Index for Contents on This Page:

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Mining Industry

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Mining Industry

GAO Software Provides Easy Integration with API

Case Studies of RFID Applications

Related Products & Systems on Other Pages on This Website

GAO RFID Industrial Sand Mining Asset Management System

GAO RFID Peat Extraction RFID Solutions

RFID, BLE, IoT & Drones for Oil and Gas Extraction Industry

Tool & Industrial Equipment Tracking System

Construction Site Access Control System

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

People Tracking RFID Tags and Wristbands

Hazardous Environment (ATEX) RFID Tags

Overview

Mining is the process of extracting valuable minerals, metals, and other geological materials from the earth. It involves drilling, blasting, digging, and transporting these materials to the surface for processing. Mining operations take place on the surface or underground and can range from small-scale artisanal mining to large-scale industrial mining. Sustainable mining practices are becoming increasingly important to balance the needs of economic development with environmental conservation and social responsibility.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the Mining Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Excavators ,Bulldozers , Loaders, Haul, trucks, Drilling rigs, Jackhammers, Rock bolters, Crushers, Screens, Conveyor belts , Stackers, Pumps, Valves, Pipelines, Ventilation systems, Safety gear, Underground mining vehicles, Explosives, Support systems, Laboratory analyzers and testing equipment’s.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the mining industry.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Mining Industry

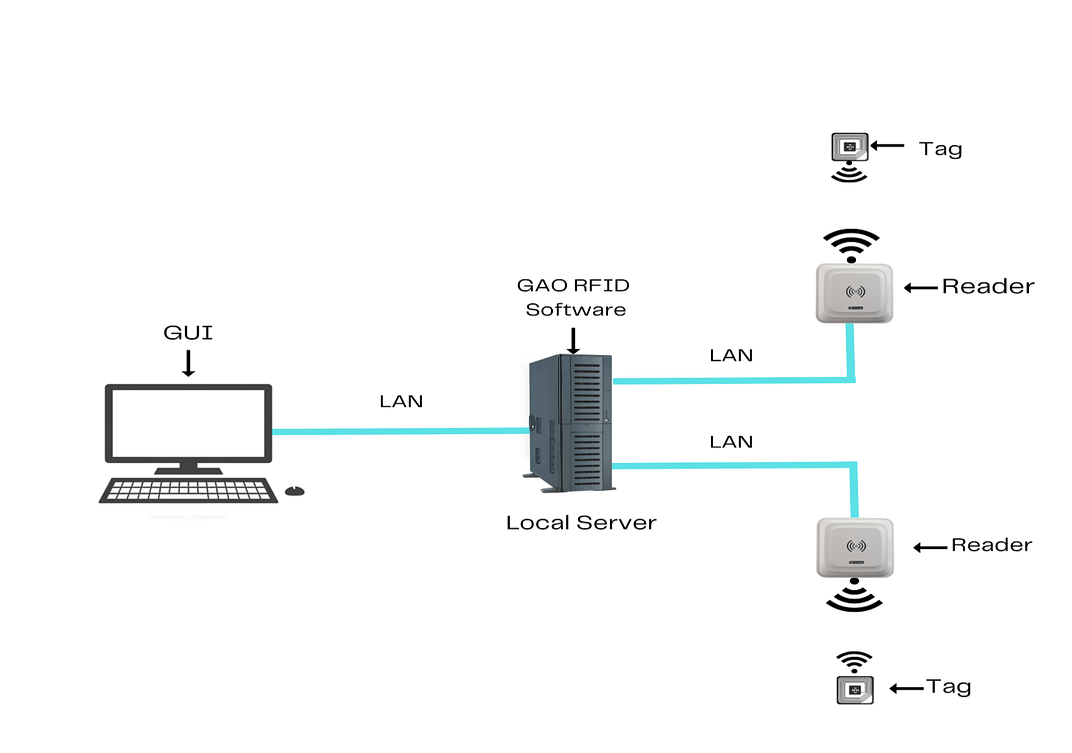

To satisfy its customers, GAO’s RFID or RFID Systems for the Mining Industry are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the mining industry with its software running on a local server

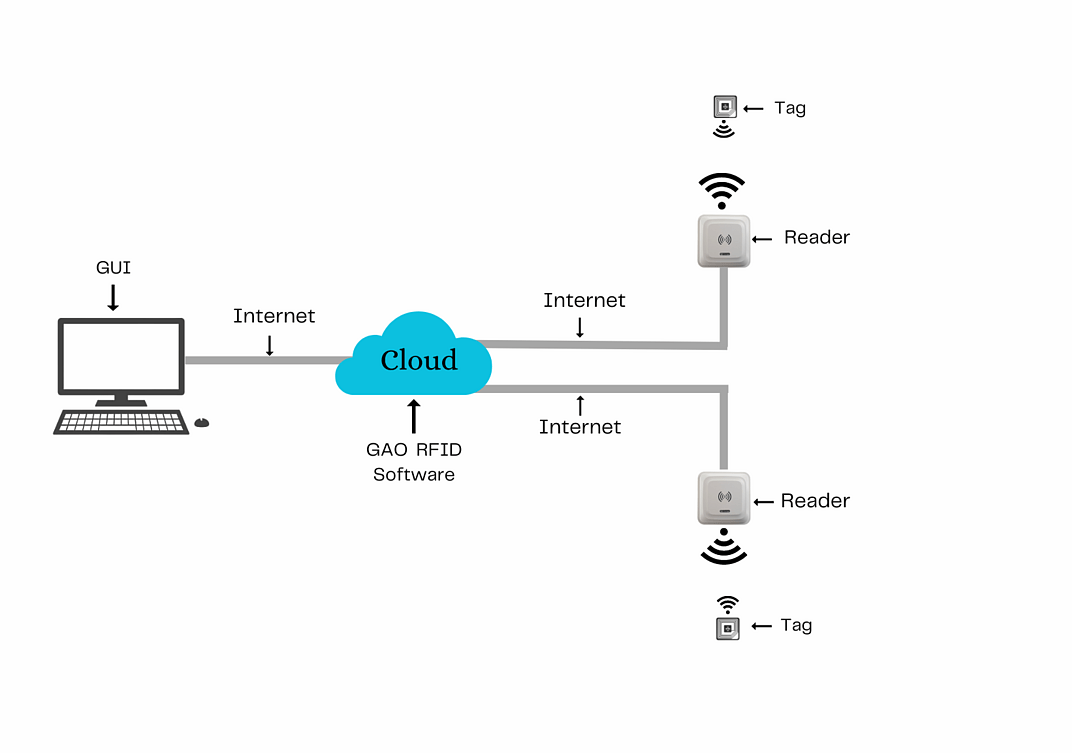

The above illustrates GAO system for the mining industry with its software running in cloud.

GAO’s RFID technologies bring the many benefits to the Mining Industry:

- Improved asset tracking and management: Our RFID tags can be attached to equipment, tools, and vehicles to monitor their location and movement in real-time, reducing the risk of loss or theft.

- Enhanced safety: GAO’s RFID tags worn by workers can track their location and provide real-time information on their safety and whereabouts in emergency situations.

- Increased efficiency: Our RFID technology can automate processes such as inventory management and equipment maintenance, reducing the need for manual intervention and improving overall efficiency.

- Reduced downtime: By monitoring equipment condition in real-time, our RFID technology can detect potential failures and schedule maintenance before a breakdown occurs, reducing costly downtime.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger workspaces within the mining Industry:

- Cost savings: By improving safety, productivity, and efficiency, and reducing downtime and inventory costs, our BLE can help mining companies realize significant cost savings over time.

- Enhanced productivity: By providing accurate real-time data, GAO’s BLE can help optimize mining processes and equipment usage, leading to improved productivity and efficiency.

- Better inventory management: By tracking the location and status of equipment and materials, our company’s BLE can help optimize inventory management and reduce the risk of shortages or overstocking.

- Improved workflow: GAO’s BLE technology can streamline mining operations by automating tasks, optimizing workflows, and reducing manual labor.

GAO’s RFID and drone technologies are often combined, and such solutions offer the following benefits to the mining industry:

- Compliance: GAO’s RFID can help mining companies comply with government regulations and environmental standards by providing accurate data on materials, equipment, and waste.

- Improved data collection and analysis: Our company’s RFID technology can collect vast amounts of data on equipment usage, worker movements, and other aspects of mining operations, while drones can be used to gather high-resolution images and other data on the mining site for analysis.

- Enhanced supply chain visibility: GAO’s RFID can be used to track the movement of materials and products throughout the supply chain, providing greater visibility and traceability for stakeholders.

- Increased transparency: Our RFID and drone technology can provide stakeholders with real-time visibility into mining operations, promoting greater transparency and accountability.

Here are benefits of IoT technologies to the mining Industry:

- Predictive maintenance: IoT sensors can be used to monitor the performance of mining equipment in real-time, providing data on potential maintenance issues before they become major problems, leading to reduced downtime and increased efficiency.

- Optimized processes: IoT sensors can provide real-time data on mining processes, allowing for continuous optimization of these processes for increased efficiency and productivity.

- Remote monitoring and control: IoT technology allows for remote monitoring and control of equipment, providing greater flexibility and reducing the need for on-site personnel.

- Energy efficiency: IoT sensors can be used to monitor energy usage and identify opportunities for energy efficiency improvements, leading to reduced energy costs and environmental impact.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Mining Industry

GAO RFID Inc. has helped many companies in the mining Industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6: This is a global standard for passive RFID tags used in item management. It specifies the technical requirements for RFID tags and readers, including frequency range, data rate, and operating distance.

- ISO 15693: This is a global standard for high-frequency (HF) RFID tags and readers used in close-range applications, such as access control, inventory management, and asset tracking.

- EPC Gen2: This is a global standard for UHF (Ultra High Frequency) RFID tags and readers used in item management. It specifies the technical requirements for RFID tags and readers, including frequency range, data rate, and operating distance.

- Bluetooth SIG (Special Interest Group) standard: This is the global standard for BLE devices, including sensors and beacons used in mining applications. It specifies the technical requirements for wireless connectivity, data transfer, and energy efficiency.

- Canadian mining regulations: The Canadian government has mandated the use of BLE beacons for tracking and monitoring the movement of workers and equipment in underground mines, to improve safety and efficiency.

- IEC 62443: This is a global standard for industrial cybersecurity, including IoT devices used in mining operations. It specifies the technical requirements for cybersecurity risk assessment, mitigation, and management.

- IEEE 802.11: This is a global standard for wireless local area networks (WLAN), including IoT devices used in mining operations. It specifies the technical requirements for wireless connectivity, data transfer, and network security.

- OPC UA: This is a global standard for industrial communication and interoperability, including IoT devices used in mining operations. It specifies the technical requirements for data exchange, security, and reliability.

- Federal Aviation Administration (FAA) regulations: The FAA regulates the use of drones for commercial purposes, including mining operations. It specifies the technical requirements for drone operations, including flight restrictions, registration, and licensing.

- European Union Aviation Safety Agency (EASA) regulations: The EASA regulates the use of drones for commercial purposes in Europe, including mining operations. It specifies the technical requirements for drone operations, including flight restrictions, registration, and licensing.

US. Government Regulations

- Mine Safety and Health Act (MSHA): This law requires mine operators to take steps to prevent accidents and injuries, such as providing training and personal protective equipment to workers. It also mandates inspections of mines by the MSHA to ensure compliance with safety standards.

- Clean Air Act (CAA): This law regulates air emissions from mining operations, including dust and other pollutants that can harm human health and the environment. It requires mining operators to obtain permits and comply with emissions standards.

- Clean Water Act (CWA): This law regulates water pollution from mining operations, including discharges of wastewater and other contaminants into surface and ground waters. It requires mining operators to obtain permits and comply with water quality standards.

- Resource Conservation and Recovery Act (RCRA): This law regulates the disposal of hazardous waste, including waste generated by mining operations. It requires mining operators to manage and dispose of hazardous waste in an environmentally responsible manner.

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA): This law provides for the cleanup of hazardous waste sites, including abandoned mines and mine tailings. It can require mining operators to pay for cleanup costs and take other actions to address environmental contamination.

Canadian Government Regulations

- Canadian Environmental Protection Act (CEPA): This law regulates the use, import, and export of substances that may be harmful to the environment or human health, including those used in mining operations. It requires mining operators to assess the environmental and health risks of their activities and take steps to minimize those risks.

- Canadian Environmental Assessment Act (CEAA): This law requires environmental assessments of proposed mining projects to identify and mitigate potential environmental and social impacts. It also requires consultation with Indigenous communities and other stakeholders.

- Canadian Nuclear Safety and Control Act (CNSC): This law regulates the use of nuclear materials in mining and milling operations. It requires mining operators to obtain licenses and comply with safety standards to protect workers, the public, and the environment.

- Canadian Labour Code (CLC): This law regulates working conditions in federally regulated industries, including mining. It sets standards for hours of work, overtime pay, and other employment conditions to protect workers’ health and safety.

- Mineral Resources Act (MRA): This law regulates the exploration, development, and production of minerals in Canada. It sets standards for mining practices, including the protection of surface and groundwater, reclamation of mining sites, and management of tailings

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the Mining Industry such as:

Personnel management

- Workforce planning

- Training and development

- Health and safety management

- Employee engagement and communication

- Performance management

- Diversity and inclusion

Equipment management

- Asset management

- Preventive maintenance

- Condition monitoring

- Inventory management

- Equipment optimization

- Safety management

Access control

- Asset management

- Preventive maintenance

- Condition monitoring

- Inventory management

- Equipment optimization

- Safety management

Warehouse Management

- Inventory management

- Materials handling

- Order fulfillment

- Warehouse layout and design

- Safety management

- Performance management

Supply chain management

- Supplier management

- Logistics management

- Inventory management

- Demand planning

- Performance management

- Risk management

Other Applications

- Construction

- Energy production

- Agriculture

- Manufacturing

- Transportation

- Electronics

- Medical

- Defense

GAO has integrated its RFID, BLE, IoT and drone systems with some of leading software and cloud services in the mining industry. Below are some of popular software and cloud services in the mining industry.

- MineSafe – A comprehensive software solution for managing safety, health, and compliance in mining operations, including personnel management.

- Pulse Mining ERP – A software solution for managing mining operations, including equipment management, supply chain management, and financial management.

- SAP for Mining – An integrated software solution for managing all aspects of mining operations, including personnel management, equipment management, and supply chain management.

- Hexagon Mining – A suite of software solutions for managing all aspects of mining operations, including personnel management, equipment management, and safety management.

- CAT MineStar – A suite of software solutions for managing mining operations, including equipment management, production management, and safety management.

- MinePlan – A software solution for mine planning and management, including personnel management, equipment management, and production planning.

- Deswik – A software solution for mine planning and management, including personnel management, equipment management, and production planning.

- iSolutions – A software solution for managing mining operations, including personnel management, equipment management, and safety management.

- Oracle Cloud HCM – A cloud-based human capital management solution for managing personnel, including payroll, benefits, and employee self-service.

- Workday HCM – A cloud-based human capital management solution for managing personnel, including time tracking, payroll, and talent management.

- Microsoft Dynamics 365 Field Service – A cloud-based solution for equipment management, including maintenance, repair, and asset tracking.

- Amazon Web Services (AWS): A cloud-based service that provides scalable computing resources for data processing and analysis in the mining industry.

- IBM Maximo Asset Management – A cloud-based solution for equipment management, including asset tracking, work order management, and predictive maintenance.

GAO has worked with some of the leading technology companies in the mining industry to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the mining industry

- Hexagon Mining – A company that offers software solutions for mine planning, operations management, safety management, and enterprise analytics.

- Caterpillar – A company that offers equipment, technology, and services for the mining industry, including autonomous mining systems, digital solutions for fleet management, and data analytics tools.

- Komatsu – A company that offers equipment, technology, and services for the mining industry, including autonomous haulage systems, mining operation management software, and data analytics tools.

- Schneider Electric – A company that offers digital solutions for energy management, automation, and control systems for the mining industry.

- Rockwell Automation – A company that offers automation and information solutions for the mining industry, including control systems, data analytics, and asset management tools.

- SAP – A company that offers enterprise resource planning (ERP) software and digital solutions for the mining industry, including asset management, supply chain management, and workforce management tools.

- IBM – A company that offers digital solutions for the mining industry, including data analytics, artificial intelligence, and blockchain-based supply chain management tools.

- Accenture – A company that offers digital solutions and consulting services for the mining industry, including automation, digital transformation, and innovation strategies.

- Siemens – A company that offers electrification, automation, and digitalization solutions for the mining industry, including power distribution systems, control systems, and data analytics tools.

- ABB – A company that offers electrification, automation, and digitalization solutions for the mining industry, including power distribution systems, control systems, and robotics solutions.

- Honeywell – A company that offers automation and control solutions for the mining industry, including process control systems, safety systems, and instrumentation tools.

- Phoenix Contact – A company that offers electrical connection and automation solutions for the mining industry, including industrial networking, power supply systems, and control systems.

Case Studies of RFID Applications

Below are some RFID application cases in the mining industry:

Goldcorp, a Canadian gold mining company, used RFID technology to improve safety and efficiency at its Musselwhite Mine in Ontario. Goldcorp implemented an RFID-based system called “Proximity Detection System” to monitor the movement of personnel and equipment in the underground mine. The system uses RFID tags worn by miners and attached to equipment to track their location and proximity to one another. The RFID tags communicate with readers installed throughout the mine, which alert miners and equipment operators when they are too close to one another, reducing the risk of accidents and injuries. The Proximity Detection System has helped to improve safety at the Musselwhite Mine, and has also increased productivity by allowing miners and equipment to operate more efficiently and effectively.

Coeur Mining, a mining company that specializes in silver, gold, and other precious metals, used UHF RFID application to improve the tracking and management of its ore at its Rochester Mine in Nevada. Coeur Mining implemented an UHF RFID-based system called “Ore Tracker” to monitor the movement of ore trucks as they transport ore from the mine to the processing plant. The system uses UHF RFID tags attached to each truck, which are scanned by UHF RFID readers installed at various points along the transportation route. The Ore Tracker system provides real-time information about the location and quantity of the ore, enabling Coeur Mining to optimize its transportation logistics and improve the efficiency of its production process and reduce costs with increase profitability at the Rochester Mine.

At Stillwater Mine in Montana. The mine uses RFID tags to track the location and movement of equipment and personnel underground. The tags are attached to vehicles, tools, and personal protective equipment, allowing for real-time monitoring of their whereabouts. This helps improve safety by ensuring that workers are not in danger zones and that equipment is being used in the correct areas. It also helps with inventory management by tracking the location of tools and equipment, reducing the time and effort needed for manual inventory checks. The RFID system has been credited with improving efficiency and safety at the mine.

GAO RFID Systems & Hardware for the Mining Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the Mining Industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the Mining Industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the Mining Industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the Mining Industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the Mining Industry

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the Mining Industry:

- High Frequency 30.56 MHz Passive RFID Tags

- Low Frequency 134 kHz Passive RFID Tags

- Low Frequency 125 kHz Passive RFID Tags

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the Mining Industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- Excavators: Excavators are heavy machines equipped with a bucket and hydraulic arms used for digging and removing soil, rocks, and ore from the earth. They are crucial for tasks such as open-pit mining, quarrying, and material handling.

- Bulldozers: Bulldozers in the mining industry are typically larger and more rugged than those used in construction. They are used for pushing and moving large amounts of soil, rocks, and debris. Bulldozers play a vital role in creating access roads and leveling mining sites.

- Haul Trucks: Haul trucks, also known as dump trucks, are designed to transport large quantities of materials within mining sites. These trucks are specially built to handle rough terrains and heavy loads, allowing for the efficient transportation of mined materials.

- Drills: Drills are used in mining to create holes for exploration, blasting, and extracting minerals. There are various types of drills, including rotary drills, blasthole drills, and underground drills, depending on the mining method and the type of material being extracted.

- Loaders: Loaders are used to load mined materials, such as coal, ore, or gravel, into trucks or conveyors for transportation. They are equipped with a front bucket or scoop for efficient material handling.

- Crushers and Screens: Crushers and screens are used to process and separate mined materials. Crushers break large rocks into smaller pieces, and screens are used to separate different sizes of materials based on their particle size.

- Conveyor Systems: Conveyor systems are widely used in the mining industry for the transportation of materials over long distances or across rugged terrains. They help streamline the handling of mined materials, reducing manual labor and improving efficiency.

- Underground Mining Equipment: In underground mining operations, specialized equipment is used due to the unique conditions and challenges. This equipment may include underground loaders, haulage trucks, drill jumbos, and roof bolters, among others.

- Explosives and Blasting Equipment: Blasting is an important process in mining to break and fragment rocks for easier extraction of minerals. This involves the use of explosives, detonators, and blasting equipment to safely and efficiently fragment the rock formations.

- Safety Equipment: Safety is a critical aspect of the mining industry, and specialized safety equipment is used to protect workers. This includes personal protective equipment (PPE) such as helmets, goggles, gloves, and safety clothing, as well as gas detectors and ventilation systems for underground mining operations.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Mining Extensively

GAO’s products and technologies have helped its customers in the mining Industry to achieve success in automation, robotics, the Internet of Things (IoT), artificial intelligence (AI) and machine learning, big data analytics, augmented and virtual reality (AR/VR), sustainability and ESG concerns, the circular economy, electric vehicles and renewable energy, mine-to-market supply chain transparency zero harm and safety culture, social license to operate, innovation and disruption, future of work, and diversity and inclusion.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the Mining Industry, including many in its various divisions such as

- Exploration: The initial stage of the mining process, involving the search for mineral deposits.

- Development: The stage in which an economically viable deposit is identified and developed into a mine, including construction of infrastructure such as roads, railways, and processing facilities.

- Extraction: The stage in which the minerals are extracted from the mine through various methods, such as underground or surface mining, drilling, or blasting.

- Processing: The stage in which the extracted minerals are processed and refined into usable products, such as metals or industrial minerals.

- Marketing and sales: The stage in which the finished products are marketed and sold to customers, including manufacturers, construction companies, and other end-users.

- Support services: The various services and technologies that support the mining industry, such as equipment suppliers, logistics and transportation companies, consulting firms, and technology providers.

Here are some of the leading companies in the mining industry