Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Home Textile Manufacturing Industry

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Home Textile Manufacturing Industry

GAO Makes Efforts to Satisfy Customers

GAO Has Served Home Textile Manufacturing Industry Extensively

Overview

The Home Textile Manufacturing Industry is a sector that encompasses the production of various textile products used in residential settings. These products include items such as bedding, towels, curtains, table linens, rugs, and other fabric-based goods that enhance the comfort, aesthetics, and functionality of homes. The industry involves several stages of production, from sourcing raw materials like cotton, linen, polyester, and various blends, to processes like weaving, knitting, dyeing, printing, and finishing.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the Home Textile Manufacturing Industry to improve their work processes, their operations, and productivity by better management of their staff, materials, and operational equipment such as RFID technology, BLE technology, IoT technology, and drone technology.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the Home Textile Manufacturing Industry. Its sister company, GAO Tek Inc.

https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Home Textile Manufacturing Industry

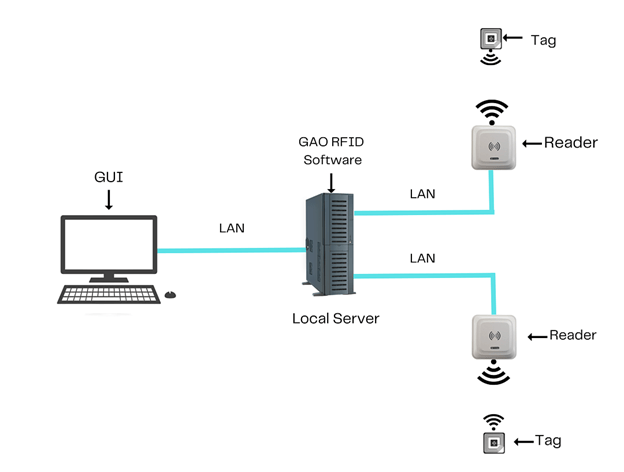

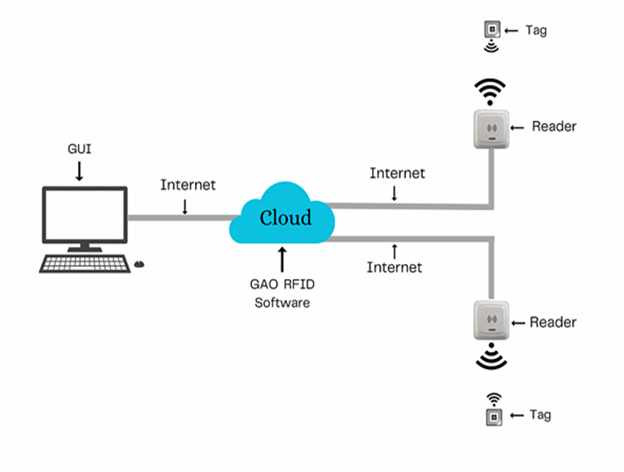

To satisfy its customers, GAO’s RFID or RFID Systems for Home Textile Manufacturing Industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for Home Textile Manufacturing Industry.

The above illustrates GAO system for Home Textile Manufacturing Industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Home Textile Manufacturing Industry:

- Inventory Management: RFID tags can be attached to raw materials, fabrics, and finished products. This enables real-time tracking of inventory levels, reducing stockouts and overstocking while optimizing supply chain operations.

- Production Tracking: RFID can track the movement of textiles through various production stages. This enhances visibility into the manufacturing process, allowing for better production planning and monitoring.

- Quality Control: RFID tags can store information about the materials used and the manufacturing processes applied to a textile product. This helps in quality control by ensuring that products meet specified standards and requirements.

- Asset Tracking: RFID tags can be affixed to equipment, machinery, and tools. This simplifies asset tracking, maintenance scheduling, and ensures that equipment is used efficiently.

- Work-in-Progress Monitoring: RFID technology can be used to monitor the progress of products as they move through different manufacturing stages. This aids in identifying bottlenecks and optimizing the production workflow.

- Authentication and Anti-Counterfeiting: RFID tags with unique identifiers can be used to authenticate the origin and authenticity of textile products, helping in the prevention of counterfeiting.

- Supply Chain Visibility: RFID enables real-time tracking of shipments, enhancing visibility into the movement of materials and products throughout the supply chain.

- Labor Management: RFID can track employee movements, help in managing labor resources, ensuring safety protocols, and optimizing workforce allocation.

- Warehouse Management: RFID facilitates automated identification and tracking of materials in warehouses, improving picking, packing, and shipping processes.

- Smart Shelves and Displays: Retailers can use RFID to create interactive and smart displays, enabling customers to access product information and enhancing the shopping experience.

GAO’s drone technologies find the following applications in the Home Textile Manufacturing Industry:

- Inventory Surveillance: Drones can conduct aerial surveys of warehouses and storage yards, providing a comprehensive view of textile inventory. This aids in accurate inventory management and reduces the time spent on manual counts.

- Facility Inspection: Drones can inspect manufacturing facilities, identifying maintenance needs, structural issues, and potential safety hazards. This proactive approach enhances operational safety and reduces downtime.

- Quality Control: Drones equipped with high-resolution cameras can capture detailed images of textile products during production. This enables quality control teams to identify defects and ensure products meet quality standards.

- Supply Chain Monitoring: Drones can monitor the movement of raw materials and finished products within the manufacturing facility and across the supply chain. This real-time visibility improves logistics management.

- Large-Scale Measurement: Drones can accurately measure large textile materials, such as rolls of fabric or carpets, for precise material estimation and order fulfillment.

- Site Planning and Design: Drones can provide aerial views of production areas, assisting in layout planning, equipment arrangement, and optimizing workflow.

- Environmental Compliance: Drones can monitor environmental conditions within and around manufacturing facilities, ensuring compliance with regulations and promoting sustainability practices.

- Marketing and Promotion: Drones can capture captivating aerial shots of textile products for marketing materials, enhancing product presentations and attracting potential customers.

- Security and Surveillance: Drones equipped with video cameras can enhance security by monitoring the premises, helping prevent unauthorized access and potential theft.

- Emergency Response: In the event of emergencies such as fires or accidents, drones can provide real-time aerial footage to emergency responders, aiding in swift and informed decision-making.

GAO’s IoT technologies, consisting of IoT sensors, sensor networks, and systems, find the following applications in the Home Textile Manufacturing Industry:

- Environmental Monitoring: IoT sensors can monitor temperature, humidity, and air quality in manufacturing facilities, ensuring optimal conditions for textile production and storage.

- Machine Health Monitoring: IoT sensors attached to machinery can collect real-time data on performance, allowing for predictive maintenance and reducing downtime.

- Energy Management: IoT sensors can track energy consumption patterns in manufacturing processes, enabling energy-efficient operations and cost savings.

- Predictive Analytics: IoT systems can analyze data from sensors to predict production bottlenecks, optimize workflow, and improve overall efficiency.

- Remote Equipment Control: IoT-enabled devices allow remote monitoring and control of machinery, enhancing operational flexibility and minimizing the need for physical presence.

- Real-time Tracking: IoT sensors can track the movement of materials and products within the manufacturing facility, improving inventory management and order fulfillment.

- Worker Safety: IoT sensors can monitor worker locations and conditions, ensuring compliance with safety protocols and providing assistance in case of emergencies.

- Waste Reduction: IoT systems can identify inefficiencies in production processes, helping to reduce material waste and improve resource utilization.

- Product Customization: IoT-enabled processes can gather customer preferences and tailor production, accordingly, allowing for greater personalization of textile products.

- Supply Chain Optimization: IoT sensors can monitor the status of shipments in real time, providing visibility into the movement of raw materials and finished products across the supply chain.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Home Textile Manufacturing Industry.

GAO RFID Inc. has helped many companies in Home Textile Manufacturing Industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6C

- EPC Gen2

- Bluetooth 4.0

- Bluetooth 5.0

- MQTT

- CoAP

- OPC UA

- ASTM F38

- ISO 21384

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Home Textile Manufacturing Industry such as:

Personnel Management:

- Employee Records and HR Management

- Compliance Training and Certification

- Performance Management

- Talent Acquisition

Equipment Management:

- IT Asset Management

- Office Equipment Inventory

- Physical Asset Tracking

- Maintenance and Repairs

Access Control:

- Physical Security

- Identity Verification

- Visitor Management

- Secure Data Access

Warehouse Management:

- Inventory Tracking

- Order Management

- Quality Control

Supply Chain Management:

- Supplier Management

- Logistics and Transportation

- Demand Forecasting

Other Applications:

- Compliance and Regulatory Reporting

- Data Security and Privacy

- Disaster Recovery and Business Continuity

- Document Management

- Customer Relationship Management (CRM)

- Fraud Detection and Risk Management

GAO has enabled its customers to make use of some of the leading software and cloud services in the Home Textile Manufacturing Industry. Below are some of popular software and cloud services in Home Textile Manufacturing Industry:

SAP SuccessFactors, Oracle Human Capital Management, Workday Human Capital Management, UltiPro, Kronos Workforce Central, Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), IBM Cloud, Salesforce Platform, SAP Extended Warehouse Management, Oracle Warehouse Management, Microsoft Dynamics 365 Supply Chain Management, Blue Yonder (formerly JDA) Warehouse Management, Manhattan Associates Warehouse Management, Blue Yonder Luminate Platform (formerly JDA Luminate), IBM Sterling Supply Chain Suite, Oracle Cloud Supply Chain Management, SAP Integrated Business Planning, Lectra Fashion PLM, Gerber Technology AccuMark, Tukatech TUKAcad, Optitex, EFI Optitex, Adobe Creative Cloud, Autodesk Fusion 360, Dropbox Business, Box Platform, and Slack.

GAO has worked with some of the leading technology companies in the Nursing Care Facilities Industry to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in Home Textile Manufacturing Industry:

SAP, Oracle, Microsoft, IBM, Salesforce, Intel, Texas Instruments, Qualcomm, Broadcom, NVIDIA, Siemens, Honeywell, Schneider Electric, ABB, Rockwell Automation.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in Home Textile Manufacturing Industry

In the context of the Home Textile Manufacturing Industry, RFID technology has been applied in various regions. In the USA, RFID-enabled inventory tracking streamlined production workflows, optimizing order accuracy and delivery times. This technology also facilitated quality control processes by ensuring material traceability and compliance. Personnel tracking using RFID improved labor allocation efficiency.

In Canada, RFID played a significant role in warehouse management, enhancing efficiency through precise inventory tracking. It was employed to monitor raw materials and finished products, leading to improved supply chain visibility and streamlined operations. In the realm of UHF RFID, implementations included efficient inventory management, quality assurance in production, and real-time visibility into distribution centers.

In Mexico, RFID technology improved inventory accuracy, automated production processes, and enabled real-time tracking of textile products throughout the supply chain. In Europe, RFID applications varied from interactive retail displays to efficient equipment tracking, streamlined warehouse operations, data-driven process optimization, and real-time monitoring of environmental conditions.

Many applications of RFID by GAO can be found here: Manufacturing Industry | RFID Solutions

Case Studies of IoT Applications

Below are some IoT application cases in Home Textile Manufacturing Industry

In the USA, IoT technology has been harnessed to optimize various aspects of the Home Textile Manufacturing Industry. Smart inventory management systems, empowered by IoT integration, have led to enhanced production efficiency by providing real-time insights into stock levels and reducing material wastage. Additionally, real-time machine health monitoring through IoT sensors has facilitated proactive maintenance, ensuring equipment remains operational and minimizing downtime. IoT-driven data analytics have played a pivotal role in improving supply chain visibility, enabling better decision-making and ultimately improving overall operational efficiency.

Moving to Canada, IoT applications have revolutionized the textile manufacturing landscape. Warehouse management has seen significant improvements through IoT-integrated systems that enhance material handling efficiency, reducing errors and delays. Real-time production tracking, enabled by IoT solutions, has brought greater visibility to manufacturing processes, leading to process optimization and timely order fulfillment. IoT-enhanced environmental monitoring has ensured compliance with regulations and sustainable practices, contributing to both operational efficiency and responsible production methods.

In Mexico, IoT solutions have made substantial contributions to the Home Textile Manufacturing Industry. IoT-enabled inventory tracking has streamlined material flow, resulting in improved order fulfillment processes and reduced delays. Real-time production monitoring and control have increased manufacturing efficiency by providing immediate insights into production progress and bottlenecks. IoT-driven predictive maintenance practices have reduced equipment downtime, increased productivity and optimized maintenance schedules. Moreover, the integration of IoT into supply chain management has enhanced logistics, ensuring timely deliveries and a smoother overall supply chain process.

In Europe, IoT applications have transformed various aspects of the Home Textile Manufacturing Industry. IoT sensors integrated into retail displays have created interactive customer engagement experiences, enhancing product presentation and customer interaction. Through data-driven process optimization using IoT analytics, operational efficiency has been maximized, leading to reduced waste and improved resource utilization. Real-time equipment tracking and monitoring have contributed to workforce safety by providing insights into equipment performance and potential hazards. Sustainability efforts have been bolstered by IoT-enabled practices, ensuring responsible resource consumption and waste reduction. Additionally, IoT-integrated warehouse management systems have improved order accuracy and fulfillment speed, enhancing overall customer satisfaction.

Case Studies of Drone Applications

Below are some drone application cases in Home Textile Manufacturing Industry

In the USA, drones have become instrumental in enhancing the operations of the Home Textile Manufacturing Industry. A prominent textile manufacturer utilized drones for comprehensive aerial surveys of their production facilities, providing valuable insights into factory layouts. This data-driven approach enabled the optimization of equipment placement, contributing to improved production workflows. Drones were also employed to monitor outdoor inventory yards, offering real-time visibility into material stocks and ensuring efficient space utilization. Additionally, a US-based textile company adopted an innovative strategy, utilizing drones to capture high-resolution images of their product line for marketing purposes. This initiative led to visually engaging product presentations and heightened customer engagement.

Moving to Canada, drones have revolutionized the way textile manufacturers approach facility management. A textile manufacturing company embraced drones for routine inspections of their premises, identifying maintenance needs and ensuring structural integrity. By employing drones to conduct aerial surveys of expansive warehouse spaces, another Canadian textile manufacturer gained valuable insights into material storage optimization, enhancing inventory management efficiency.

In Mexico, drones have found diverse applications within the Home Textile Manufacturing Industry. A textile manufacturer leveraged drones for outdoor surveillance of their manufacturing premises, bolstering security measures and deterring unauthorized access. Environmental monitoring and compliance enforcement were also significantly improved through drone technology, ensuring adherence to regulatory standards and sustainable practices.

In Europe, drones have played a pivotal role in optimizing various aspects of textile manufacturing. A European industry leader integrated drones for real-time monitoring of manufacturing processes, providing visual insights that contributed to enhanced production efficiency. Additionally, drones were harnessed for site planning and design, aiding in layout optimization and equipment arrangement at a textile manufacturing company. These case studies collectively underscore the transformative impact of drones on the Home Textile Manufacturing Industry, offering innovative solutions for improved operations and resource utilization.

GAO RFID Systems & Hardware for Home Textile Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Home Textile Manufacturing Industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the Home Textile Manufacturing Industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Home Textile Manufacturing Industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Home Textile Manufacturing Industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Home Textile Manufacturing Industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Home Textile Manufacturing Industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Module

- Find Your 13.56 MHz High Frequency RFID Module

- Find Your 125 kHz RFID Reader Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in Home Textile Manufacturing Industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include special equipment used by the Home Textile Manufacturing Industry, such as weaving machines, knitting machines, cutting tables, sewing machines, embroidery machines, printing machines (screen, digital, etc.), finishing equipment (calendars, compactors, etc.), dyeing machines, looms, inspection and quality control machines, fabric spreading machines, material handling equipment (conveyors, forklifts, etc.), packaging and labeling machines, material cutting equipment (die cutters, laser cutters, etc.), CNC machines for fabric manipulation, rollers and winding machines, textile testing equipment (strength, color fastness, etc.), heat press machines, quilting machines, and automatic garment folding machines.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Home Textile Manufacturing Industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe: Services

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Home Textile Manufacturing Industry we have worked with to serve our joint customers:

- TechIntegrate Solutions

- InnovateIT Consulting

- TextileTech Integrators

- NexaTech Services

- FabricIT Consultants

- Seamless Systems

- TextileTech Dynamics

- ProTech Integration

- WeaveConnect Solutions

- IntegraText IT Services

- PrecisionTech Consulting

- WarpWeave Technologies

- IntelliTex Integration

- CloudFabric Consultants

- ThreadTech Solutions

GAO Has Served Home Textile Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in the Home Textile Manufacturing Industry to achieve success in various trends and buzzwords, such as sustainable manufacturing, smart textiles, Industry 4.0, digital transformation, automation, supply chain optimization, personalization, IoT integration, data analytics, circular economy, eco-friendly fabrics, smart fabrics, AI and machine learning, cloud computing, and predictive maintenance.

GAO RFID Inc. has served many customers in Home Textile Manufacturing Industry, including its various divisions such as

- Fabric Weaving and Knitting: This division focuses on creating various types of textile fabrics by weaving or knitting threads together, forming the foundation of textile products.

- Textile Printing and Dyeing: This sub-industry involves applying color and designs to textiles through techniques like dyeing, printing, and other surface embellishments.

- Apparel Manufacturing: This division centers on producing clothing items made from textile materials, encompassing everything from casual wear to formal attire.

- Bedding and Linen Production: This sub-industry specializes in manufacturing bed linens, sheets, pillowcases, and other textile products related to bedding and interior decor.

- Upholstery and Furniture Fabrics: Focused on producing textiles for upholstery, this division provides fabrics that cover furniture, enhancing both comfort and aesthetics.

- Technical Textiles: Covering diverse applications, this sub-industry involves creating textiles for specialized functions like geotextiles for construction or medical textiles for healthcare applications.

- Textile Accessories and Trimmings: This division focuses on crafting smaller textile items, such as ribbons, lace, and other decorative elements used for embellishing various products.

- Home Textile Export and Distribution: This sub-industry involves the export, import, and distribution of home textile products across national and international markets.

- Textile Research and Innovation: Centered on advancements, this division delves into research and development to enhance manufacturing processes, materials, and product functionalities.

- Sustainable Textile Production: Focused on eco-conscious practices, this sub-industry prioritizes environmentally friendly methods in all stages of textile manufacturing, from sourcing to production.

GAO’s technologies enable its customers in the Home Textile Manufacturing Industry to effectively track their workforces such as weavers, knitters, printers, sewers, inspectors, and supervisors. Additionally, GAO’s solutions also help track common operational equipment including weaving machines, knitting machines, cutting tables, sewing machines, embroidery machines, printing machines, finishing equipment, dyeing machines, looms, inspection systems, fabric spreading machines, material handling equipment, packaging machines, material cutting equipment, and CNC machines.

Here are some of the leading companies in Home Textile Manufacturing Industry GAO has served:

- Parachute Home

- Brooklinen

- Casper

- Purple

- Nest Bedding

- Coyuchi

- West Elm

- Pottery Barn

- Williams Sonoma

- Restoration Hardware

- IKEA

- Target

- Walmart

- Amazon

- Wayfair

- Overstock

- HomeGoods

- TJ Maxx

- Marshalls

- Canadian Down & Feather

- DownEast Home

- Pendleton Woolen Mills

- Hudson’s Bay Company

- Winners

- Eleventh Floor Apparel

- Uptick Apparel

- King Garment Manufacturing Co

- Peros Garment Factory

- DC Fashion Ltd

- Shenzhou International Group Holdings

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com