Overview

Metal furniture manufacturing is the process of creating furniture items primarily from metal materials. It encompasses design, fabrication, and assembly stages. Designers and engineers conceive furniture concepts, considering aesthetics and functionality. Metal sheets or profiles are cut, shaped, and formed using techniques like welding and machining. Finishing processes such as sanding and coating enhance appearance and durability. Quality control ensures safety and structural integrity, while customization options cater to individual preferences. The industry ranges from sleek modern designs to rugged industrial styles, providing a diverse array of durable and versatile furniture options for residential and commercial settings. Sustainability initiatives often emphasize eco-friendly practices and materials, contributing to a dynamic sector within the furniture market.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the Metal Furniture Manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as storage tanks and containers for bulk chemicals, chemical pumps and transfer equipment, specialized handling equipment like forklifts and pallet jacks, safety equipment such as CNC plasma cutters and laser cutting machines, forming machines including hydraulic press brakes and roll bending machines, welding gear such as MIG and TIG welders, machining equipment like CNC machining centers and lathes, surface finishing tools such as sandblasting machines and powder coating booths, assembly tools, material handling equipment such as forklifts and conveyors, measurement tools, safety equipment, design and CAD/CAM software, material storage systems, environmental control equipment like dust collectors and fume extractors, and packaging and shipping equipment.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for metal furniture manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Metal Furniture Manufacturing

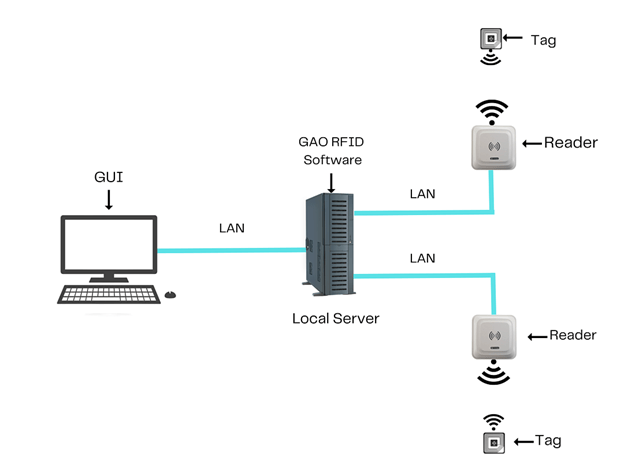

To satisfy its customers, GAO’s RFID or RFID Systems for Metal Furniture Manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for metal furniture manufacturing software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for Metal Furniture Manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for metal furniture manufacturing software running on a local server.

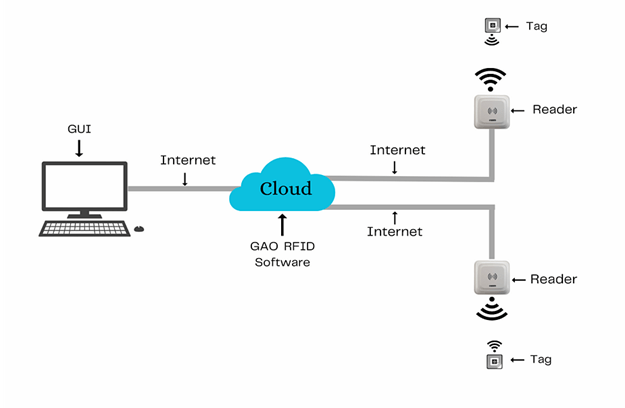

The above illustrates GAO system for metal furniture manufacturing with its software running in cloud.

The above illustrates GAO system for metal furniture manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in metal furniture manufacturing industry:

- Inventory Management: GAO RFID tags can be attached to metal furniture components and products to track their movement throughout the manufacturing process. This helps in real-time inventory management, reducing the risk of overstocking or understocking materials.

- Asset Tracking: GAO RFID tags can be used to monitor the location and status of manufacturing equipment, tools, and machinery, ensuring they are efficiently utilized and maintained.

- Quality Control: GAO RFID tags can store data related to the quality and specifications of metal materials and components. This information can be accessed quickly during quality control checks to ensure compliance with standards.

- Work-in-Progress (WIP) Tracking: GAO RFID technology can be employed to track the progress of furniture pieces as they move through different stages of production, providing visibility into manufacturing timelines.

- Production Traceability: GAO RFID tags can be used to record the history and manufacturing details of each furniture item, facilitating traceability in case of defects or recalls.

- Supply Chain Visibility: GAO RFID can enhance visibility across the supply chain by tracking the movement of raw materials, semi-finished products, and finished furniture items from suppliers to manufacturers and ultimately to customers.

- Tool Management: GAO RFID-enabled tool tracking systems ensure that tools are readily available when needed, reducing downtime and improving efficiency in metalworking processes.

- Maintenance and Repairs: GAO RFID can be used to schedule and track maintenance activities on manufacturing equipment and machinery, helping to prevent breakdowns and costly repairs.

- Security: RFID access control systems can restrict access to sensitive areas within the manufacturing facility, safeguarding valuable materials and designs.

- Shipping and Logistics: GAO RFID tags on finished furniture items assist in automating shipping and logistics processes, ensuring the right products are delivered to the correct destinations efficiently.

- Customer Service: GAO RFID can be integrated into products to provide customers with information about care instructions, warranties, and product details, enhancing the overall customer experience.

- Energy Management: GAO RFID can contribute to energy-efficient manufacturing by automating lighting, heating, and cooling systems based on the presence of workers or materials in specific areas.

- Worker Safety: GAO RFID-enabled badges or wearable devices can enhance worker safety by monitoring their location and alerting in case of emergencies.

- Production Analytics: GAO RFID data can be analyzed to identify production bottlenecks, improve workflow efficiency, and optimize manufacturing processes.

GAO’s drone technologies find the following applications in the Metal Furniture Manufacturing industry:

- Inventory Management: GAO Drones equipped with cameras and sensors can be used to conduct regular inventory checks of raw materials, work-in-progress, and finished products. This helps in maintaining accurate inventory records and optimizing stock levels.

- Site Surveys: GAO Drones can perform aerial surveys of manufacturing facilities, providing a comprehensive view of the layout, infrastructure, and potential areas for expansion or improvement.

- Quality Inspections: GAO Drones equipped with high-resolution cameras and sensors can perform detailed quality inspections of metal furniture components and finished products, identifying defects or imperfections that may be difficult to spot manually.

- Safety Inspections: GAO Drones can be used to inspect hard-to-reach or hazardous areas within the manufacturing facility, ensuring compliance with safety regulations and identifying potential safety hazards.

- Facility Maintenance: GAO Drones can monitor and inspect the condition of manufacturing equipment

- Security and Surveillance: GAO Drones equipped with cameras and thermal imaging technology can enhance security by patrolling manufacturing facilities and providing real-time surveillance to prevent unauthorized access and theft.

- Material Handling: GAO Drones with lifting capabilities can assist in moving heavy metal components and products within the manufacturing facility, reducing manual labor and improving efficiency.

- Environmental Monitoring: GAO Drones can monitor air quality, emissions, and environmental conditions in and around the manufacturing facility, ensuring compliance with environmental regulations.

- Workflow Optimization: GAO Drones can monitor the flow of materials and products within the manufacturing process, identifying bottlenecks and inefficiencies and suggesting workflow improvements.

- Transportation and Logistics: GAO Drones can be used to transport small parts or tools between different production areas, reducing the time and labor required for intra-facility transportation.

- Marketing and Promotion: GAO Drones can capture aerial footage and images of finished furniture products for marketing and promotional materials, providing unique and captivating visuals.

- Data Collection and Analysis: GAO Drones can collect data on various aspects of the manufacturing process, such as temperature, humidity, and machine performance, enabling data-driven decision-making and process optimization.

- Training and Simulation: GAO Drones can be used in training scenarios for employees, simulating real-life scenarios and emergency response situations.

- Remote Monitoring: Manufacturers can remotely monitor their production facilities through the use of d GAO rones, enabling real-time oversight and management of operations, even from a remote location.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the Metal Furniture Manufacturing industry:

- Machine Monitoring and Maintenance: GAO IoT sensors can be installed on manufacturing equipment to monitor their performance and detect signs of wear or malfunction. This data helps in scheduling preventive maintenance and reducing unplanned downtime.

- Inventory Management: GAO IoT sensors can track the location and quantity of raw materials, work-in-progress, and finished products in real-time. This enables accurate inventory control and minimizes the risk of stockouts or overstocking.

- Quality Control: GAO IoT devices can collect data on product quality and specifications during the manufacturing process. Deviations from quality standards can trigger alerts, enabling immediate corrective actions.

- Supply Chain Visibility: GAO IoT can provide real-time visibility into the movement of materials and components throughout the supply chain, from suppliers to manufacturing facilities and distribution centers.

- Energy Management: GAO IoT systems can optimize energy consumption by monitoring and controlling lighting, heating, and cooling systems based on occupancy and usage patterns.

- Asset Tracking: GAO IoT-enabled asset tracking systems can monitor the location and condition of tools, equipment, and materials, preventing loss or theft.

- Predictive Analytics: GAO IoT data can be used to develop predictive maintenance models, which forecast when equipment is likely to fail and recommend maintenance actions to avoid disruptions.

- Remote Monitoring: Manufacturers can remotely monitor production processes, equipment, and facility conditions using GAO IoT-connected sensors and cameras, allowing for real-time oversight and remote management.

- Worker Safety: GAO Wearable IoT devices can monitor worker safety by tracking vital signs, detecting hazardous conditions, and sending alerts in case of emergencies.

- Product Customization: GAO IoT-enabled machinery can facilitate product customization by automatically adjusting settings and configurations based on customer preferences or design specifications.

- Data Analytics: GAO IoT generates a wealth of data that can be analyzed to identify trends, inefficiencies, and opportunities for process optimization.

- Process Automation: GAO IoT can automate routine tasks and processes, improving overall manufacturing efficiency and reducing the need for manual intervention.

- Environmental Monitoring: GAO IoT sensors can track environmental conditions within the manufacturing facility, such as temperature, humidity, and air quality, ensuring compliance with regulatory standards.

- Maintenance Scheduling: GAO IoT data can help schedule maintenance tasks based on equipment usage and wear patterns, optimizing maintenance schedules for cost-effectiveness.

- Customer Insights: GAO IoT can collect data on how customers interact with furniture products, providing insights into usage patterns and preferences that can inform product design and marketing strategies.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Metal Furniture Manufacturing Industry

GAO RFID Inc. has helped many companies in Metal Furniture Manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- EPCglobal UHF Class 1 Gen 2

- ISO 18000 Series

- ISO 15693

- ISO 14443

- ISO 17367

- Bluetooth 4.0 and Later (Bluetooth SIG)

- GATT (Generic Attribute Profile)

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- OPC UA (Open Platform Communications Unified Architecture)

- Zigbee

- LoRaWAN (Long Range Wide Area Network

- FAA Part 107 (U.S. Federal Aviation Administration)

- ASTM F3322 (Standard Specification for UAS Remote ID)

- ISO 21384 (International Standard for Unmanned Aircraft Systems)

- RFID in Aerospace and Defense (DoD MIL-STD-129)

- Pharmaceutical Traceability (FDA Drug Supply Chain Security Act)

- Food Traceability (FDA Food Safety Modernization Act)

- Retail RFID Tagging (Retailer-Specific Mandates)

- FAA Part 107 (U.S. Federal Aviation Administration Regulations)

- National Regulations (Varies by Country)

- Local Municipal Regulations (Varies by Location)

Government Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- Environmental Protection Agency (EPA) Regulations

- Consumer Product Safety Commission (CPSC) Regulations

- Department of Commerce Regulations (e.g., Export Controls)

- Department of Transportation (DOT) Regulations (if applicable)

- Internal Revenue Service (IRS) Tax Regulations

- National Fire Protection Association (NFPA) Standards (e.g., NFPA 70 – National Electrical Code)

- Local Building Codes and Zoning Regulations

- State Labor and Employment Regulations (varies by state)

Canadian Government Regulations

- Canadian Centre for Occupational Health and Safety (CCOHS) Regulations

- Environment and Climate Change Canada Regulations

- Health Canada Regulations (e.g., Product Safety)

- Canadian Standards Association (CSA) Standards

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in metal furniture manufacturing such as:

Personnel Management Applications:

- Workforce Scheduling and Shift Management

- Employee Training and Certification Tracking

- Health and Safety Compliance Monitoring

- Employee Performance Evaluation and Management

Equipment Management Applications:

- Machinery Maintenance and Asset Tracking

- Tool Inventory and Calibration Management

- Equipment Utilization and Downtime Tracking

- Preventive Maintenance Scheduling

Access Control Applications:

- Secure Facility Access and Authentication

- Visitor Management and Access Logs

- Security Camera Monitoring and Surveillance

Warehouse Management Applications:

- Inventory Tracking and Management

- Receiving and Shipping Process Optimization

- Stock Replenishment and Demand Forecasting

- Warehouse Space Utilization Optimization

Supply Chain Management Applications:

- Supplier Relationship Management (SRM)

- Demand Planning and Forecasting

- Order Fulfillment and Tracking

- Supplier Performance Monitoring

Other Applications:

- Quality Control and Inspection

- Energy Management and Sustainability Tracking

- Customer Relationship Management (CRM)

- Product Lifecycle Management (PLM)

- Data Analytics and Reporting

- Regulatory Compliance Monitoring

- Customization and Personalization for Customers

- IoT Integration for Smart Furniture

- Marketing and Sales Analysis

- Financial Management and Cost Control

- Facility Layout Optimization

- Production Process Automation and Optimization

GAO has enabled its customers to make use of some of the leading software and cloud services in the Metal Furniture Manufacturing industry. Below are some of the popular software and cloud services in metal furniture manufacturing SAP SuccessFactors, Workday HCM, ADP Workforce Now, Oracle HCM Cloud, Kronos Workforce Central, IBM Maximo, Infor EAM, UpKeep, Fiix, Fleet Complete, Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform, and Salesforce. Access Control: HID Global’s EasyLobby, Brivo Access Control, Genetec Security Center, Kisi Cloud-Based Access Control. Warehouse Management: Fishbowl Warehouse, SkuVault, Logiwa WMS, PeopleVox. Supply Chain Management: SAP Integrated Business Planning, Oracle Supply Chain Management Cloud, Kinaxis RapidResponse, JDA Software, SAP S/4HANA, Oracle NetSuite, Infor CloudSuite Distribution, Epicor Prophet 21, Microsoft Dynamics 365 for Finance and Supply Chain Management, QuickBooks Commerce, TradeGecko, Zoho Inventory, Fishbowl Inventory, IBM Sterling Order Management, Amazon Web Services (AWS), Microsoft Azure, Google Cloud Platform, and Salesforce Commerce Cloud.

GAO has worked with some of the leading technology companies metal furniture manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in sub-industry Metal Furniture Manufacturing IBM, Oracle, SAP, Microsoft, Cisco Systems, Honeywell, Siemens, Emerson Electric, ABB Group, Schneider Electric, Rockwell Automation, Thermo Fisher Scientific, Dow, BASF, and 3M.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in metal furniture manufacturing industry.

In Canada, Teknion Corporation embedded RFID tags in metal components, resulting in improved inventory accuracy and increased productivity. This allowed for automated tracking and tracing throughout the production process, reducing manual errors and improving overall operational efficiency.

Grupo Industrial Saltillo in Mexico utilized RFID technology to optimize their supply chain. By implementing RFID tags, they were able to track raw materials, work-in-progress items, and finished products in real-time. This provided visibility into inventory levels, reduced lead times, and enhanced order fulfillment.

Similarly, Steelcase Europe integrated RFID tags into their metal furniture manufacturing operations. This allowed for accurate inventory counts, reducing stock discrepancies and improving overall production efficiency. The implementation of RFID technology in metal furniture manufacturing has proven to be beneficial, improving inventory management, reducing errors, and enhancing production processes.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in the metal furniture manufacturing industry.

In Canada, Teknion Corporation deployed IoT sensors throughout their metal furniture production line to collect data on temperature, humidity, and vibration. This data was analyzed in real-time to identify potential quality issues and optimize production parameters, leading to improved product quality and reduced waste.

Grupo Industrial Saltillo in Mexico leveraged IoT technology to enhance process automation and supply chain visibility. By utilizing IoT devices to monitor inventory levels, track shipments, and optimize logistics operations, they achieved improved inventory management, reduced lead times, and enhanced customer satisfaction.

Similarly, Steelcase Europe integrated IoT devices into their metal furniture manufacturing operations to enable smart factory capabilities. Real-time data on machine performance, energy consumption, and worker safety was collected and analyzed to optimize production processes, reduce energy waste, and ensure a safe working environment.

Case Studies of Drone Applications

Below are some drone application cases in the metal furniture manufacturing industry.

Steelcase Inc. in the USA implemented drones for aerial inventory tracking, enabling efficient and accurate stock counts. This streamlined warehouse operations, reduced manual labor, and improved inventory accuracy.

In Canada, Teknion Corporation utilized drones equipped with high-resolution cameras for quality control and inspection processes. These drones captured detailed images of furniture components, allowing for remote inspection and identification of defects. This resulted in improved product quality and reduced inspection time.

Grupo Industrial Saltillo in Mexico integrated drones into their metal furniture manufacturing facilities to optimize logistics and warehouse management. Drones were used for inventory tracking, locating specific products within the warehouse, and monitoring stock levels. This improved inventory accuracy, reduced search time, and enhanced overall warehouse efficiency.

Similarly, Steelcase Europe in Europe implemented drone technology for safety and security purposes. Drones equipped with thermal imaging cameras were used to monitor and inspect equipment, identify potential safety hazards, and ensure compliance with safety regulations. This led to improved worker safety and enhanced security measures.

GAO RFID Systems & Hardware for Metal Furniture Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including metal furniture manufacturing.

BLE (Bluetooth Low Energy)

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including metal furniture manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Metal Furniture Manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Metal Furniture Manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Metal Furniture Manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including metal furniture manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selectioon of high quality drones are offered:

The RFID systems by GAO are highly popular for clients in metal furniture manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include storage tanks and containers, chemical pumps and transfer equipment, forklifts and pallet jacks, safety equipment (e.g., protective clothing, gloves, respirators), labeling and packaging machinery, quality control and testing equipment, computer systems for inventory management, transportation vehicles (e.g., trucks, tankers), climate-controlled storage warehouses, and specialized handling equipment for hazardous materials.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Metal Furniture Manufacturing and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in metal furniture manufacturing we have worked with to serve our joint customers:

- Accenture

- Deloitte

- Capgemini

- Cognizant

- IBM Global Business Services

- PricewaterhouseCoopers (PwC)

- Wipro

- Ernst & Young (EY)

- Infosys

- DXC Technology

- HCL Technologies

- Tata Consultancy Services (TCS)

- Atos

- NTT Data

- CGI Group

- Compugen Inc.

- Long View Systems

- Scalar Decisions

- CDW Canada

- Softchoice

- OnX Enterprise Solutions

- Sierra Systems (an NTT Data Company)

- Bell Canada

- Insight Canada

- TeraMach Technologies

- Cogeco Peer 1

- Scalar Decisions

- OnX Enterprise Solutions

- Compufix Solutions

- PCL Constructors Canada Inc. (PCL)

- Sopra Steria

- TietoEVRY

GAO Has Served Metal Furniture Manufacturing Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in Metal Furniture Manufacturing Industry to achieve success in Sustainable Manufacturing, Customization, Industry 4.0, Lean Manufacturing, Ergonomics, Digitalization, Lightweight Materials, Circular Economy, Smart Furniture, Collaborative Design.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in metal furniture manufacturing, including many in its various divisions such as:

- Residential Furniture Manufacturing: This division focuses on the production of metal furniture for residential use, such as metal beds, dining sets, chairs, tables, and cabinets.

- Commercial Furniture Manufacturing: This sub-industry specializes in manufacturing metal furniture for commercial spaces, including office furniture, hospitality furniture, restaurant furniture, and retail displays.

- Institutional Furniture Manufacturing: This division caters to the production of metal furniture for institutional settings, such as schools, universities, hospitals, government offices, and public spaces. It includes items like metal desks, chairs, lockers, and storage units.

- Outdoor Furniture Manufacturing: This sub-industry focuses on the production of metal furniture designed for outdoor use, such as metal patio sets, garden furniture, outdoor seating, and metal structures like pergolas and gazebos.

- Industrial Furniture Manufacturing: This division specializes in manufacturing metal furniture for industrial settings, including workbenches, storage racks, industrial shelving, and specialized metal furniture for factories and warehouses.

- Hospitality Furniture Manufacturing: This sub-industry caters to the production of metal furniture for the hospitality sector, including metal furniture for hotels, resorts, restaurants, bars, and cafes.

- Healthcare Furniture Manufacturing: This division focuses on manufacturing metal furniture specifically designed for healthcare facilities, including metal hospital beds, medical carts, waiting room furniture, and examination tables.

- Educational Furniture Manufacturing: This sub-industry specializes in producing metal furniture for educational institutions, including metal desks, chairs, tables, and storage units for classrooms, libraries, and laboratories.

GAO’s technologies enable its customers in metal furniture manufacturing to effectively track their workforces such as sales representatives, product specialists, warehouse managers, logistics coordinators, chemical engineers, safety officers, quality control analysts, procurement specialists, inventory managers, customer service representatives, compliance officers, and supply chain managers effectively track operational assets such as storage tanks, chemical pumps, drum handling equipment, forklifts, pallet jacks, labeling machines, packaging machinery, conveyor systems, quality control and testing equipment, temperature and humidity sensors, RFID systems, inventory management software, safety showers and eyewash stations, hazmat storage cabinets, spill containment pallets, and transportation vehicles such as trucks and tankers.

Here are some of the leading companies in metal furniture manufacturing industry GAO has served:

- Steelcase Inc.

- Herman Miller Inc.

- Haworth Inc.

- Knoll, Inc.

- HNI Corporation

- Ashley Furniture Industries

- La-Z-Boy Incorporated

- Kimball International

- Global Furniture Group

- OFS Brands

- National Office Furniture

- Allsteel Inc.

- Hon Company

- Virco Manufacturing Corporation

- KI Furniture

- Falcon Products

- Jasper Group

- Bernhardt Furniture Company

- Sauder Woodworking Co.

- American Furniture Manufacturing

- Coaster Furniture

- Hooker Furniture Corporation

- Bassett Furniture Industries

- Flexsteel Industries

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com