Overview

Other Fabricated Metal Product Manufacturing is a subsector of the manufacturing sector that includes establishments primarily engaged in fabricating metal products, except machinery and equipment. Establishments in this subsector use a variety of metal fabrication processes, such as forging, stamping, bending, forming, machining, welding, and assembling. They may also use finishing processes such as coating, plating, and painting. Other Fabricated Metal Product Manufacturing is a diverse and important sector of the economy. Its products are used in a wide range of industries, including construction, transportation, manufacturing, and consumer goods. GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the other fabricated metal product manufacturing to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Metal Cutting Equipment, Metal Forming Equipment, Welding and Joining Equipment, CNC Machining Equipment, Metal Finishing and Surface Treatment Equipment, Material Handling Equipment, Heat Treatment Equipment, Quality Control and Testing Equipment, Tooling and Toolroom Equipment, Safety Equipment, Material Handling and Storage Equipment, Computer Systems and Software, Dust and Fume Extraction Systems, Maintenance and Repair Tools, Packaging and Shipping Equipment. Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the other fabricated metal product manufacturing. Its sister company, GAO Tek Inc. is a leading supplier of industrial or commercial testers and analyzers, drones, and network products. The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Other Fabricated Metal Product Manufacturing

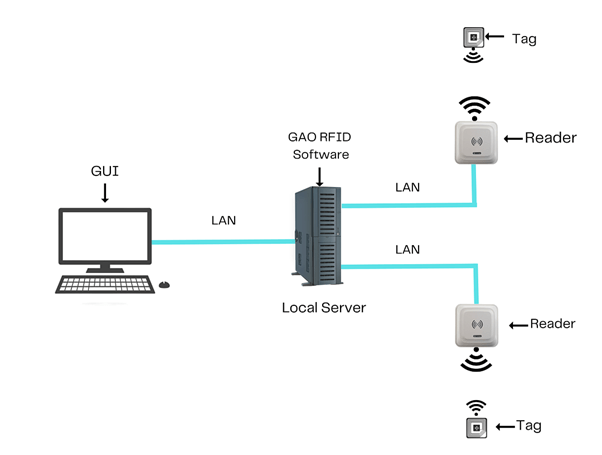

To satisfy its customers, GAO’s RFID or RFID Systems for other fabricated metal product manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for other fabricated metal product manufacturing software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for other fabricated metal product manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for other fabricated metal product manufacturing software running on a local server.

The above illustrates GAO system for other fabricated metal product manufacturing with its software running in cloud.

The above illustrates GAO system for other fabricated metal product manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in other fabricated metal product manufacturing:

- Inventory tracking: GAO’s RFID tags can be attached to metal products to track their location and movement throughout the manufacturing process. This can help to improve inventory accuracy and reduce waste.

- Asset tracking: GAO’s RFID tags can also be used to track the location and movement of assets, such as tools and equipment. This can help to prevent loss and theft and ensure that assets are available when needed.

- Quality control: GAO’s RFID tags can be used to store and track data about the manufacturing process, such as the date and time of production, the type of materials used, and the results of quality control tests. This data can be used to identify and correct problems in the manufacturing process, and to ensure that products meet quality standards.

- Work-in-progress tracking: GAO’s RFID tags can be used to track the progress of metal products through different stages of the manufacturing process. This can help to identify bottlenecks and improve efficiency.

- Security: GAO’s RFID tags can be used to restrict access to sensitive areas of the manufacturing plant, or to track the movement of people and materials. This can help to improve security and reduce the risk of theft.

- Metal forging companies: GAO’s RFID tags are being used to track the movement of metal forgings through the forging process. This helps to ensure that forgings are heated to the correct temperature and forged to the correct specifications.

- Metal stamping companies: GAO’s RFID tags are being used to track the movement of metal stampings through the stamping process. This helps to ensure that stampings are produced in the correct order and that they meet quality standards.

- Metal coating companies: GAO’s RFID tags are being used to track the movement of metal products through the coating process. This helps to ensure that products are coated with the correct type of coating and that they are coated to the correct thickness.

- Metal fabrication companies: GAO’s RFID tags are being used to track the movement of metal products through the fabrication process. This helps to ensure that products are fabricated to the correct specifications and that they are completed on time.

- Product authentication: GAO’s RFID tags can be used to authenticate metal products and prevent counterfeiting.

- Shipping and logistics: GAO’s RFID tags can be used to track the shipment of metal products from the manufacturer to the customer. This can help to improve visibility and reduce the risk of loss or theft.

- Maintenance and repair: GAO’s RFID tags can be used to track the maintenance and repair history of metal products. This information can be used to identify potential problems and to schedule preventive maintenance.

GAO’s drone technologies find the following applications in the other fabricated metal product manufacturing:

- Inspection: GAO’s Drones can be used to inspect metal products for defects and damage. This can be especially useful for inspecting large or complex products, or products that are difficult to reach.

- Inventory management: GAO’s Drones can be used to count inventory and track the movement of materials throughout the manufacturing plant. This can help to improve accuracy and efficiency.

- Security: GAO’s Drones can be used to patrol the manufacturing plant and deter theft and vandalism.

- Delivery: GAO’s Drones can be used to deliver small parts and supplies to different areas of the manufacturing plant. This can help to reduce downtime and improve efficiency.

- Maintenance: GAO’s Drones can be used to inspect and maintain manufacturing equipment. This can help to reduce downtime and extend the life of equipment.

- Metal forging companies: GAO’s Drones are being used to inspect metal forgings for defects and damage. This is especially useful for inspecting large forgings that would be difficult to inspect manually.

- Metal stamping companies: GAO’s Drones are being used to count inventory and track the movement of metal stampings through the stamping process. This helps to ensure that stampings are produced in the correct order and that they meet quality standards.

- Metal coating companies: GAO’s Drones are being used to inspect metal products for coating defects. This helps to ensure that products are coated to the correct thickness and that they meet quality standards.

- Metal fabrication companies: GAO’s Drones are being used to inspect metal fabrications for defects and damage. This is especially useful for inspecting large or complex fabrications.

- Mapping and surveying: GAO’s Drones can be used to create detailed maps and surveys of the manufacturing plant and its surroundings. This information can be used for planning purposes, as well as for security and emergency response.

- Training: GAO’s Drones can be used to create training materials and simulations. This can help to improve the skills and knowledge of employees.

- Public relations: GAO’s Drones can be used to take photos and videos of the manufacturing plant and its products. This content can be used for marketing and public relations purposes.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the other fabricated metal product manufacturing:

- Predictive maintenance: GAO’s IoT sensors can be used to monitor the condition of machinery and equipment. This data can be used to predict when maintenance is needed, which can help to reduce downtime and extend the life of equipment.

- Quality control: GAO’s IoT sensors can be used to collect data about the manufacturing process, such as temperature, pressure, and flow rate. This data can be used to identify and correct problems in the manufacturing process, and to ensure that products meet quality standards.

- Process optimization: GAO’s IoT data can be used to analyze and optimize the manufacturing process. This can help to improve efficiency and reduce waste.

- Inventory management: GAO’s IoT sensors can be used to track the location and movement of inventory. This data can be used to improve inventory accuracy and reduce stockouts.

- Safety monitoring: GAO’s IoT sensors can be used to monitor the environment for safety hazards, such as gas leaks and fire hazards. This data can be used to alert workers and prevent accidents.

- Metal forging companies: GAO’s IoT sensors are being used to monitor the temperature and pressure of forging presses. This data is used to ensure that forgings are heated to the correct temperature and forged to the correct specifications.

- Metal stamping companies: GAO’s IoT sensors are being used to monitor the performance of stamping presses. This data is used to identify and correct problems in the stamping process, and to ensure that stampings are produced to the correct specifications.

- Metal coating companies: GAO’s IoT sensors are being used to monitor the thickness of coatings on metal products. This data is used to ensure that products are coated to the correct thickness and that they meet quality standards.

- Metal fabrication companies: GAO’s IoT sensors are being used to track the progress of metal products through the fabrication process. This data is used to identify bottlenecks and improve efficiency.

- Energy management: GAO’s IoT sensors can be used to monitor energy consumption and identify areas for improvement. This can help manufacturers to reduce their energy costs and environmental impact.

- Sustainability: GAO’s IoT can be used to support sustainable manufacturing practices. For example, IoT sensors can be used to monitor waste production and identify opportunities to reduce waste.

- New product development: GAO’s IoT data can be used to develop new products and services that meet the needs of customers. For example, manufacturers can use IoT data to develop products that are more efficient, durable, or sustainable.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Other Fabricated Metal Product Manufacturing

GAO RFID Inc. has helped many companies in other fabricated metal product manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO/IEC 14443: Proximity cards

- ISO/IEC 15693: Vicinity cards

- ISO/IEC 18000: Radio frequency identification

- ISO/IEC 24265: High frequency RFID technology

- ISO/IEC 29167: UHF RFID technology

- Bluetooth 4.2

- Bluetooth 5.0

- Bluetooth 5.1

- Bluetooth 5.2

- IEEE 802.11a/b/g/n/ac/ax: Wi-Fi

- IEEE 802.15.4: ZigBee

- IEEE 802.15.4: Thread

- IEEE 802.15.4: Low-power Wi-Fi (LP-Wi-Fi)

- Narrowband-IoT (NB-IoT)

- Long Term Evolution for Machines (LTE-M)

- 5G NR

- ASTM International F3107: Standard Specification for Unmanned Aircraft Systems (UAS)

- ASTM International F3348: Standard Guide for Remote Pilots of Unmanned Aircraft Systems

- ASTM International F3411: Standard Practice for Operation of Unmanned Aircraft Systems (UAS)

- ISO/IEC 20671: Unmanned aircraft systems (UAS)

- RTCA DO-178B: Software Considerations in Airborne Systems and Equipment Certification

- RTCA DO-254: Design Assurance Guidance for Airborne Electronic Hardware

US. Government Regulations

- Clean Air Act

- Clean Water Act

- Resource Conservation and Recovery Act (RCRA)

- Toxic Substances Control Act (TSCA)

- Occupational Safety and Health Act (OSH Act)

- Department of Transportation (DOT)

- Hazardous Materials Transportation Act

- Pipeline Safety Act

- Consumer Product Safety Commission (CPSC)

- Consumer Product Safety Improvement Act (CPSIA)

- National Highway Traffic Safety Administration (NHTSA)

- Motor Vehicle Safety Act

Canadian Government Regulations

- Canadian Environmental Protection Act, 1999 (CEPA 1999)

- Canadian Occupational Safety and Health Regulations (COSHR)

- Transportation of Dangerous Goods Act, 1992 (TDG Act)

- Canada Consumer Product Safety Act (CCPSA)

- Motor Vehicle Safety Act (MVSA)

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in other fabricated metal product manufacturing such as:

Personnel management:

- Time and attendance tracking

- Payroll processing

- Employee training and development

- Performance management

- Workforce analytics

Equipment management:

- Asset tracking and maintenance

- Predictive maintenance

- Inventory management

- Procurement

Access control:

- Physical access control (e.g., key cards, biometrics)

- Logical access control (e.g., passwords, multi-factor authentication)

- Visitor management

Warehouse management:

- Inventory tracking

- Order fulfillment

- Picking and packing

- Shipping and receiving

Supply chain management:

- Supplier management

- Transportation management

- Inventory planning

- Demand forecasting

Other applications:

- Quality control

- Production planning

- Product lifecycle management

- Customer relationship management (CRM)

- Enterprise resource planning (ERP)

GAO has enabled its customers to make use of some of the leading software and cloud services in the manufacturing of other fabricated metal products. Below are some of the popular software and cloud services in other fabricated metal product manufacturing such as Workday, SAP SuccessFactors, ADP Workforce Now, Oracle HCM Cloud, Infor HCM, IBM Maximo, SAP Asset Manager, WorkWave, Infor EAM, IFS Maintenix, Genetec Security Center, Honeywell Pro-Watch, Salto Systems, Allegion Schlage, HIDt, Manhattan Associates Warehouse Management System, JDA Warehouse Management System, Infor WMS, SAP EWM, Oracle WMS Cloud, JDA Transportation Management System, Oracle Transportation Management, SAP Transportation Management, Manhattan Associates Transportation Management, MercuryGate International, Siemens NX, Dassault Systèmes SOLIDWORKS, PTC Creo, Autodesk Inventor, Hexagon Manufacturing Intelligence EDGECAM. GAO has worked with some of the leading technology companies’ other fabricated metal product manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in other fabricated metal product manufacturing such as Siemens, Dassault Systèmes, PTC, Autodesk, Hexagon Manufacturing Intelligence, IBM, SAP, Oracle, Infor, JDA Software, Manhattan Associates, MercuryGate International, Honeywell, Salto Systems, Allegion Schlage, HID Global.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

In the USA, RFID Improves Asset Tracking at Metal Fabrication Company. Metal Fab was struggling to track its inventory and equipment. The company was using a manual system. Metal Fab implemented an RFID system to track its inventory and equipment. The company attached RFID tags to all its assets. RFID readers were placed at key locations throughout the manufacturing plant. The RFID system has helped Metal Fab to improve its inventory accuracy and reduce its asset loss. The system has also helped to improve the company’s efficiency and productivity. RFID Helps Metal Stamping Company to Improve Quality Control. Metal Stamping Inc. was struggling to ensure the quality of its products. The company was using a manual system to inspect its products. Metal Stamping Inc. implemented an RFID system to inspect its products. The company attached RFID tags to all its products. RFID readers were placed at key locations throughout the manufacturing plant. The RFID system has helped Metal Stamping Inc. to improve the quality of its products. The system has also helped to reduce the company’s scrap rate and improve its efficiency. FID Helps Metal Fabrication Company to Reduce Costs. Metal Fabrication Company was struggling to reduce its costs. The company was using a manual system to manage its inventory and production. Metal Fabrication Company implemented an RFID system to manage its inventory and production. The company attached RFID tags to all its raw materials, work-in-progress, and finished goods. RFID readers were placed at key locations throughout the manufacturing plant. The RFID system has helped Metal Fabrication Company to reduce its costs. The system has helped the company to improve its inventory accuracy, reduce its waste, and improve its efficiency.

RFID Helps Canadian Metal Fabrication Company to Improve Efficiency. Canadian Metal Fabrication Company was struggling to improve its efficiency. The company was using a manual system to track its inventory and production. Canadian Metal Fabrication Company implemented an RFID system to track its inventory and production. The company attached RFID tags to all its raw materials, work-in-progress, and finished goods. RFID readers were placed at key locations throughout the manufacturing plant. The RFID system has helped Canadian Metal Fabrication Company to improve its efficiency. The system has helped the company to reduce its inventory cycle times, improve its production planning, and improve its customer service.

RFID Helps Canadian Metal Stamping Company to Reduce Waste. Canadian Metal Stamping Company was struggling to reduce its waste. The company was using a manual system to inspect its products, which was time-consuming and error prone. Canadian Metal Stamping Company implemented an RFID system to inspect its products. The company attached RFID tags to all its products. RFID readers were placed at key locations throughout the manufacturing plant. The RFID system has helped Canadian Metal Stamping Company to reduce its waste. The system has helped the company to identify and correct quality problems early in the manufacturing process. This has helped the company to reduce its scrap rate and improve its profitability.

RFID Helps Canadian Metal Fabrication Company to Improve Security. Canadian Metal Fabrication Company was struggling to improve its security. The company was using a manual system to track its inventory and employees. Canadian Metal Fabrication Company implemented an RFID system to track its inventory and employees. The company attached RFID tags to all its assets and employees. RFID readers were placed at key locations throughout the manufacturing plant. The RFID system has helped Canadian Metal Fabrication Company to improve its security. The system has helped the company to prevent theft and improve its employee safety.

Many applications of RFID by GAO can be found here.

Manufacturing RFID Systems & Solutions (gaorfid.com)

Case Studies of IoT Applications

Below are some IoT application cases in the other fabricated metal product manufacturing.

In the USA, The IoT system has helped US Metal Fabrication Company to improve its efficiency. The system has helped the company to reduce its inventory cycle times, improve its production planning, and improve its customer service. The IoT system has helped US Metal Stamping Company to reduce its waste. The system has helped the company to identify and correct quality problems early in the manufacturing process. This has helped the company to reduce its scrap rate and improve its profitability. The IoT system has helped US Metal Fabrication Company to reduce its costs. The system has helped the company to reduce its energy consumption by up to 20%. The IoT system has helped US Metal Fabrication Company to improve its safety. The system has helped the company to identify and correct safety hazards before they can cause accidents. This has helped the company to reduce its workplace injuries and improve its safety record.

In Canada, The IoT system has helped Canadian Metal Fabrication Company to improve its efficiency. The system has helped the company to reduce its inventory cycle times, improve its production planning, and improve its customer service. The IoT system has helped Canadian Metal Stamping Company to reduce its waste. The system has helped the company to identify and correct quality problems early in the manufacturing process. This has helped the company to reduce its scrap rate and improve its profitability. The IoT system has helped Canadian Metal Fabrication Company to improve its safety. The system has helped the company to identify and correct safety hazards before they can cause accidents. This has helped the company to reduce its workplace injuries and improve its safety record.

In Mexico, Mexican Metal Fabrication Company implemented an IoT system to track its inventory and production. The company installed IoT sensors on its machines and equipment. The sensors collect data on the status of the equipment and the progress of production. This data is transmitted to a central server, where it is analyzed to identify areas for improvement. The IoT system has helped Mexican Metal Fabrication Company to improve its efficiency. The system has helped the company to reduce its inventory cycle times, improve its production planning, and improve its customer service. The IoT system has helped Mexican Metal Stamping Company to reduce its waste. The system has helped the company to identify and correct quality problems early in the manufacturing process. This has helped the company to reduce its scrap rate and improve its profitability. Mexican Metal Fabrication Company implemented an IoT system to manage its energy consumption. The company installed IoT sensors on its equipment and machinery. The sensors collect data on the energy consumption of the equipment. This data is transmitted to a central server, where it is analyzed

In Europe, The IoT system has helped German Metal Fabrication Company to improve its efficiency. The system has helped the company to reduce its inventory cycle times, improve its production planning, and improve its customer service. Italian Metal Stamping Company implemented an IoT system to inspect its products. The company installed IoT sensors on its production lines. The sensors collect data on the quality of the products. This data is transmitted to a central server, where it is analyzed to identify quality problems. The IoT system has helped Italian Metal Stamping Company to reduce its waste. The system has helped the company to identify and correct quality problems early in the manufacturing process. This has helped the company to reduce its scrap rate and improve its profitability.

French Metal Fabrication Company implemented an IoT system to manage its energy consumption. The company installed IoT sensors on its equipment and machinery. The sensors collect data on the energy consumption of the equipment. This data is transmitted to a central server, where it is analyzed to identify areas where energy consumption can be reduced. The IoT system has helped French Metal Fabrication Company to reduce its costs. The system has helped the company to reduce its energy consumption by up to 20%.

Spanish Metal Fabrication Company implemented an IoT system to monitor its equipment for safety hazards. The company installed IoT sensors on its machines and equipment. The sensors collect data on the condition of the equipment and the presence of safety hazards. This data is transmitted to a central server, where it is analyzed to identify potential safety hazards. The IoT system has helped Spanish Metal Fabrication Company to improve its safety. The system has helped the company to identify and correct safety hazards before they can cause accidents. This has helped the company to reduce its workplace injuries and improve its safety record.

Case Studies of Drone Applications

Below are some drone application cases in the other fabricated metal product manufacturing.

In the US Metal Fabrication Company implemented a drone-based inventory management system. The company uses drones to fly through its warehouse and scan its inventory. The data collected by the drones is transmitted to a central server, where it is used to generate real-time inventory. The drone-based inventory management system has helped US Metal Fabrication Company to improve its inventory accuracy and reduce its inventory costs. The system has also helped the company to improve its customer service by enabling it to fulfill orders more quickly and accurately. US Metal Stamping Company implemented a drone-based quality inspection system. The company uses drones to fly over its production lines and inspect its products for defects. The drones are equipped with high-resolution cameras that can capture images and videos of the products. The images and videos are transmitted to a central server, where they are analyzed by quality control personnel. The drone-based quality inspection system has helped US Metal Stamping Company to improve the quality of its products. The system has helped the company to identify and correct quality problems early in the manufacturing process. This has helped the company to reduce its scrap rate and improve its profitability.US Metal Fabrication Company implemented a drone-based delivery system. The company uses drones to deliver its products to customers within a certain radius of its manufacturing plant. The drones can fly directly to the customer’s location, which saves time and money. The drone-based delivery system has helped US Metal Fabrication Company to improve its customer service and reduce its shipping costs. The system has also helped the company to expand its reach and deliver its products to customers in new areas.

In Canada, Canadian Metal Fabrication Company used drones to inspect the pipeline. The drones were able to fly over the pipeline and take high-resolution images and videos. The images and videos were transmitted to a central server, where they were analyzed by engineers. The drone-based inspection system helped Canadian Metal Fabrication Company to identify and repair several defects in the pipeline. The system saved the company time and money, and it also helped to improve the safety of the pipeline. Canadian Metal Stamping Company used drones to deliver its products to customers in the remote area. The drones were able to fly directly to the customer’s location, which saved time and money. The drone-based delivery system helped Canadian Metal Stamping Company to expand its reach and deliver its products to customers in new areas. The system also helped the company to improve its customer service by enabling it to deliver products to customers more quickly and accurately.

In Mexico, Mexican Metal Fabrication Company Uses Drones to Survey.

In Europe, German Metal Fabrication Company used drones to inspect its wind turbines. The drones were able to fly over the turbines and take high-resolution images and videos. The images and videos were transmitted to a central server, where they were analyzed by engineers. The drone-based inspection system helped German Metal Fabrication Company to identify and repair several defects in its wind turbines. The system saved the company time and money, and it also helped to improve the safety and performance of its wind turbines. Italian Metal Stamping Company used drones to deliver its products to customers in both urban and rural areas. The drones were able to fly directly to the customer’s location, which saved time and money. The drone-based delivery system helped Italian Metal Stamping Company to improve its customer service and reduce its shipping costs. The system also helped the company to expand its reach and deliver its products to customers in new areas. Spanish Metal Fabrication Company used drones to map its construction sites. The drones were able to fly over the sites and collect data that was used to create accurate and up-to-date maps. The drone-based mapping system helped Spanish Metal Fabrication Company to improve its efficiency and reduce its costs. The system also helped the company to track progress and ensure that projects were on schedule.

GAO RFID Systems & Hardware for Other Fabricated Metal Product Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the other fabricated metal product manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the other fabricated metal product manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the other fabricated metal product manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the other fabricated metal product manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the other fabricated metal product manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the other fabricated metal product manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in the other fabricated metal product manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

CNC laser cutters, CNC plasma cutters, waterjet cutters, press brakes, shears, rolling mills, arc welders, MIG welders, TIG welders, grinders, sanders, buffing wheels

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for the other fabricated metal product manufacturing and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in the other fabricated metal product manufacturing we have worked with to serve our joint customers:

- Accenture

- Avanade

- Capgemini

- Cognizant

- Deloitte

- DXC Technology

- Ernst & Young

- Fujitsu

- Hitachi Vantara

- IBM

- Infosys

- KPMG

- Kyndryl

- NTT DATA

- PwC

- SAP

- TCS

- Wipro

GAO Has Served Other Fabricated Metal Product Manufacturing Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products. GAO’s products and technologies have helped its customers in other fabricated metal product manufacturing to achieve success in Artificial intelligence, machine learning, robotics, automation, Internet of Things, digital twins, additive manufacturing, big data, analytics, cloud computing, cybersecurity, sustainability, green manufacturing, circular economy. GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in other fabricated metal product manufacturing, including many in its various divisions such as:

- Architectural and structural metals manufacturing: This sub-industry manufactures metal products that are used in the construction of buildings and other structures, such as beams, columns, trusses, and metal roofing and siding.

- Boiler, tank, and shipping container manufacturing: This sub-industry manufactures metal products that are used to store and transport liquids, gases, and solids, such as boilers, tanks, pressure vessels, and shipping containers.

- Hardware manufacturing: This sub-industry manufactures a wide range of metal products that are used in construction and manufacturing, such as screws, nails, bolts, nuts, hinges, and locks.

- Kitchen utensil, cutlery, and flatware manufacturing: This sub-industry manufactures metal products that are used in the preparation and serving of food, such as pots, pans, skillets, knives, forks, and spoons.

- Metal forgings and stampings manufacturing: This sub-industry manufactures metal products by heating and shaping metal blanks using forging and stamping processes. Forged and stamped metal products are used in a wide range of industries, including automotive, aerospace, and construction.

- Metal valve manufacturing: This sub-industry manufactures metal valves that are used to control the flow of liquids and gases in pipelines and other piping systems. Metal valves are used in a wide range of industries, including oil and gas, chemical processing, and power generation.

- Ornamental and architectural metal manufacturing: This sub-industry manufactures metal products that are used for decorative purposes, such as railings, fences, gates, and metal signage.

- Safes and vault doors manufacturing: This sub-industry manufactures metal safes and vault doors that are used to protect valuables from theft and fire.

- Screw, nut, rivet, and washer manufacturing: This sub-industry manufactures a wide range of metal fasteners, such as screws, nuts, rivets, and washers. Metal fasteners are used in a wide range of industries, including construction, manufacturing, and automotive.

- Spring and wire product manufacturing: This sub-industry manufactures metal springs and wire products, such as springs for mattresses, cars, and appliances, and wire for fences, cages, and other applications.

- Tools and hardware manufacturing: This sub-industry manufactures a wide range of metal tools and hardware, such as hand tools, power tools, and construction hardware.

- Welding and soldering equipment manufacturing: This sub-industry manufactures welding and soldering equipment, such as arc welders, MIG welders, TIG welders, and soldering irons. Welding and soldering equipment is used in a wide range of industries, including construction, manufacturing, and automotive.

GAO’s technologies enable its customers in other fabricated metal product manufacturing to effectively track their workforces such as Metalworker, Fabricator, Machinist, Welder, Inspector, Engineer, Technician, Manager, Supervisor, Operator, Laborer and effectively track operational assets such as Cutting machine, forming machine, welding machine, finishing equipment. Here are some of the leading companies in the fabricated metal product manufacturing GAO has served:

- Precision Metal Products

- General Metal Industries

- New England Metal Fabricators

- Metalcraft

- MacDermid Alpha Electronics Solutions

- Kennametal

- Morton Industries

- Jernberg Industries

- Triad Manufacturing

- Fabco Metals

- Accurate Stamping

- Badger Die Casting

- Alaska Welding

- Southwest Metal

- Arizona Metal

- Utah Metal Fab

- Idaho Steel Products

- Nevada Metal Fab

- Stelco Inc.

- Gerdau Steel North America Inc.

- ArcelorMittal Dofasco

- Russel Metals Inc.

- MetalMart Inc.

- Samuel, Son & Co. Limited

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com