Overview

The nonmetallic mineral product manufacturing industry encompasses the production of various products derived from minerals or rocks, excluding metal and mineral fuel extraction. It includes the manufacturing of cement, glass, clay, and ceramic products, concrete items, lime, gypsum, and other nonmetallic mineral-based products. These products are widely used in construction, infrastructure development, manufacturing, and consumer goods.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the nonmetallic mineral product manufacturing industry to improve their work processes, their operations, and productivity through better management of their staff, materials, and operational equipment such as crushers, grinders, kilns, furnaces, mixers, blenders, conveyors, and belt systems.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at an ultra-high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with IoT and drone technologies, have been widely used in nonmetallic mineral product manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Nonmetallic Mineral Product Manufacturing

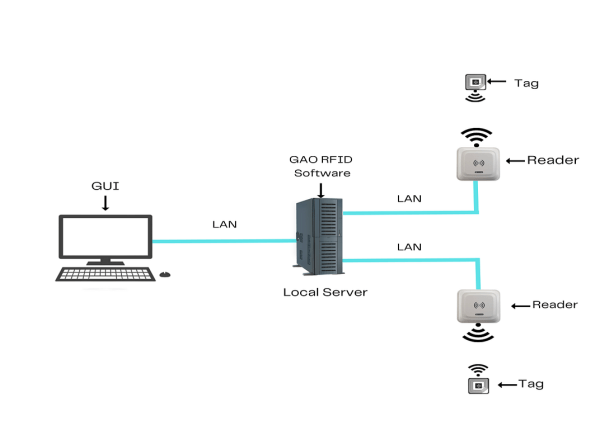

To satisfy its customers, GAO’s RFID or RFID Systems for nonmetallic mineral product manufacturing are offered in two versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates the GAO system for nonmetallic mineral product manufacturing with its software running on a local server.

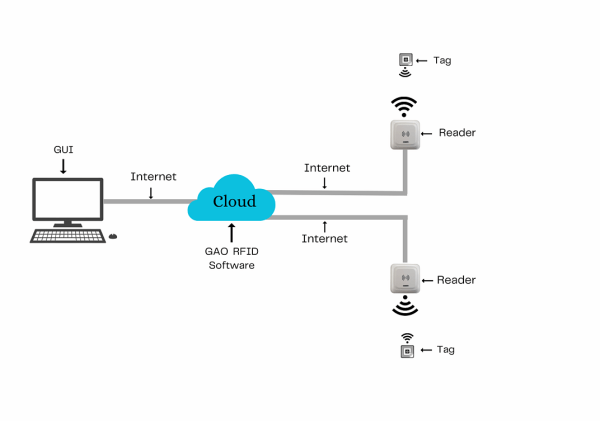

The above illustrates the GAO system for the nonmetallic mineral product manufacturing with its software running in the cloud.

GAO’s RFID technologies bring many benefits to the nonmetallic mineral product manufacturing industry:

- Enhanced Inventory Management: GAO’s RFID enables real-time and accurate tracking of raw materials, such as dolomite and gypsum throughout the manufacturing process.

- Supply Chain Visibility: GAO’s RFID technology allows for seamless tracking of materials and products, such as limestone, clay, silica, and dolomite, as they move through the supply chain. This enhances visibility, improves traceability, and enables more efficient logistics planning and coordination.

- Process Automation: GAO’s RFID tags and readers can automate data capture and reduce the need for manual data entry, paperwork, and barcode scanning. This streamlines processes, reduces human errors, and increases productivity.

GAO’s BLE technologies offer a longer reading range and are particularly attractive for applications with larger workspaces within the nonmetallic mineral product manufacturing industry:

- Indoor Localization and Navigation: GAO’s BLE technology can enable indoor positioning systems, providing accurate location information within manufacturing facilities. This helps employees locate equipment, such as grinders, crushers, and materials, such as gypsums and dolomite.

- Worker Safety: GAO’s BLE-enabled wearables or tags can be used to monitor the location and movement of workers such as production workers, machine operators within the manufacturing environment.

- Seamless Data Exchange: GAO’s BLE technology enables wireless communication and data transfer between systems. This facilitates seamless integration of various components such as environmental control systems, packaging, and shipping within the manufacturing process.

GAO’s RFID and drone technologies are often combined, and such solutions offer the following benefits to the nonmetallic mineral product manufacturing industry:

- Site Inspection and Safety Monitoring: Drones equipped with cameras and GAO’s RFID technology can conduct aerial inspections of manufacturing sites, mines, or quarries. This allows automated identification of specific locations or assets during inspections.

- Rapid Surveys and Data Collection: Drones equipped with GAO’s RFID readers can quickly perform surveys and collect data in large areas or difficult-to-access locations. This streamlines data collection processes, reduces manual effort, and provides accurate and up-to-date information.

- Improved Security and Loss Prevention: GAO’s RFID technology combined with drones can enhance security measures within manufacturing facilities or remote sites.

Here are the benefits of IoT technologies to the nonmetallic mineral product manufacturing industry:

- Improved Efficiency: IoT sensors and devices can help monitor and optimize various processes, leading to improved efficiency in manufacturing operations. This can result in reduced costs and increased productivity.

- Predictive Maintenance: IoT sensors can help detect potential equipment failures before they occur, allowing for preventive maintenance to be carried out. This can help reduce downtime and maintenance costs.

- Quality Control: IoT sensors can be used to monitor the quality of products such as ceramics, abrasives, synthetic gemstones and throughout the manufacturing process, allowing for early detection of defects and reducing waste.

GAO’s Assists Clients with Standards, Mandates & Regulations of the Nonmetallic Mineral Product Manufacturing

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in the nonmetallic mineral product manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- GATT (Generic Attribute Profile): GATT is a protocol that defines how BLE devices exchange data and communicate with each other. It provides a framework for the development of custom profiles and services that can be used in specific applications, such as temperature sensing or machine monitoring.

- iBeacon: iBeacon is a proprietary protocol developed by Apple that uses BLE technology for indoor positioning and location-based services. iBeacons can be used in manufacturing environments to track the location of assets or workers or to provide contextual information about equipment or processes.

- MQTT (Message Queuing Telemetry Transport): MQTT is a lightweight messaging protocol designed for IoT devices with low power and bandwidth constraints. It enables efficient and reliable communication between devices and is widely used in industrial IoT applications, including monitoring and control systems in the Nonmetallic mineral product manufacturing industry.

- Zigbee: Zigbee is a wireless communication standard widely used in industrial IoT applications. It provides a low-power, low-data-rate network for connecting and controlling IoT devices, making it suitable for monitoring and control systems in the Nonmetallic mineral product manufacturing industry.

- FAA Part 107: In the United States, the Federal Aviation Administration (FAA) has established Part 107 regulations for the commercial operation of small and unmanned aircraft systems (sUAS), commonly known as drones. These regulations cover various aspects, including pilot certification, operational limitations, and safety requirements.

- ISO 21384 (UAS): ISO 21384 is an international standard that defines terms and concepts related to unmanned aircraft systems (UAS). While not specific to the Nonmetallic mineral product manufacturing industry, this standard can help establish common terminology and understanding within the drone ecosystem.

- ASTM F38: ASTM International, a standards organization, has developed ASTM F38, a standard practice for unmanned aircraft system pilot training. This standard provides guidelines for the training and certification of drone pilots, emphasizing safety, knowledge, and operational proficiency.

US Government Regulations

- Environmental Protection Agency (EPA) Regulations: The EPA regulates environmental aspects related to air quality, water pollution, waste management, and hazardous materials handling.

- Mine Safety and Health Administration (MSHA) Regulations: If your nonmetallic mineral product manufacturing operations involve mining activities, MSHA regulations come into play.

- Federal Trade Commission (FTC) Regulations: FTC regulations primarily focus on fair trade practices, consumer protection, and advertising standards.

- Department of Transportation (DOT) Regulations: If your Nonmetallic mineral product manufacturing operations involve the transportation of goods, you may be subject to DOT regulations.

Canadian Government Regulations

- Canadian Environmental Protection Act (CEPA): CEPA is a federal law that governs the protection of the environment and human health from risks associated with hazardous substances.

- Canadian Occupational Health and Safety Regulations (COHSR): COHSR, under the Canada Labor Code, establishes health and safety standards for workplaces, including those in the nonmetallic mineral product manufacturing industry.

- Transportation of Dangerous Goods Act (TDGA): TDGA regulates the transportation of hazardous materials, including those produced or used in the nonmetallic mineral product manufacturing industry.

- Canadian Standards Association (CSA) Standards: CSA develops and maintains a wide range of standards in Canada.

Federal Trade Commission

Environmental Protection Agency

Mine Safety and Health Administration

U.S. Department of Transportation

National Institute for Occupational Safety and Health

American National Standards Institute

Federal Energy Regulatory Commission

Canadian Standards Association

Consumer Product Safety Commission

Standards Council of Canada

Department of Transportation Pipeline and Hazardous Materials Safety Administration

U.S. Food and Drug Administration

GAO Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the Nonmetallic mineral product manufacturing such as:

Personnel Management:

- Employee scheduling and shift management systems.

- Time and attendance tracking software.

- Performance management and evaluation systems.

Equipment Management:

- Equipment maintenance and asset management software.

- Condition monitoring systems for machinery and equipment.

- Remote monitoring and control systems for equipment performance.

Access Control:

- Physical access control systems (e.g., keycards, biometric systems).

- Visitor management systems for controlled site access.

- Identity and credential management solutions.

- Security incident and threat management software.

Warehouse Management:

- Inventory management systems for tracking raw materials and finished goods.

- Warehouse automation and robotics solutions.

- Order fulfillment and picking optimization software.

- Real-time location tracking for warehouse assets.

- Barcode or RFID-based tracking systems for inventory control.

Supply Chain Management:

- Demand forecasting and planning software.

- Supplier relationship management systems.

- Logistics and transportation management platforms.

- Supply chain visibility and tracking solutions.

- Vendor-managed inventory (VMI) systems.

Other applications:

- Quality control and assurance systems

- Regulatory compliance monitoring

- Environmental health and safety management

- Data analytics and reporting tools

- Project management and collaboration platforms

- Customer relationship management (CRM) systems

GAO has enabled its customers to make use of some of leading software and cloud services in the nonmetallic mineral product manufacturing industry. Below are some of popular software and cloud services in the nonmetallic mineral product manufacturing industry:

- Oracle HCM Cloud: A comprehensive human capital management software that enables organizations to manage their entire HR lifecycle. Oracle HCM Cloud helps businesses optimize HR processes, improve employee engagement, and drive strategic workforce planning.

- IBM Maximo: Provides a cloud-based enterprise asset management (EAM) solution for managing equipment maintenance, work orders, inventory, and asset tracking.

- Oracle Warehouse Management Cloud: Offers a cloud-based warehouse management system with features for inventory tracking, order management, and labor optimization.

- 3PL Warehouse Manager: Provides a cloud-based warehouse management system (WMS) with features for inventory management, order fulfillment, and reporting.

- Oracle Supply Chain Management (SCM) Cloud: Offers a comprehensive suite of cloud-based supply chain management solutions, including demand planning, procurement, and logistics optimization.

- SAP Integrated Business Planning (IBP): Provides real-time data and analytics to facilitate collaborative decision-making, improve forecast accuracy, optimize inventory levels, and align business goals across different departments and functions.

- Microsoft Dynamic 365: Offers a cloud-based supply chain management platform with features for demand planning, warehouse management, and transportation management.

- Siemens Teamcenter: Helps organizations effectively manage and collaborate on product data, processes, and workflows, enabling streamlined innovation and improved productivity and offers a centralized platform for managing product information.

- Sparta Systems TrackWise: A powerful enterprise quality management software that enables organizations to effectively manage and track quality processes and compliance activities. TrackWise helps businesses enhance operational efficiency, ensure regulatory compliance, and drive continuous improvement in quality management.

- IQS Enterprise Quality Management Software: Offers comprehensive tools for managing audits, corrective actions, document control, and supplier quality, empowering businesses to drive continuous improvement, ensure compliance, and deliver high-quality products and services.

- Intelex EHS Management Software: Facilitates proactive risk assessment and management by enabling organizations to identify and evaluate potential hazards, assess their impact, and implement control measures to minimize risks.

- JDA Supply Chain Management: Offers a robust supply chain management platform with features for demand forecasting, inventory optimization, and transportation management.

Oracle HCM Cloud

Siemens Teamcenter

IQS Enterprise Quality Management Software

Sparta Systems TrackWise

Intelex EHS Management Software

Microsoft Dynamics 365

JDA Supply Chain Management

IBM Maximo

Oracle SCM Cloud

3PL Warehouse Manager

Oracle Warehouse Management Cloud

SAP Integrated Business

GAO has worked with some of the leading technology companies in nonmetallic mineral product manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the nonmetallic mineral product manufacturing industry:

- Amazon Web Services (AWS): Offers a wide range of cloud services, including storage, database, analytics, machine learning, and IoT, through its global infrastructure.

- Microsoft Azure: Provides a comprehensive suite of cloud services, including virtual machines, storage, databases, AI, analytics, and IoT, with global data centers and enterprise-grade security.

- Alibaba Cloud: Provides a wide range of cloud services, including storage, databases, networking, and AI, with a focus on serving businesses in the Asia-Pacific region.

- SAP Cloud Platform: Offers a robust and scalable platform-as-a-service (PaaS) solution, enabling businesses to develop, deploy, and manage cloud-based applications and services, with integrated analytics, machine learning, and IoT capabilities, for enhanced business agility and innovation.

- Siemens AG: Offer a wide range of products and services for various industries, including the Nonmetallic mineral product manufacturing sector, to optimize efficiency, enhance productivity, and drive sustainable growth.

- Schneider Electric SE: Provides a comprehensive portfolio of products and services for the nonmetallic mineral product manufacturing industry, helping organizations optimize energy usage, increase operational efficiency, and drive sustainability.

- ABB Ltd: Offers advanced technology solutions in robotics, power grids, industrial automation, and electrification, enabling industries to enhance productivity, efficiency, and sustainability.

- Rockwell Automation Inc: Provides innovative industrial automation and information solutions, empowering businesses to optimize their operations, improve productivity, and drive sustainable growth.

- Honeywell International Inc: Delivers cutting-edge technologies and solutions in aerospace, building technologies, performance materials, and safety to improve the quality of life and efficiency in various industries.

- Emerson Electric Corporation: Specializes in providing automation solutions, control systems, and measurement instruments for industries such as energy, manufacturing, and healthcare, enhancing operational performance and sustainability.

- Mitsubishi Electric Corporation: Offers a wide range of electrical and electronic products, including air conditioning systems, industrial automation equipment, and energy systems, contributing to a more comfortable and sustainable society.

Amazon Web Services

Microsoft Azure

IBM Cloud

Alibaba Cloud

Alibaba Cloud

Siemens AG

Schneider Electric SE

ABB Limited

Rockwell Automation Incorporation

Honeywell International Incorporation

SAP Cloud Platform

Mitsubishi Electric Corporation

Emerson Electric Corporation

Case Studies of RFID Applications

Below are some case studies for RFID and UHF RFID applications in the nonmetallic mineral product manufacturing industry:

LafargeHolcim, a key player in construction materials, revolutionized their operations using Radio Frequency Identification (RFID) technology. By integrating RFID tags into their products, LafargeHolcim achieved impressive gains in supply chain efficiency and automated inventory management. This case study exemplifies the successful implementation of RFID technology, showcasing its profound impact on optimizing the supply chain. As a central element of their supply chain strategy, LafargeHolcim adopted RFID tags, embedding them into concrete blocks and other construction materials. These tags facilitated seamless tracking and monitoring across the entire supply chain, with strategically placed RFID readers capturing unique identifiers emitted by the tags at manufacturing facilities, distribution centers, and construction sites.

CEMEX, a renowned global building materials company, embarked on a transformative journey by adopting Radio Frequency Identification (RFID) technology in their manufacturing processes. By integrating RFID tags into their cement products, CEMEX achieved significant improvements in inventory management, quality control, and production optimization. This case study highlights the successful implementation of RFID technology within CEMEX’s operations, showcasing its profound impact on manufacturing efficiency. CEMEX implemented RFID tags as a fundamental component of their manufacturing strategy. These tags were seamlessly integrated into their cement products, allowing for efficient tracking, and monitoring throughout the production processes. RFID readers strategically placed along the manufacturing line captured the unique identifiers emitted by the RFID tags, enabling real-time data capture.

Owens Corning, a renowned manufacturer specializing in insulation, roofing, and fiberglass composites, revolutionized their quality control and product authentication practices through the implementation of Ultra High Frequency Radio Frequency Identification (UHF RFID) technology. By integrating UHF RFID tags into product packaging, Owens Corning can monitor the product’s journey, ensure quality control, and authenticate genuine products. This case study highlights the successful integration of UHF RFID technology within Owens Corning’s operations, showcasing its significant impact on quality control. UHF RFID tags became a pivotal component of their quality control and product authentication, seamlessly integrated into product packaging to enable efficient tracking and monitoring.

CertainTeed, a leading building materials manufacturer, underwent a transformative journey by integrating Ultra High Frequency Radio Frequency Identification (UHF RFID) technology into maintenance and inspection operations. By utilizing UHF RFID tags, CertainTeed can monitor usage, schedule maintenance tasks, and track inspection history. This case study highlights the successful adoption of UHF RFID technology in CertainTeed’s operations and its substantial impact on maintenance and inspection operations. UHF RFID tags were implemented as a key element of their maintenance and inspection operations, securely attached to their machinery for seamless tracking and monitoring throughout the entire maintenance and inspection operations. UHF RFID readers strategically placed at manufacturing facilities captured the unique identifiers emitted by the UHF RFID tags, enabling efficient management.

Many applications of RFID by GAO can be found here:

GAO RFID Systems & Hardware for the Nonmetallic Mineral Product Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Nonmetallic mineral product manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

GAO’s BLE technology is suitable for many industries, including Nonmetallic mineral product manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Nonmetallic mineral product manufacturing.:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, and wristbands for various industries, including Nonmetallic mineral product manufacturing.

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications), and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Nonmetallic mineral product manufacturing.:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC, and LF RFID tags, labels, badges, and wristbands for various industries, including Nonmetallic mineral product manufacturing.:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF, and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 56 MHz High-Frequency RFID Modules

- 125 kHz Low-Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in Nonmetallic mineral product manufacturing.

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Crushers: Used to break down large rocks or minerals into smaller pieces for further processing.

- Mixers: Used to combine different raw materials, such as aggregates, cement, and water, to produce concrete or other composite materials.

- Kilns: High-temperature furnaces used for heating materials, such as clay, limestone, or gypsum, to produce ceramics, cement, or other calcined products.

- Extruders: Machines used to shape materials by forcing them through a die, commonly used in the production of ceramic tiles, pipes, or clay bricks.

- Molds and dies: Used to give shape to materials like glass, ceramics, or concrete during the manufacturing process.

- Dryers: Equipment used to remove moisture from materials, such as clay, before further processing or firing.

- Presses: Used to compress materials, such as powders or clay, into specific shapes or forms.

- Glass forming machines: Specialized equipment used in glass manufacturing, including glass blowing machines, glass pressing machines, and glass drawing machines.

- Spray dryers: Used in the production of powdered materials such as silica powder, pigments.

- Bagging and packaging machines: Used to package finished products into bags, containers, or other packaging materials such as polyethylene bags, cardboard boxes.

- Environmental control systems: Equipment like dust collectors, air scrubbers, and emission control systems used to maintain air quality and control dust and emissions during manufacturing processes.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Nonmetallic Mineral Product Manufacturing Extensively

GAO’s products and technologies have helped its customers in the nonmetallic mineral product manufacturing industry to achieve success in sustainability, circular economy, lightweight material, energy efficiency, digitalization and Industry 4.0, customization and personalization, advanced ceramics, 3D printing and additive manufacturing, smart building materials, nanomaterials, green certification, and standard, and resilient infrastructure.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the nonmetallic mineral product manufacturing, including many in its various divisions such as:

- Cement Manufacturing: This division involves the production of cement, which is a key component in concrete and used extensively in construction.

- Clay Product and Refractory Manufacturing: It includes the production of clay-based products such as bricks, tiles, pottery, and refractory materials, such as fireclay and High-Alumina Refractories, used in high-temperature applications like furnaces and kilns.

- Glass and Glass Product Manufacturing: This division involves the production of glass products, including flat glass used in windows and mirrors, containers, fiberglass, and various glassware.

- Lime and Gypsum Product Manufacturing: It includes the production of lime and gypsum products. Lime is used in construction, water treatment, and manufacturing processes, while gypsum is primarily used in the construction industry for wallboard and plaster.

- Concrete Pipe, Brick, and Block Manufacturing: This division involves the production of concrete pipes, bricks, and blocks used in construction projects.

- Mineral Wool Manufacturing: It encompasses the production of mineral wool insulation materials made from natural or synthetic minerals, such as Synthetic Vitreous Fiber (SVF) and Synthetic Rock Wool. These materials are used for thermal and acoustic insulation.

- Abrasive Product Manufacturing: This division involves the production of abrasive products such as sandpaper, grinding wheels, and abrasive coatings used for cutting, grinding, and polishing.

- Other Nonmetallic mineral product manufacturing: This category includes a range of other products like nonmetallic minerals used in manufacturing processes, such as talc, carbon black, graphite, and certain chemical compounds.

Here are some of the leading companies in the nonmetallic mineral product manufacturing industry:

Ash Grove Cement Company

Continental Building Products Company

GCP Applied Technologies

Martin Marietta Materials Company

US Silica Holdings Company

Eagle Materials Company

Oldcastle APG

Owens Corning Company

Boral Limited

CRH Public Limited Company

Vulcan Materials Company

Saint-Gobain Company

USG Corporation

CanWel Building Materials Group Limited

LafargeHolcim Company

3M Company

James Hardie Industries

CEMEX USA

Votorantim Cimentos

Polycor Incorporation

Georgia-Pacific Limited Liability Company

Mohawk Industries

Unilock Limited

Burnco Rock Products Limited