Overview

The iron and steel mills and ferroalloy manufacturing industry involves the production of iron, steel, and alloys. It includes processes like smelting, refining, and shaping raw materials to create various products used in construction, manufacturing, and infrastructure development. The industry plays an important role in global economies, providing essential materials for a wide range of industries and applications.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the iron and steel mills and ferroalloy manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as blast furnaces, coke ovens, sinter plants, basic oxygen furnaces, electric arc furnaces, ladle furnaces, continuous casting machines, rolling mills, reheating furnaces, pickling lines, annealing furnaces, slitting machines, forging presses, heat treatment furnaces, coating lines, scrap shredders, pollution control systems, cranes, conveyors, and various specialized tools and instruments.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in the iron and steel mills and ferroalloy manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Iron and Steel Mills and Ferroalloy Manufacturing

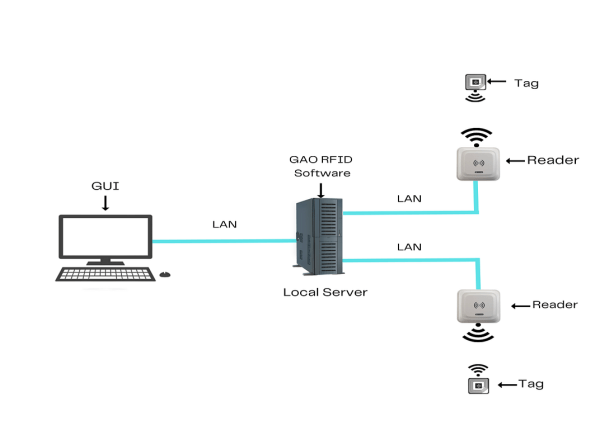

To satisfy its customers, GAO’s RFID or RFID Systems for the iron and steel mills and ferroalloy manufacturing are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the iron and steel mills and ferroalloy manufacturing with its software running on a local server.

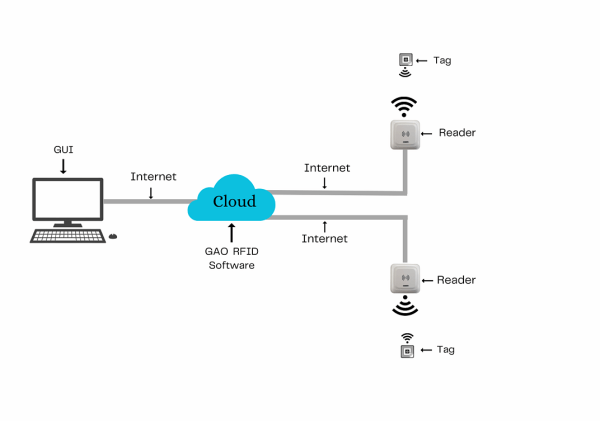

The above illustrates GAO system for the iron and steel mills and ferroalloy manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies bring the many benefits to the iron and steel mills and ferroalloy manufacturing industry:

- Enhanced Inventory Management: GAO’s RFID enables real-time tracking and monitoring of raw materials, finished products, and equipment, minimizing manual errors and ensuring accurate inventory data. For example, can quickly locate and identify specific steel coils within a vast storage facility, streamlining supply chain operations.

- Increased Operational Efficiency: Our RFID technology automates data capture and streamlines processes, reducing labor-intensive tasks and improving overall efficiency. For instance, can automatically record the movement of steel billets through various production stages, eliminating the need for manual data entry and saving time.

- Improved Asset Tracking: GAO RFID provides precise asset tracking capabilities, allowing to monitor the location and status of critical equipment, such as cranes, conveyors, and molds. By using RFID tags on these assets, can optimize maintenance schedules, minimize downtime, and enhance overall productivity.

- Streamlined Maintenance and Repairs: Our RFID technology can be integrated into maintenance processes to track the history, maintenance schedules, and repair records of machinery and equipment. This enables proactive maintenance planning, reduces unexpected breakdowns, and ensures optimal performance throughout the manufacturing process.

- Efficient Supply Chain Management: GAO RFID enables seamless integration with suppliers and logistics partners, facilitating real-time data exchange and enhancing supply chain visibility. For example, can track the movement of raw materials from suppliers to facility, allowing for accurate demand forecasting and efficient production planning.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to the iron and steel mills and ferroalloy manufacturing industry:

- Improved Safety Inspections: GAO’s RFID combined with drones can facilitate safety inspections of critical infrastructure and equipment. By equipping drones with RFID readers, it can perform automated inspections, ensuring that safety equipment, such as fire extinguishers or emergency exit signs, are in place and functioning properly.

- Enhanced Security Surveillance: GAO RFID with drones offers advanced security surveillance capabilities. By deploying drones equipped with RFID readers, it can monitor access points and detect any unauthorized movement of tagged assets, providing real-time alerts and enhancing overall facility security.

- Efficient Environmental Monitoring: Our RFID technology integrated with drones enables environmental monitoring within the manufacturing facility. Drones equipped with RFID readers and environmental sensors can collect data on parameters like air quality, temperature, and humidity, providing valuable insights for maintaining a safe and compliant working environment.

- Streamlined Maintenance and Repairs: Our RFID technology integrated with drones enables proactive maintenance by automatically identifying equipment requiring servicing or repairs. Drones equipped with RFID readers can swiftly scan RFID tags on machinery, triggering maintenance requests and generating work orders, reducing downtime and optimizing maintenance schedules.

Here are benefits of GAO’s IoT technologies to the iron and steel mills and ferroalloy manufacturing industry:

- Predictive Maintenance: GAO IoT enables predictive maintenance by collecting real-time data from sensors on equipment, detecting potential issues, and scheduling proactive repairs. For example, IoT system can monitor motor vibrations to identify abnormal patterns, alerting to imminent failures and avoiding costly downtime.

- Improved Energy Management: GAO’s IoT technology helps optimize energy usage by collecting data from sensors and meters, identifying areas of energy inefficiency, and implementing energy-saving measures. For instance, IoT system can monitor electricity consumption in different areas of the facility, enabling to identify and rectify wasteful practices.

- Remote Monitoring and Control: Our IoT system enables remote monitoring and control of manufacturing processes and equipment. With GAO IoT, can remotely access and manage machinery, adjust parameters, and monitor production performance from anywhere, increasing operational flexibility and reducing the need for on-site personnel.

- Quality Assurance: GAO IoT facilitates real-time monitoring of production parameters and quality metrics. By integrating sensors and IoT devices, can continuously monitor variables such as temperature, pressure, and humidity, ensuring that production conditions are within specified ranges and maintaining product quality standards.

- Data-driven Decision Making: Our IoT solution provides actionable insights through data analytics. By collecting and analyzing data from various sensors and devices, can identify trends, optimize processes, and make informed decisions to improve overall operational efficiency and productivity.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Iron and Steel Mills and Ferroalloy Manufacturing

GAO RFID Inc. has helped many companies in the iron and steel mills and ferroalloy manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6C: This international standard specifies the air interface protocol for RFID systems, ensuring compatibility and interoperability of RFID tags and readers.

- FCC Part 15: The Federal Communications Commission (FCC) regulates radio frequency devices in the United States, including RFID, BLE, and IoT devices, to ensure they operate within approved frequency ranges and power limits.

- Health Canada Guidelines: Health Canada provides guidelines for the safe and responsible use of radio frequency devices, including RFID, BLE, and IoT, to protect public health and minimize electromagnetic interference.

- NIST SP 800-53: The National Institute of Standards and Technology (NIST) in the U.S. provides guidelines for securing information systems and protecting sensitive data, including IoT devices used in industrial environments.

- CSA Z462: This Canadian standard addresses electrical safety requirements for workplaces, including those involving IoT devices, ensuring a safe working environment for employees.

- FAA Regulations: The Federal Aviation Administration (FAA) in the U.S. regulates the use of drones, including those equipped with RFID, BLE, and IoT technologies, ensuring safe and compliant operations in airspace.

- Transport Canada Regulations: Transport Canada sets regulations for the use of drones in Canada, including those equipped with RFID, BLE, and IoT, ensuring compliance with airspace restrictions and safety requirements.

- ANSI/RIA R15.06: This standard by the Robotic Industries Association (RIA) provides safety requirements for industrial robots used in manufacturing processes, including those integrated with IoT technologies.

- UL 2900: Underwriters Laboratories (UL) 2900 provides cybersecurity certification for IoT devices, ensuring they meet rigorous security standards and protect against potential cyber threats.

- OSHA Guidelines: The Occupational Safety and Health Administration (OSHA) in the U.S. provides guidelines for workplace safety, including the use of RFID, BLE, IoT, and drones, to prevent accidents and protect workers.

- IEC 62443: The International Electrotechnical Commission (IEC) 62443 standard focuses on industrial automation and control systems’ security, including IoT devices used in the manufacturing industry.

- Privacy Laws and Regulations: Both the U.S. and Canada have privacy laws and regulations, such as the General Data Protection Regulation (GDPR) in the European Union, which govern the collection, storage, and use of personal data obtained through RFID, BLE, IoT, and drone technologies.

US. Government Regulations

- Clean Air Act: This federal law sets standards to regulate air pollution emissions, including those produced by iron and steel mills and ferroalloy manufacturing, promoting environmental protection.

- Occupational Safety and Health Act: OSHA establishes workplace safety standards, ensuring the well-being of employees by addressing hazards and promoting safe practices within the industry.

- Environmental Protection Agency Regulations: The EPA enforces regulations on various aspects such as water and waste management, pollution control, and hazardous materials handling to safeguard the environment.

- Mine Safety and Health Administration Regulations: MSHA sets safety standards and conducts inspections in mines and mining-related facilities, including those involved in the extraction of raw materials for the industry.

- Resource Conservation and Recovery Act: RCRA governs the safe management and disposal of hazardous waste generated by iron and steel mills and ferroalloy manufacturing facilities, ensuring proper handling and disposal procedures.

Canadian Government Regulations

- Canadian Environmental Protection Act: CEPA regulates the use and release of harmful substances, ensuring environmental protection and promoting sustainable practices within the industry.

- Canada Labour Code: The Canada Labour Code establishes occupational health and safety standards, ensuring a safe working environment for employees in the iron and steel mills and ferroalloy manufacturing industry.

- Canadian Environmental Assessment Act: CEAA mandates environmental assessments for major industrial projects, including iron and steel mills and ferroalloy manufacturing facilities, to evaluate potential environmental impacts and mitigate risks.

- Canadian Minerals and Metals Plan: CMMP provides a strategic framework for the mining and minerals industry, including iron and steel mills and ferroalloy manufacturing, to promote sustainable development and competitiveness.

- Transportation of Dangerous Goods Act: TDGA regulates the transportation of hazardous materials, including those used in the iron and steel mills and ferroalloy manufacturing industry, ensuring safe handling, storage, and transportation procedures.

Occupational Safety and Health Administration (OSHA)

International Organization for Standardization

Canadian Centre for Occupational Health and Safety

Underwriters Laboratories

Federal Aviation Administration

National Institute of Standards and Technology

The Federal Communications Commission

The Federal Communications Commission

Environmental Protection Agency

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the iron and steel mills and ferroalloy manufacturing such as:

Personnel Management:

- Employee scheduling and shift management

- Training and skills management

- Performance evaluation and appraisal

- Labor tracking and productivity monitoring

Equipment Management:

- Asset tracking and maintenance scheduling

- Equipment performance monitoring

- Inventory management of spare parts

- Equipment calibration and testing

Access Control:

- Restricted access to high-risk areas

- Employee identification and authentication

- Visitor management and tracking

- Compliance with safety regulations

Warehouse Management:

- Inventory tracking and management

- Real-time stock monitoring

- Warehouse layout optimization

- Order fulfillment and picking processes

Supply Chain Management:

- Supplier relationship management

- Demand forecasting and planning

- Order management and tracking

- Logistics and transportation optimization

Other Applications:

- Quality control and defect tracking

- Environmental monitoring and compliance

- Energy management and efficiency

- Data analytics for process optimization

- Regulatory compliance and reporting.

GAO has enabled its customers to make use of some of leading software and cloud services in the iron and steel mills and ferroalloy manufacturing industry. Below are some of popular software and cloud services in the iron and steel mills and ferroalloy manufacturing industry:

- SAP SuccessFactors: SAP SuccessFactors offers cloud-based human capital management (HCM) software that covers personnel management, including employee scheduling, training management, and performance evaluation. Their solution helps streamline HR processes and improve workforce productivity.

- IBM Maximo: IBM Maximo is a leading enterprise asset management (EAM) software that assists in equipment management, including asset tracking, maintenance scheduling, and inventory management. It enables efficient maintenance practices and optimizes equipment performance.

- Oracle Warehouse Management: Oracle Warehouse Management provides comprehensive warehouse management capabilities, including inventory tracking, stock monitoring, and order fulfillment. It optimizes warehouse operations, enhances inventory accuracy, and improves overall supply chain efficiency.

- JDA Supply Chain Management: JDA Supply Chain Management software offers end-to-end supply chain solutions, including demand forecasting, order management, and logistics optimization. It helps streamline supply chain processes, reduce costs, and improve customer satisfaction.

- Infor CloudSuite Industrial (SyteLine): Infor CloudSuite Industrial, formerly known as SyteLine, is an industry-specific cloud-based solution that covers personnel management, equipment management, warehouse management, and supply chain management. It offers integrated functionalities to streamline operations and improve overall efficiency.

- Plex Manufacturing Cloud: Plex Manufacturing Cloud is a comprehensive cloud-based solution that encompasses personnel management, equipment management, warehouse management, and supply chain management. It provides real-time visibility, supports lean manufacturing, and ensures compliance.

- Microsoft Dynamics 365 Supply Chain Management: Microsoft Dynamics 365 Supply Chain Management offers a suite of tools for warehouse management, supply chain planning, and execution. It provides real-time insights, improves operational efficiency, and enables better decision-making.

- Epicor ERP: Epicor ERP is a robust enterprise resource planning software that includes modules for personnel management, equipment management, warehouse management, and supply chain management. It helps streamline processes and drives business growth.

- Infor LN: Infor LN is an enterprise resource planning software designed specifically for complex manufacturing industries like iron and steel mills. It covers various aspects, including personnel management, equipment management, warehouse management, and supply chain management.

- Fishbowl Inventory: Fishbowl Inventory is a popular inventory management software that provides warehouse management functionalities, including inventory tracking, stock monitoring, and order management. It integrates with other systems and enhances overall warehouse efficiency.

- Sage X3: Sage X3 is an enterprise resource planning solution that covers various functionalities, including personnel management, equipment management, warehouse management, and supply chain management. It offers comprehensive features to support the iron and steel industry.

- NetSuite Supply Chain Management: NetSuite Supply Chain Management is a cloud-based solution that offers advanced functionalities for supply chain management, including demand planning, procurement, and order fulfillment. It enables efficient supply chain operations and improves customer service.

SAP SuccessFactors

IBM Maximo

Oracle Warehouse Management

JDA Supply Chain Management

Infor CloudSuite Industrial (SyteLine)

Plex Manufacturing Cloud

Microsoft Dynamics 365 Supply Chain Management

Epicor ERP

Infor LN

Fishbowl Inventory

Sage X3

NetSuite Supply Chain Management

GAO has worked with some of the leading technology companies in the iron and steel mills and ferroalloy manufacturing in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the iron and steel mills and ferroalloy manufacturing industry:

- IBM (International Business Machines Corporation): IBM is a global technology company that provides various information technology services and solutions, including data analytics, cloud computing, and artificial intelligence. In the iron and steel industry, IBM’s technologies can be used for optimizing production processes and improving operational efficiency.

- Siemens: Siemens is a multinational conglomerate that operates in various sectors, including energy, industry, and healthcare. They offer automation and control systems for iron and steel mills, helping to optimize production, reduce energy consumption, and enhance safety.

- ABB (ASEA Brown Boveri): ABB is a leading provider of power and automation technologies. Their solutions for the iron and steel industry include electrical systems, robotics, and advanced process control systems, enabling manufacturers to achieve higher productivity and quality standards.

- Schneider Electric: Schneider Electric specializes in energy management and automation solutions. They offer integrated systems for monitoring and controlling processes in iron and steel mills, facilitating better resource utilization and improving overall operational performance.

- General Electric (GE): GE is a diversified technology and industrial company. They provide a range of solutions for the iron and steel industry, including power generation equipment, automation systems, and digital solutions for predictive maintenance and asset optimization.

- Honeywell: Honeywell is a multinational conglomerate that offers industrial automation and control systems. In the iron and steel manufacturing sector, Honeywell’s solutions can help improve plant safety, optimize production processes, and enhance energy efficiency.

- Rockwell Automation: Rockwell Automation specializes in industrial automation and information solutions. Their technologies can be applied in iron and steel mills to enable real-time data monitoring, predictive maintenance, and overall process optimization.

- Cisco Systems: Cisco is a multinational technology company known for its networking and telecommunications products. In the iron and steel industry, Cisco’s networking solutions can support seamless communication and data exchange between different systems and devices, enhancing operational efficiency and connectivity.

- Oracle: Oracle is a leading provider of database management systems and enterprise software solutions. Their offerings can be utilized in the iron and steel manufacturing industry for efficient data management, supply chain optimization, and predictive analytics.

- Microsoft: Microsoft is a multinational technology company offering a wide range of software and hardware products. Their technologies, such as cloud computing, data analytics, and artificial intelligence, can be leveraged by iron and steel manufacturers to drive innovation and improve operational processes.

- SAP: SAP is a software company that specializes in enterprise resource planning (ERP) systems. Their solutions can help iron and steel mills streamline their operations, manage resources effectively, and optimize supply chain management.

- Intel: Intel is a leading semiconductor manufacturer and technology company. Their high-performance computing solutions and processors can be utilized in the iron and steel industry for data-intensive applications, simulation, and modeling, enabling manufacturers to make informed decisions and improve productivity.

IBM (International Business Machines Corporation)

Siemens

ABB (ASEA Brown Boveri)

Schneider Electric

General Electric (GE)

Honeywell

Rockwell Automation

Cisco Systems

Oracle

Microsoft

SAP

Intel

Case Studies of RFID Applications

Below are some RFID application cases in the iron and steel mills and ferroalloy manufacturing industry:

ArcelorMittal Dofasco, a leading steel producer in Canada, implemented RFID technology to track and manage steel coils throughout their manufacturing process. RFID tags were attached to the coils, enabling real-time visibility of their location, inventory levels, and production status. This improved supply chain efficiency, reduced manual tracking errors, and enhanced overall operational performance.

Nucor Corporation, one of the largest steel producers in the United States, utilized RFID systems for their inventory management and material tracking processes. RFID tags were employed to monitor the movement of raw materials, work-in-progress items, and finished goods within their steel mills. This optimized inventory control, minimized stockouts, and facilitated accurate order fulfillment, resulting in streamlined operations and improved customer satisfaction.

Stelco Inc., a Canadian steel company, implemented RFID technology to enhance their asset management and maintenance practices. RFID tags were deployed on critical equipment and machinery, enabling automated tracking and monitoring of their usage, maintenance schedules, and performance metrics. This helped optimize maintenance processes, minimize equipment downtime, and improve overall operational efficiency.

United States Steel Corporation utilized UHF RFID systems to streamline their logistics and supply chain processes. UHF RFID tags were attached to shipping containers, allowing automated identification, tracking, and management of materials and products throughout their distribution network. This improved inventory visibility, reduced shipping errors, and enhanced overall supply chain efficiency.

Gerdau Long Steel North America, a leading steel producer in the United States, deployed UHF RFID systems to optimize their asset management and maintenance practices. UHF RFID tags were affixed to equipment and machinery, allowing automated tracking of maintenance schedules, performance data, and repair history. This enabled predictive maintenance, reduced equipment downtime, and improved overall operational efficiency.

Many applications of RFID by GAO can be found here.

GAO RFID Systems & Hardware for Iron and Steel Mills and Ferroalloy Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the iron and steel mills and ferroalloy manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the iron and steel mills and ferroalloy manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the iron and steel mills and ferroalloy manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the iron and steel mills and ferroalloy manufacturing:

- Gen 2 UHF 902-928 MHz RFID Tags

- Gen 2 UHF 865-868 MHz RFID Tags

- Semi Passive UHF Gen2 RFID Tags

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the iron and steel mills and ferroalloy manufacturing:

- HF 13.56 MHz Passive RFID Readers

- LF 134 kHz Passive RFID Readers

- LF 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the iron and steel mills and ferroalloy manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- UHF 860-960 MHz RFID Modules – GAO RFID Inc.

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the iron and steel mills and ferroalloy manufacturing:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Blast Furnaces: Blast furnaces are large, cylindrical structures used to smelt iron ore and other raw materials into molten metal by utilizing high temperatures and chemical reactions.

- Electric Arc Furnaces: Electric arc furnaces use electric arcs to melt scrap metal and other materials, allowing to produce steel and other alloys. They are more flexible and energy-efficient than traditional blast furnaces.

- Rolling Mills: Rolling mills are used to shape and form metal into various desired forms, such as sheets, plates, bars, and rods, through the application of pressure and controlled rolling processes.

- Ladles and Tundishes: Ladles and tundishes are containers used for transporting and pouring molten metal in steelmaking processes. They ensure safe and controlled transfer of liquid metal between different stages of production.

- Casting Machines: Casting machines are used to pour molten metal into molds, enabling the production of castings with specific shapes and dimensions. These machines can range from continuous casting systems to centrifugal casting machines.

- Heat Treatment Furnaces: Heat treatment furnaces are employed to subject metal products to controlled heating and cooling processes, such as annealing, tempering, and quenching, to achieve desired material properties.

- Welding Equipment: Welding equipment, including arc welders and gas welding systems, is utilized for joining metal components in fabrication and repair processes, ensuring structural integrity and quality.

- Conveyor Systems: Conveyor systems transport raw materials, finished products, and scrap metal throughout the manufacturing facility, providing efficient material handling and logistics support.

- Scrap Metal Shredders: Scrap metal shredders break down and shred large metal objects, such as automobiles or machinery, into smaller pieces, facilitating the recycling and reprocessing of metal scrap.

- Dust Collection Systems: Dust collection systems are used to capture and filter airborne particles and dust generated during various manufacturing processes, maintaining air quality and ensuring a safe working environment.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served Iron and Steel Mills and Ferroalloy Manufacturing Extensively

GAO’s products and technologies have helped its customers in the iron and steel mills and ferroalloy manufacturing industry to achieve success in automation, digital transformation, industry 4.0, smart factories, IoT, predictive maintenance, data analytics, robotics, supply chain optimization, additive manufacturing, sustainability, energy efficiency, circular economy, cloud computing, artificial intelligence, remote monitoring, real-time data, blockchain, wearables, and agile manufacturing.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the Iron and steel mills and ferroalloy manufacturing, including many in its various divisions such as

- Raw Material Extraction: Involves the mining and extraction of iron ore and other raw materials used in the production of iron and steel.

- Ironmaking: The process of converting iron ore into molten iron through blast furnaces or direct reduction techniques.

- Steelmaking: Transformation of molten iron into steel through various methods such as basic oxygen furnace (BOF) or electric arc furnace (EAF).

- Casting and Forming: Shaping molten steel into final products through casting processes like continuous casting or forming methods like rolling, forging, and extrusion.

- Finishing Operations: Involves processes like heat treatment, surface treatment, cutting, and machining to achieve desired properties and dimensions in steel products.

- Ferroalloy Manufacturing: Production of alloys containing iron and other elements like chromium, manganese, or silicon, used to impart specific properties to steel.

- Quality Control and Testing: Ensuring compliance with industry standards and specifications through rigorous testing, inspection, and quality control measures.

- Maintenance and Repair: Conducting regular maintenance, repairs, and refurbishment of plant equipment and machinery to ensure optimal performance and longevity.

- Supply Chain Management: Managing the flow of raw materials, components, and finished products, optimizing logistics, and coordinating with suppliers and customers.

- Environmental Compliance: Implementing measures to minimize environmental impact, including waste management, emissions control, and sustainable practices.

- Research and Development: Continuously exploring new technologies, materials, and processes to improve efficiency, product quality, and innovation in the industry.

- Safety and Occupational Health: Prioritizing worker safety, implementing safety protocols, and ensuring a healthy work environment to prevent accidents and occupational hazards.

Here are some of the leading companies in the Iron and steel mills and ferroalloy manufacturing industry:

Nucor Corporation

Nucor Corporation

United States Steel Corporation

Steel Dynamics Incorporated

AK Steel Holding Corporation

Cleveland-Cliffs Incorporated

Commercial Metals Company

Gerdau Ameristeel Corporation

Carpenter Technology Corporation

NLMK USA

Charter Steel

Universal Stainless & Alloy Products Incorporated

Big River Steel

TMK IPSCO

California Steel Industries

Republic Steel

Severstal North America

Schnitzer Steel Industries Incorporated

TimkenSteel Corporation

ArcelorMittal Dofasco

Stelco Holdings Incorporated

Algoma Steel Incorporated

Tenaris Global Services Canada Incorporated

EVRAZ Incorporated NA Canada

Nova Steel Incorporated