Overview

The maintenance, repair, and overhaul (MRO) services industry involves the maintenance, repair, and overhaul of various types of equipment, machinery, and infrastructure. It encompasses a wide range of activities, such as scheduled maintenance, corrective maintenance, and upgrades or modifications to improve performance. The MRO industry serves various sectors, including aviation, transportation, manufacturing, energy, and more, ensuring safe and reliable operation of assets and equipment.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the maintenance, repair, and overhaul (MRO) services to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as welding machines, plasma cutters, drills, saws, grinders, micrometers, dial indicators, torque wrenches, pressure testers, flow meters, vibration analyzers, and torches.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the maintenance, repair, and overhaul (MRO) services industry.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Maintenance, Repair, and Overhaul (MRO) Services

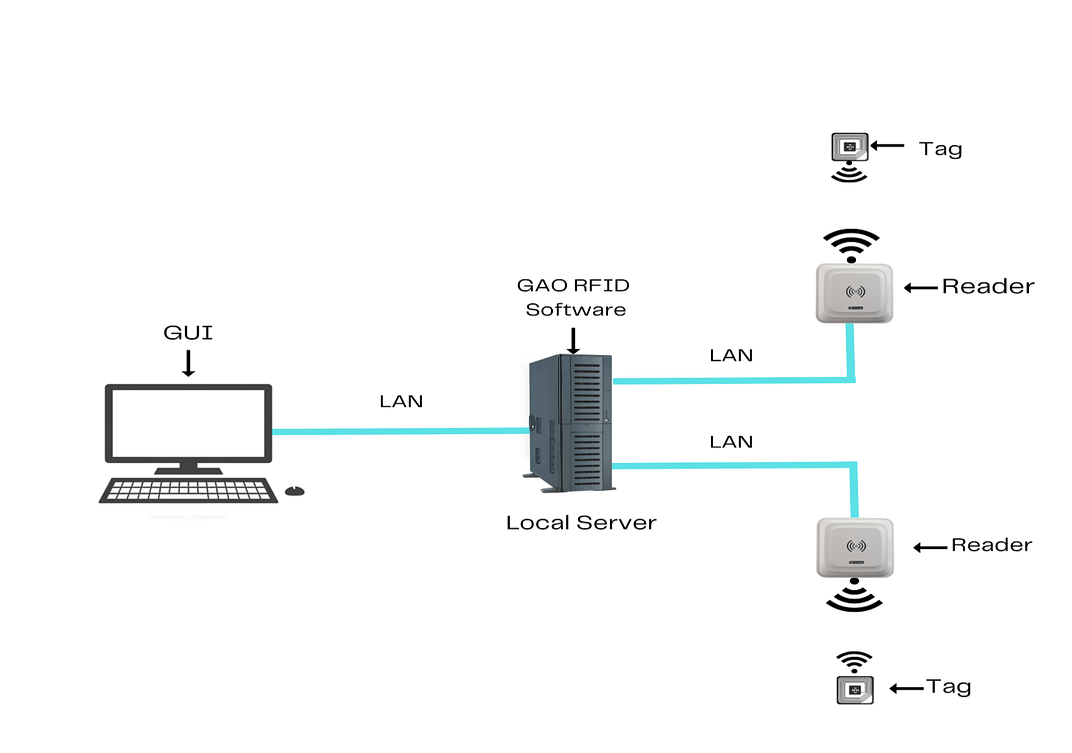

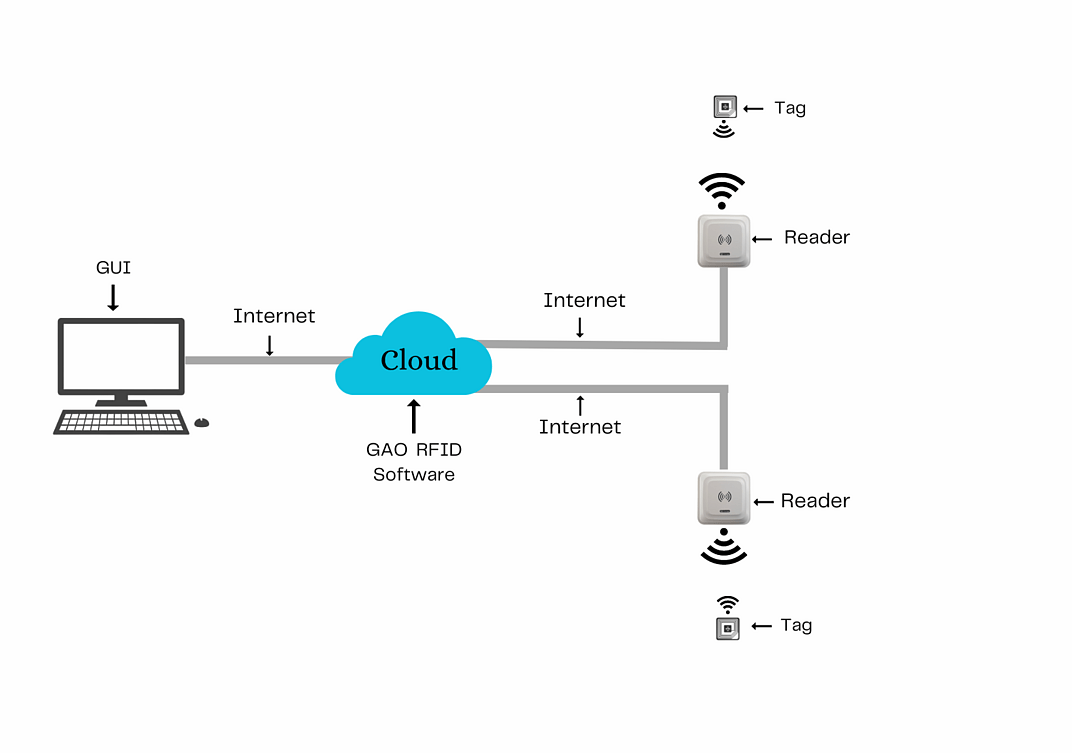

To satisfy its customers, GAO’s RFID or RFID Systems for the maintenance, repair, and overhaul (MRO) services industry are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the maintenance, repair, and overhaul (MRO) services industry with its software running on a local server.

GAO’s RFID technologies bring the many benefits to the maintenance, repair, and overhaul (MRO) services industry:

- Asset Tracking: GAO’s RFID technology can help track the location, movement, and status of assets, tools, and equipment, making it easier to manage and locate them when needed. This can lead to improved asset utilization and reduced inventory costs.

- Maintenance Management: GAO’s RFID tags can be attached to equipment and machinery to track usage and performance, helping maintenance teams to identify potential issues before they become critical. This can lead to increased uptime, improved safety, and reduced maintenance costs.

- Improved Safety: GAO’s RFID technology can be used to monitor safety compliance and identify potential hazards in the workplace. This can help prevent accidents and injuries, reducing downtime and liability.

- Inventory Management: Our RFID tags can be used to monitor inventory levels and track usage, helping to reduce waste and improve efficiency in the supply chain.

- Streamlined Operations: Our RFID technology can help automate and streamline many manual processes, such as asset tracking and inventory management, freeing up staff time and resources for more value-added activities.

- Better Data Analysis: Our RFID data can be analyzed to identify trends and patterns, providing insights into maintenance needs and performance metrics. This can help improve decision-making and drive continuous improvement.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within the maintenance, repair, and overhaul (MRO) services industry:

- Asset Tracking: GAO’s BLE beacons can be attached to equipment and machinery to track their location, movement, and status in real-time. This can help improve asset utilization and reduce inventory costs.

- Maintenance Management: GAO’s BLE sensors can be used to monitor equipment usage and performance, helping maintenance teams to identify potential issues before they become critical. This can lead to increased uptime, improved safety, and reduced maintenance costs.

- Improved Safety: GAO’s BLE technology can be used to monitor safety compliance and identify potential hazards in the workplace. This can help prevent accidents and injuries, reducing downtime and liability.

- Inventory Management: Our BLE beacons can be used to monitor inventory levels and track usage, helping to reduce waste and improve efficiency in the supply chain.

- Streamlined Operations: Our BLE technology can help automate and streamline many manual processes, such as asset tracking and inventory management, freeing up staff time and resources for more value-added activities.

- Increased Efficiency: Our BLE sensors can be used to track the location and movement of personnel and equipment, enabling better resource allocation and workflow management. This can help improve overall efficiency and productivity.

- Better Data Analysis: Our BLE data can be analyzed to identify trends and patterns, providing insights into maintenance needs and performance metrics. This can help improve decision-making and drive continuous improvement.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to the maintenance, repair, and overhaul (MRO) services industry:

- Enhanced Asset Tracking: GAO’s RFID technology can be used to track the location and status of assets, while drones can be used to capture real-time data on their condition and performance. This can provide a more comprehensive view of asset health and help identify potential issues before they become critical.

- Improved Safety: GAO’s Drones can be used to inspect equipment and infrastructure in hazardous or hard-to-reach areas, reducing the need for personnel to work in dangerous conditions. Our RFID technology can also be used to monitor safety compliance and identify potential hazards in the workplace.

- Faster Inspections: GAO’s Drones can cover large areas quickly and capture high-resolution images and videos that can be analyzed in real-time. This can speed up the inspection process and reduce downtime.

- Better Data Analysis: Our RFID and drone data can be analyzed to identify trends and patterns, providing insights into maintenance needs and performance metrics. This can help improve decision-making and drive continuous improvement.

- Improved Efficiency: GAO’s drones can be used to automate inspections and data collection. This can help reduce manual labor and improve overall efficiency.

- Cost Savings: The use of our RFID and drone technology can help reduce maintenance costs by identifying potential issues early and avoiding costly downtime. It can also help improve inventory management, reducing waste and excess inventory.

- Increased Productivity: GAO’s RFID and drone technology can help streamline operations and free up staff time for more value-added activities, improving overall productivity.

Here are benefits of GAO’s IoT technologies to the maintenance, repair, and overhaul (MRO) services industry:

- Predictive Maintenance: GAO’s IoT sensors can be used to monitor equipment and machinery in real-time, providing data on usage, performance, and condition. This data can be analyzed to identify potential issues before they become critical, enabling proactive maintenance and reducing downtime.

- Improved Asset Tracking: GAO’s IoT technology can be used to track the location and status of assets and equipment, making it easier to manage and locate them when needed. This can lead to improved asset utilization and reduced inventory costs.

- Better Data Analysis: Our IoT data can be analyzed to identify trends and patterns, providing insights into maintenance needs and performance metrics. This can help improve decision-making and drive continuous improvement.

- Enhanced Safety: Our IoT sensors can be used to monitor safety compliance and identify potential hazards in the workplace. This can help prevent accidents and injuries, reducing downtime and liability.

- Streamlined Operations: Our IoT technology can help automate and streamline many manual processes, such as asset tracking, inventory management, and maintenance scheduling, freeing up staff time and resources for more value-added activities.

- Increased Efficiency: Our IoT sensors can be used to track the location and movement of personnel and equipment, enabling better resource allocation and workflow management. This can help improve overall efficiency and productivity.

- Cost Savings: The use of GAO’s IoT technology can help reduce maintenance costs by identifying potential issues early and avoiding costly downtime. It can also help improve inventory management, reducing waste and excess inventory.

- Improved Customer Satisfaction: GAO’s IoT technology can help improve equipment uptime and reliability, ensuring that customers receive high-quality service and reducing the likelihood of service disruptions.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the maintenance, repair, and overhaul (MRO) services industry

GAO RFID Inc. has helped many companies in the maintenance, repair, and overhaul (MRO) services industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ATA Spec 2000: This standard provides guidelines for the implementation of RFID technology in the aerospace industry, including MRO services. It includes recommendations for data exchange and interoperability between different RFID systems.

- ASTM F2970: This standard provides guidelines for the use of RFID technology in the tracking and management of aircraft maintenance and repair activities. It includes recommendations for data exchange, interoperability, and data privacy and security.

- Bluetooth SIG (Special Interest Group): The Bluetooth SIG is responsible for the development and maintenance of Bluetooth standards, including those related to BLE technology. Many BLE devices used in the MRO industry conform to Bluetooth SIG standards.

- ISO 17387: This standard provides guidelines for the use of BLE technology in asset tracking and management, including in the MRO industry. It includes recommendations for data exchange, interoperability, and data privacy and security.

- FAA (Federal Aviation Administration) AC (Advisory Circular) 120-76D: This advisory circular provides guidance on the use of wireless technology, including BLE, in aircraft operations. It includes recommendations for data exchange, interoperability, and data privacy and security.

- ARINC (Aeronautical Radio, Inc.) Specification 628: This specification provides guidelines for the use of BLE technology in the aviation industry, including MRO services. It includes recommendations for data exchange, interoperability, and data privacy and security.

- ISO/IEC 30141: This standard provides a framework for IoT reference architecture and related terminology, including those related to MRO services. It helps ensure interoperability and compatibility between different IoT systems.

- OMA LightweightM2M: This standard provides a device management protocol for IoT devices, including those used in MRO services. It enables remote management and firmware updates for IoT devices, ensuring efficient maintenance and repair.

- JARUS (Joint Authorities for Rulemaking on Unmanned Systems): This organization provides guidelines for the safe and efficient integration of UAS into civil airspace, including those used in MRO services. It includes recommendations for UAS operations, safety, and certification.

- RTCA DO-362: This standard provides guidelines for the safety and performance of UAS, including those used in MRO services. It includes recommendations for system design, safety features, and testing.

US. Government Regulations

- Federal Aviation Administration (FAA) regulations: The FAA is responsible for regulating the aviation industry in the United States, including MRO services. FAA regulations cover a wide range of topics, including aircraft maintenance, repair, and overhaul procedures, safety standards, and certifications.

- Occupational Safety and Health Administration (OSHA) regulations: OSHA is responsible for ensuring workplace safety and health in the United States. OSHA regulations cover a wide range of topics related to MRO services, including hazardous materials handling, fall protection, and personal protective equipment.

- Environmental Protection Agency (EPA) regulations: The EPA is responsible for regulating environmental protection in the United States. EPA regulations cover a wide range of topics related to MRO services, including waste management, emissions control, and hazardous materials handling.

- Internal Revenue Service (IRS) regulations: The IRS is responsible for collecting taxes in the United States. IRS regulations cover a wide range of topics related to MRO services, including tax deductions, business expenses, and recordkeeping requirements.

Canadian Government Regulations

- Transport Canada regulations: Transport Canada is responsible for regulating transportation safety in Canada, including the aviation industry. Transport Canada regulations cover a wide range of topics related to MRO services, including safety standards, maintenance and inspection procedures, and certification requirements.

- Canadian Environmental Protection Act (CEPA): The CEPA is Canada’s primary environmental protection legislation. It covers a wide range of topics related to MRO services, including hazardous materials handling, waste management, and emissions control.

- Canadian Centre for Occupational Health and Safety (CCOHS) regulations: The CCOHS is responsible for ensuring workplace safety and health in Canada. CCOHS regulations cover a wide range of topics related to MRO services, including hazardous materials handling, fall protection, and personal protective equipment.

- Canadian Aviation Regulations (CARs): The CARs are a set of regulations that govern the aviation industry in Canada. They cover a wide range of topics related to MRO services, including maintenance and inspection procedures, aircraft certification, and safety standards.

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the maintenance, repair, and overhaul (MRO) services industry such as:

- Personnel management: This involves managing employees and contractors involved in MRO services. Applications include human resources management software for tracking employee information, scheduling software for managing shifts and assignments, and training and certification tracking software.

- Equipment management: This involves managing and tracking the maintenance and repair of equipment used in MRO services. Applications include asset management software for tracking equipment location, maintenance management software for scheduling and tracking maintenance tasks, and predictive maintenance software for identifying potential equipment failures.

- Access control: This involves managing access to restricted areas in MRO facilities. Applications include access control systems for securing entrances, card readers for controlling access to specific areas, and video surveillance systems for monitoring activity.

- Warehouse management: This involves managing the inventory and storage of parts and materials used in MRO services. Applications include inventory management software for tracking parts and materials, barcode scanning software for tracking inventory movement, and warehouse management software for optimizing storage and picking.

- Supply chain management: This involves managing the procurement and distribution of parts and materials used in MRO services. Applications include supply chain management software for tracking orders and deliveries, vendor management software for managing supplier relationships, and logistics management software for optimizing transportation and shipping.

- Other applications: Other applications for the MRO services industry include customer relationship management software for managing customer interactions, project management software for tracking and managing MRO projects, and quality management software for ensuring compliance with industry standards and regulations.

GAO has integrated its RFID, BLE, IoT and drone systems with some of leading software and cloud services in the maintenance, repair, and overhaul (MRO) services industry. Below are some of popular software and cloud services in the maintenance, repair, and overhaul (MRO) services industry:

- SAP ERP: SAP ERP is an enterprise resource planning software that includes modules for personnel management, equipment management, inventory management, and other functions. It is commonly used in MRO services companies.

- IBM Maximo: IBM Maximo is a comprehensive asset management software that includes modules for equipment maintenance, inventory management, and work order management. It is widely used in industries that rely heavily on equipment, including the MRO services industry.

- EZ Office Inventory: EZ Office Inventory is a cloud-based asset tracking software that includes modules for equipment maintenance, inventory management, and work order management. It is commonly used in industries that rely heavily on equipment, including the MRO services industry.

- Workday: Workday is a cloud-based human resources software that includes modules for personnel management, payroll management, and talent management. It is commonly used in MRO services companies.

- NetSuite: NetSuite is a cloud-based enterprise resource planning software that includes modules for personnel management, equipment management, inventory management, and other functions. It is widely used in MRO services companies.

- Blue Yonder: Blue Yonder is a cloud-based supply chain management software that includes modules for inventory management, demand planning, and order management. It is commonly used in the MRO services industry.

- SAP S/4HANA: SAP S/4HANA is an enterprise resource planning (ERP) software that includes modules for maintenance, repair, and overhaul (MRO) services. It provides features for managing work orders, maintenance schedules, inventory management, and other MRO-related tasks.

- IFS Applications: IFS Applications is an ERP software that includes modules for maintenance, repair, and overhaul (MRO) services, as well as supply chain management, finance, and customer management. It provides features for work order management, asset tracking, and inventory management.

- Infor EAM: Infor EAM (Enterprise Asset Management) is a software that provides features for managing maintenance, repair, and overhaul (MRO) services across various industries. It includes modules for inventory management, work order management, asset management, and predictive maintenance.

- Maintenix: Maintenix is a software designed specifically for the aviation industry, offering modules for maintenance, repair, and overhaul (MRO) services, as well as engineering, materials management, and compliance management. It provides features for inventory management, work orders, and compliance management.

- ServiceNow: ServiceNow is a cloud-based platform that provides features for IT service management, including asset management and maintenance management, which can be used to support MRO services. It provides features for work order management, asset tracking, and inventory management.

GAO has worked with some of the leading technology companies in the maintenance, repair, and overhaul (MRO) services industry in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the maintenance, repair, and overhaul (MRO) services industry:

- Cisco: Cisco provides a range of networking solutions, including IoT and data analytics that can be used to support MRO services. Cisco’s solutions can be used for equipment management, predictive maintenance, and supply chain management.

- Siemens: Siemens provides a range of technology solutions, including IoT and data analytics that can be used to support MRO services. Siemens’ solutions can be used for equipment management, predictive maintenance, and supply chain management.

- Oracle: Oracle provides a range of technology solutions, including cloud computing and data analytics that can be used to support MRO services. Oracle’s solutions can be used for equipment management, predictive maintenance, and supply chain management.

- SAP: SAP provides a range of technology solutions, including cloud computing and data analytics that can be used to support MRO services. SAP’s solutions can be used for equipment management, predictive maintenance, and supply chain management.

- Rockwell Automation: Rockwell Automation provides a range of electronic technologies, including control systems, sensors, and data analytics tools that can be used to support MRO services. Rockwell Automation’s solutions can be used for equipment monitoring, predictive maintenance, and asset tracking.

- General Electric: General Electric offers a range of electronic technologies, including sensors, wireless communication devices, and data analytics tools, that can be used to support MRO services. GE’s solutions can be used for equipment monitoring, predictive maintenance, and asset tracking.

- Emerson: Emerson provides a range of electronic technologies, including sensors, control systems, and data analytics tools, which can be used to support MRO services. Emerson’s solutions can be used for equipment monitoring, predictive maintenance, and asset tracking.

- ABB: ABB offers a range of electronic technologies, including sensors, control systems, and data analytics tools, which can be used to support MRO services. ABB’s solutions can be used for equipment monitoring, predictive maintenance, and asset tracking.

- Schneider Electric: Schneider Electric provides a range of electronic technologies, including sensors, control systems, and data analytics tools, that can be used to support MRO services. Schneider Electric’s solutions can be used for equipment monitoring, predictive maintenance, and asset tracking.

Case Studies of RFID Applications

Below are some RFID application cases in the maintenance, repair, and overhaul (MRO) services industry,

One case of RFID application in the maintenance, repair, and overhaul (MRO) services industry is the use of RFID technology to improve the tracking and management of aircraft parts during maintenance operations. This can include RFID tagging of components such as engines, landing gear, and avionics equipment, as well as tools and other equipment used during maintenance. For example, Delta Air Lines implemented an RFID system to track aircraft components and tools during maintenance operations at its Atlanta hub. Each component was assigned an RFID tag with a unique identifier, which was scanned at various points during the maintenance process to track its location and status. The system also tracked the use and location of tools, which helped to improve efficiency and reduce the risk of tools being misplaced or lost.

Another case of RFID application in the MRO services industry is the use of RFID technology for the tracking and management of industrial machinery and equipment. For example, Mitsubishi Electric implemented an RFID-based maintenance management system for its industrial equipment, including robots and other automation systems. Each piece of equipment was fitted with an RFID tag that contained information such as the equipment’s maintenance history, repair schedule, and usage data. When the equipment was brought in for maintenance, the RFID tag was scanned to retrieve this information, which helped to streamline the maintenance process and reduce downtime. The system also used real-time data from sensors in the equipment to monitor its condition and detect potential issues before they became critical.

Another case of UHF RFID application in the maintenance, repair, and overhaul (MRO) services industry is the use of UHF RFID tags and readers to track and manage aviation maintenance tools and equipment. For example, companies like Delta Air Lines and Southwest Airlines have implemented UHF RFID systems to improve their tool control and inventory management processes. Delta Air Lines uses UHF RFID tags to track and manage its maintenance tools and equipment. Each tool is affixed with a UHF RFID tag, which contains information such as the tool’s unique identifier and maintenance history. Delta uses handheld and fixed UHF RFID readers to scan the tags, allowing them to track the location and usage of each tool in real-time. The system also alerts maintenance personnel when a tool is missing or not returned to its proper storage location.

Another case of UHF RFID application in the maintenance, repair, and overhaul (MRO) services industry is the use of UHF RFID tags to track aircraft components in a repair and overhaul facility. For example, Delta TechOps, the maintenance division of Delta Airlines, implemented a UHF RFID system to track aircraft components in their maintenance and repair facility in Atlanta. The UHF RFID system includes fixed readers at various locations within the facility and RFID tags attached to each aircraft component. When a component enters or leaves a work area, the RFID tag is read by the fixed reader, and the component’s location is automatically updated in the system. This allows Delta TechOps to track the status and location of each component in real-time, reducing the time and effort required for manual tracking and improving overall efficiency in the maintenance and repair process.

GAO RFID Systems & Hardware for the Maintenance, Repair, and Overhaul (MRO) Services

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the maintenance, repair, and overhaul (MRO) services industry:

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the maintenance, repair, and overhaul (MRO) services industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the maintenance, repair, and overhaul (MRO) services industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the maintenance, repair, and overhaul (MRO) services industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the maintenance, repair, and overhaul (MRO) services industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including themaintenance, repair, and overhaul (MRO) services industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the maintenance, repair, and overhaul (MRO) services industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- Diagnostic Equipment: Tools and devices used for diagnosing faults and issues in machinery, vehicles, or equipment. This can include diagnostic scanners, oscilloscopes, engine analyzers, and fault code readers.

- Hand Tools: A wide range of hand tools is used for various maintenance and repair tasks, including wrenches, pliers, screwdrivers, hammers, sockets, and ratchets.

- Power Tools: Electric or pneumatic power tools used for faster and more efficient maintenance and repair work. These can include drills, impact wrenches, grinders, sanders, saws, and pneumatic nail guns.

- Welding and Soldering Equipment: Tools and machinery used for welding and soldering tasks, such as welding machines, soldering irons, torches, and plasma cutters.

- Lifts and Hoists: Equipment used to lift and support heavy vehicles, machinery, or components for inspection, maintenance, and repair. This includes vehicle lifts, hydraulic jacks, engine hoists, and cranes.

- Lubrication Equipment: Tools and systems used for lubricating machinery and equipment, including grease guns, oil dispensers, lubrication pumps, and lubricant storage and handling equipment.

- Cleaning Equipment: Tools and machines used for cleaning and degreasing components and machinery, such as pressure washers, steam cleaners, parts washers, and ultrasonic cleaners.

- Testing and Measurement Instruments: Equipment used for testing and measuring various parameters, including multimeters, pressure gauges, temperature sensors, vibration analyzers, and leak detectors.

- Inspection Equipment: Devices used for inspecting and assessing the condition of components and machinery, such as borescopes, thermal cameras, vibration meters, and alignment tools.

- Calibration Equipment: Instruments and tools used for calibrating and adjusting measurement equipment, ensuring accuracy and reliability. This includes calibration kits, reference standards, and calibration software.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Maintenance, Repair, and Overhaul (MRO) Services Extensively

GAO’s products and technologies have helped its customers in the maintenance, repair, and overhaul (MRO) services industry to achieve success in predictive maintenance, big data analytics, digital twins, augmented reality (AR) and virtual reality (VR), internet of things (IoT) sensors, robotics and automation, artificial intelligence (ai) and machine learning (MI), 3D printing and additive manufacturing, cloud computing and edge computing, block chain technology, cybersecurity and data privacy, sustainability and environmental responsibility, and wearable technology.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the maintenance, repair, and overhaul (MRO) services industry, including many in its various divisions such as

- Aviation MRO: Maintenance, repair, and overhaul of aircraft including inspections, component repair, engine maintenance, and avionics systems servicing.

- Automotive MRO: Maintenance and repair of vehicles including routine maintenance, mechanical repairs, bodywork, painting, and parts replacement.

- Industrial Machinery MRO: Maintenance, repair, and overhaul of industrial machinery and equipment used in manufacturing and construction, including inspections, preventive maintenance, repairs, and part replacements.

- Electronics MRO: Maintenance, repair, and overhaul of electronic equipment and systems, troubleshooting, component repair or replacement, software updates, and system testing.

- Power Generation MRO: Maintenance, repair, and overhaul of power generation equipment such as generators, turbines, and transformers, including inspections, testing, maintenance, and repairs.

- Marine and Offshore MRO: Maintenance, repair, and overhaul of ships, vessels, offshore structures, including inspections, hull repairs, engine maintenance, electrical systems servicing, and navigational equipment calibration.

- Rail MRO: Maintenance, repair, and overhaul of rail systems, locomotives, rolling stock, including track maintenance, rolling stock inspections and repairs, electrical systems servicing, and signaling equipment maintenance.

- Facility MRO: Maintenance, repair, and overhaul of building facilities including HVAC system maintenance, plumbing repairs, electrical systems servicing, and general facility maintenance.

Here are some of the leading companies in the maintenance, repair, and overhaul (MRO) services industry