Index

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Computer and Electronic Product Manufacturing industry

GAO Makes Efforts to Satisfy Customers

Gao has served computer and electronic product manufacturing industry extensively

Overview

Computer and Electronic Product Manufacturing is a dynamic sub-industry within the manufacturing sector that specializes in producing a diverse range of electronic devices and computer-related hardware. These products encompass everything from personal computers, laptops, and smartphones to semiconductors, electronic components, and communication equipment. This sector is at the heart of the technology-driven economy, serving as the foundation for various industries and consumer applications. It is characterized by rapid innovation, continuous technological advancement, and extensive global supply chain networks. Due to its competitive nature and responsiveness to market trends and consumer preferences, Computer and Electronic Product Manufacturing remains a pivotal and evolving component of the manufacturing landscape.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the Computer and Electronic Product Manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as PCB etching machines, PCB drilling machines, PCB plating and coating machines, PCB solder mask and legend printing equipment, SMT placement machines, Reflow soldering ovens, SMT solder paste printers, SMT inspection machines, Automated assembly machines, Functional and in-circuit testing equipment, Environmental testing chambers, X-ray inspection equipment, Lithography machines, Ion implantation machines, Etching and deposition equipment, Chemical mechanical planarization machines, Wire bonding machines, Die attach equipment, Encapsulation and molding machines, Optical inspection systems, Coordinate measuring machines, Automated optical inspection machines, Conveyors and material transport systems, Automated guided vehicles, Robotic arms for material handling, Labeling and barcoding machines, Oscilloscopes, Multimeters, Spectrum analyzers, Signal generators, Robotics and Automation Systems, Environmental Control Equipment, Electrostatic Discharge Control Equipment, Power and Energy Management Equipment, Safety Equipment, Material Processing Equipment, Inventory Management Systems.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for computer and electronic product manufacturing. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Computer and Electronic Product Manufacturing

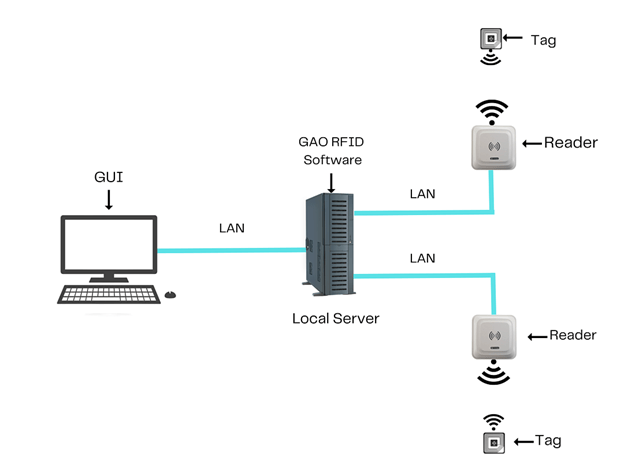

To satisfy its customers, GAO’s RFID or RFID Systems for Computer and Electronic Product Manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for computer and electronic product manufacturing industry software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for Computer and Electronic Product Manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for computer and electronic product manufacturing industry software running on a local server.

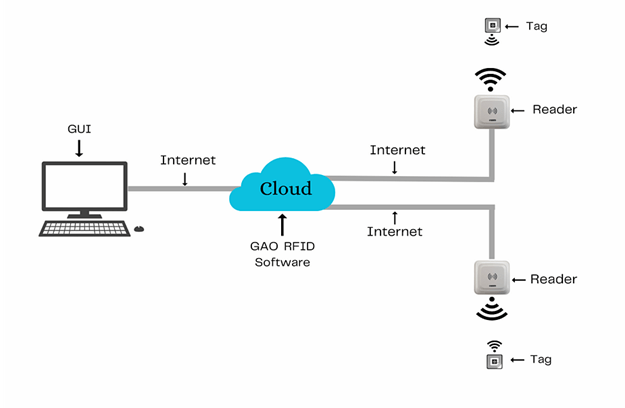

The above illustrates GAO system for computer and electronic product manufacturing with its software running in cloud.

The above illustrates GAO system for computer and electronic product manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in computer and electronic product manufacturing industry:

- Inventory Management: GAO RFID tags are used to track the movement and status of electronic components and products throughout the manufacturing process. This ensures accurate inventory control and reduces the risk of shortages or overstock.

- Work-in-Progress Tracking: GAO’s RFID is employed to monitor the progress of electronic products as they move through various stages of assembly and testing. This helps streamline production workflows and identify bottlenecks.

- Quality Control: GAO RFID tags can be attached to individual components or subassemblies to track their quality and performance data. This information can be used to identify and address any issues in real-time.

- Asset Tracking: GAO’s RFID tags are used to track and manage valuable assets, such as testing equipment, tools, and machinery, ensuring their availability when needed.

- Supply Chain Management: GAO RFID technology is used to track electronic components and products as they move through the supply chain, from suppliers to manufacturers and distributors. This improves visibility and enhances the efficiency of the supply chain.

- Anti-Counterfeiting: GAO’s RFID tags can be embedded in products or packaging to verify their authenticity. This helps combat counterfeit electronics and ensures the integrity of the supply chain.

- Maintenance and Repairs: GAO RFID is used to track maintenance schedules and history for machinery and equipment in electronic manufacturing facilities. It helps in scheduling timely maintenance and repairs to minimize downtime.

- Shipping and Receiving: GAO’s RFID tags on products and packaging facilitate automated and accurate tracking of shipments, reducing errors and expediting the receiving process.

- Security and Access Control: GAO RFID access cards or badges are used to control access to sensitive areas within electronic manufacturing facilities, enhancing security.

- Traceability and Recall Management: GAO’s RFID tags enable rapid identification and recall of specific batches or lots of electronic products in case of defects or safety concerns.

- Production Line Efficiency: GAO RFID technology is used to monitor the efficiency of production lines, providing data on cycle times, downtime, and production rates, which can be used for process optimization.

- Employee Tracking: GAO’s RFID badges or tags can be used to track employee movements and attendance within manufacturing facilities, enhancing security and safety.

- Energy Management: GAO’s RFID can be used to monitor energy consumption in manufacturing facilities, helping to identify areas for energy efficiency improvements.

- Customization and Personalization: GAO RFID tags can store product-specific information, enabling customization and personalization of electronic products during the manufacturing process.

- Compliance and Reporting: GAO’s RFID technology assists in maintaining compliance with industry regulations and standards by providing accurate and real-time data for reporting purposes.

GAO’s drone technologies find the following applications in the computer and electronic product manufacturing industry:

- Inventory Management: GAO’s Drones equipped with cameras and RFID technology can be used to conduct aerial inventory counts in large warehouses, ensuring accurate stock levels of electronic components and products.

- Warehouse Monitoring: GAO Drones can provide real-time surveillance and monitoring of manufacturing and storage facilities, enhancing security and detecting any unauthorized access or potential threats.

- Logistics and Supply Chain Management: GAO’s Drones can assist in the efficient transportation of electronic components and products between manufacturing facilities, distribution centers, and suppliers, reducing delivery times and costs.

- Environmental Monitoring: GAO Drones equipped with sensors can monitor environmental conditions in manufacturing facilities, ensuring that temperature, humidity, and other factors remain within the specified ranges for electronic product assembly.

- Quality Control Inspections: GAO’s RFID Drones equipped with high-resolution cameras and imaging technology can perform aerial inspections of electronic components and products, identifying defects or inconsistencies in manufacturing processes.

- Site Surveys: GAO Drones can be used to conduct aerial surveys of manufacturing sites, helping in the planning and design of new production facilities or expansions.

- Asset Tracking: GAO’s RFID or GPS-enabled drones can track the location and movement of valuable assets, such as machinery and equipment, within manufacturing facilities.

- Maintenance Inspections: GAO’s Drones can access hard-to-reach areas of manufacturing equipment for routine inspections and maintenance checks, reducing downtime and improving equipment reliability.

- Security Patrols: GAO Drones equipped with thermal imaging and surveillance cameras can patrol manufacturing facilities to identify security breaches, unauthorized personnel, or safety hazards.

- Prototype Testing: GAO’s Drones can transport prototypes and new electronic products for field testing or customer demonstrations, saving time and resources.

- Emergency Response: GAO RFID Drones can provide a rapid aerial assessment of any emergencies or incidents within manufacturing facilities, helping first responders and emergency personnel.

- Environmental Compliance: GAO’s Drones can monitor emissions and environmental compliance in manufacturing processes to ensure adherence to environmental regulations.

- Data Collection: GAO’s RFID Drones can collect data on various aspects of manufacturing operations, helping in the analysis and optimization of processes.

- Transportation of Fragile Components: GAO Drones with specialized cargo compartments can transport fragile electronic components and products without subjecting them to the vibrations and shocks associated with traditional ground transportation.

- Prototype and Product Testing: GAO’s Drones can be used to carry electronic prototypes or products for field testing, demonstrating functionality or conducting test flights for drones themselves.

- Aerial Mapping: GAO Drones equipped with mapping technology can create accurate 3D maps of manufacturing facilities and their surroundings, aiding in planning and logistics.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the Computer and Electronic Product Manufacturing industry:

- Predictive Maintenance: GAO IoT sensors embedded in manufacturing equipment and machinery can monitor their performance in real-time, predicting maintenance needs and reducing unplanned downtime.

- Quality Control: GAO RFID IoT devices can monitor and record data during the manufacturing process, identifying defects or deviations from quality standards, leading to improved product quality.

- Inventory Management: GAO’s RFID IoT-enabled RFID tags and sensors can track the location and status of electronic components and products throughout the manufacturing process, optimizing inventory levels and reducing losses.

- Supply Chain Visibility: GAO’s RFID IoT sensors and GPS tracking can provide real-time visibility into the movement and location of electronic components and products along the supply chain, improving logistics and reducing delays.

- Energy Management: GAO RFID IoT systems can monitor energy consumption in manufacturing facilities, allowing for energy-efficient operations and cost savings.

- Process Optimization: GAO RFID IoT analytics can analyze data from various stages of production to identify bottlenecks, inefficiencies, and areas for process improvement.

- Remote Monitoring: GAO Manufacturers can remotely monitor and control equipment, production lines, and processes through IoT-enabled devices, reducing the need for on-site personnel.

- Equipment Health Monitoring: GAO’s IoT sensors can continuously monitor the health of manufacturing equipment, detecting early signs of wear and tear, and preventing costly breakdowns.

- Customization and Personalization: GAO RFID IoT-enabled production lines can adapt to changing product specifications and customer preferences, enabling greater customization and personalization of electronic products.

- Environmental Monitoring: GAO IoT sensors can monitor environmental conditions within manufacturing facilities, ensuring compliance with regulations and maintaining optimal working conditions for sensitive electronic components.

- Safety and Compliance: GAO RFID IoT systems can track safety parameters and compliance with safety regulations, ensuring the well-being of workers and adherence to industry standards.

- Remote Diagnostics and Troubleshooting: GAO Manufacturers can remotely diagnose and troubleshoot issues with electronic products or equipment through IoT-connected devices, reducing service and repair times.

- Asset Tracking: IoT sensors and GPS technology can track the location and usage of valuable assets, such as machinery and tools, improving asset utilization and preventing theft.

- Demand Forecasting: GAO’s RFID IoT data can be used to forecast demand for electronic products and components more accurately, helping manufacturers plan production schedules and inventory levels.

- Real-time Data Analytics: GAO RFID IoT systems can provide real-time data analytics and insights, enabling faster decision-making and proactive problem-solving.

- Lifecycle Management: GAO RFID IoT technology can assist in tracking the entire lifecycle of electronic products, from design and manufacturing to customer use and disposal, improving sustainability practices.

Gao helps customers comply with standards, mandates & regulations of computer and electronic product manufacturing industry

GAO RFID Inc. has helped many companies in computer and electronic product manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 Series

- EPCglobal UHF Gen2

- Bluetooth Core Specification

- MQTT

- CoAP

- OneM2M

- ISO 21384 Series

- EPCglobal

- Bluetooth SIG

- Industry-specific Regulations

- FAA

Government Regulations

- FCC

- OSHA

- EPA

- NIST

- FDA

- DOT

- CBP

- FTC)

- EAR

Canadian Government Regulations

- CEPA

- HPA

- CRTC

- Radiocommunication Act

- ITE

- HAC

- Industry Canada Certification Requirements for Radio Apparatus

- CCPSA

- Competition Act

- Copyright Act

- Patent Act

- Trade-marks Act

- PIPEDA

- CSA

- Export Control List (ECL) and Export and Import Permits Act (EIPA)

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in such as:

Personnel Management:

- Employee Attendance Tracking

- HR Records and Compliance Management

- Training and Certification Tracking

- Health and Safety Compliance Monitoring

- Employee Scheduling and Shift Management

Equipment Management:

- Equipment Maintenance and Preventive Maintenance Scheduling

- Asset Tracking and Inventory Management

- Equipment Health Monitoring (e.g., sensors for temperature, pressure)

- Calibration and Certification Tracking

Access Control:

- Restricted Area Access Control

- Visitor Management

- Security Surveillance

- Intrusion Detection

- Biometric Authentication

Warehouse Management:

- Inventory Management and Tracking

- RFID-Based Inventory Control

- Temperature and Humidity Monitoring

- Order Fulfillment and Picking Optimization

- Shelf-Life Monitoring for Perishable Goods

- Packaging and Labeling Automation

Supply Chain Management:

- Demand Forecasting and Inventory Optimization

- Supplier Relationship Management

- Route Optimization and Fleet Management

- Supplier and Customer Collaboration Portals

- Track and Trace for Product Visibility

- Compliance with Hazardous Materials Handling Regulations

Other Applications:

- Environmental Monitoring (e.g., air quality, water quality)

- Product Quality Control and Testing

- Product Authentication to Prevent Counterfeiting

- Emergency Response Planning and Management

- Customer Relationship Management (CRM)

- Regulatory Compliance Reporting

- Data Analytics for Decision Support

GAO has enabled its customers to make use of some of the leading software and cloud services in the Computer and Electronic Product Manufacturing Industry. Below are some of the popular software and cloud services in Computer and Electronic Product Manufacturing Industry IBM (International Business Machines Corporation), Hewlett Packard Enterprise (HPE), Dell Technologies, Cisco Systems, Oracle Corporation, Lenovo Group, EMC Corporation (now part of Dell), Fujitsu Limited, NetApp, Nutanix, Electronic Tech.

GAO has worked with some of the leading technology companies’ computer and electronic product manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in computer and electronic product manufacturing IBM, Oracle, SAP, Microsoft, Cisco Systems, Honeywell, Siemens, Emerson Electric, ABB Group, Schneider Electric, Rockwell Automation, Thermo Fisher Scientific, Dow, BASF, and 3M.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in computer and electronic product manufacturing industry

Industry Publications and Websites: Look for case studies and articles in industry-specific publications, such as electronics manufacturing journals and websites. These publications often feature real-world implementations of RFID technology.

RFID Solution Providers: Visit the websites of RFID solution providers and technology companies that serve the electronics manufacturing sector in the USA. Many of these companies publish case studies showcasing successful implementations.

Government and Industry Associations: Explore the websites and resources of government agencies and industry associations related to electronics manufacturing in the USA. They may provide information on RFID implementations and case studies.

Business News Sources: Check online business news sources for reports and articles on RFID applications in the electronics manufacturing industry in the USA. Business and technology news outlets often cover noteworthy implementations.

Academic Research: Look for academic papers and research studies related to RFID technology in electronics manufacturing. Universities and research institutions in the USA may have conducted studies on this topic.

Networking and Industry Events: Attend industry conferences, seminars, and trade shows related to electronics manufacturing and RFID technology in the USA. These events often feature presentations and case studies.

Consulting Firms: Consulting firms in the USA may publish reports and case studies on technology implementations in various industries, including electronics manufacturing.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in the computer and electronic product manufacturing industry.

In a case study within the computer and electronic product manufacturing industry in the USA, a major chemical wholesaler implemented IoT technology to enhance safety and efficiency in their operations. They deployed IoT sensors throughout their warehouses and chemical storage facilities to monitor environmental conditions like temperature, humidity, and chemical leaks in real-time. These sensors were connected to a central IoT platform that provided alerts and notifications to warehouse managers and safety officers. This proactive monitoring allowed the company to respond quickly to any adverse conditions, prevent accidents, and maintain compliance with strict safety and environmental regulations, ultimately improving the overall safety and reliability of their chemical distribution operations.

Case Studies of Drone Applications

Below are some drone application cases in the computer and electronic product manufacturing industry.

Finding specific case studies for drone applications in Computer and Electronic Product Manufacturing can be a valuable source of insights and best practices. However, these case studies are typically scattered across various sources and may not be readily available in organized lists. To locate relevant case studies, it’s essential to leverage multiple resources and approaches. Industry publications, government reports, academic research, and technology providers’ websites can all be fruitful sources. Additionally, engaging with industry professionals, attending conferences, and exploring online communities can provide valuable leads. By focusing your search on the type of drone application and the specific region of interest.

GAO RFID Systems & Hardware for Computer and Electronic Product Manufacturing industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the computer and electronic product manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the computer and electronic product manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Computer and Electronic Product Manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Computer and Electronic Product Manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Computer and Electronic Product Manufacturing industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Computer and Electronic Product Manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860-960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Reader Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in Computer and Electronic Product Manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include storage tanks and containers, chemical pumps and transfer equipment, forklifts and pallet jacks, safety equipment (e.g., protective clothing, gloves, respirators), labeling and packaging machinery, quality control and testing equipment, computer systems for inventory management, transportation vehicles (e.g., trucks, tankers), climate-controlled storage warehouses, and specialized handling equipment for hazardous materials.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for computer and electronic product manufacturing industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in computer and electronic product manufacturing industry we have worked with to serve our joint customers:

- Accenture

- Deloitte

- Capgemini

- Cognizant

- IBM Global Business Services

- PricewaterhouseCoopers (PwC)

- Wipro

- Ernst & Young (EY)

- Infosys

- DXC Technology

- HCL Technologies

- Tata Consultancy Services (TCS)

- Atos

- NTT Data

- CGI Group

- Compugen Inc.

- Long View Systems

- Scalar Decisions

- CDW Canada

- Softchoice

- OnX Enterprise Solutions

- Sierra Systems (an NTT Data Company)

- Bell Canada

- Insight Canada

- TeraMach Technologies

- Cogeco Peer 1

- Scalar Decisions

- OnX Enterprise Solutions

- Compufix Solutions

- PCL Constructors Canada Inc. (PCL)

- Sopra Steria

- TietoEVRY

Gao has served computer and electronic product manufacturing industry extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in computer and electronic product manufacturing industry to achieve success in sustainability, digital transformation, supply chain optimization, e-commerce, regulatory compliance, blockchain, data analytics, IoT (Internet of Things), chemical safety, chemical traceability, environmental responsibility, predictive maintenance, inventory management, and green chemistry.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in computer and electronic product manufacturing industry, including many in its various divisions such as:

- Industry 4.0: The fourth industrial revolution, characterized by the integration of digital technologies, data analytics, and automation into manufacturing processes.

- Internet of Things: The network of interconnected devices and sensors that can collect and exchange data, enabling smart manufacturing and predictive maintenance.

- Digital Twins: Virtual replicas of physical products or processes that enable simulation, analysis, and optimization.

- Additive Manufacturing: The use of 3D printing technology to create prototypes and even final products, reducing production time and costs.

- Artificial Intelligence (AI): The use of machine learning and AI algorithms to optimize production processes, quality control, and supply chain management.

- Blockchain: A distributed ledger technology that enhances supply chain transparency, traceability, and security.

- Edge Computing: Processing data closer to the source (e.g., on the factory floor) to reduce latency and improve real-time decision-making.

- Cybersecurity: Protecting manufacturing systems and data from cyber threats and attacks.

- Predictive Maintenance: Using data analytics and IoT sensors to predict when equipment and machinery will require maintenance, reducing downtime and costs.

- Sustainability: Emphasizing environmentally friendly manufacturing processes, energy efficiency, and recycling of electronic waste.

- Circular Economy: Focusing on recycling and reusing materials to minimize waste in the product lifecycle.

- Smart Factories: Fully connected and digitized manufacturing facilities that optimize production and resource allocation.

- Human-Machine Collaboration: The integration of robotics and automation with human workers to improve efficiency and safety.

- Supply Chain Resilience: Strategies and technologies to ensure supply chain continuity, even in the face of disruptions.

- Big Data Analytics: Leveraging large volumes of data to gain insights into manufacturing processes, quality, and customer preferences.

- 5G Connectivity: High-speed and low latency 5G networks enable faster data transmission and connectivity in smart manufacturing environments.

- Digital Transformation: The comprehensive use of digital technologies to overhaul traditional manufacturing processes and business models.

- Energy Efficiency: Reducing energy consumption in manufacturing processes and facilities.

- Customization and Personalization: Meeting customer demands for personalized electronic products and configurations.

GAO’s technologies enable its customers in computer and electronic product manufacturing industry to effectively track their workforces such as sales representatives, product specialists, warehouse managers, logistics coordinators, chemical engineers, safety officers, quality control analysts, procurement specialists, inventory managers, customer service representatives, compliance officers, and supply chain managers effectively track operational assets such as storage tanks, chemical pumps, drum handling equipment, forklifts, pallet jacks, labeling machines, packaging machinery, conveyor systems, quality control and testing equipment, temperature and humidity sensors, RFID systems, inventory management software, safety showers and eyewash stations, hazmat storage cabinets, spill containment pallets, and transportation vehicles such as trucks and tankers.

Here are some of the leading companies in electronic product manufacturing industry GAO has served:

- Ibm

- Dell Technologies

- Corning incorporated

- Xerox corporation

- Bose corporation

- Motorola solutions

- John deer

- Rockwell automation

- Garmin

- Lexmark international

- Apple inc.

- Hewlett Packard enterprise

- Tesla, inc.

- Intel corporation

- Adobe inc.

- Microsoft corporation

- Texas instruments

- Oracle corporation

- Nvidia corporation

- Western digital corporation

- Blackberry limited

- Celestica inc.

- Shopify inc.

- OpenText corporation

- Sierra wireless

- Foxconn

- Flex Ltd.

- Sanmina corporation

- Jabil inc.

- Continental AG

- ASML holding N.V.

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com