Overview

The plastic and rubber manufacturing industry is a pivotal sector responsible to produce synthetic materials used in a multitude of applications. Plastics, originating from petrochemical sources, are divided into thermoplastics and thermosetting plastics, each serving diverse purposes. Common examples include polyethylene, polypropylene, and PVC. On the other hand, rubber materials, renowned for their elasticity and flexibility, can be sourced naturally from latex or produced synthetically to meet specific performance criteria. Manufacturing processes encompass extrusion, injection molding, compression molding, blow molding, and vulcanization, each tailored to the material and product requirements. These materials play essential roles across various industries, with plastics utilized in packaging, automotive, electronics, and more, while rubber finds applications in tires, seals, industrial equipment, and footwear. Regulatory compliance is crucial in ensuring product safety, environmental responsibility, and workplace safety within this dynamic and evolving industry.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the plastic and rubber manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as extrusion machines, injection molding machines, compression molding machines, calendaring machines, blow molding machines, mixing and compounding equipment, vulcanization equipment, extruders, cooling and heating systems, molds and dyes, cutting and trimming machinery, material handling systems, quality control and testing equipment, melt filter and screens, grinders and shredders, mixing blades and rotors and safety equipment.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the plastic and rubber manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Plastic and Rubber Manufacturing Industry

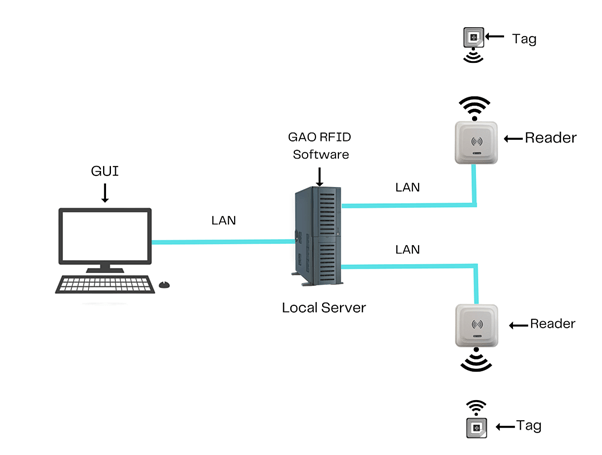

To satisfy its customers, GAO’s RFID or RFID Systems for plastic and rubber manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for plastic and rubber manufacturing software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for plastic and rubber manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for plastic and rubber manufacturing software running on a local server.

The above illustrates GAO system for plastic and rubber manufacturing with its software running in cloud.

The above illustrates GAO system for plastic and rubber manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in plastic and rubber manufacturing industry:

- Inventory and Asset Management: GAO’s RFID tags enable real-time tracking of raw materials, components, equipment, and molds, optimizing inventory management and asset utilization.

- Quality Control and Traceability: GAO’s RFID ensures traceability of materials and products, facilitating quality control, regulatory compliance, and quick identification of any defects or issues.

- Worker Safety: GAO’s RFID-based access control and safety badges enhance worker safety by restricting access to authorized personnel and ensuring they have the necessary training and protective equipment.

- Maintenance Optimization: GAO’s RFID-triggered maintenance alerts help prevent equipment breakdowns, reducing downtime, and optimizing maintenance schedules for critical machinery.

- Supply Chain Visibility: GAO’s RFID technology provides end-to-end visibility in the supply chain, improving coordination among suppliers, manufacturers, and distributors, ultimately enhancing efficiency and customer satisfaction.

GAO’s drone technologies find the following applications in the plastic and rubber manufacturing industry:

- Equipment Inspection: GAO’s drones equipped with cameras and sensors are employed to conduct aerial inspections of specialized manufacturing equipment, such as injection molding machines and extruders, ensuring their operational efficiency and identifying maintenance needs.

- Inventory Management: GAO’s drones equipped with RFID technology perform automated aerial inventory checks in warehouses holding plastic and rubber raw materials, molds, and finished products, streamlining inventory tracking and reducing manual labor.

- Site Surveys and Layout Planning: GAO’s drones are used to conduct site surveys of manufacturing facilities, aiding in the planning and optimization of equipment layout and assisting in decision-making for facility expansion or reorganization.

- Environmental Monitoring: GAO’s drones equipped with environmental sensors monitor critical factors like temperature, humidity, and air quality within the manufacturing environment, ensuring compliance with industry standards and regulations.

- Security and Safety: GAO’s drones enhance security by monitoring worker activities in large production areas, helping to enforce safety protocols and ensuring worker well-being. They also survey perimeter security to safeguard valuable equipment and materials.

- Logistics and Supply Chain: GAO’s drones assist in streamlining logistics within the Plastic and Rubber Manufacturing industry by tracking the movement of materials, components, and finished products between manufacturing facilities and distribution centers.

- Emergency Response: GAO’s drones can be deployed for rapid assessment in case of accidents or emergencies within manufacturing plants, providing real-time data to support decision-making and ensuring the safety of workers and responders.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the plastic and rubber manufacturing industry:

- Machine Monitoring and Predictive Maintenance: GAO’s IoT sensors can be integrated into specialized equipment like injection molding machines, extruders, and curing ovens. These sensors collect data on equipment performance, allowing for real-time monitoring and predictive maintenance to prevent breakdowns and optimize production.

- Quality Control and Defect Detection: GAO’s IoT sensors can monitor various parameters during the manufacturing process, such as temperature, pressure, and material composition. This data helps detect defects or deviations from quality standards in real-time, ensuring consistent product quality.

- Inventory Management: GAO’s RFID and IoT sensors can be used to track the movement of raw materials, molds, and finished products within warehouses and manufacturing facilities. This improves inventory accuracy and ensures the availability of materials when needed.

- Energy Efficiency: GAO’s IoT sensors can monitor energy consumption in manufacturing plants, identifying areas where energy-saving measures can be implemented, such as optimizing heating and cooling systems or lighting.

- Worker Safety: GAO’s IoT wearables can enhance worker safety by monitoring environmental conditions, providing location tracking, and alerting workers to potential hazards. This is particularly crucial in environments with heavy machinery and specialized worker roles like mold setters and process engineers.

- Supply Chain Visibility: GAO’s IoT technology provides real-time visibility into the supply chain, helping manufacturers track the movement of materials and products from suppliers to production facilities and distribution centers, ensuring timely deliveries and reducing disruptions.

- Process Automation: GAO’s IoT-enabled devices can automate routine tasks and adjustments in the manufacturing process, improving efficiency and reducing the need for constant manual intervention from operators and process technicians.

- Remote Monitoring and Control: GAO’s plant managers and engineers can remotely monitor and control equipment and processes using IoT-enabled devices, allowing for real-time adjustments and troubleshooting, even from off-site locations.

- Maintenance Scheduling: GAO’s IoT data analytics can assist in creating maintenance schedules based on actual equipment performance rather than fixed time intervals, optimizing maintenance efforts and reducing downtime.

- Data Analytics and Decision Support: GAO’s IoT-generated data can be analyzed to gain insights into production trends, identify areas for improvement, and support data-driven decision-making by roles such as production supervisors and quality control engineers.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Plastic and Rubber Manufacturing Industry

GAO RFID Inc. has helped many companies in plastic and rubber manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 series

- EPCglobal Gen2

- ISO 15693

- ISO 14443

- Bluetooth SIG(Special Interest Group)

- ASTM International(American Society for Testing and Materials)

- ASTM F2910

US Government Regulations

- Clean Air Act (CAA)

- Clean Water Act (CWA)

- Resource Conservation and Recovery Act (RCRA)

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- Occupational Safety and Health Act (OSHA)

- Toxic Substances Control Act (TSCA)

- Federal Food, Drug, and Cosmetic Act (FFDCA)

- National Emission Standards for Hazardous Air Pollutants (NESHAPs)

- Environmental Protection Agency (EPA) Regulations

- Hazard Communication Standard (HCS)

- Consumer Product Safety Commission (CPSC) Regulations

- Department of Transportation (DOT) Regulations

- National Fire Protection Association (NFPA) Standards

- S. Food and Drug Administration (FDA) Regulations

- Federal Trade Commission (FTC) Regulations

- National Institute for Occupational Safety and Health (NIOSH) Regulations

- S. Department of Agriculture (USDA) Regulations

- Occupational Safety and Health Administration (OSHA) Regulations for Lockout/Tagout (LOTO)

- Clean Energy Standard (CES) Programs

- Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)

Canadian Government Regulations

- Canadian Environmental Protection Act, 1999 (CEPA 1999)

- Canadian Environmental Assessment Act, 2012 (CEAA 2012)

- Canadian Consumer Product Safety Act (CCPSA)

- Canadian Standards Association (CSA) Standards

- Transportation of Dangerous Goods (TDG) Regulations

- Workplace Hazardous Materials Information System (WHMIS) Regulations

- Environment and Climate Change Canada (ECCC) Regulations

- National Energy Board (NEB) Regulations

- Food and Drugs Act

- Health Canada Regulations

- Pest Control Products Act

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in plastic and rubber manufacturing such as:

Personnel Management:

- Employee Scheduling and Shift Management

- Training and Certification Tracking

- Health and Safety Compliance

- Workforce Analytics and Performance Monitoring

- Payroll and Compensation Management

Equipment Management:

- Equipment Maintenance and Preventive Maintenance

- Asset Tracking and Inventory Management

- Equipment Performance Monitoring

- Equipment Calibration and Quality Control

- Downtime Analysis and Optimization

Access Control:

- Access Control Systems for Secure Areas

- RFID-Based Access Control

- Biometric Authentication for Sensitive Equipment

- Visitor Management and Security Clearance

Warehouse Management:

- Inventory Tracking and Replenishment

- Warehouse Layout Optimization

- Barcode and RFID-Based Inventory Control

- Order fulfilment and Picking Optimization

- Material Handling Equipment Integration

Supply Chain Management:

- Supplier Relationship Management (SRM)

- Demand Forecasting and Planning

- Just-In-Time (JIT) Inventory Management

- Transportation Management and Routing

- Vendor Managed Inventory (VMI) Programs

Other Applications:

- Emission Monitoring and Reporting

- Environmental Impact Assessment

- Waste Management and Recycling

- Sustainable Material Sourcing

- Energy Efficiency and Conservation

- Material Requirement Planning (MRP)

- Lean Manufacturing and Six Sigma

- Batch Processing and Recipe Management

- Real-Time Production Monitoring

GAO has enabled its customers to make use of some of the leading software and cloud services in the plastic and rubber manufacturing industry. Below are some of the popular software and cloud services in plastic and rubber manufacturing

SAP SuccessFactors, Workday HCM, Oracle HCM Cloud, ADP Workforce Now, and BambooHR. For equipment management, notable options are eMaint CMMS, Flix, UpKeep, Maintenance Connection, Hippo CMMS. Access control solutions encompass LenelS2, Honeywell Access Control, AMAG Technology, Brivo, Paxton. In the realm of warehouse management, the top choices consist of Manhattan Associates Warehouse Management, HighJump Warehouse Management System (WMS), Oracle Warehouse Management Cloud, SAP Extended Warehouse Management and Blue Yonder Warehouse Management. In supply chain management, SAP Integrated Business Planning (IBP), Oracle Supply Chain Management Cloud, Kinaxis RapidResponse, JDA Software, Manhattan Associates SCM. General application software is SAP ERP, Oracle ERP Cloud, Microsoft Dynamics 365, Plex Manufacturing Cloud.

GAO has worked with some of the leading technology companies’ plastic and rubber manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in plastic and rubber manufacturing.

SAP, Oracle, IBM, Plex Systems, ABB, Siemens, Rockwell Automation, Mitsubishi Electric, Honeywell, Fanuc, Yokogawa Electric, Emerson Electric, etc.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in plastic and rubber manufacturing industry.

In a major U.S. plastic and rubber manufacturing plant, RFID technology was implemented to optimize inventory management. RFID tags were used to track the movement of components and equipment throughout the production process, resulting in a 20% reduction in inventory carrying costs and a 15% increase in production efficiency.

A Canadian plastic and rubber manufacturer integrated RFID for quality control purposes. RFID tags were attached to individual products, allowing for real-time monitoring of production parameters and quality checks. This system helped reduce defects by 18% and improved overall product quality.

In Mexico, a plastic and rubber manufacturer deployed RFID to enhance its supply chain efficiency. RFID-enabled containers and pallets were used to track the movement of materials between manufacturing facilities and distribution centers. This initiative reduced transit times by 25% and improved overall supply chain visibility.

A leading European plastic and rubber manufacturer adopted RFID for asset tracking across multiple facilities. RFID tags were attached to valuable equipment, ensuring their accurate location and status. This implementation reduced equipment loss and improved asset utilization rates.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in the plastic and rubber manufacturing industry.

In the USA, a plastic and rubber manufacturer utilized IoT sensors to monitor the condition of manufacturing machinery. Predictive maintenance algorithms analyzed data from sensors, resulting in a 30% reduction in downtime and a 20% increase in equipment lifespan.

A Canadian plastic and rubber manufacturer implemented IoT for environmental monitoring in its production facilities. Sensors tracked temperature, humidity, and air quality, ensuring compliance with safety regulations and creating a safer working environment.

In Mexico, a plastic and rubber manufacturer embraced IoT for supply chain optimization. IoT devices provided real-time visibility into the movement of materials and components, improving logistics and reducing transit times by 15%.

A European plastic and rubber manufacturer leveraged IoT for remote monitoring of equipment performance. IoT-enabled sensors allowed engineers to assess equipment status and performance from a central location, reducing the need for on-site visits and enhancing overall operational efficiency.

Case Studies of Drone Applications

Below are some drone application cases in the plastic and rubber manufacturing industry.

A prominent U.S. plastic and rubber manufacturer employed drones for facility inspection. Drones equipped with cameras and sensors conducted aerial inspections of manufacturing facilities, identifying maintenance needs and ensuring compliance with safety standards.

In Canada, a plastic and rubber manufacturer used drones for inventory surveillance. Aerial drones monitored outdoor inventory storage areas, enhancing security and minimizing the risk of theft.

A Mexican plastic and rubber manufacturer employed drones for environmental monitoring. Drones assessed environmental factors in and around their manufacturing facilities, ensuring a safe and compliant working environment.

A leading European plastic and rubber manufacturer utilized drones for site surveying and mapping. Drones created accurate 3D maps of manufacturing sites, aiding in site planning and infrastructure maintenance.

GAO RFID Systems & Hardware for Plastic and Rubber Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including plastic and rubber manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including plastic and rubber manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including plastic and rubber manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including plastic and rubber manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Plastic and rubber manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Plastic and rubber manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selectioon of high quality drones are offered:

The RFID systems by GAO are highly popular for clients in Plastic and rubber manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include storage tanks and containers, chemical pumps and transfer equipment, forklifts and pallet jacks, safety equipment (e.g., protective clothing, gloves, respirators), labeling and packaging machinery, quality control and testing equipment, computer systems for inventory management, transportation vehicles (e.g., trucks, tankers), climate-controlled storage warehouses, and specialized handling equipment for hazardous materials.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Plastic and rubber manufacturing and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in plastic and rubber manufacturing we have worked with to serve our joint customers:

- Accenture

- Capgemini

- Deloitte

- PricewaterhouseCoopers (PwC)

- Cognizant

- IBM Global Business Services

- CGI Group

- Ernst & Young (EY)

- KPMG

- Tata Consultancy Services (TCS)

- Infosys

- Wipro

- Tech Mahindra

- HCL Technologies

- Atos

- LTI (Larsen & Toubro Infotech)

- DXC Technology

- NTT DATA

GAO Has Served Plastic and Rubber Manufacturing Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in plastic and rubber manufacturing industry to achieve success in

Industry 4.0, smart manufacturing, additive manufacturing (3D printing), bioplastics, supply chain resilience, reducing plastic waste, advanced materials, big data analytics, supply chain visibility, bio-compatibility, IoT and energy efficiency.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in plastic and rubber manufacturing, including many in its various divisions such as:

- Injection Molding: Producing plastic components by injecting molten plastic into molds.

- Extrusion: Creating plastic profiles, pipes, and sheets by forcing molten plastic through a die.

- Blow Molding: Forming hollow plastic objects by inflating a heated plastic parison inside a mold.

- Thermoforming: Shaping plastic sheets into products by heating and vacuum forming.

- Rotational Molding: Producing hollow plastic parts by rotating a mold with heated plastic.

- Tire Manufacturing: Producing tires for vehicles, including cars, trucks, and bicycles.

- Rubber Hose and Belting: Manufacturing hoses, belts, and conveyor systems.

- Gasket and Sealing Products: Producing seals, gaskets, and O-rings for various applications.

- Rubber Flooring and Matting: Creating rubber flooring and anti-fatigue mats.

- Custom Rubber Products: Designing and manufacturing specialized rubber components.

- Compounding: Blending additives, fillers, and polymers to create custom plastic and rubber compounds for specific applications.

- Colour Masterbatch: Producing colour concentrates used for colouring plastics.

- Recycling Facilities: Processing and recycling plastic and rubber materials.

- Reclaimed Rubber: Repurposing rubber from discarded tires and other sources.

- Profiles and Trim: Manufacturing plastic or rubber profiles used in construction, automotive, and other industries.

- Tubing and Hosing: Producing plastic and rubber tubing for various applications.

- Polyurethane Foam: Producing foam for insulation, cushioning, and packaging.

- Expanded Polystyrene (EPS): Manufacturing foam products used in construction and packaging.

- Medical Devices: Manufacturing medical-grade plastic and rubber components.

- Pharmaceutical Packaging: Producing containers and packaging materials.

- Plastic Housewares: Manufacturing plastic containers, utensils, and household items.

- Rubber Toys and Sporting Goods: Producing rubber-based toys, sporting equipment, and recreational items.

- Plastic and Rubber Automotive Parts: Manufacturing components such as bumpers, seals, and interior parts.

- Aerospace Seals and Gaskets: Producing specialized rubber components for the aerospace industry.

- Cable and Wire Insulation: Creating insulation materials for electrical wiring.

- Plastic and Rubber Electronics Components: Manufacturing components used in electronic devices

GAO’s technologies enable its customers in plastic and rubber manufacturing to effectively track their workforces such as extruder operator, molder, compounder, press operator, quality control inspector, die cutter, tool and die maker, process technician, materials handler, maintenance technician, calibration technician, machine setter, extrusion operator, rubber mixer, batch mixer, forklift operator, and effectively track operational assets such as screw, die, barrel, cooling bath, mold, platen, runner system, clamping unit, blow pin, parison, extruder head, banbury mixer, batch mixer, two roll mill, mold cart, mold storage rack, hydraulic press, compression press, transfer press, CMM, durometer, tensile tester, belt conveyor, roller conveyor, die cutter and trim press.

Here are some of the leading companies in plastic and rubber manufacturing industry GAO has served:

- Berry Global

- Saint-Gobain Performance Plastics

- Teknor Apex

- PolyOne Corporation

- Nypro

- Goodyear Tire & Rubber Company

- Cooper Tire & Rubber Company

- Bemis Company, Inc.

- Veyance Technologies

- The Dow Chemical Company

- PACCAR Inc.

- Precision Castparts Corp.

- Carlisle Companies Inc.

- Bridgestone Americas

- Michelin North America

- Shaw Industries Group, Inc.

- Nova Chemicals

- Intertape Polymer Group

- Winpak Ltd.

- IPL Plastics

- Schulman Canada Ltd.

- Grupo Kuo

- Mexichem

- Resirene

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com