Index for Contents on This Page:

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Oil and Gas Extraction

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Oil and Gas Extraction

Case Studies of RFID Applications

Related Products & Systems on Other Pages on This Website

GAO RFID Peat Extraction Asset Management System

Tool & Industrial Equipment Tracking System

Employee & Attendance Access Control System

Asset Tracking Systems Software | RFID Tracking – GAO RFID

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

Rugged RFID Tags | GAO RFID Inc.

Hazardous Environment RFID Tags | ATEX RFID Tags (gaorfid.com)

On Metal RFID Tags – All Types

High Temperature RFID Tags – GAO RFID

Overview

The oil and gas extraction industry involves the exploration, drilling, and production of hydrocarbons from underground reserves. It includes from locating potential reserves to extracting and processing crude oil and natural gas. The industry employs advanced technologies and equipment to extract these resources. It plays a significant role in the global economy, providing fuel for transportation, energy for industries, and raw materials for various products.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the oil and gas extraction industry to improve their work processes, their operations and productivity by better management of their staff, materials, and operational equipment such as wellhead equipment, christmas trees, downhole tools, submersible pumps, artificial lift systems, production separators, flowlines and gathering lines, metering equipment, storage tanks, gas processing equipment, oil processing equipment and flare systems.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in the oil and gas extraction industry.

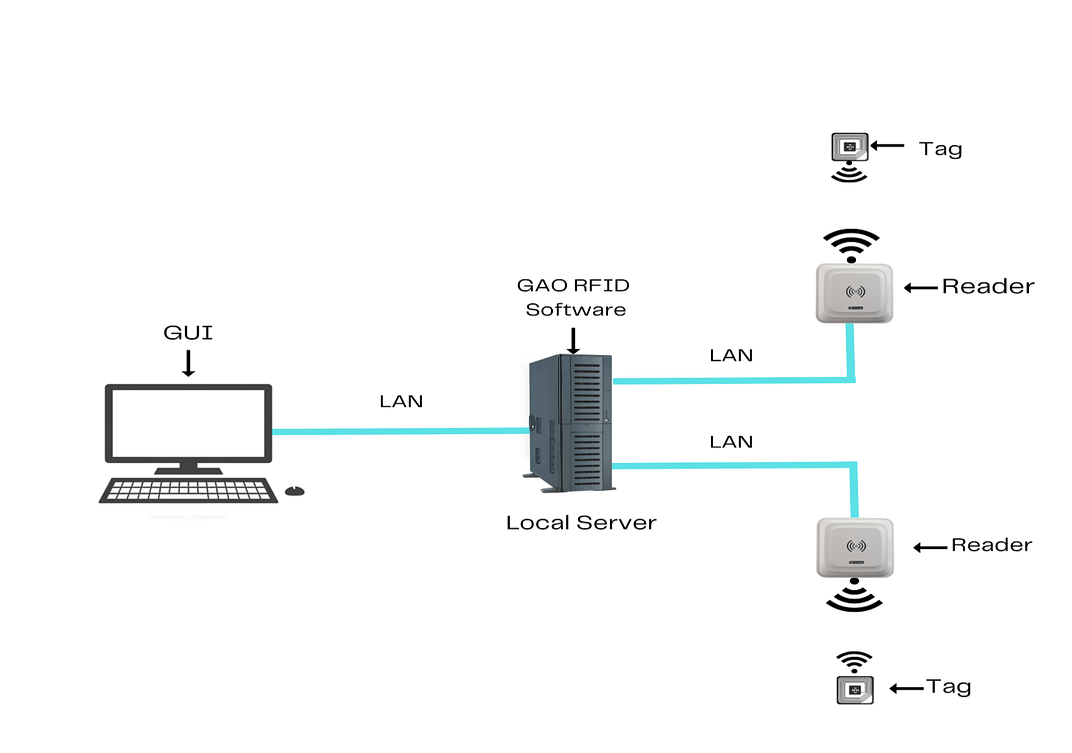

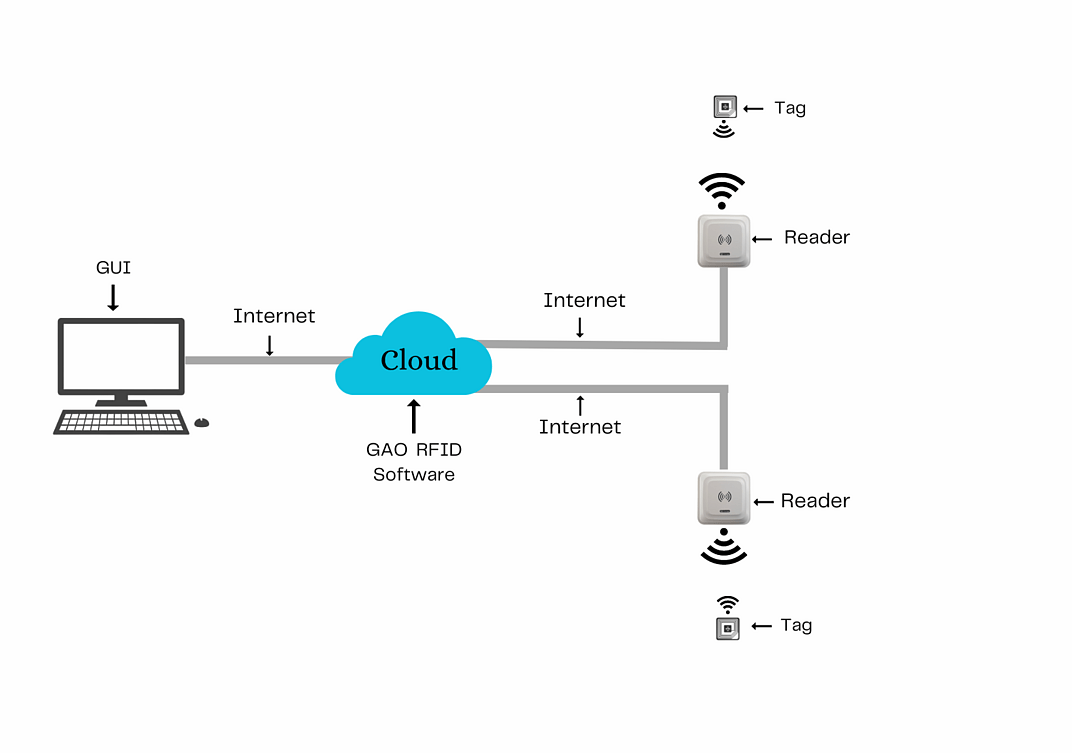

To satisfy its customers, GAO’s RFID or RFID Systems for the oil and gas extraction industry are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the oil and gas extraction industry with its software running on a local server.

GAO’s RFID technologies bring the many benefits to the oil and gas extraction industry:

- Asset Tracking and Management: Our RFID tags enable accurate and real-time tracking of equipment, tools, and assets throughout the extraction process. This improves asset visibility, reduces loss, enhances inventory management, and enables efficient resource allocation.

- Enhanced Safety and Personnel Tracking: GAO’s RFID-enabled badges or tags worn by workers allow for real-time monitoring of their location and movement within the work site. This improves safety by enabling quick response in emergencies, ensuring accountability, and enhancing personnel tracking in hazardous environments.

- Streamlined Supply Chain Operations: GAO’s RFID technology enables efficient tracking and management of supplies, materials, and equipment along the supply chain. It enhances inventory control, reduces errors, optimizes logistics, and facilitates seamless coordination between suppliers, contractors, and operators.

- Efficient Maintenance and Inspections: Our RFID tags can be used to track maintenance schedules, inspection records, and equipment maintenance histories. This streamlines maintenance operations, improves asset reliability, reduces downtime, and enables proactive maintenance planning.

- Improved Pipeline Integrity Management: GAO’s RFID technology can be employed for pipeline integrity management. RFID tags embedded within pipelines enable accurate identification, tracking, and monitoring of pipeline sections. This facilitates efficient inspections, maintenance planning, and leak detection, minimizing the risk of pipeline failures.

- Real-time Data Collection and Monitoring: Our RFID-enabled sensors can be used for real-time data collection on various parameters such as pressure, temperature, and fluid levels. This data enables continuous monitoring, early detection of anomalies, and proactive decision-making to optimize production and ensure regulatory compliance.

- Automation and Efficiency: Our RFID technology enables automation of various processes, reducing manual labor, minimizing errors, and improving operational efficiency. It streamlines data collection, inventory management, and asset tracking, leading to cost savings and increased productivity.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within the oil and gas extraction industry:

- Enhanced Environmental Monitoring:GAO’s BLE sensors can be deployed to monitor environmental factors such as air quality, temperature, humidity, and gas leaks. Real-time monitoring helps in identifying potential hazards, ensuring compliance with environmental regulations, and enhancing overall environmental safety.

- Efficient Workflow and Communication:Our BLE technology allows for seamless communication and data transfer between devices, enabling efficient workflow management. It facilitates the exchange of real-time information, task assignments, and coordination among workers, improving overall operational efficiency.

- Remote Monitoring and Control:Our BLE-enabled devices and sensors can be remotely monitored and controlled, allowing for efficient management of remote or unmanned sites. This reduces the need for physical presence, minimizes operational costs, and enables remote troubleshooting and adjustments.

- Enhanced Security and Access Control:GAO’s BLE technology can be utilized for access control, providing secure and convenient entry to restricted areas. BLE-enabled locks and badges enhance site security, prevent unauthorized access, and provide audit trails for accountability.

- Data Analytics and Optimization:Our BLE data collected from various sensors and devices can be analyzed to gain insights into operational patterns, identify inefficiencies, and optimize processes. This facilitates data-driven decision-making, improves productivity, and reduces operational costs.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to the oil and gas extraction industry:

- Remote Inspection and Monitoring: GAO’s Drones equipped with GAO’s RFID scanners can perform remote inspections of equipment, pipelines, and infrastructure. It can quickly scan our RFID tags to identify assets, track maintenance history, and monitor conditions. This enables proactive maintenance planning, reduces inspection time and costs, and enhances overall safety.

- Site Security and Surveillance:GAO’s Drones integrated with GAO’s RFID technology can provide aerial surveillance of oil and gas sites, monitoring for unauthorized access and potential security threats. Our RFID tags on personnel badges or access points can be used to validate identities and ensure compliance with security protocols.

- Emergency Response and Safety:OurDrones equipped with GAO’s RFID technology can assist in emergency response situations. It can quickly locate and assess the status of personnel and assets during emergencies, facilitating rapid response and ensuring the safety of workers.

- Infrastructure and Pipeline Management:GAO’s Drones integrated with GAO’s RFID scanners can perform aerial inspections of pipelines, identifying and locating assets, detecting leaks or damages, and assessing infrastructure conditions. This helps in proactive maintenance planning, reducing downtime, and optimizing pipeline management.

- Improved Efficiency and Cost Savings: The combination of GAO’s RFID and drone technologies streamlines operations, reduces manual effort, and improves efficiency. It optimizes asset management, enhances safety measures, facilitates proactive maintenance, and reduces inspection and monitoring costs.

Here are the benefits of GAO’s IoT technologies to the oil and gas extraction industry:

- Predictive Maintenance: IoT technologies facilitate predictive maintenance by collecting real-time data from sensors embedded in equipment. This data is analyzed to identify patterns and indicators of potential failures, allowing for timely maintenance interventions. This reduces downtime, improves equipment reliability, and lowers maintenance costs.

- Data-driven Decision Making: IoT technologies provide a wealth of real-time data that can be analyzed to gain insights, identify trends, and make data-driven decisions. This improves operational efficiency, resource allocation, and overall performance in the extraction processes.

- Energy Efficiency and Sustainability: IoT technologies can optimize energy usage by monitoring and controlling energy-intensive processes. By collecting and analyzing data on energy consumption, operators can identify areas for improvement, reduce energy waste, and enhance sustainability practices.

- Integration and Interoperability: IoT platforms allow for seamless integration with existing systems, such as SCADA (Supervisory Control and Data Acquisition), enterprise resource planning (ERP), and maintenance management systems. This ensures interoperability, streamlines data exchange, and enhances overall system efficiency.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Oil and Gas Extraction

GAO RFID Inc. has helped many companies in the to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates, and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- API RP 86: The American Petroleum Institute’s covers topics such as asset tracking, inventory management, safety, and personnel tracking. API RP 86 helps standardize the implementation of RFID technology within the industry.

- ISO 18000-6: This standard specifies the air interface protocol for RFID systems operating in the UHF (Ultra-High Frequency) band. It defines parameters such as frequency range, data encoding, communication protocols, and anti-collision methods.

- ISO 15926: ISO 15926 is an international standard for data integration and interoperability in industrial plants and facilities. It provides a common data model and ontology for sharing and exchanging information across various systems and disciplines within the oil and gas industry.

- ISO 21384: It covers topics such as flight operations, crew qualification and training, safety considerations, and operational procedures. These guidelines can be applied to drone operations within the oil and gas industry.

- ISA-95: It defines models and protocols for data exchange between enterprise resource planning (ERP) systems, supervisory control and data acquisition (SCADA) systems, and other operational technology (OT) systems commonly used in the oil and gas industry.

- OPC UA (Unified Architecture): It provides a secure and reliable communication framework for exchanging data between devices, sensors, and software applications. OPC UA facilitates interoperability and data integration across different systems and vendors within the oil and gas industry.

- IEC 61850: IEC 61850 is also relevant to the oil and gas industry, especially in terms of power distribution and automation. It defines protocols and data models for the communication and interoperability of devices within power systems, ensuring efficient and reliable control and monitoring.

- FAA Part 107: In the United States, the Federal Aviation Administration (FAA) has established Part 107 and includes drones used in the oil and gas industry. Part 107 covers requirements for pilot certification, airspace restrictions, operational limitations, and safety considerations.

- ICAO Standards: The International Civil Aviation Organization (ICAO) sets global standards and guidelines for aviation safety and operations. Itprovides general guidelines for the integration of drones into airspace and promotes the harmonization of regulations among member countries.

US. Government Regulations

- Environmental Protection Agency (EPA): The EPA enforces regulations to protect human health and the environment. The EPA’s regulations include the Clean Air Act, which addresses air emissions from oil and gas operations, and the Clean Water Act, which regulates the discharge of pollutants into water bodies.

- Occupational Safety and Health Administration (OSHA): OSHA’s standards aim to prevent workplace accidents, injuries, and illnesses in oil and gas operations. In the oil and gas extraction industry, OSHA regulations cover various aspects of worker safety, such as hazard communication, personal protective equipment, and process safety management.

- Department of Transportation (DOT): The DOT, through its Pipeline and Hazardous Materials Safety Administration (PHMSA), regulates the transportation of oil, natural gas, and hazardous materials by pipeline.

- Bureau of Safety and Environmental Enforcement (BSEE): The BSEE is responsible for promoting safety, environmental protection, and resource conservation in offshore oil and gas operations in federal waters. BSEE develops and enforces regulations that govern offshore drilling, production, and decommissioning activities.

Canadian Government Regulations

- Canada Energy Regulator Act:Provides the regulatory framework for the energy sector, including oil and gas extraction, and governs the regulation and oversight of energy projects and the safety of pipelines.

- National Energy Board (NEB) Act:Regulates the exploration, development, and production of oil and gas resources in areas under federal jurisdiction, including the Arctic and offshore areas.

- Canadian Environmental Assessment Act, 2012: This act requires environmental assessments for designated projects, including major oil and gas extraction activities, to evaluate potential environmental impacts and ensure sustainable development.

- Canada-Newfoundland and Labrador Offshore Petroleum Board (C-NLOPB):Regulates oil and gas activities in the offshore areas of Newfoundland and Labrador, including exploration, development, production, and environmental protection.

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the oil and gas extraction industry such as:

Personnel Management:

- Human Resources Management Systems (HRMS)

- Workforce Management Systems

- Employee Time and Attendance Systems

- Training and Certification Tracking Systems

- Performance Management Systems

- Health and Safety Management Systems

Equipment Management:

- Computerized Maintenance Management Systems (CMMS)

- Asset Tracking Systems

- Condition Monitoring Systems

- Equipment Maintenance and Inspection Systems

- Inventory Management Systems (for spare parts and equipment)

- Fleet Management Systems (for vehicle and transportation equipment)

Access Control:

- Physical Access Control Systems (PACS)

- Biometric Identification Systems

- Card Access Systems

- Visitor Management Systems

- Surveillance and CCTV Systems

- Intrusion Detection Systems

Warehouse Management:

- Warehouse Control Systems

- Material Tracking Systems

- Barcode and RFID Systems

- Order Fulfillment Systems

- Picking and Packing Systems

Supply Chain Management:

- Supply Chain Planning Systems

- Procurement and Sourcing Systems

- Supplier Relationship Management Systems

- Transportation Management Systems

- Demand Forecasting and Planning Systems

- Logistics and Distribution Systems

Other Applications:

- Document Management Systems

- Regulatory Compliance Systems

- Environmental Management Systems

- Health, Safety, and Environment (HSE) Management Systems

- Remote Monitoring and Control Systems

- Energy Management Systems

GAO has integrated its RFID, BLE, IoT and drone systems with some of leading software and cloud services in the oil and gas industry. Below are some of popular software and cloud services in the oil and gas industry:

- SAP(Systems,Application and Products)SuccessFactors:Comprehensive HCM software with modules for employee onboarding, performance management, learning, and workforce planning.

- Oracle HCM (Human Capital Management)Cloud: Integrated HR management system offering features for recruitment, talent management, compensation, and employee self-service.

- ADP (Automatic Data Processing) Workforce Now: Cloud-based HR solution providing modules for payroll, time and attendance, benefits administration, and talent management.

- IBM (International Business Machines) Maximo: Asset management software for equipment tracking, preventive maintenance, work order management, and inventory control.

- Infor EAM (Enterprise Asset Management): Enterprise asset management solution facilitating asset tracking, preventive maintenance, work order management, and inventory control.

- eMaint CMMS (Computerized Maintenance Management System): CMMS software for asset management, work order management, preventive maintenance, and inventory control.

- Honeywell Forge Asset Performance Management: Asset performance management software that enables predictive maintenance, asset optimization, and risk mitigation.

- Microsoft Azure: Cloud computing platform offering a range of services for data storage, analytics, and application development.

- Amazon Web Services (AWS): Comprehensive cloud platform providing scalable infrastructure, storage, and computing resources for various business applications.

- Honeywell Forge Industrial IoT: Industrial IoT platform for real-time monitoring, data analysis, and optimization of equipment and operational processes.

- Genetec Security Center: Integrated security management platform offering video surveillance, access control, and intrusion detection for facility security.

- Infor Supply Chain Management: Supply chain management software providing features for demand planning, inventory management, logistics, and order fulfillment.

GAO has worked with some of the leading technology companies in the oil and gas extraction industry to provide integrated RFID, BLE, IoT, and drone solutions to customers. Here are some of the technology leaders in the oil and gas extraction industry:

- IBM (International Business Machines Corporation): A leading information technology company that offers advanced analytics, cloud computing, and artificial intelligence solutions for the oil and gas extraction industry in both the United States and Canada.

- Microsoft Corporation: A technology giant that provides a range of software and cloud services, including Azure, for the oil and gas extraction industry in both the United States and Canada.

- Cisco Systems: A global technology company specializing in networking and communications solutions for the oil and gas extraction industry in both the United States and Canada.

- Honeywell: A diversified technology and manufacturing company that offers solutions for process automation, control systems, and safety in the oil and gas extraction industry in both the United States and Canada.

- Siemens: A multinational conglomerate that provides industrial automation and control systems, digitalization solutions, and energy management technologies for the oil and gas extraction industry in both the United States and Canada.

- Schneider Electric: A global company offering energy management and automation solutions for the oil and gas extraction industry in both the United States and Canada.

- Emerson Electric: A technology and engineering company that provides automation, measurement, and control solutions for the oil and gas extraction industry in both the United States and Canada.

- ABB (ASEA Brown Boveri): A multinational company specializing in power and automation technologies for the oil and gas extraction industry in both the United States and Canada.

- General Electric (GE): A conglomerate that offers a wide range of technologies, including digital solutions and industrial automation, for the oil and gas extraction industry in both the United States and Canada.

- Rockwell Automation: A provider of industrial automation and control systems for the oil and gas extraction industry in both the United States and Canada.

- National Oilwell Varco (NOV): A leading provider of equipment and technology solutions for the oil and gas extraction industry, including drilling systems and production equipment, in both the United States and Canada.

- Suncor Energy: A Canadian integrated energy company involved in oil sands development, offshore production, and refining, with a focus on sustainable and responsible energy extraction practices.

Case Studies of RFID Applications

Here are four cases of applying RFID in the oil and gas extraction industry:

ExxonMobil implemented RFID technology to optimize asset tracking and management in its oil refineries. RFID readers were strategically installed at key locations throughout the refineries, automatically detecting and recording tag information.The RFID system provided ExxonMobil with accurate and up-to-date asset information, including location, maintenance history, and inspection records. This allowed for streamlined maintenance scheduling, reducing unplanned downtime and optimizing asset performance. The system also enhanced inventory management by providing real-time visibility into equipment availability, reducing inventory carrying costs, and minimizing stockouts. ExxonMobil experienced significant improvements in operational efficiency and cost savings through the RFID implementation. The system facilitated proactive maintenance, reduced manual data entry, and enhanced asset utilization, ultimately leading to increased productivity and profitability.

British Petroleum implemented RFID technology for the tracking and management of hazardous materials in its pipeline operations.The RFID system provided BP with accurate and traceable data on the movement of hazardous materials, ensuring compliance with safety regulations and reducing the risk of incidents. It facilitated real-time monitoring of inventory levels, allowing for efficient replenishment and reducing the likelihood of shortages or excess inventory. The system also enhanced safety protocols by providing alerts and notifications for any anomalies or deviations in material handling.BP achieved improved regulatory compliance, enhanced safety practices, and streamlined inventory management through the RFID implementation.

Schlumberger, a leading provider of technology and services to the oil and gas industry, implemented UHF RFID technology to improve inventory management and optimize the supply chain. The objective was to enhance visibility, accuracy, and efficiency in tracking assets, equipment, and supplies across multiple locations.The UHF RFID system enabled real-time tracking and monitoring of inventory movements, allowing for precise inventory control and accurate stock levels.The system reduced inventory carrying costs, improved asset utilization rates, and enhanced customer satisfaction by ensuring timely and accurate delivery of products and services.

Halliburton, a global provider of products and services to the oil and gas industry, utilized UHF RFID technology for asset tracking and maintenance in offshore platforms. UHF RFID readers were strategically placed throughout the platforms, including storage areas and maintenance facilities. The UHF RFID system enabled real-time asset visibility and automated data capture.It facilitated accurate and efficient asset tracking, reducing the time and effort required for manual inspections. Halliburton witnessed significant improvements in operational efficiency and cost savings through the UHF RFID implementation. The system optimized maintenance schedules, reduced inventory carrying costs, and enhanced overall asset utilization, ultimately leading to improved productivity and profitability.

GAO RFID Systems & Hardware for the Oil and Gas Extraction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the oil and gas extraction.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the seafood product preparation and packaging industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the seafood product preparation and packaging industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the seafood product preparation and packaging industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the seafood product preparation and packaging industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the seafood product preparation and packaging industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the oil and gas extraction industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- Drilling Rigs: Includes various types of rigs used for drilling wells, such as land-based rigs, offshore rigs, and drilling ships. This equipment is used to reach underground oil and gas reservoirs.

- Wellhead Equipment: Consists of components installed at the top of the well to control the flow of oil and gas. It includes blowout preventers (BOPs), wellheads, and Christmas trees.

- Pumping Units: Used to extract oil from wells by mechanically lifting fluids to the surface. This can include beam pumps, electric submersible pumps (ESPs), and hydraulic pumping systems.

- Pressure Vessels and Separators: Equipment used to separate oil, gas, and water from the produced fluids. It includes separators, treaters, and various types of tanks and vessels.

- Compressors: Used to compress and transport natural gas through pipelines. Compressors can include reciprocating compressors, centrifugal compressors, and screw compressors.

- Pumps and Valves: Various types of pumps and valves are used in oil and gas operations, including centrifugal pumps, positive displacement pumps, control valves, and safety valves.

- Pipelines and Flowlines: Infrastructure for transporting oil and gas over long distances. This includes pipelines, flowlines, gathering systems, and associated fittings and connectors.

- Measurement and Monitoring Equipment: Instruments used to measure and monitor various parameters, including flow rates, pressure, temperature, and composition of oil and gas. This can include flow meters, pressure gauges, temperature sensors, and gas analyzers.

- Offshore Production Platforms: Structures installed in offshore locations to extract oil and gas. They can include fixed platforms, floating production systems, and subsea equipment.

- Refining Equipment: Equipment used in oil refineries to process crude oil into refined products, such as gasoline, diesel, and jet fuel. This can include distillation towers, catalytic converters, and various refining vessels.

- Storage Tanks: Large tanks used to store crude oil, refined products, and natural gas liquids. They can include above-ground storage tanks (ASTs), underground storage tanks (USTs), and floating roof tanks.

- Safety Equipment: Equipment and systems used to ensure worker safety and prevent accidents, including personal protective equipment (PPE), gas detectors, fire suppression systems, and emergency shutdown systems.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Oil and Gas Extraction Extensively

GAO’s products and technologies have helped its customers in oil and gas extraction industry to achieve success in digital transformation, Internet of Things (IoT), Artificial Intelligence (AI), data analytics, energy transition, remote monitoring, big data, blockchain, predictive maintenance and ESG (Environmental, Social, and Governance).

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the oil and gas extraction industry, including many in its various divisions such as:

- Upstream: This division focuses on exploration and production activities, including locating and extracting oil and gas reserves from the ground or underwater.

- Midstream: The midstream division involves the transportation, storage, and processing of crude oil, natural gas, and other petroleum products. This includes activities such as pipeline transportation, storage terminals, and natural gas processing plants.

- Downstream: The downstream division involves refining crude oil into usable products such as gasoline, diesel, jet fuel, and lubricants. It also includes distribution and marketing activities, such as operating fuel stations and delivering petroleum products to end consumers.

- Services and Equipment: This division comprises companies that provide specialized services and equipment to support the oil and gas extraction industry. This includes drilling services, well maintenance, equipment manufacturing, and technological solutions for the industry.

- Offshore and Onshore: This division categorizes operations based on their location. Offshore activities involve extracting oil and gas reserves from offshore locations, often in deep water, while onshore activities take place on land.

- Unconventional Resources: This division focuses on the extraction of oil and gas from unconventional sources, such as shale gas, tight oil, and oil sands. These resources require advanced extraction techniques, including hydraulic fracturing (fracking) and enhanced oil recovery methods.

Some of the leading companies in the oil and gas extraction industry