Index

Applications & Benefits of GAO’s RFID, BLE, IoT& Drones for Dairy Product Manufacturing Industry

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Dairy Product Manufacturing Industry

GAO Makes Efforts to Satisfy Customers

GAO Has Served Dairy Product Manufacturing Industry Extensively

Overview

Raw milk is sourced from dairy farms and transported to processing facilities. It undergoes quality testing to ensure it meets safety and regulatory standards. Pasteurization/Homogenization: Milk is heated to specific temperatures to eliminate harmful bacteria, extend shelf life, and improve safety. Homogenization breaks down fat molecules to ensure uniform distribution. Depending on the product being produced, milk is processed further. For instance, cheese involves curdling and separating the solids from the whey, while yogurt is created through fermentation. Different dairy products may require the addition of various ingredients like cultures, enzymes, flavorings, and stabilizers to achieve the desired taste, texture, and shelf life. Processed products are packaged in various forms such as bottles, cartons, tubs, or bulk containers. Packaging ensures product safety, hygiene, and preservation.

The products are distributed to various retail outlets, supermarkets, restaurants, and foodservice establishments. Marketing strategies play a crucial role in promoting these products to consumers. Consumers purchase dairy products for direct consumption or for use as ingredients in cooking and baking. Increasing awareness about health and nutrition has led to demand for products with reduced fat, sugar, and additives, as well as a rise in lactose-free and plant-based alternatives. Concerns about environmental impact and animal welfare have prompted efforts to make dairy production more sustainable, from responsible farming practices to reducing packaging waste. The industry continually develops new products, flavors, and packaging formats to cater to changing consumer preferences. Dairy products are often traded internationally, making the industry susceptible to shifts in global demand, supply, and trade policies. Automation and technology are being integrated into dairy processing, leading to improved efficiency, quality control, and traceability.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in dairy product manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Milk Tanks, Milk Receival Stations, Pasteurizers, Homogenizers, Separators, Clarifiers, Cheese Vats, Cheese Presses, Cheese Molds, Yogurt Fermenters, Incubation Tanks, Cream Separators, Butter Churns, Batch Freezers, Continuous Freezers, Filling Machines, Capping Machines, Fermentation Tanks, Culture Adders, Cooling Tanks, Refrigeration Units, CIP (Clean in Place) Systems, Sanitizing Equipment, Testing Equipment, Laboratory Tools, Storage Tanks, Silos, Transportation: Tanker Trucks, Refrigerated Containers, Boilers, Water Treatment Systems.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for dairy product manufacturing industry. Its sister company, GAO Tek Inc. Test & Measurement, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT& Drones for Dairy Product Manufacturing Industry

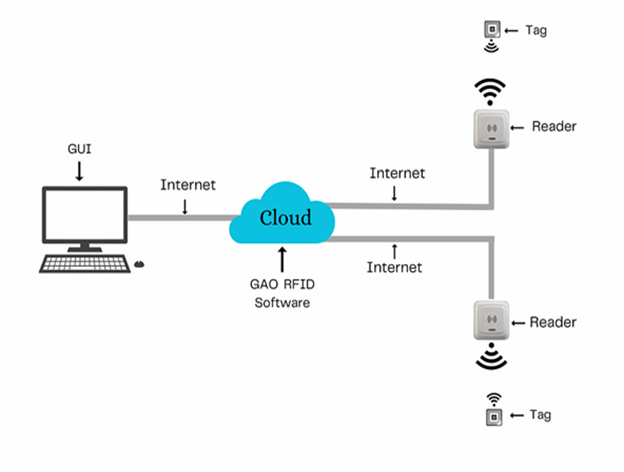

To satisfy its customers, GAO’s RFID or RFID Systems for dairy product manufacturing industry are offered in2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server fromone of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace.The above illustrates GAO system for dairy product manufacturing industry with its software running on a local server.

The above illustrates the GAO system insurance career and related industry with its software running in the cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in dairy product manufacturing industry:

- Inventory Management: RFID tags can be attached to dairy products and packaging materials, enabling real-time tracking of inventory levels. This helps in optimizing stock levels, reducing waste, and ensuring timely replenishment.

- Traceability and Quality Control: RFID tags can store information about the origin, production date, processing steps, and other relevant data for each dairy product. This aids in maintaining traceability throughout the supply chain and ensures quality control.

- Product Authentication: RFID tags can be used to authenticate the authenticity of dairy products, helping consumers and retailers identify counterfeit or adulterated items.

- Cold Chain Monitoring: Temperature-sensitive RFID tags can be employed to monitor and record temperature fluctuations during storage and transportation of dairy products. This ensures that products are maintained within the required temperature range to prevent spoilage and maintain freshness.

- Process Automation: RFID technology can be integrated into manufacturing processes to automate various stages, such as ingredient verification, mixing, pasteurization, and packaging. This reduces the likelihood of errors and improves production efficiency.

- Work-in-Progress Tracking: RFID tags can track the progress of dairy products through different production stages. This allows manufacturers to identify bottlenecks, streamline workflows, and optimize resource allocation.

- Product Recalls: In case of a product recall, RFID-enabled systems can quickly locate affected products within the supply chain, facilitating targeted recalls and minimizing waste.

- Supply Chain Visibility: RFID technology provides real-time visibility into the movement of raw materials, ingredients, and finished dairy products as they move through the supply chain. This improves supply chain transparency and efficiency.

- Automated Packaging and Labeling: RFID technology can be used to automate the labeling and packaging of dairy products, reducing manual labor and the likelihood of labeling errors.

- Maintenance Tracking: RFID tags can be applied to equipment and machinery used in dairy production to monitor maintenance schedules and optimize equipment uptime.

- Waste Reduction: By accurately tracking inventory levels and expiration dates, RFID technology helps reduce waste by ensuring that products are used or sold before they expire.

- Consumer Engagement: RFID-enabled packaging can provide consumers with access to additional information about the dairy product, including nutritional data, recipes, and sourcing information.

- Supply Chain Optimization: RFID technology facilitates data-driven decision-making by providing insights into production and distribution patterns, allowing manufacturers to optimize routes, schedules, and resource allocation.

- Efficient Receiving and Shipping: RFID tags can streamline the receiving and shipping processes by automating data capture and verification, reducing manual errors and speeding up operations.

- Regulatory Compliance: RFID technology can assist in complying with regulatory requirements by providing accurate data records and traceability documentation.

GAO’s drone technologies find the following applications in the dairy product manufacturing industry:

- Aerial Imaging: Drones can capture high-resolution aerial images of dairy farms, allowing farmers to monitor the health and growth of crops, pastures, and livestock.

- Pest and Disease Detection: Drones equipped with specialized sensors can identify signs of pests or diseases in crops and livestock, enabling early intervention.

- Herd Management: Drones can help monitor the movement, health, and behavior of dairy cattle, aiding in identifying individual animals that may need attention.

- Headcount and Tracking: Drones can perform headcounts of livestock in large areas, helping farmers maintain accurate records and prevent losses.

- Vegetation Analysis: Drones can assess the health and growth of pastures, assisting in optimizing grazing patterns and ensuring proper nutrition for the livestock.

- Facility Maintenance: Drones can inspect dairy farm infrastructure, such as barns, silos, and equipment, to identify maintenance needs and assess structural integrity.

- Forage Assessment: Drones can monitor forage crops used as feed for dairy cattle, providing insights into growth patterns and helping with timely harvesting.

- Water Source Analysis: Drones can survey water sources on the farm, ensuring the availability of clean water for the livestock.

- Remote Sensing: Drones equipped with various sensors (multispectral, thermal, LiDAR) can collect data on soil moisture, temperature, and other environmental parameters, aiding in decision-making.

- Variable Rate Applications: Drones can assist in applying fertilizers, pesticides, and other inputs at precise rates, minimizing waste and optimizing resource usage.

- Disaster Assessment: Drones can quickly assess the extent of damage to dairy farms and infrastructure in the aftermath of natural disasters, facilitating timely recovery efforts.

- 3D Mapping: Drones can create accurate 3D maps of farms and facilities, assisting in land planning and infrastructure development.

- Stress Detection: Drones equipped with thermal cameras can identify signs of stress or illness in livestock by detecting abnormal body temperature patterns.

- Remote Tasks: Drones can be used for tasks such as distributing feed, collecting samples, and monitoring livestock, reducing the need for manual labor.

- Environmental Compliance: Drones can help monitor and document compliance with environmental regulations, such as waste management and water runoff.

- Marketing and Promotion: Drones can capture captivating aerial footage of dairy farms for use in promotional materials, showcasing the sustainability and quality of products.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the dairy product manufacturing industry:

- Milk Quality Monitoring: Sensors attached to milking equipment can monitor the quality of milk in real time, detecting any abnormalities such as changes in temperature or composition.

- Automated Milking Systems: IoT-enabled robotic milking systems can identify individual cows, determine their milking schedule, and adjust milking parameters based on data such as milk yield and udder health.

- Livestock Health Monitoring: Wearable sensors can be attached to dairy cattle to monitor their health, activity levels, and vital signs. This data helps in identifying early signs of illness or stress.

- Feed Management: IoT devices can monitor feed consumption by individual animals, ensuring that each cow receives the appropriate amount of nutrition for optimal milk production.

- Environmental Monitoring: Sensors can track environmental conditions such as temperature, humidity, and air quality in barns and milking parlors to ensure a comfortable and healthy environment for cattle.

- Precision Feeding: IoT-enabled feeding systems can dispense customized feed rations for each cow based on their nutritional requirements and milk production stage.

- Milk Storage and Refrigeration: IoT sensors in storage tanks and refrigeration units can monitor milk temperature, ensuring that milk is stored at the proper temperature to prevent spoilage.

- Supply Chain Tracking: IoT-enabled tracking devices can monitor the movement and conditions of dairy products as they move through the supply chain, ensuring quality and compliance.

- Predictive Maintenance: IoT sensors on equipment and machinery can collect data on usage patterns and performance metrics, enabling predictive maintenance to prevent breakdowns.

- Energy Management: IoT systems can monitor energy consumption in dairy facilities, optimizing energy usage and identifying opportunities for efficiency improvements.

- Automated Cleaning and Sanitization: IoT-enabled cleaning systems can automate the cleaning of milking equipment and facilities, ensuring hygiene standards are maintained.

- Real-time Data Analytics: IoT-generated data can be analyzed in real time to gain insights into production processes, animal behavior, and environmental conditions, enabling data-driven decision-making.

- Regulatory Compliance: IoT systems can assist in monitoring compliance with regulations related to food safety, animal welfare, and environmental standards.

- Waste Reduction: IoT devices can help monitor and reduce waste by optimizing processes and ensuring accurate inventory management.

- Remote Monitoring and Management: Dairy farmers can remotely monitor and manage their operations through IoT-enabled devices and applications, improving overall efficiency and reducing the need for on-site presence.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Dairy Product Manufacturing Industry

GAO RFID Inc. has helped many companies in dairy product manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6C

- FDA Food Safety Modernization Act (FSMA)

- Bluetooth SIG Standards

- ISO/IEC 30141

- EU General Data Protection Regulation (GDPR)

- ASTM F38

- FAA Regulations (U.S

US. Government Regulations

- Grade A Pasteurized Milk Ordinance (PMO)

- Federal Food, Drug, and Cosmetic Act (FFDCA)

- Food Safety Modernization Act (FSMA)

- Hazard Analysis and Critical Control Points (HACCP) Regulations

- Food and Drug Administration (FDA) Regulations for Dairy Products

- Standards of Identity for Dairy Products

- Dairy Market Enhancement Program (Dairy MEP)

- Agricultural Marketing Agreement Act (AMAA) Programs

- Federal Milk Marketing Orders (FMMOs)

- Environmental Protection Agency (EPA) Regulations for Dairy Operations

- Occupational Safety and Health Administration (OSHA) Regulations for Worker Safety

Canadian Government Regulations

- Dairy Products Regulations

- Food and Drugs Act (Part 13 – Food)

- Canadian Agricultural Products Act

- Safe Food for Canadians Regulations

- Canadian Food Inspection Agency (CFIA) Requirements for Dairy

- Health of Animals Act (Part XII – Dairy)

- Agriculture and Agri-Food Administrative Monetary Penalties Regulations (Dairy)

- Canadian Dairy Commission Act

- Canadian Dairy Commission Regulations

- Farm Products Agencies Act (Canadian Dairy Commission)

- Canadian Dairy Information Centre Act

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in dairy product manufacturing industry such as:

Personnel Management:

- Employee Scheduling and Shift Management

- Workforce Training and Development

- Health and Safety Compliance

- Employee Performance Tracking

- Labor Cost Management

Equipment Management:

- Equipment Maintenance and Preventive Maintenance

- Asset Tracking and Inventory Management

- Quality Control and Equipment Calibration

- Equipment Downtime Monitoring

- Energy Efficiency Monitoring

Access Control:

- Restricted Access to Production Areas

- Biometric Identification for Personnel

- Security Camera Surveillance

- Visitor Management

- Access Logging and Reporting

Warehouse Management:

- Inventory Tracking and Management

- Temperature and Humidity Monitoring

- Real-time Stock Replenishment

- Order Picking and Fulfillment

- Barcode and RFID Tracking

Supply Chain Management:

- Supplier Management and Compliance

- Demand Forecasting and Planning

- Logistics and Transportation Management

- Supplier Quality Assurance

- Traceability and Recall Management

Other Applications:

- Product Quality Assurance and Control

- Regulatory Compliance Tracking

- Environmental Monitoring (Waste Management, Sustainability)

- Data Analytics for Process Optimization

- Customer Relationship Management (CRM) for B2B Clients

- Financial Management and Cost Control

- Traceability and Provenance Tracking for Product Authenticity

GAO has enabled its customers to make use of some of the leading software and cloud services in dairy product manufacturing industry. Below are some of popular software and cloud services in dairy product manufacturing industry:

SAP Success Factors, Workday, Oracle HCM Cloud, and BambooHR, Fiix, eMaint CMMS, UpKeep, and Asset Panda, Brivo Access, S2 Security, Honeywell Access Control, and LenelS2, Manhattan Associates, JDA Warehouse Management, SAP Extended Warehouse Management, and Blue Yonder (formerly JDA), Kinaxis RapidResponse, SAP Integrated Business Planning, Oracle SCM Cloud, and Blue Yonder (formerly JDA), dairy process optimization software, quality control systems, and dairy traceability solutions.

GAO has worked with some of the leading technology companies in dairy product manufacturing industry in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in dairy product manufacturing industry:

SAP, Oracle, IBM, Microsoft, Infor, Electronic Technology Companies, Siemens, ABB, Schneider Electric, Rockwell Automation, Emerson Electric, Tetra Pak, GEA Group, Alfa Laval, SPX FLOW, DeLaval.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in dairy product manufacturing industry:

Implemented RFID for tracking and managing the production and distribution of milk products. This improved traceability and reduced errors in inventory management.

Utilized RFID technology to improve supply chain visibility, track raw milk collection, and enhance production efficiency.

Implemented RFID-based systems for tracking raw materials and finished goods in their dairy production process, leading to better inventory management and reduced losses.

Implemented RFID in its production and distribution operations to enhance traceability and quality control of dairy products.

Employed UHF RFID for real-time tracking of milk containers and monitoring temperature during transportation, ensuring product quality.

Implemented UHF RFID to track cheese containers, ensuring proper storage conditions and reducing the risk of spoilage.

Utilized UHF RFID for tracking dairy products through the supply chain, enabling better inventory management and reducing losses.

Implemented UHF RFID for tracking milk containers and improving inventory accuracy in their dairy operations.

Many applications of RFID by GAO can be found here. Manufacturing Industry | RFID Solutions

Case Studies of IoT Applications

Below are some IoT application cases in dairy product manufacturing industry:

In the USA, a prominent dairy manufacturer utilized IoT technology to enhance its production processes. By integrating sensors into various stages of production, from milk collection to packaging, the company achieved real-time monitoring of equipment performance, temperature, and quality parameters. This enabled proactive maintenance, reduced downtime, and ensured the consistent quality of dairy products throughout the supply chain.

A leading Canadian dairy cooperative implemented IoT solutions to optimize its raw milk collection process. Sensors installed on milk collection tanks and trucks enabled real-time monitoring of milk quantity and quality. Data collected from these sensors allowed the cooperative to streamline collection routes, reduce waste, and improve the overall efficiency of their operations.

In Mexico, a dairy producer embraced IoT technology to address challenges in cold chain management. By deploying IoT-enabled temperature and humidity sensors in storage facilities and transportation trucks, the company ensured that dairy products were maintained at optimal conditions. This approach minimized spoilage, enhanced product safety, and maintained product quality from production to distribution.

A European dairy manufacturer leveraged IoT solutions to enhance traceability and quality control. Through the integration of sensors and RFID technology, the company established end-to-end visibility of its products across the supply chain. This enabled them to track production data, monitor storage conditions, and ensure compliance with regulatory standards, ultimately delivering safer and higher-quality dairy products to consumers.

Case Studies of Drone Applications

Below are some drone application cases in dairy product manufacturing industry:

In the USA, a dairy farm integrated drone technology to enhance its herd management practices. Drones equipped with thermal cameras and sensors were used to monitor the health and behavior of dairy cattle. By conducting aerial surveys, the farm could identify early signs of illness, monitor grazing patterns, and optimize feeding schedules, leading to improved overall herd well-being and milk production.

A Canadian dairy cooperative adopted drone technology to optimize pasture management. Drones equipped with imaging and mapping capabilities were employed to assess the condition of grazing areas. By analyzing vegetation health and density, the cooperative was able to make informed decisions about rotation patterns, ensuring that dairy cattle had access to nutritious grazing areas, ultimately enhancing milk quality.

In Mexico, a dairy manufacturer harnessed drone technology to monitor and manage large-scale dairy farms efficiently. Drones equipped with high-resolution cameras were used to survey expansive fields and monitor the health of crops used for cattle feed. This approach allowed the company to ensure an adequate and high-quality feed supply, contributing to improved milk production and product quality.

A European dairy industry leader employed drones to optimize land and resource management. Drones equipped with multispectral cameras were used to assess soil quality and health across the dairy’s farmland. The data collected enabled precision agriculture techniques, optimizing fertilizer usage and irrigation practices, resulting in increased crop yield for cattle feed production.

GAO RFID Systems & Hardware for Dairy Product Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including dairy product manufacturing Industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including dairy product manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including dairy product manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including dairy product manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including dairy product manufacturing industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including dairy product manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

In collaboration with its sister company GAO Tek Inc, a wide selectioon of high quality drones are offered:

The RFID systems by GAO are highly popular for clients in dairy product manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include Homogenizer, Pasteurizer, Separator, Cheese Vat, Curd Cutter, Butter Churn, Cream Separator, Yogurt Fermenter, Milk Evaporator, Ice Cream Freezer, Cheese Press, Milk Tanker, Milk Silo, UHT Sterilizer, Cheese Moulds, Whey Processor, Milk Clarifier, CIP (Clean-in-Place) System, Cheese Aging Room, Milk Powder Spray Dryer.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for dairy product manufacturing industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe: Services

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in dairy product manufacturing industry we have worked with to serve our joint customers:

- ABC IT Solutions

- TechMinds Integrators

- DairyTech Solutions

- IT Dairy Innovations

- DataStream Integrations

- Maple IT Integrations

- DairyNet Systems

- IT MilkMasters

- NovaTech Solutions

- CowTech Integrators

- QuesoTech Integrations

- DairySys México

- IT LecheTech

- TecnoLácteos

- AgroIT Solutions

- EuroDairy Tech

- DairyIT Europe

- IT MilkTech Europe

- Fromage Systems

- TechLait Integrators

GAO Has Served Dairy Product Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in dairy product manufacturing industry to achieve success in Microbiome, Plant-Based Alternatives, Clean Label, Probiotics and Functional Foods, Sustainability, Personalization, Premiumization, Traceability and Transparency, Digitalization, Reduced Sugar Nutraceuticals, Blockchain, Precision Dairy Farming, Cultured Dairy, Crispy Cheese Bites, Biomimicry, Shelf-Life Extension, Biodegradable Packaging, Functional Fermented Foods.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in dairy product manufacturing industry, including many in its various divisions such as:

- Milk Processing: This division involves the collection, transportation, and processing of raw milk into various products like pasteurized milk, flavored milk, and milk powder.

- Cheese Production: Cheese manufacturing includes processes such as curd formation, cutting, pressing, and aging. Different types of cheeses like cheddar, mozzarella, and Swiss fall under this category.

- Yogurt and Fermented Products: This division covers the production of yogurt, kefir, and other fermented dairy products. It involves the introduction of live cultures for fermentation.

- Butter and Ghee: The manufacturing of butter involves churning cream to separate the butterfat from the buttermilk. Ghee is clarified butter often used in cooking.

- Ice Cream and Frozen Desserts: Ice cream, gelato, frozen yogurt, and other frozen dairy desserts are produced in this sub-industry. It includes processes like pasteurization, homogenization, and freezing.

- Dairy Ingredients and Powders: This division involves the production of various dairy-derived ingredients like whey protein, casein, and milk powders used in food and beverage manufacturing.

- Cream and Whipped Toppings: Cream is processed and packaged for retail or commercial use. Whipped toppings are often used in desserts and baked goods.

- Specialty Dairy Products: This category includes products like sour cream, cottage cheese, ricotta, and cream cheese, which have specific production processes and uses.

- Lactose and Lactose-Free Products: Lactose is extracted from whey and used in various applications. Lactose-free dairy products cater to individuals with lactose intolerance.

- Dairy Alternatives: While not traditional dairy, this division involves the production of plant-based alternatives like almond milk, coconut yogurt, and soy-based cheeses.

- Packaging and Distribution: This division involves the packaging of dairy products for retail and commercial distribution, including various packaging materials and designs.

- Quality Control and Safety: Ensuring the safety, quality, and compliance of dairy products through rigorous testing, monitoring, and adherence to regulations.

- Dairy Farming Technology: Although not directly manufacturing, this division includes technological advancements used on dairy farms, such as automated milking systems and data analytics for herd management.

GAO’s technologies enable its customers in dairy product manufacturing industry to effectively track their workforces such as Production Supervisor, Quality Control Technician, Packaging Operator, Dairy Processing Operator, Maintenance Technician, Lab Technician, Production Manager, Plant Manager, R&D Scientist (Research and Development), Supply Chain Coordinator, Logistics Specialist, Quality Assurance Manager, Equipment Operator, Packaging Supervisor, Sanitation Worker, Warehouse Manager, Dairy Chemist, Dairy Technologist, Process Engineer, Continuous Improvement Specialist and effectively track operational assets such as Pasteurizer, Homogenizer, Separator, Cheese Vat, CIP System (Clean-in-Place), Ultrafiltration Unit, Fermentation Tank, Filling Machine, Evaporator, Chiller, Cheese Press, Packaging Line, Batch Pasteurizer, Milk Receiving Dock, Butter Churn, Curd Cutter, Cream Separator, Yogurt Incubator, Powder Mixer, Homogenizing Valve.

Here are some of the leading companies in dairy product manufacturing industry GAO has served:

- Land O’Lakes

- Dean Foods

- Kraft Heinz

- Tillamook

- Darigold

- Organic Valley

- Leprino Foods

- Shamrock Farms

- Prairie Farms Dairy

- HP Hood

- Sargento

- Agropur

- Dairy Farmers of America

- Hiland Dairy

- Borden Dairy

- California Dairies, Inc.

- Dairyland

- Foremost Farms

- Yoplait

- Cabot Creamery

- Blue Bell Creameries

- Saputo

- Gay Lea Foods

- Natrel

- Liberté

- Organic Meadow

- Beatrice

- Arla Foods

- Yili Group

- Nestle

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com