Index for Contents on This Page:

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Electric Vehicle Manufacturing

GAO’s Assists Clients with Standards, Mandates & Regulations of the Electric Vehicle Manufacturing

GAO Software Provides Easy Integration with API

Case study of RFID Applications

GAO RFID Systems & Hardware for the Electric Vehicle Manufacturing

GAO Has Served the Electric Vehicle Manufacturing Extensively

Related Products & Systems on Other Pages on This Website

Work In Process WIP Asset Tracking System

Employee & Attendance Access Control System

People Tracking System for Manufacturing Facilities

Tool & Industrial Equipment Tracking System (gaorfid.com)

Fleet & Rental Car Parking Control System | RFID Tracking by GAO (gaorfid.com)

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

On Metal RFID Tags – All Types

Overview

The electric vehicle industry has gained momentum due to environmental concerns, government support, and battery advancements. Key players include car manufacturers, tech firms, and startups. Crucial components include batteries, motors, power electronics, and charging infrastructure. Research focuses on battery efficiency, range, and cost reduction. Challenges include expensive batteries, limited charging infrastructure, and production/disposal concerns. Investments and collaborations drive sustainable and affordable development, supported by governments for a greener transportation sector.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the electric vehicle manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as batteries, electric motors, power electronics, charging infrastructure, welding robots, assembly line conveyors, battery testing equipment, battery management systems, battery cell production equipment, and battery pack assembly machines.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra-high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in electric vehicle manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Electric Vehicle Manufacturing

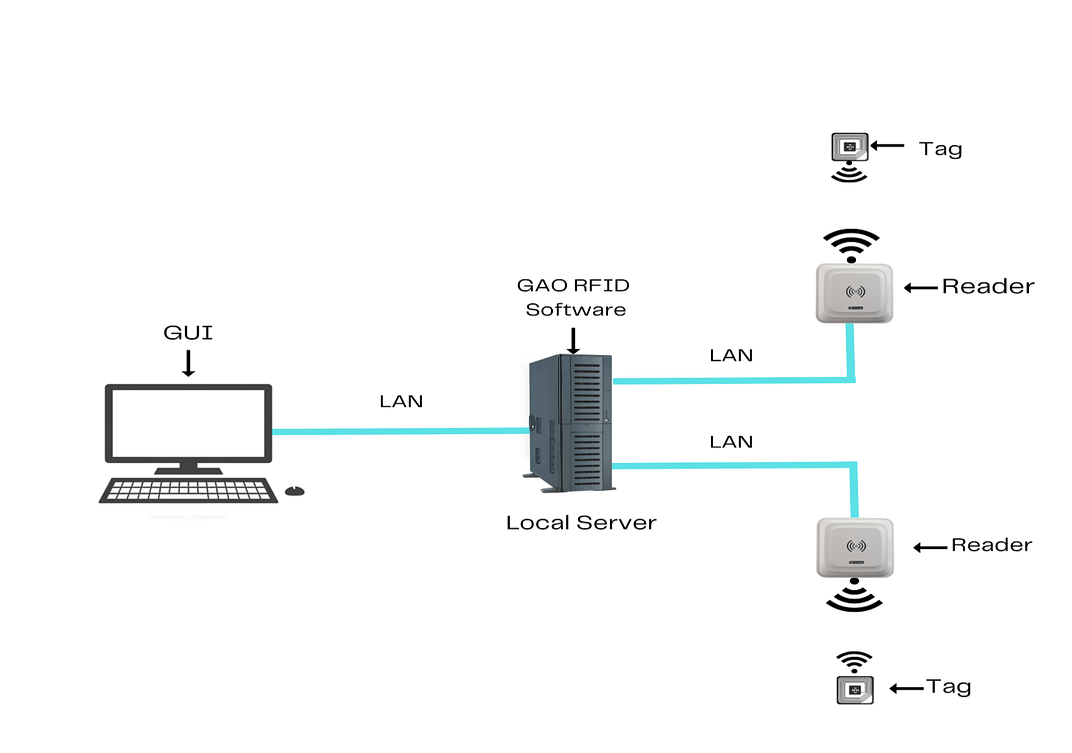

To satisfy its customers, GAO’s RFID or RFID Systems for electric vehicle manufacturing are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates the GAO system for electric vehicle manufacturing with its software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for electric vehicle manufacturing are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates the GAO system for electric vehicle manufacturing with its software running on a local server.

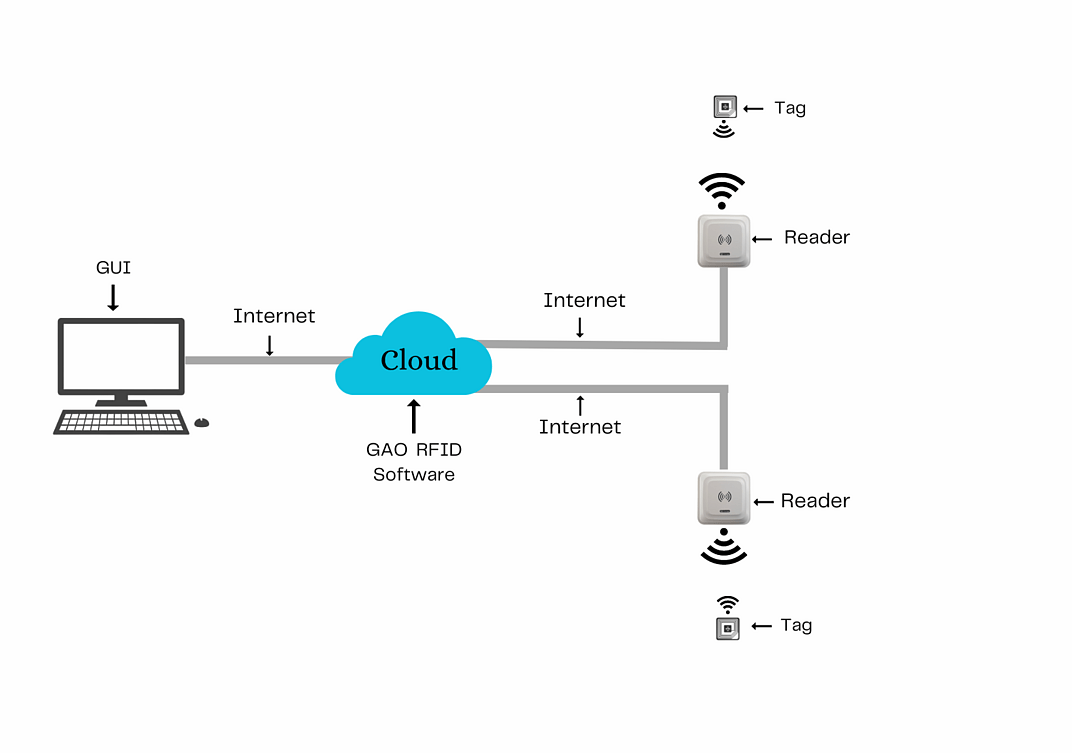

The above illustrates GAO system for electric vehicle manufacturing with its software running in cloud.

The above illustrates GAO system for electric vehicle manufacturing with its software running in cloud.

GAO’s RFID technologies bring the many benefits to the electric vehicle manufacturing industry:

- Enhanced Supply Chain Visibility: GAO’s RFID optimizes inventory management, tracking electric motor, battery pack, power electronics, and on-board charger in real-time to avoid delays and ensure timely delivery.

- Streamlined Production Processes: Our RFID technology automates assembly line processes, reducing errors, improving efficiency, and ensuring correct electric vehicle control software, and safety systems usage.

- Efficient Asset Management: GAO’s RFID tags track motor coils, assembly fixtures, balancing machines, forklifts, and delivery trucks, preventing loss, minimizing downtime, and enabling proactive maintenance scheduling.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger workspaces within the electric vehicle manufacturing industry:

- Seamless Vehicle Connectivity: GAO’s BLE tech enables electric vehicle connectivity, enhancing user experience with remote monitoring and control.

- Smart Maintenance and Diagnostics: GAO’s BLE enables predictive maintenance, collecting real-time data for proactive scheduling and issue identification.

- Personalized In-Vehicle Experience: Our BLE tech offers personalized settings for drivers, enhancing comfort and convenience with seat positions, climate control, and entertainment.

- Fleet Management Optimization: With GAO’s BLE solutions, fleet managers track electric vehicle location, performance, and maintenance, optimizing route planning, scheduling, and resource allocation.

GAO’s RFID and drone technologies are often combined, and such solutions offer the following benefits to the electric vehicle manufacturing industry:

- Efficient Inventory Management: Combine GAO’s RFID with drones for automated inventory counting and tracking. This combination allows for streamlined and efficient inventory management processes, reducing human effort and potential errors while improving overall inventory visibility and control.

- Enhanced Security and Anti-Theft Measures: GAO’s RFID integrated with drones for real-time monitoring and detection, allows for continuous real-time monitoring and detection, enhancing security measures and enabling swift responses to potential theft or security breaches.

- Augmented Safety Conformity: GAO’s RFID technology and drones monitor and enforce safety compliance, ensuring adherence to safety standards, while drones provide a flexible and efficient means of monitoring.

Here are benefits of GAO’s IoT technologies to the electric vehicle manufacturing industry:

- Predictive Maintenance: GAO’s IoT enables real-time monitoring for early failure detection, optimizing maintenance schedules and reducing downtime.

- Energy Optimization: Our IoT solutions identify energy inefficiencies, optimizing consumption through monitoring and control, adjusting systems based on occupancy or production needs.

- Quality Assurance: GAO’s IoT implements real-time quality control, capturing and analyzing data for consistency and compliance with standards.

- Detecting Hazardous Conditions: GAO’s Internet of Things (IoT) technology enhances safety measures by monitoring safety parameters, identifying dangerous situations, and guaranteeing a secure work environment through the use of alerts.

GAO’s Assists Clients with Standards, Mandates & Regulations of the Electric Vehicle Manufacturing

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in the electric vehicle manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- NIST Cybersecurity Framework: The National Institute of Standards and Technology framework provides guidelines and best practices for securing IoT devices and networks, addressing cybersecurity risks and vulnerabilities.

- National Fire Protection Association (NFPA) 70: The NFPA 70, also known as the National Electrical Code (NEC), provides safety standards and requirements for electrical systems, including those used in IoT devices.

- NIST SP 800-53: This cybersecurity framework provides guidelines and controls for securing IoT devices used in the electric vehicle manufacturing industry, ensuring data protection and privacy.

- UL 3030: This safety standard sets requirements for battery management systems used in electric vehicles, ensuring their safety and reliability during manufacturing and operation.

- ANSI/UL 2271: This standard specifies safety requirements for lithium-ion battery packs used in electric vehicles, addressing concerns related to overheating, fire hazards, and overall battery performance.

- FCC Part 15: This regulation governs the use of radio frequency devices, including RFID, BLE, and IoT devices, ensuring compliance with transmission power limits and minimizing interference with other wireless devices.

- Transport Canada Drone Regulations: These regulations outline the requirements for operating drones in Canada, including licensing, registration, and safety guidelines, for utilizing drones in the electric vehicle manufacturing industry.

- FAA Part 107: The Federal Aviation Administration’s regulations for operating drones in the United States, including licensing, flight restrictions, and safety guidelines, impacting the use of drones in the electric vehicle manufacturing industry.

- CRTC CASL: The Canadian Anti-Spam Legislation (CASL) regulates electronic communications, including IoT devices, ensuring compliance with consent and privacy requirements when collecting and transmitting data in the electric vehicle manufacturing industry.

- California IoT Security Law: This law requires manufacturers of IoT devices to implement reasonable security features, such as unique passwords and security updates, to protect against unauthorized access and data breaches.

- Energy Star: The Energy Star program promotes energy efficiency in products, including IoT devices used in the electric vehicle manufacturing industry, helping reduce energy consumption and environmental impact.

- CAN/CSA C22.2 No. 0.15: This Canadian standard addresses electrical safety requirements for electronic equipment, including IoT and BLE devices, ensuring safe and reliable operation in the electric vehicle manufacturing industry.

Government Regulations

- Corporate Average Fuel Economy (CAFE) Standards: These regulations set fuel economy targets for automakers, incentivizing the production of electric vehicles and reducing greenhouse gas emissions.

- Zero Emission Vehicle (ZEV) Mandate: Implemented by certain states, this regulation requires automakers to sell a certain percentage of zero-emission vehicles, encouraging the adoption of electric vehicles.

- Federal Tax Credits: The U.S. government offers tax credits to consumers who purchase electric vehicles, promoting their affordability and encouraging adoption.

- Advanced Technology Vehicles Manufacturing (ATVM) Loan Program: This program provides loans to manufacturers to produce advanced technology vehicles, including electric vehicles, supporting research and development in the industry.

- Electric Vehicle Charging Infrastructure Grants: The government provides grants to expand the charging infrastructure network, ensuring convenient access to charging stations and supporting the growth of electric vehicle adoption.

Canadian Government Regulations

- iZEV Program: The Canadian government offers incentives, such as rebates, to consumers who purchase or lease eligible electric vehicles, encouraging their adoption and reducing emissions.

- Federal ZEV Sales Mandate: This regulation requires automakers to sell a certain percentage of zero-emission vehicles in Canada, promoting the production and availability of electric vehicles in the market.

- Federal Charging and Refueling Infrastructure Deployment Initiative: The government provides funding to support the installation of electric vehicle charging stations and hydrogen refueling stations, expanding the charging infrastructure across Canada.

- Canadian Energy Regulator (CER) Regulations: These regulations ensure fair and transparent access to electricity grids for electric vehicle charging, promoting competition and affordability in the charging market.

Provincial Incentive Programs: Various provinces in Canada, such as British Columbia and Quebec, offer additional incentives, rebates, or grants to promote the purchase and use of electric vehicles within their respective jurisdictions.

NIST Cybersecurity Framework

NIST Cybersecurity Framework

National Fire Protection Association (NFPA)

National Fire Protection Association (NFPA)

NIST SP 800-53

NIST SP 800-53

ANSI/UL 2271

ANSI/UL 2271

FCC Part 15

FCC Part 15

FAA Part 107

FAA Part 107

CRTC CASL

CRTC CASL

Energy Star

Energy Star

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the electric vehicle manufacturing such as:

Personnel Management

- Employee scheduling and shift management

- Training and certification tracking

- Performance evaluation and feedback

- HR record keeping and employee information management

- Health and safety compliance monitoring

Equipment Management

- Asset tracking and maintenance scheduling

- Equipment utilization monitoring

- Predictive maintenance and failure detection

- Calibration and testing management

- Inventory management of spare parts and tools

Access Control

- Restricted area access management

- Employee identification and authentication

- Visitor management and tracking

- Integration with security systems (CCTV, alarms, etc.)

- Audit trails and access logs for regulatory compliance

Warehouse Management

- Inventory tracking and management

- Real-time stock level monitoring

- Order fulfillment and picking optimization

- Warehouse layout and storage optimization

- Demand forecasting and planning

Supply Chain Management

- Supplier relationship management

- Vendor performance monitoring and evaluation

- Procurement and purchase order management

- Logistics and transportation management

- Demand and supply forecasting for component and raw material sourcing

Other Applications

- Quality control and assurance

- Production line monitoring and optimization

- Energy management and sustainability tracking

- Environmental compliance monitoring

- Warranty and product lifecycle management

GAO has integrated its RFID, BLE, IoT and drone systems with some of the leading software and cloud services in the electric vehicle manufacturing industry. Below are some of the popular software and cloud services in the electric vehicle manufacturing industry.

- SAP SuccessFactors: A comprehensive human capital management software that offers features for personnel management, employee performance tracking, and training programs.

- Oracle NetSuite: A cloud-based ERP system that provides modules for equipment management, warehouse management, and supply chain management.

- Microsoft Dynamics 365: An integrated business management solution that offers modules for personnel management, equipment management, and supply chain management.

- Infor CloudSuite Industrial: An industry-specific cloud-based ERP solution that provides functionalities for equipment management, warehouse management, and supply chain management.

- Zoho People: A cloud-based HR management system that offers employees self-service, time and attendance tracking, leave management, and performance appraisal features.

- IBM Sterling Supply Chain: A cloud-based supply chain management platform that enhances visibility, collaboration, and optimization across the supply chain network.

- Epicor ERP: A comprehensive ERP system that offers modules for equipment management, warehouse management, and supply chain management.

- HighJump Warehouse Management System: A robust warehouse management software that optimizes inventory tracking, order fulfillment, and labor management.

- Blue Yonder: A cloud-based supply chain management platform that provides end-to-end visibility, planning, and optimization capabilities.

- Salesforce CRM: A leading customer relationship management software that enables efficient management of customer interactions, sales, and after-sales support.

- Plex Manufacturing Cloud: An end-to-end cloud-based ERP system specifically designed for manufacturing, offering features for equipment management, production planning, and supply chain management.

- Fishbowl Warehouse: A warehouse management software that integrates with popular accounting systems, providing inventory tracking, order management, and reporting capabilities.

SAP SuccessFactors

SAP SuccessFactors

Oracle NetSuite

Oracle NetSuite

Microsoft Dynamics 365

Microsoft Dynamics 365

Infor CloudSuite Industrial

Infor CloudSuite Industrial

Zoho People

Zoho People

IBM Sterling Supply Chain

IBM Sterling Supply Chain

Epicor ERP

Epicor ERP

HighJump Warehouse Management System

HighJump Warehouse Management System

Blue Yonder

Blue Yonder

Salesforce CRM

Salesforce CRM

Plex Manufacturing Cloud

Plex Manufacturing Cloud

Fishbowl Warehouse

Fishbowl Warehouse

GAO has worked with some of the leading technology companies in electric vehicle manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the electric vehicle manufacturing industry:

- Tesla: A leading electric vehicle manufacturer known for its innovative technology, including electric vehicles, energy storage solutions, and renewable energy products.

- LG Chem: A global electronics company that supplies lithium-ion batteries for electric vehicles, offering high-performance and energy-efficient battery solutions.

- NVIDIA: A technology company that specializes in artificial intelligence (AI) and computer graphics, providing advanced computing platforms for autonomous driving and in-vehicle infotainment systems.

- Panasonic: A multinational electronics corporation that manufactures lithium-ion batteries, electric vehicle charging infrastructure, and other components for electric vehicles.

- Samsung SDI: A leading supplier of lithium-ion batteries for electric vehicles, offering high-capacity and long-lasting battery solutions.

- Siemens: A technology company that provides electrical systems, automation, and digital solutions for electric vehicle manufacturing, including charging infrastructure and power distribution systems.

- Bosch: A global supplier of automotive technologies and systems, offering electric vehicle components, charging solutions, and advanced driver assistance systems (ADAS).

- ABB: A multinational corporation specializing in robotics, automation, and power technologies, providing charging infrastructure and energy management solutions for electric vehicles.

- BYD Company: A Chinese manufacturer of electric vehicles and batteries, offering a wide range of electric cars, buses, and energy storage systems.

- Infineon Technologies: A semiconductor manufacturer that supplies power electronics and microcontrollers for electric vehicles, enabling efficient energy conversion and control systems.

- Continental: A technology company specializing in automotive components and systems, providing solutions for electric vehicle powertrain, charging infrastructure, and driver assistance systems.

- CATL (Contemporary Amperex Technology Co. Limited): A leading manufacturer of lithium-ion batteries for electric vehicles, offering high-energy density and long-life battery solutions.

Tesla

Tesla

LG Chem

LG Chem

NVIDIA

NVIDIA

Panasonic

Panasonic

Samsung SDI

Samsung SDI

Siemens

Siemens

Bosch

Bosch

ABB

ABB

BYD Company

BYD Company

Infineon Technologie

Infineon Technologie

Continental

Continental

CATL (Contemporary Amperex Technology Co. Limited)

CATL (Contemporary Amperex Technology Co. Limited)

Case study of RFID Applications

Below are some RFID application cases in the electric vehicle manufacturing industry.

General Motors has achieved remarkable progress by integrating RFID technology into its electric vehicle production procedures, heralding a new era of enhanced efficiency and component monitoring. Through the employment of RFID tags, the company now possesses the capability to oversee inventory levels, trace the whereabouts of parts and materials, and guarantee precise assembly of vehicles. This innovative technology is a game-changer, optimizing production processes, minimizing errors, and streamlining the supply chain, leading to heightened operational efficiency and increased customer satisfaction. With these advancements, General Motors is poised to make a significant impact in the automotive industry, setting new standards for excellence and innovation.

Tesla, a leading force in the electric vehicle sector, has revolutionized its manufacturing operations through the integration of RFID technology. Strategically placed RFID tags now play a crucial role in tracking and overseeing the seamless movement of components and parts across the production process. This groundbreaking implementation brings forth a myriad of advantages, including improved inventory management, heightened traceability, and enhanced manufacturing efficiency. Tesla’s adept utilization of RFID technology empowers precise identification and retrieval of components, effectively curbing production delays and magnifying productivity. As a result, Tesla continues to cement its position as an industry pioneer, setting new benchmarks for the future of electric vehicles.

Nissan leverages RFID technology to streamline its assembly process by precisely matching components with vehicle configurations. The integration of RFID tags within different parts facilitates the retrieval of crucial information about the vehicle’s specifications and customization choices. As the vehicle advances through the assembly line, RFID readers swiftly identify the necessary components and validate their compatibility with the designated configuration. This meticulous process guarantees precise assembly, minimizes errors, and empowers efficient customization aligned with customer preferences. By harnessing RFID technology, Nissan optimizes its production line, ensuring accurate and seamless assembly while accommodating diverse customer needs and preferences. The utilization of RFID technology not only enhances efficiency but also enables a more personalized and tailored manufacturing experience.

Magna International, a leading automotive supplier, has wholeheartedly adopted UHF RFID technology in its electric vehicle manufacturing processes. The incorporation of UHF RFID tags serves as a crucial element in monitoring and tracing the movement of components, tools, and equipment within their production facility. This implementation brings about streamlined inventory management, reducing the chances of loss or misplacement of items, thereby greatly boosting overall productivity. With the power of UHF RFID technology at their disposal, Magna International maintains an uninterrupted workflow and exerts precise control over their manufacturing operations. Their commitment to this innovative solution ensures operational excellence in the automotive industry.

Ford Motor Company has successfully integrated UHF RFID technology into its electric vehicle production processes, enhancing efficiency and precision. Through the use of RFID tags, the company can track and trace parts and components throughout the entire assembly journey. This implementation offers immediate access to inventory information, resulting in improved quality control and a smoother production workflow. By leveraging UHF RFID technology, Ford ensures effective inventory management, minimizing errors and optimizing productivity in their electric vehicle manufacturing operations. This technological integration represents a remarkable stride forward in their manufacturing capabilities, empowering them to meet customer demands with heightened accuracy and effectiveness.

Implementing UHF RFID technology in BMW Group’s electric vehicle manufacturing processes brought significant advantages. The automation of component tracking and sequencing on the assembly line improved efficiency, reducing errors and assembly times. Real-time inventory data enhanced accuracy, optimizing supply chain operations and minimizing shortages or excess inventory. Detailed manufacturing data captured by RFID enabled proactive quality control, resulting in higher product quality, reduced defects, and increased customer satisfaction. The RFID-based traceability system streamlined recall management, after-sales service, and warranty tracking, fostering customer trust and loyalty. Leveraging UHF RFID technology enabled BMW Group to excel operationally, meeting the rising demand for electric vehicles while upholding production standards and customer satisfaction.

GAO RFID Systems & Hardware for the Electric Vehicle Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including electric vehicle manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including electric vehicle manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including electric vehicle manufacturing:

Gen2 UHF 902-928 MHz Passive RFID Readers

Gen 2 UHF 865-868 MHz Passive RFID Readers

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including electric vehicle manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including electric vehicle manufacturing:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including electric vehicle manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- UHF 860-960 MHz RFID Modules – GAO RFID Inc.

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in electric vehicle manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Battery Assembly Equipment: Specialized machinery for assembling and testing electric vehicle batteries.

- Electric Motor Manufacturing Equipment: Equipment used for manufacturing electric motors, including winding machines and motor testing equipment.

- Power Electronics Manufacturing Equipment: Equipment for manufacturing and testing power electronics components like inverters and converters.

- Charging Infrastructure Manufacturing Equipment: Machinery for manufacturing charging connectors, cables, and charging station components.

- Body and Chassis Manufacturing Equipment: Equipment like robotic welders and assembly lines for modifying body and chassis structures of electric vehicles.

- High-Voltage Cable Manufacturing Equipment: Specialized equipment for manufacturing and testing high-voltage cables used in electric vehicles.

- Battery Management System (BMS) Manufacturing Equipment: Machinery for manufacturing battery management systems, including circuit board assembly machines and testing equipment.

- Testing and Quality Control Equipment: Equipment for rigorous testing and quality control processes of electric vehicle components.

- Automation and Robotics Systems: Robotic systems used for automated tasks such as assembly, welding, and painting in electric vehicle manufacturing.

- Environmental Control Systems: Specialized systems for maintaining optimal conditions like temperature and humidity in electric vehicle manufacturing facilities.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Electric Vehicle Manufacturing Extensively

GAO’s products and technologies have helped its customers in the electric vehicle manufacturing industry to achieve success in unsustainable mobility, electrification, battery technology, autonomous driving, connected vehicles, vehicle-to-grid (V2G), range anxiety, fast charging, energy storage, regenerative braking.

GAO RFID Inc. has served many customers in the electric vehicle manufacturing, including its various divisions such as:

- Battery Manufacturing: Production of high-capacity lithium-ion batteries, the key component in electric vehicles, responsible for storing and supplying power.

- Electric Motor Manufacturing: Manufacture of electric motors that drive the wheels of electric vehicles, providing efficient and reliable propulsion.

- Charging Infrastructure: Development and deployment of charging stations and networks to support convenient and accessible recharging of electric vehicles.

- Power Electronics: Design and manufacture of electronic systems that control the flow of electricity in electric vehicles, including inverters, converters, and controllers.

- Vehicle Integration: Integration of various electric vehicle components, such as batteries, motors, and power electronics, into a cohesive and functional electric vehicle system.

- Lightweight Materials: Utilization of lightweight materials, such as aluminum and carbon fiber, to reduce the weight of electric vehicles and enhance energy efficiency.

- Software and Connectivity: Development of software systems that enable connectivity, data analysis, and enhanced functionalities in electric vehicles, including infotainment and autonomous driving capabilities.

- Sustainable Manufacturing: Implementation of environmentally friendly manufacturing processes and practices to reduce the carbon footprint and enhance sustainability in electric vehicle production.

- Research and Development: Continuous exploration and innovation in electric vehicle technologies, including advancements in battery chemistry, motor efficiency, and overall vehicle performance.

- Supply Chain and Logistics: Management of the complex supply chain network involved in sourcing, transporting, and delivering electric vehicle components and assemblies.

Here are some of the leading companies in the electric vehicle manufacturing industry

Tesla Inc.

Tesla Inc.

General Motors Company

General Motors Company

Ford Motor Company

Ford Motor Company

Rivian Automotive LLC

Rivian Automotive LLC

Proterra Inc.

Proterra Inc.

Byton Ltd.

Byton Ltd.

Lucid Motors Inc.

Lucid Motors Inc.

Fisker Inc.

Fisker Inc.

Motors Corp.

Motors Corp.

NIO Inc.

NIO Inc.

Faraday Future Inc.

Faraday Future Inc.

Nikola Corporation

Nikola Corporation

Workhorse Group Inc.

Workhorse Group Inc.

Canoo Inc.

Canoo Inc.

Bollinger Motors

Bollinger Motors

Karma Automotive

Karma Automotive

Arrival Ltd.

Arrival Ltd.

Atlis Motor Vehicles

Atlis Motor Vehicles

ElectraMeccanica Vehicles Corp.

ElectraMeccanica Vehicles Corp.

Lion Electric Company

Lion Electric Company

Electrovaya Inc.

Electrovaya Inc.

Ballard Power Systems Inc.

Ballard Power Systems Inc.

GreenPower Motor Company Inc.

GreenPower Motor Company Inc.

TM4 Inc.

TM4 Inc.