Technologies, National Instruments, Omron Corporation, Yokogawa Electric Corporation, Bosch Rexroth, Fanuc Corporation, Cognex Corporation.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in Component Manufacturing industry.

RFID Implementation for Inventory Management in Component Manufacturing, RFID-Enabled Quality Control and Traceability in Component Manufacturing, RFID for Process Optimization in Component Manufacturing, RFID-Driven Lean Manufacturing in the Component Industry, Improving Supply Chain Visibility with RFID in Component Manufacturing, RFID Applications for Asset Tracking and Management in Component Manufacturing, Enhancing Production Efficiency with RFID in the Component Manufacturing Sector, RFID Use Cases for Work-in-Progress Tracking in Component Manufacturing, RFID-Enhanced Safety and Compliance Measures in Component Manufacturing, RFID Applications for Product Authentication and Anti-counterfeiting in the Component Industry.

Many applications of RFID by GAO can be found here

Case Studies of IoT Applications

Below are some IoT application cases in Component Manufacturing industry

Search Online Databases, Industry Associations Solution Providers, Business News and Magazines, Contact Manufacturers

Case Studies of Drone Applications

Below are some drone application cases in Component Manufacturing industry

Online Research, Industry Associations, Drone Service Providers, Government Agencies, Business News and Magazines, Contact Manufacturers

GAO RFID Systems & Hardware for Component Manufacturing industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Component Manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including Component Manufacturing industry

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Component Manufacturing industry

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Component Manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Component Manufacturing industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Component Manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones are offered:

The RFID systems by GAO are highly popular for clients in Component Manufacturing industry :

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

CNC Machines, Injection Molding Machines, Metal Stamping Presses, Die-Casting Machines, Extrusion Machines, 3D Printers, Heat Treatment Furnaces, Welding Equipment, Assembly Machines, Material Handling Equipment, Quality Control and Inspection Equipment, Laser Cutting and Marking Machines, Plasma Cutting Machines, Waterjet Cutting Machines, Abrasive Blasting Machines, Painting and Coating Equipment, Ultrasonic Cleaning Machines, Press Brakes, Grinding and Polishing Machines, Milling Machines.

People or workers tracking system:

- PERSONNEL TRACKING SOFTWARE

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Aftermarket Manufacturing and Services and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Component Manufacturing industry we have worked with to serve our joint customers:

- Accenture

- Deloitte

- IBM Global Business Services

- PwC (PricewaterhouseCoopers)

- KPMG

- Capgemini

- Cognizant

- EY (Ernst & Young)

- Wipro

- Tata Consultancy Services (TCS)

GAO Has Served Component Manufacturing industry

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in Component Manufacturing industry to achieve success in Digital Transformation, Industry 4.0, Additive Manufacturing, Supply Chain Optimization, Sustainability, Lean Manufacturing, Robotics and Automation, Advanced Materials, Smart Sensors, Predictive Maintenance, Digital Twin, Blockchain, Augmented Reality (AR), Machine Learning, Big Data Analytics, IoT (Internet of Things), Cybersecurity, Just-in-Time (JIT), Quality Assurance, Reshoring.

GAO RFID Inc. has served many customers in Component Manufacturing industry, including its various divisions such as

- Metal Component Manufacturing: Production of metal-based components, including machining, stamping, and die-casting.

- Plastic Component Manufacturing: Manufacturing of plastic components through processes like injection molding and extrusion.

- Electronic Component Manufacturing: Production of electronic components, such as microchips, printed circuit boards (PCBs), and sensors.

- Precision Component Manufacturing: Specialization in the fabrication of high-precision components used in various industries, including aerospace and medical devices.

- Automotive Component Manufacturing: Manufacturing of components used in the automotive industry, including engine parts, transmissions, and suspension components.

- Aerospace Component Manufacturing: Production of components and parts used in aircraft and aerospace applications, including airframes and engine components.

- Medical Component Manufacturing: Manufacturing of components used in medical devices and equipment, including surgical instruments and implants.

- Consumer Electronics Component Manufacturing: Production of components used in consumer electronics products, such as smartphones, tablets, and laptops.

- Energy Component Manufacturing: Manufacturing components used in the energy sector, including wind turbines, solar panels, and oil and gas equipment.

- Tool and Die Manufacturing: Fabrication of specialized tools, dies, and molds used in manufacturing processes across various industries.

- Composite Component Manufacturing: Production of components made from composite materials, which offer high strength and lightweight properties.

- Custom Component Manufacturing: Specialized in producing custom-designed components based on customer specifications.

GAO’s technologies enable its customers in “Component Manufacturing industry” to effectively track their workforces such as Machinist, Tool and Die Maker, Assembler, Welder, CNC Operator, Quality Inspector, Production Supervisor, Materials Handler, Maintenance Technician, Process Engineer, Materials Planner, Production Scheduler, Safety Coordinator, Quality Control Technician, Lean Manufacturing Specialist, Logistics Coordinator, Engineering Technician, Inventory Clerk, Machine Operator, Maintenance Manager. track operational assets such as Lathe, Milling Machine, Injection Molding Machine, Press Brake, Die-Casting Machine, CNC Router, Extrusion Machine, 3D Printer, Welding Machine, CNC Lathe, Stamping Press, Heat Treatment Furnace, Assembly Line, Conveyor System, Robotic Arm, Laser Cutter, Plasma Cutter, Waterjet Cutter, Inspection CMM, Ultrasonic Cleaner, Industrial Oven, Grinding Machine, Hydraulic Press, Material Handling Crane, Industrial Washer, Automated Guided Vehicle (AGV), Paint Booth, Compressor, Industrial Saw, Sandblasting Cabinet, Coordinate Measuring Machine (CMM), Surface Grinder.

Here are some of the leading companies in Component Manufacturing industry GAO has served:

I apologize, but I don’t have access to logos or the ability to display images. Additionally, providing logos requires visual content, which I cannot generate or display. However, I can provide you with the names of some leading Component Manufacturing companies in the U.S. and Canada, and you can search for their logos separately:

- General Electric

- Boeing

- Honeywell

- Caterpillar

- 3M

- Emerson Electric

- Parker-Hannifin

- Raytheon Technologies

- Cummins Inc.

- Rockwell Automation

- Johnson Controls

- Lockheed Martin

- Illinois Tool Works

- Northrop Grumman

- Deere & Company

- Eaton Corporation

- Textron Inc.

- General Dynamics

- Corning Inc.

- Ball Corporation

- Ametek Inc.

- Kennametal Inc.

- Flowserve Corporation

- Alcoa Corporation

- Magna International

- Linamar Corporation

- Martinrea International

- Celestica Inc.

- Methode Electronics

- ATS Automation Tooling Systems